Content

All issues / Volume 20 (2026) / Issue 1 (January)

Eva Kuželová Košťáková

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

This is an editorial article. It has no abstract.

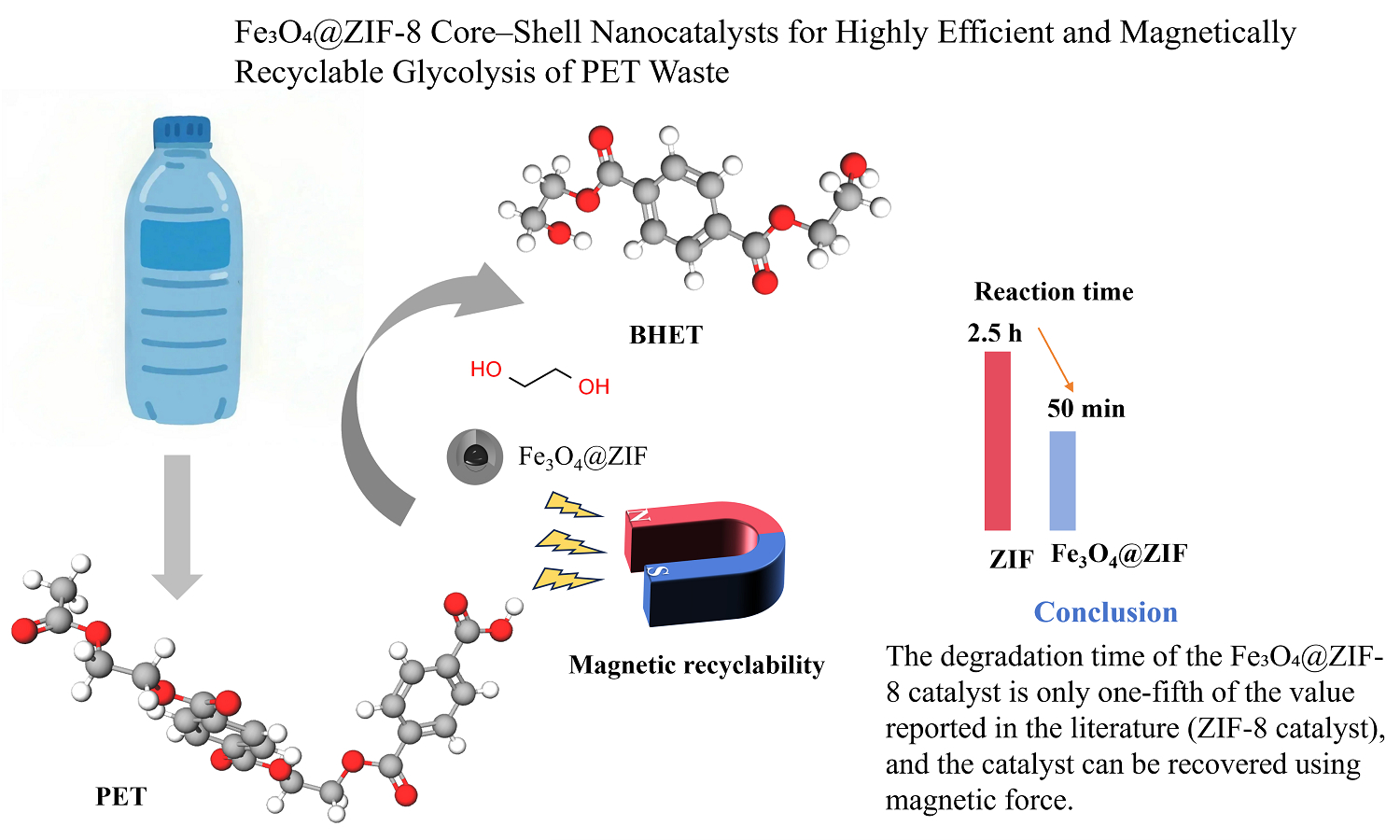

Longqiang Xiao, Weijia Huang, Kaihong Lin, Shucui Han, Zuyun Luo, Linxi Hou, Yan’gen LV

Vol. 20., No.1., Pages 3-17, 2026

DOI: 10.3144/expresspolymlett.2026.2

Vol. 20., No.1., Pages 3-17, 2026

DOI: 10.3144/expresspolymlett.2026.2

In this study, magnetic core-shell Fe3O4@ZIF-8 was synthesized via a hydrothermal method and applied to Polyethylene terephthalate(PET) degradation. The catalytic degradation of PET by Fe3O4@ZIF-8 was carried out under atmospheric pressure, yielding high-value bis(2-hydroxyethyl) terephthalate (BHET) monomers. The as-synthesized Fe3O4@ZIF-8 core-shell composites possess hierarchical porosity with tunable nanoscale cavities. SEM and TEM analyses confirmed the core-shell morphology, with nanoparticles having a size distribution of 180–280 nm. The degradation product was identified as a high-purity, colorless, and transparent monomeric BHET through 1H NMR and LC analyses. Based on a series of onefactor experiments and a Box-Behnken experimental design, the optimal process conditions were determined to be an alcoholysis temperature of 200°C, a catalyst dosage of 0.5 wt% (relative to PET mass), a reaction time of 50 min, and an ethylene glycol-to-PET mass ratio of 4.5:1. Under these conditions, the actual BHET yield reached 81.12%, closely matching the predicted value.

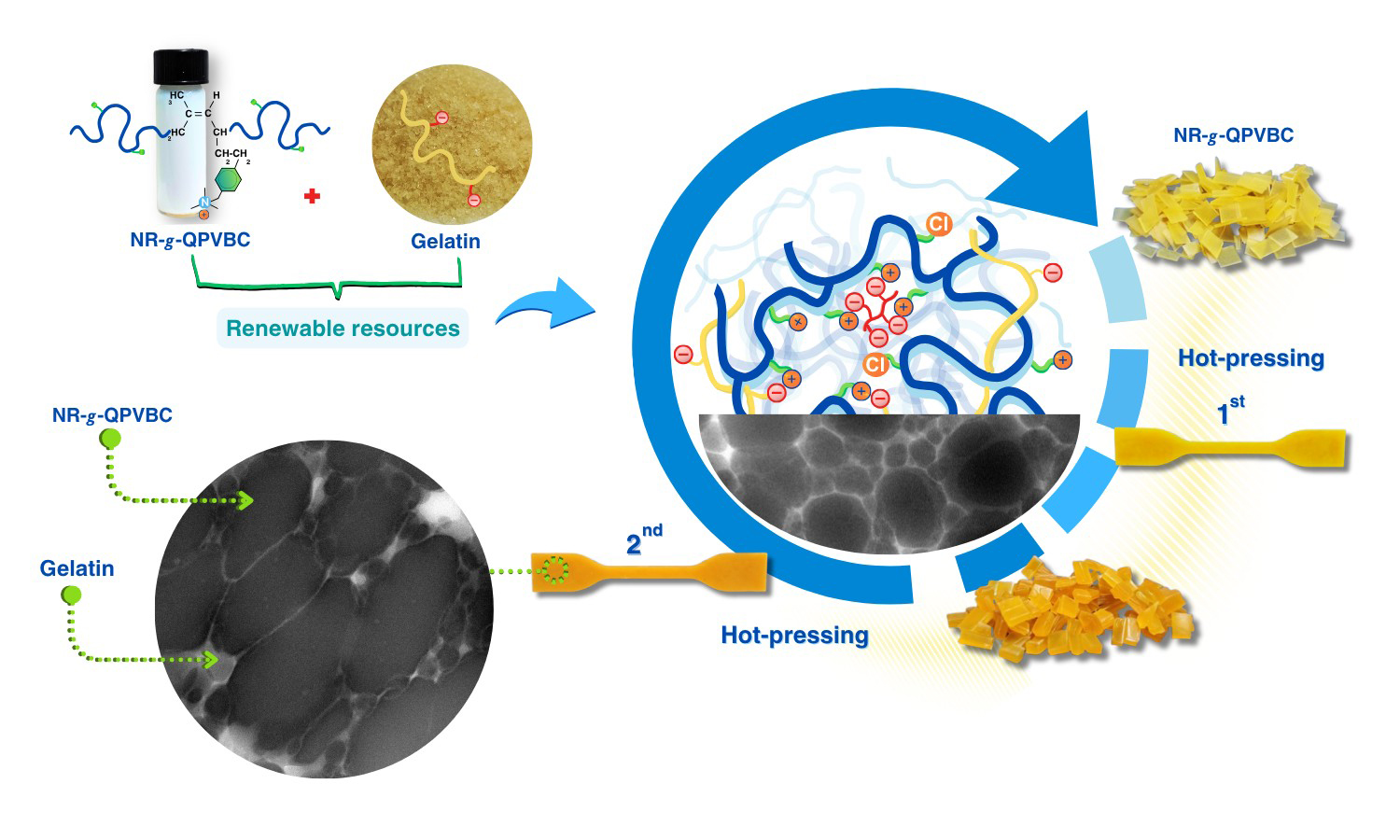

Rattanawadee Ninjan, Bencha Thongnuanchan, Phakawat Tongnuanchan, Subhan Salaeh, Jutharat Intapun, Abdulhakim Masa, Natinee Lopattananon

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

The present study has proposed a straightforward method to improve the reprocessability of modified natural rubber (NR) by blending it with gelatin (GT). The reprocessable characteristics of these blends were evaluated based on their remolding capabilities and mechanical recovery performance. In this method, poly(vinylbenzyl chloride) (PVBC) was first grafted onto NR chains to create graft copolymers known as NR-g-PVBC. The benzyl chloride groups in the graft copolymers were subsequently converted into quaternary ammonium groups, referred to as NR-g-QPVBC. This modification enabled ionic crosslinking when NR-g-QPVBC reacted with ethylenediamine tetraacetic acid. Blends were created by incorporating GT powder into the NR-g-QPVBC latex. The optimal loading level of GT was determined to be 30 wt%, as the resulting film exhibited the highest recovery of tensile properties. Initially, the film's tensile strength was measured at 15 MPa. After being remolded at 160 °C, the tensile strength decreased to 9.3 MPa, resulting in a recovery rate of 60.7% and withstanding a tensile strain of 144%. Although the NR-g-QPVBC/GT films could be remolded, their tensile properties declined with increasing remolding cycles. Therefore, this work demonstrated a practical method for producing NR-based films that could be reshaped through hot-pressing after being formed into products, increasing their reusability.

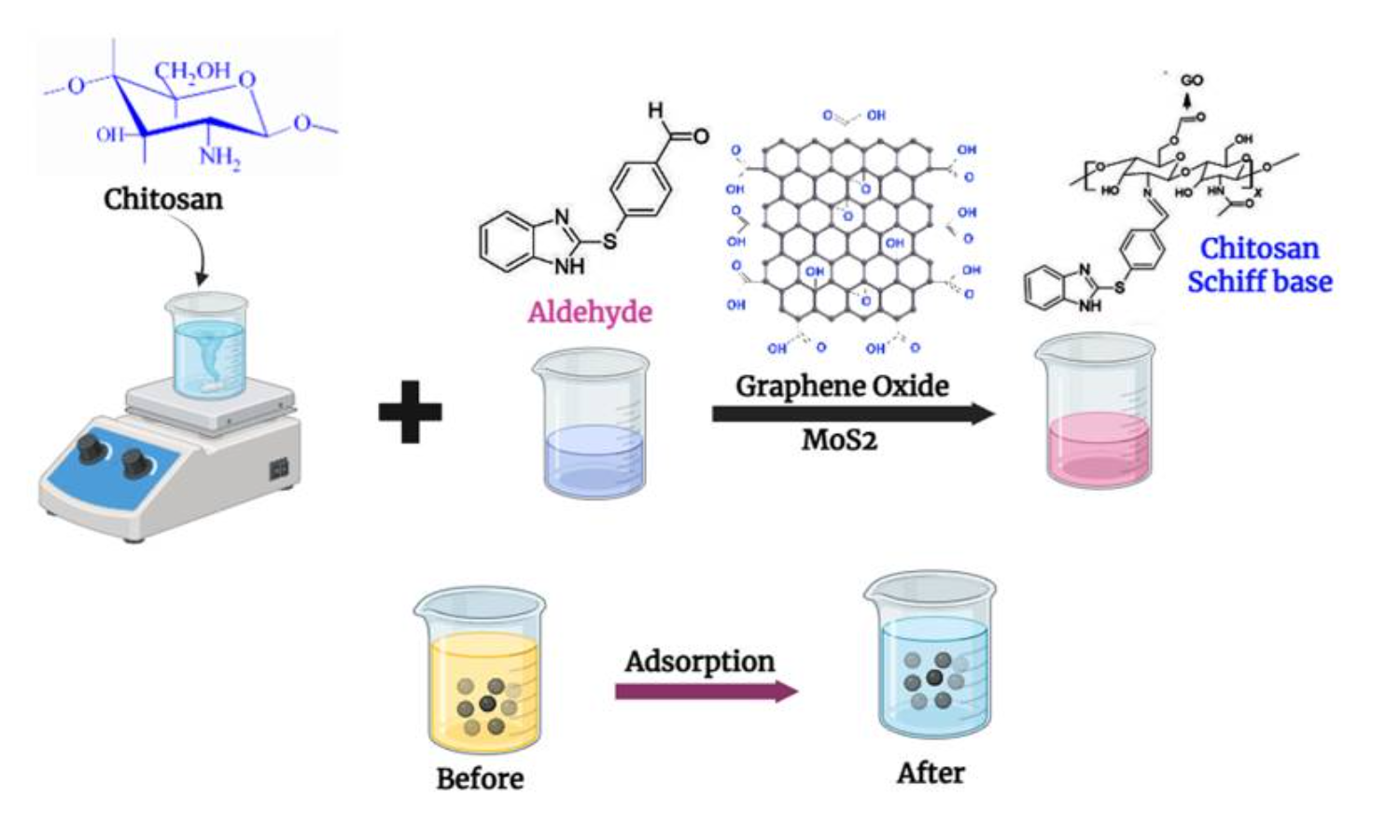

Narayanapura Mahadevappa Tanuja, Sommenahalli Machegowda Chaithra, Chikkahalkur Shivanandappa Kaliprasad, Mangaravalli Hombalegowda Harshitha, Shivapura Manchaiah Anush, Kalappa Prashantha

Vol. 20., No.1., Pages 36-51, 2026

DOI: 10.3144/expresspolymlett.2026.4

Vol. 20., No.1., Pages 36-51, 2026

DOI: 10.3144/expresspolymlett.2026.4

In this work, we have developed a novel absorbent material using chitosan (CS), and further it was structurally modified via reaction with thiocarbaldehyde, forming a Schiff base intermediate. Simultaneously, graphene oxide was functionalized at the C-6 position of CS through an effective esterification process and composited with the incorporation of molybdenum disulfide (MoS2) nanoparticles to synthesize a hybrid adsorbent material. The resulting material was characterized using Fourier transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), X-ray diffraction (XRD), and scanning electron microscopy (SEM). The synthesized adsorbent was subjected to the adsorptive removal of Cu(II) and Cr(VI) ions from dilute solutions. The maximum uptake of 66.66 mg/g for Cu(II) and 76.92 mg/g for Cr(VI) were recorded during the adsorption process, further following pseudo-second-order kinetics adsorptive nature and fitted well with the Langmuir isotherm model. Desorption studies indicated the material’s reusability, and the thermodynamic studies indicated a spontaneity with an endothermic adsorptive nature. These studies highlight the material’s potential as an effective adsorbent as a sustainable approach for efficient environmental remediation.

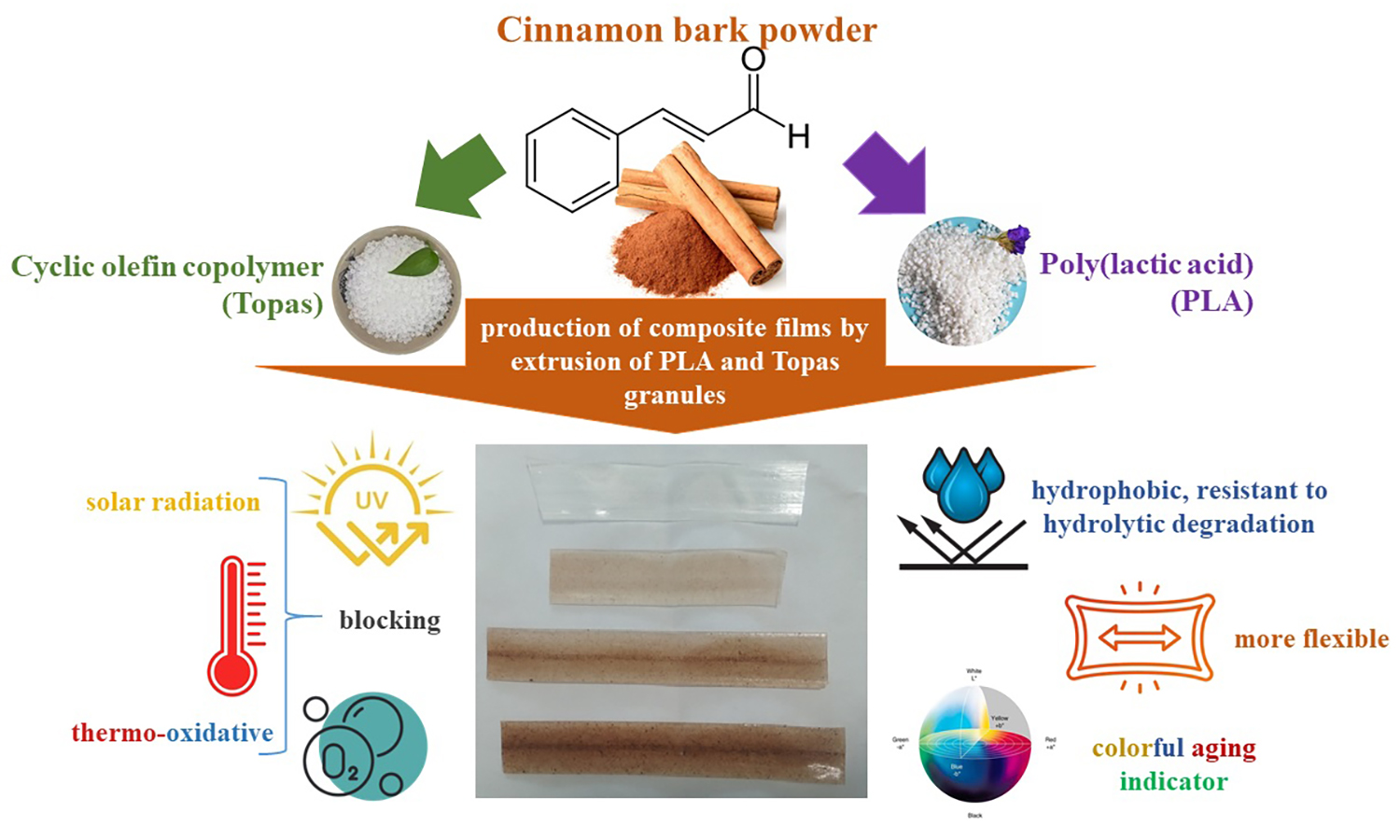

Effect of natural cinnamon extract on the stabilizing properties of biodegradable packaging polymers

Anna Kosmalska-Olańska, Anna Masek

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

The growing focus on sustainability, eco-friendly technologies, decarbonization, and reducing carbon footprints shapes current industry challenges. This article reviews the potential of cinnamon as a bio-additive for polymer stabilization in packaging. Samples were prepared from ethylene-norbornene copolymer (Topas), a cyclic olefin copolymer known for purity, transparency, and low gas permeability, and poly(lactic acid) (PLA), a bio-based alternative to petroleum plastics. Cinnamon powder was added in 0.5, 1.0, and 1.5 wt%. After solar and thermo-oxidative aging, hydrophobicity, chemical composition, mechanical, and color properties were analyzed. Results showed higher hydrophobicity and resistance to hydrolytic degradation due to reduced water penetration. PLA, normally brittle, became more flexible, with 0.5 wt% cinnamon showing optimal performance after 100 h of solar aging, similar to Topas composites. Overall, PLA and cyclic olefin copolymer (COC) films with cinnamon improved durability, extended food shelf life, and acted as natural color indicators of material aging.

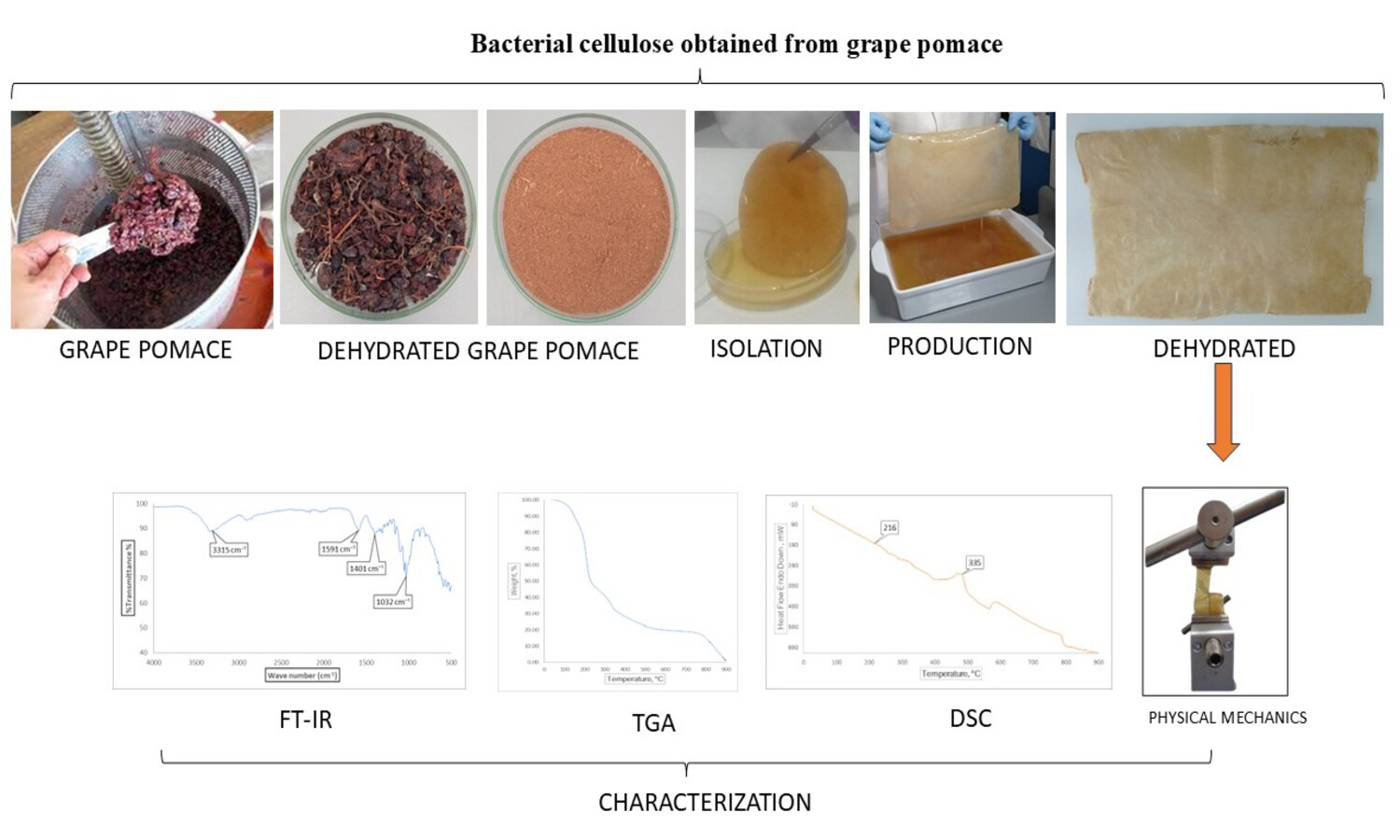

Isabel Milagros Gavilan-Figari

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Bacterial cellulose (BC) is an eco-friendly biopolymer with outstanding structural and functional properties, offering promising applications in sustainable packaging and bio-based materials. In this study, we demonstrate the feasibility of producing BC via spontaneous fermentation, using grape pomace supplemented with sucrose as the sole carbon source, nutrient substrate, and microbial inoculum, without the addition of commercial strains or nitrogen supplements. Fermentation was conducted under static conditions, yielding biofilms with stable structural characteristics and BC production of up to 14.1 g/L, thereby confirming the efficiency of this low-cost, residue-based process. The films obtained exhibited well-organized polymeric networks, with thermal stability in the range of Tg ≈ 159–266 °C and mechanical resistance comparable to or higher than conventional biopolymers. Characterization confirmed reproducible chemical profiles, thermal stability, and measurable variation in mechanical performance, with a tensile strength ranging from 0.0001 to 105 MPa and an elongation at break of 15±5%. The process highlights a resource-efficient and sustainable pathway, adaptable to rural contexts and aligned with circular economic principles. While minor variations among replicates reflected the intrinsic variability of biological systems, mean values and standard deviations demonstrated reproducible physicochemical and mechanical properties. These findings demonstrate that BC derived from agro-industrial residues can be produced under simple, low-input conditions, opening opportunities for scalable valorization in functional and sustainable materials.

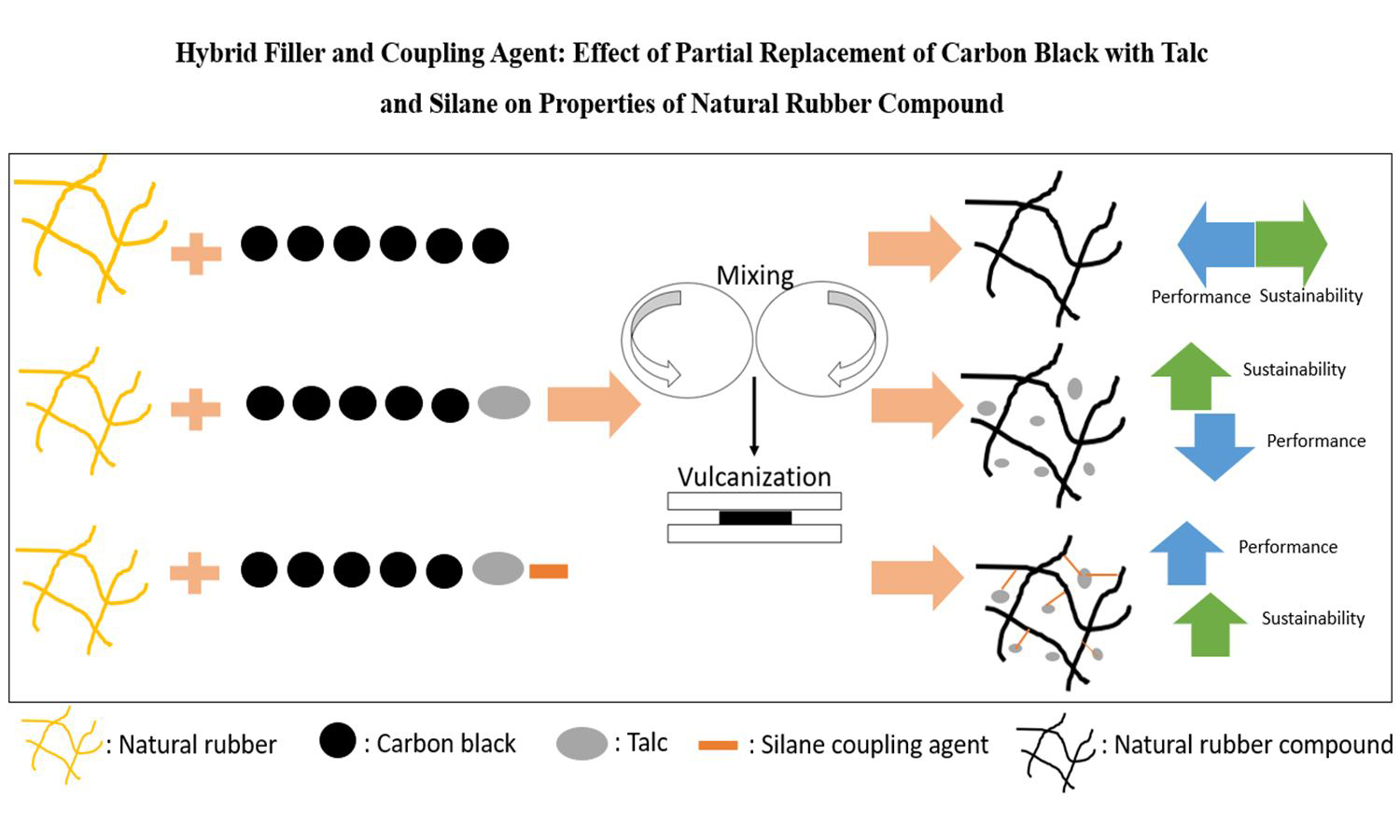

Hatay Cöcen, Nilgün Kızılcan

Vol. 20., No.1., Pages 82-96, 2026

DOI: 10.3144/expresspolymlett.2026.7

Vol. 20., No.1., Pages 82-96, 2026

DOI: 10.3144/expresspolymlett.2026.7

This study investigates a sustainable hybrid-filler strategy for natural rubber (NR) compound by partially replacing petroleum-based carbon black (CB) with talc and introducing a silane coupling agent to mitigate interfacial incompatibility. Compounds containing CB, CB+talc and CB+talc+increasing silane were produced via two-stage mixing and characterized for morphology (dispersion/mapping), curing and flow behavior (differential scanning calorimetry DSC/moving die rheometer, MDR/Mooney), crosslink density (Flory–Rehner), physical–mechanical properties, dynamic performance (Payne effect/heat build-up/tension–fatigue), and thermal stability (aging/thermogravimetric analysis,TGA). Talc reduced the compound viscosity, offering processing benefits. The swelling test indicated that talc decreased crosslink density, but silane recovered it, forming covalent linkages. Tensile strength and elongation at break were improved without altering hardness. Dynamically, talc increased heat build-up, whereas silane inverted the trend and reduced the temperature rise gradually from 41.5 to 29.4°C at 2 phr. Fatigue life was improved with talc (~10%), and further with silane (up to 36% at 2 phr), highlighting a favorable stiffness–fatigue balance with compatibilization. Overall, partial CB replacement by talc, in combination with silane, delivers meaningful sustainability gains with improved dynamic performance while preserving key mechanical properties of NR compounds.

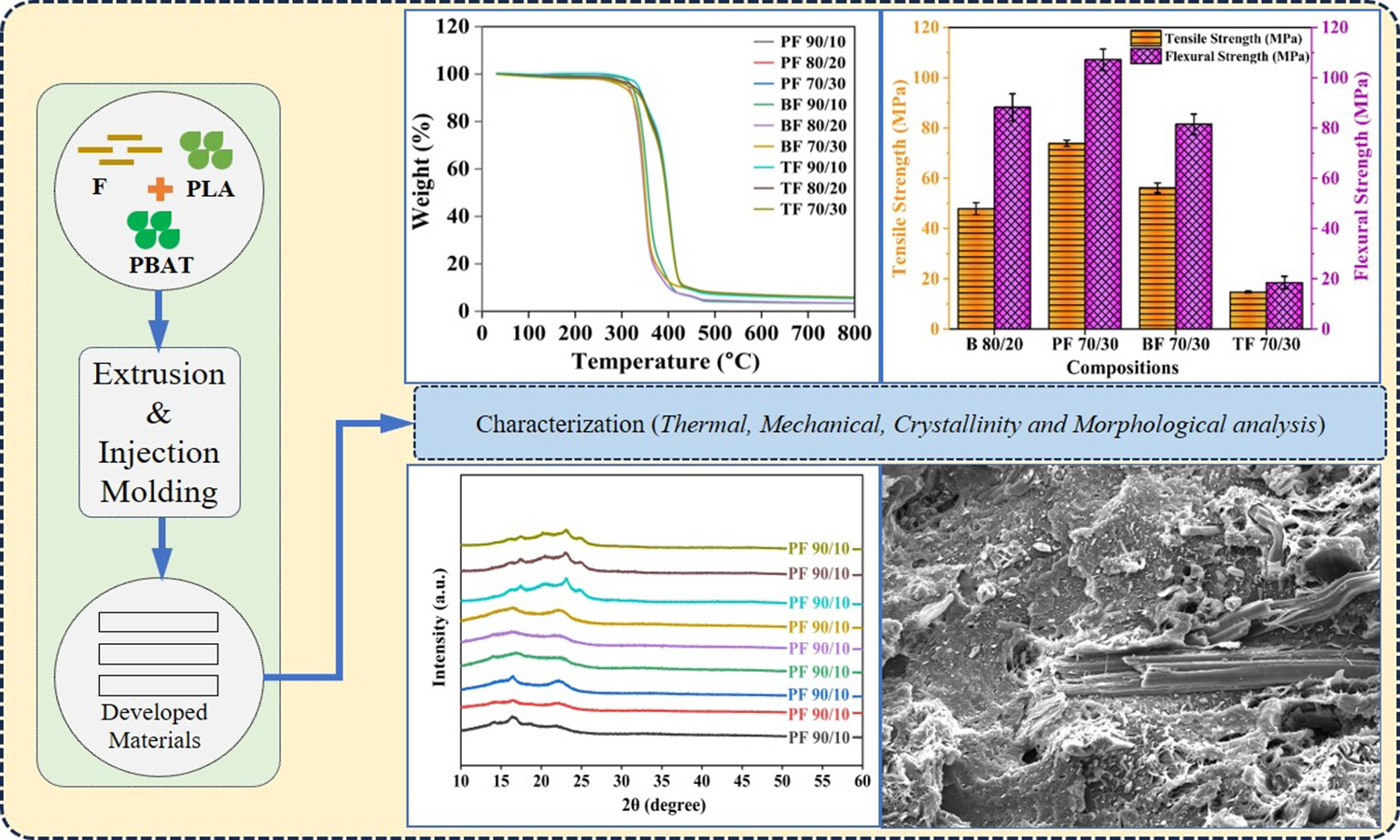

Yashpal Singh, Raj Kumar, Nikhil Chauhan, Tejas Pramod Naik, Inderdeep Singh

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

The current experimental investigation presents a comparative evaluation of selected biodegradable polymer blends and their composites, focusing on their material properties. Two biopolymers, polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), along with pineapple fibers (F), as bio-reinforcement were taken for the analysis, which was conducted in two stages: During first stage, PBAT was melt-blended with PLA in varying weight fractions (10, 20, 30, 40, and 50 wt%) to produce PLA/PBAT blend (B) and in second stage, PLA, PBAT, B 80/20 blend were reinforced with pineapple fiber (10, 20, and 30 wt%). The samples were fabricated using extrusion-injection molding. The samples were characterized for density, thermal degradation, crystallinity, and mechanical behaviour. Among the blends, the optimal B 80/20 combination exhibited tensile strength, flexural strength, and elongation at break of 47.9±2.4, 88.2±5.4 MPa, and 330.6±10.47%, respectively. Results indicate that the PLA-based composites (PF) exhibit significantly better density, tensile strength, and flexural strength as compared to neat polymers, blends, blend-based composites (BF), and PBAT-based composites (TF). Among the PF composites, the PF 70/30 composite demonstrated superior performance, with maximum tensile and flexural strength values of 73.9±1.3 and 107.1±4.3 MPa, respectively.