Multifunctional MoS₂/GO–chitosan schiff base composite for efficient chromium and copper ion removal from wastewater

Narayanapura Mahadevappa Tanuja, Sommenahalli Machegowda Chaithra, Chikkahalkur Shivanandappa Kaliprasad, Mangaravalli Hombalegowda Harshitha, Shivapura Manchaiah Anush, Kalappa Prashantha

Vol. 20., No.1., Pages 36-51, 2026

DOI: 10.3144/expresspolymlett.2026.4

DOI: 10.3144/expresspolymlett.2026.4

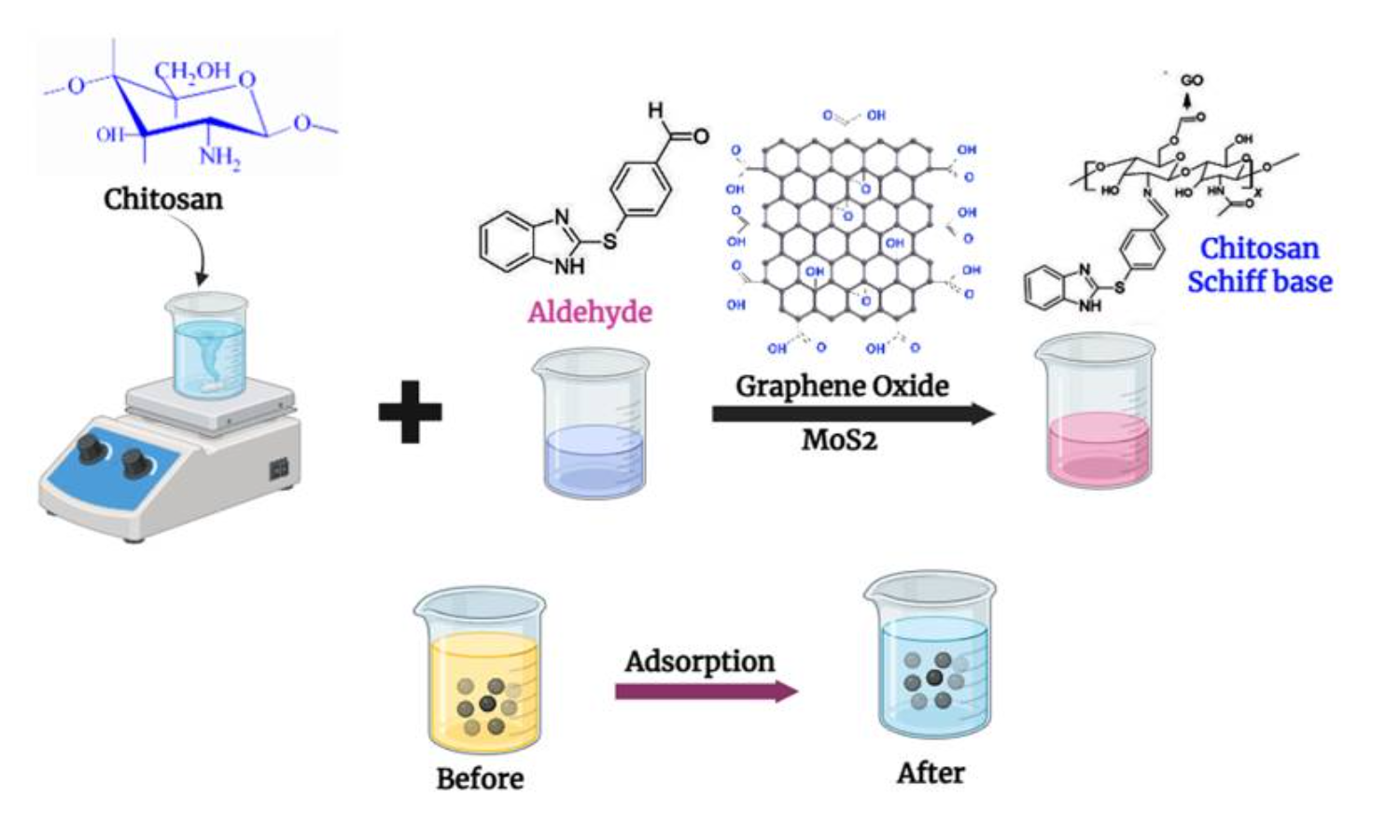

GRAPHICAL ABSTRACT

ABSTRACT

In this work, we have developed a novel absorbent material using chitosan (CS), and further it was structurally modified via reaction with thiocarbaldehyde, forming a Schiff base intermediate. Simultaneously, graphene oxide was functionalized at the C-6 position of CS through an effective esterification process and composited with the incorporation of molybdenum disulfide (MoS2) nanoparticles to synthesize a hybrid adsorbent material. The resulting material was characterized using Fourier transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), X-ray diffraction (XRD), and scanning electron microscopy (SEM). The synthesized adsorbent was subjected to the adsorptive removal of Cu(II) and Cr(VI) ions from dilute solutions. The maximum uptake of 66.66 mg/g for Cu(II) and 76.92 mg/g for Cr(VI) were recorded during the adsorption process, further following pseudo-second-order kinetics adsorptive nature and fitted well with the Langmuir isotherm model. Desorption studies indicated the material’s reusability, and the thermodynamic studies indicated a spontaneity with an endothermic adsorptive nature. These studies highlight the material’s potential as an effective adsorbent as a sustainable approach for efficient environmental remediation.

RELATED ARTICLES

Soni Thakur, Amal M. Sindi, Rahul Dev Bairwan, Rasha A. Mahmoud, Eman Alfayez, Nurul Fazita Mohammad Rawi, Kanchan Jha, H.P.S. Abdul Khalil

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

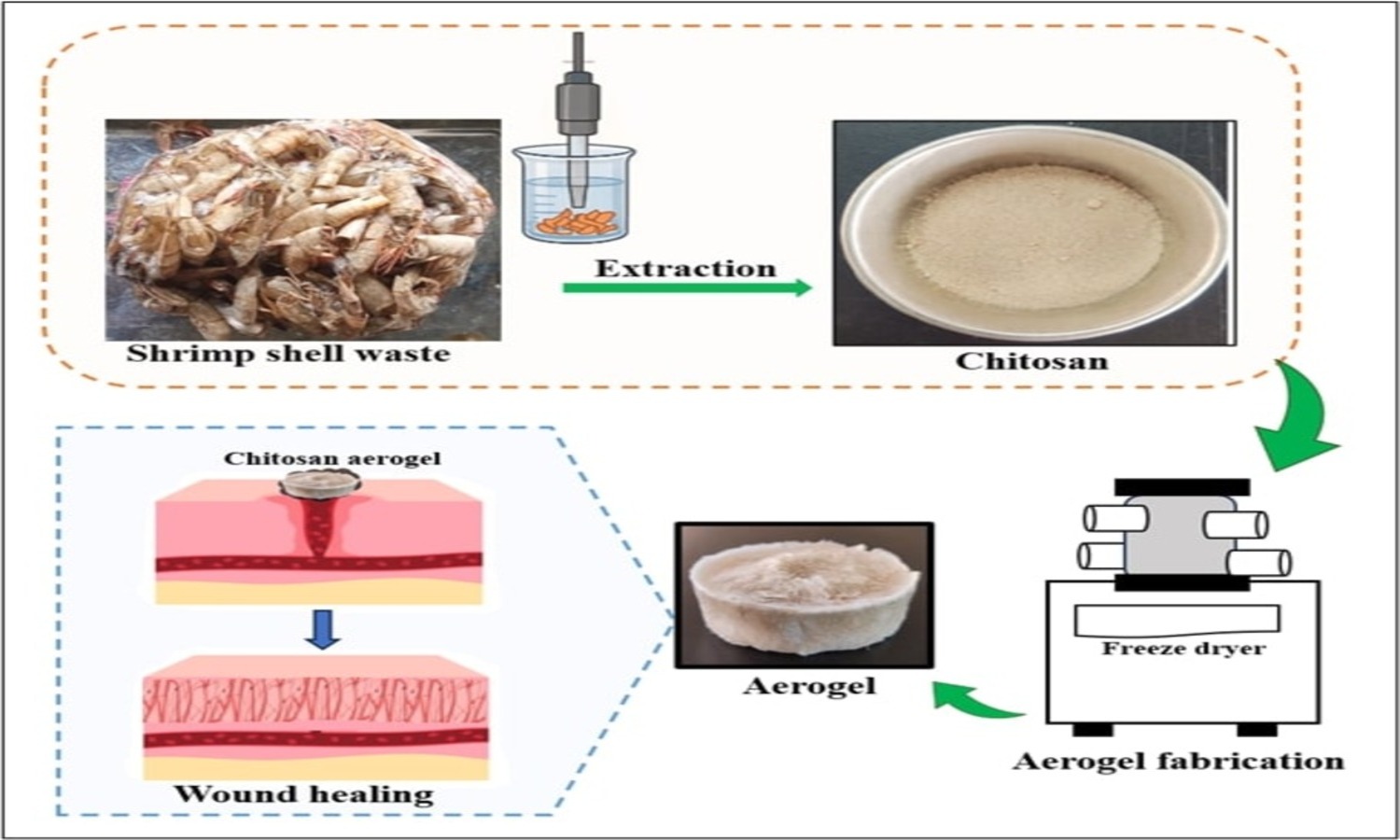

This research presents an eco-friendly approach for extracting chitosan from shrimp shell waste through ultrasound-assisted extraction (UAE) to prepare biocompatible aerogel scaffolds for biomedical applications. The study investigates the influence of various ultrasonic treatment times (10, 20, 30, 40 min) on the yield and structural and physicochemical properties of the extracted chitosan via characterization using Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Among the tested conditions, the 30 min UAE-treated chitosan aerogels showed optimal porosity and structural integrity. Biocompatibility of the aerogels was evaluated, and the results confirmed their non-cytotoxic nature. The bioactivity of the chitosan aerogels was evaluated in terms of their in vitro wound closure ability and antibacterial properties. The aerogels demonstrated a wound closure rate of around 51% after 72 h, significantly higher than the untreated control (37%). In addition, they exhibited clear antibacterial activity against Escherichia coli and Staphylococcus aureus. This sustainable extraction and fabrication method not only adds value to marine waste but also produces functional biomaterials with potential applications in wound healing, tissue engineering, and regenerative medicine, supporting global efforts toward sustainability and circular bioeconomy.

Mpho Phillip Motloung, Mokgaotsa Jonas Mochane

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Polylactic acid (PLA) is one of the most widely used biopolymers, and it has demonstrated a huge potential for replacing some of the conventional plastics in certain application fields. However, due to a lack of other attributes such as antimicrobial properties and slow degradation rates, it is often blended with other polymers to impart these properties. Chitosan has desirable features including antimicrobial and antioxidant properties, biodegradability and biocompatibility, and environmental friendliness. Thus, it is widely blended with PLA to generate materials that can be applied in various fields. In recent years, PLA/chitosan blend composites and nanocomposites have been produced to develop sustainable and ecofriendly materials that can be suitable in active food packaging, water treatment, air filtration, and biomedical applications. This review provides an overview of the recent advancements in the development of PLA/chitosan blend composites and nanocomposites for various applications. The processing strategies, mechanical and thermal properties, together with utilization in biomedical, air filtration, water treatment, and packaging applications, are provided.

Katalin Litauszki, Tamás Tábi, László Mészáros

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

This is an editorial article. It has no abstract.

Mohammad Mehdi Alighanbari, Firoozeh Danafar, Araam Namjoo, Asma Saeed

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

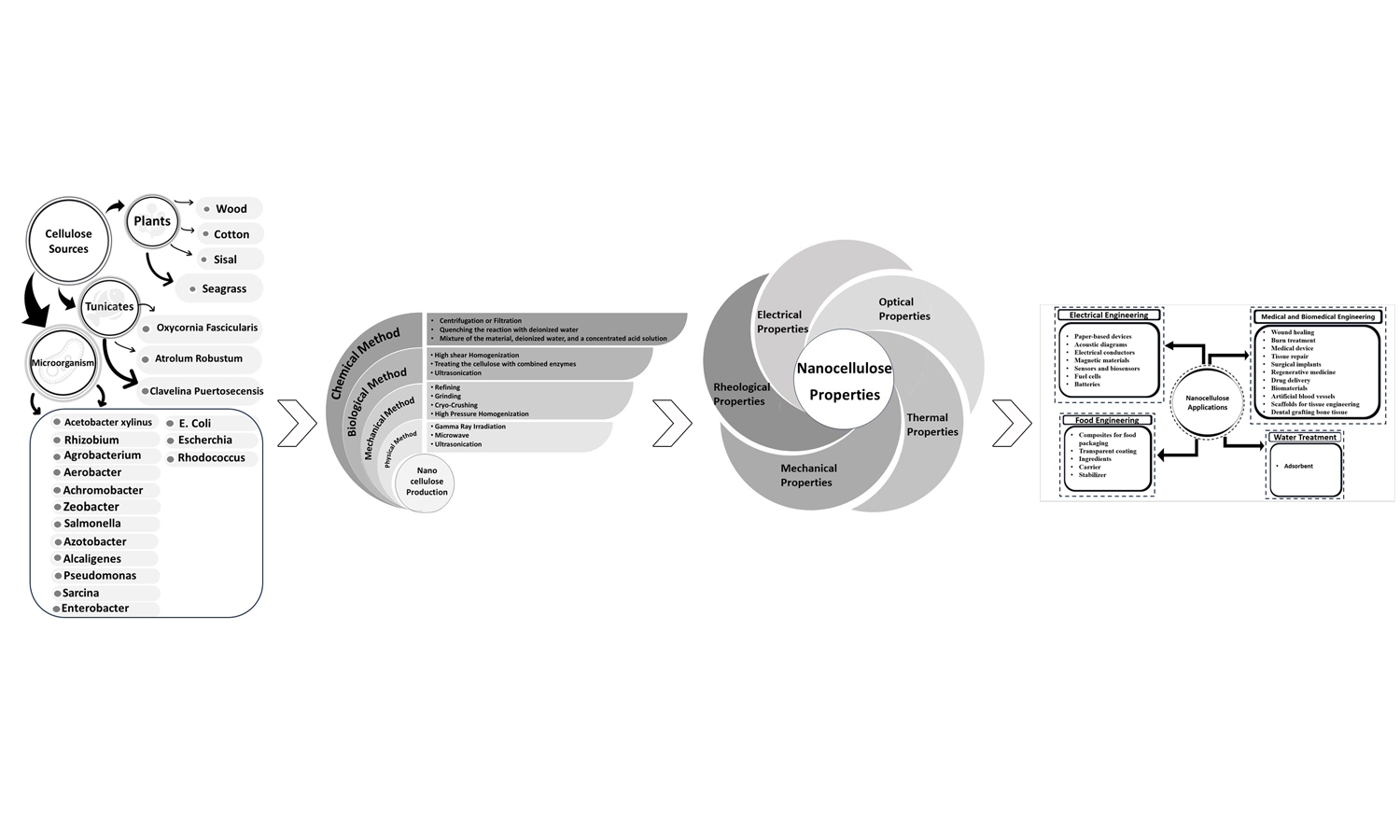

The environmental and ecological concerns drive researchers to synthesize functional materials using components from natural resources. Nanocellulose (NC), derived from plants, marine animals, or microorganisms, is a green material attracting attention due to its abundance, biocompatibility, and biodegradability. NC’s interstice properties enable the synthesis of functional nanocomposites in forms like aerogels, foams, paper, sheets, or hollow filaments. This review briefly describes NC classification and production while comprehensively presenting its mechanical, rheological, optical, and electrical properties, offering foundational knowledge for future research. Additionally, it highlights recent developments in NC-based products across fields such as papermaking, water treatment, civil engineering, electronics, cosmetics, food, and medicine. For the first time, this paper explores recent advances in NC molecular simulation, providing insights into structure, arrangement, and interactions through molecular dynamic simulation. Finally, future prospects for NC-based applications are discussed to encourage studies addressing current challenges.

Forough Abbasi Shahir, Zahed Ahmadi, Sayed Mahmood Rezaee Darvishi

Vol. 18., No.6., Pages 592-606, 2024

DOI: 10.3144/expresspolymlett.2024.44

Vol. 18., No.6., Pages 592-606, 2024

DOI: 10.3144/expresspolymlett.2024.44

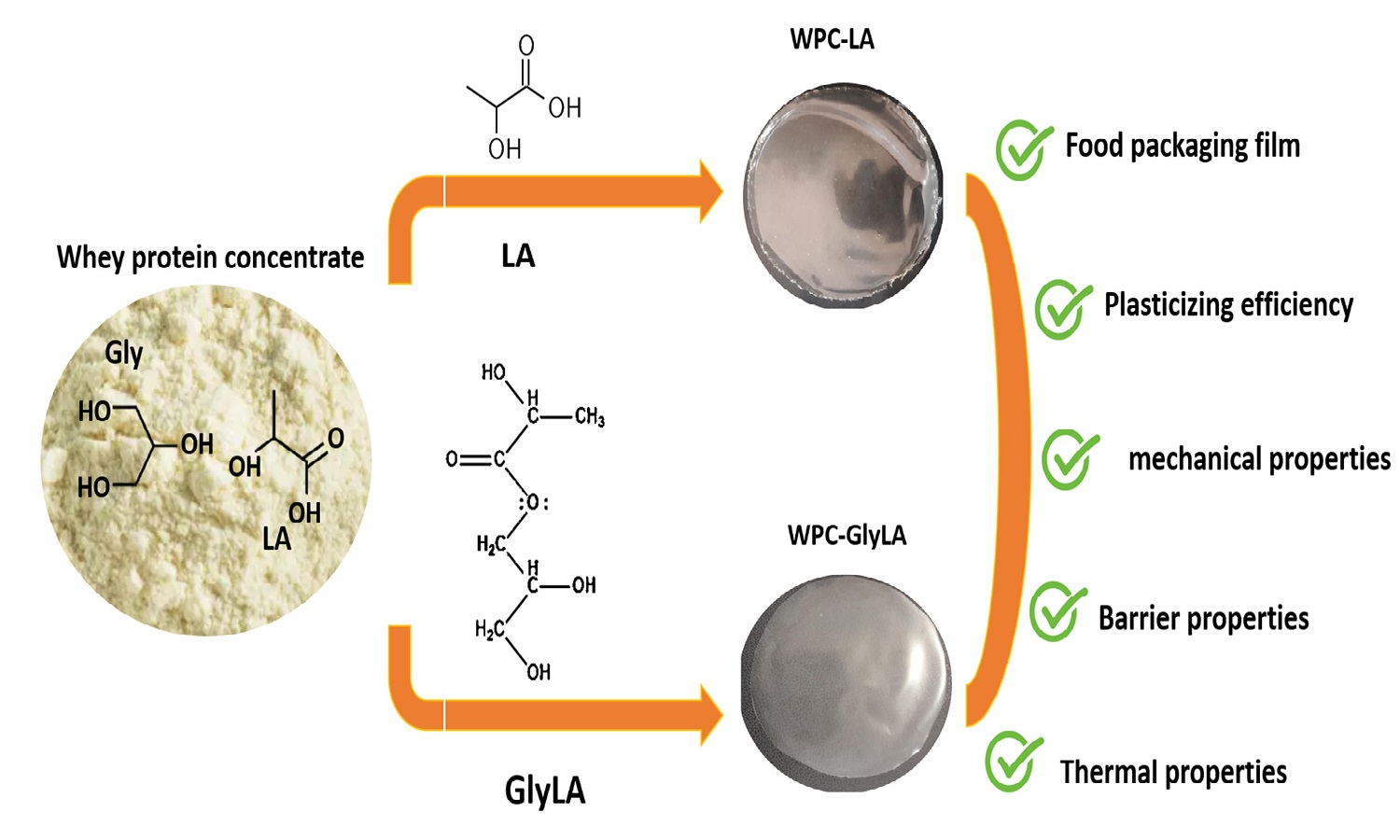

Glyceryl lactate (GlyLA) was synthesized through the esterification of glycerol (Gly) and lactic acid (LA) to plasticize whey protein concentrate (WPC) films with three different ratios of WPC to plasticizer (85, 90, and 100% w/w). LA was also introduced as a new plasticizer of whey protein films and compared in similar contents. Gly-plasticized films were also used as control groups. The synthesized GlyLA, including compatible esterification degree with WPC, was characterized by Fourier transform infrared Spectroscopy (FTIR) and hydrogen nuclear magnetic resonance spectroscopy (H-NMR) analyses. Then, the plasticizing effect of different types of plasticizers on the optical, thermal, mechanical, and water resistivity properties of the prepared films was evaluated. FTIR in attenuated total reflectance (ATR), Differential Scanning Calorimetry (DSC), tensile measurements, and cup method were also employed to examine the molecular structure, transition temperatures, mechanical resistivity, and water vapor permeability (WVP) of the modified films. The results showed a lower glasstransition temperature (Tg) and better ductility. By Increasing plasticizer content, solubility and WVP were increased in all groups. Furthermore, WPC-based films plasticized with 80 or 90% w/w of LA and GlyLA exhibited not only higher tensile strength and flexibility but also remarkably lower WVP than Gly plasticized films, turning them into potential alternatives for application as food packaging.