What are polymeric nanofibers? Materials with a secret

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

DOI: 10.3144/expresspolymlett.2026.1

GRAPHICAL ABSTRACT

RELATED ARTICLES

Mark Shneider, Xiaomeng Sui, Iddo Pinkas, Ulyana Shimanovich, Israel Greenfeld, Daniel Wagner

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Electrospinning is a widely used technique for manufacturing nanofibers from polymers. The formation of continuous fibers during the drawing of a viscous solution typically depends on entanglements between polymer chains, making thermoplastics the preferred choice. In this study, we have shown that thermosetting polymers such as epoxy, which have crosslinked covalent bonds, can also be electrospun. The resulting fibers have diameters ranging from 150 nm to 6 μm. Tensile mechanical properties of fibers with diameters varying between 410 nm and 4 μm are compared with those of molded epoxy bulk. The electrospun fibers exhibit approximately 555% higher strength, 300% greater stiffness, and a strain of about 109% compared to the equivalent properties of bulk epoxy. When compared with brittle molded bulk, these fibers showed ductile properties. We also observed a correlation between the fiber diameter and the mechanical properties. The molecular morphology of the fibers was monitored and analyzed using polarized micro-Raman spectroscopy to detect molecular orientation. A comparison with epoxy fibers of different diameters from previous studies was conducted to better understand the size effect. This study shows, explains and models the evolution of epoxy molecular morphology from the solution (soft matter) to fiber (solid-state), explaining the transition from brittle to ductile in epoxy fibers, and clarifying the molecular mechanisms that lead to improved mechanical properties.

Jian Zhao, Xun Meng, Hongwei Piao, Hao Zhang, Zhibo Ren, Qi Han, Qinglin Huang, Hanli Wang

Vol. 19., No.5., Pages 531-543, 2025

DOI: 10.3144/expresspolymlett.2025.39

Vol. 19., No.5., Pages 531-543, 2025

DOI: 10.3144/expresspolymlett.2025.39

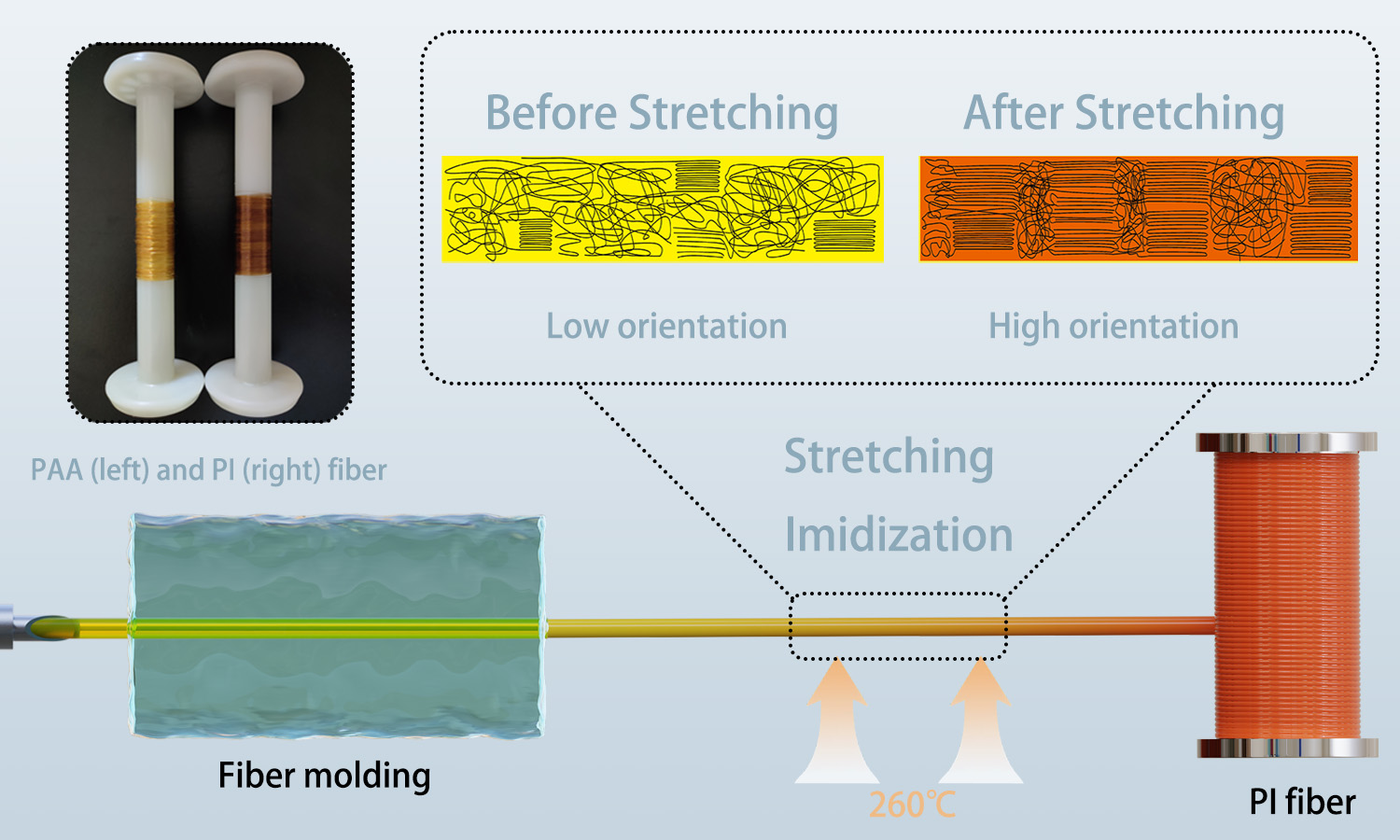

Polyimide (PI) fiber is a promising and high-performance polymer fiber with high temperature resistance and low density; however, much energy is needed during the thermal imidization process. Here, PI fiber with excellent mechanical properties and high-temperature resistance was fabricated via the dry-jet wet spinning method for polyamic acid (PAA) precursor fiber, followed by stretching and thermal imidization reaction at a lower temperature. With the increase of the stretching ratio, the mechanical properties of the PI fiber increase significantly. When the stretching was twice as long, the tensile strength and initial modulus of the fiber were as high as 6.23 and 114.13 cN·dtex–1, respectively. Fourier transform infrared results revealed that all samples were completely imidized at 260 °C. The resulting PI fibers exhibit only 5% weight loss at 539.53 °C, and its limiting oxygen index (LOI) can reach up to 32.6%, showing excellent high temperature resistance and flame-retardant properties as well as commendable mechanical performance, which compare favorably with those of other imidization methods.

Jiadong Hu, Huiling Chen, Junpeng Zhong, Changming Li, Ronggui Li, Rong Zhou, Hongwei He

Vol. 19., No.4., Pages 351-360, 2025

DOI: 10.3144/expresspolymlett.2025.26

Vol. 19., No.4., Pages 351-360, 2025

DOI: 10.3144/expresspolymlett.2025.26

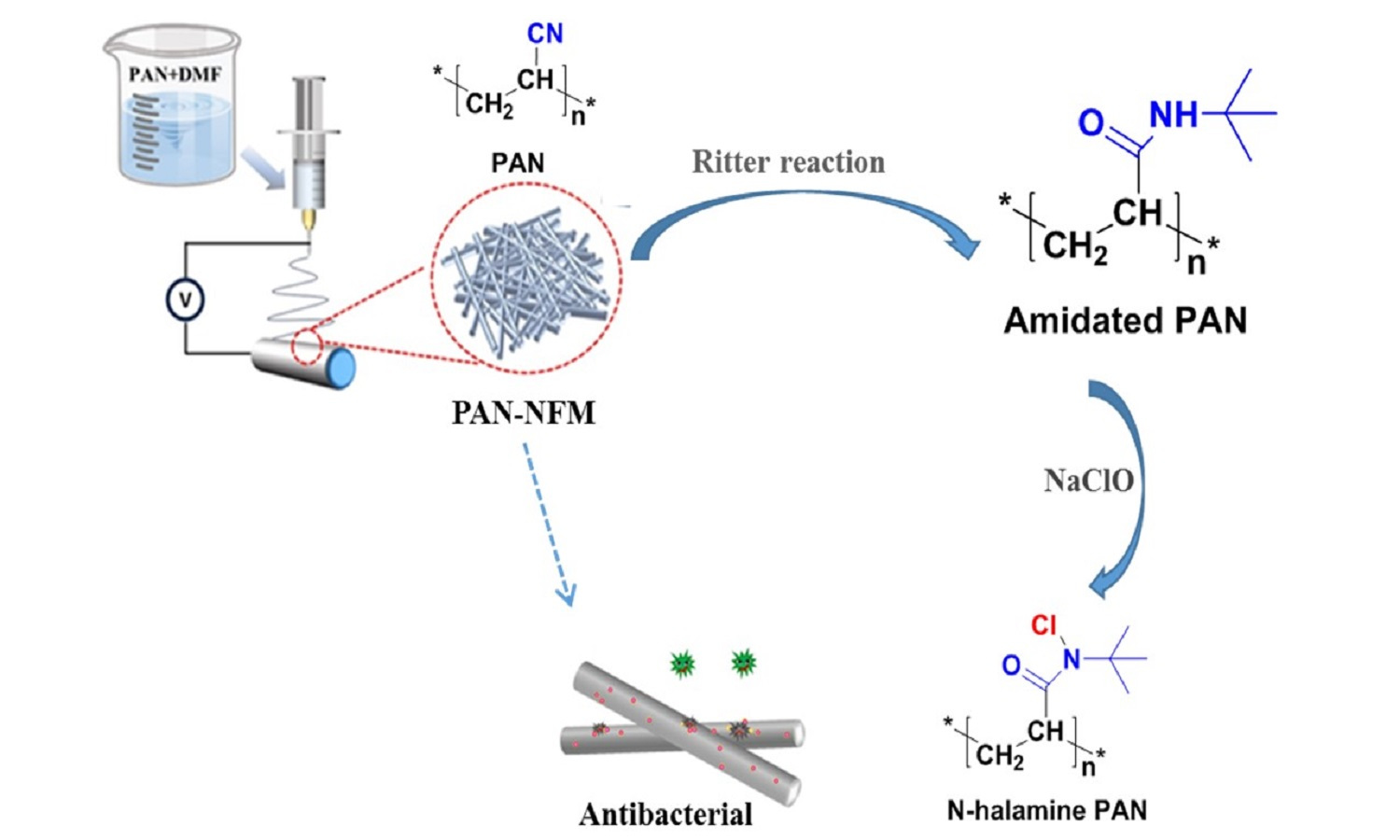

Electrospun (e-spun) nanofiber materials have emerged as a prominent research focus owing to their extensive and promising potential applications across biomedical, energy, and environmental domains. Polyacrylonitrile (PAN) is a commonly used polymer for electrospinning (e-spinning). Due to insufficient hydrophilic properties of nitrile groups of PAN, its e-spun nonwoven membranes had low water absorption and moisture absorption, which limited application in medical and health fields. In this study, it was investigated that the hydrophilic modification of e-spun PAN nanofiber membrane (NFM) was conducted via Ritter reaction to convert nitrile groups into hydrophilic amide ones, thereby improving the hydrophilicity of PAN NFMs. The surface morphologies and structure of the modified e-spun fibers were characterized and verified by SEM, FTIR and XPS. After 60–90 min of Ritter reaction, the fiber diameter of the PAN NFM became thicker, transforming from a hydrophobic membrane to a hydrophilic one, and the water contact angle decreased from 124.2 to 40.7°. The amidated PAN obtained membrane was post-treatment with sodium hypochlorite to make some amide groups change to N-halamine, which took the PAN NFM antibacterial activity or bacteriostasis. This work suggested a strategy that the espun PAN NFMs modified would have a promising application in medical dressings, air filtration, etc.

Sanjay Mavinkere Rangappa, Suchart Siengchin

Vol. 18., No.12., Pages 1176-1177, 2024

DOI: 10.3144/expresspolymlett.2024.89

Vol. 18., No.12., Pages 1176-1177, 2024

DOI: 10.3144/expresspolymlett.2024.89

This is an editorial article. It has no abstract.

Aleksandra Sierakowska-Byczek, Julia Radwan-Pragłowska, Łukasz Janus, Tomasz Galek, Karol Łysiak, Mirosław Tupaj, Dariusz Bogdał

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

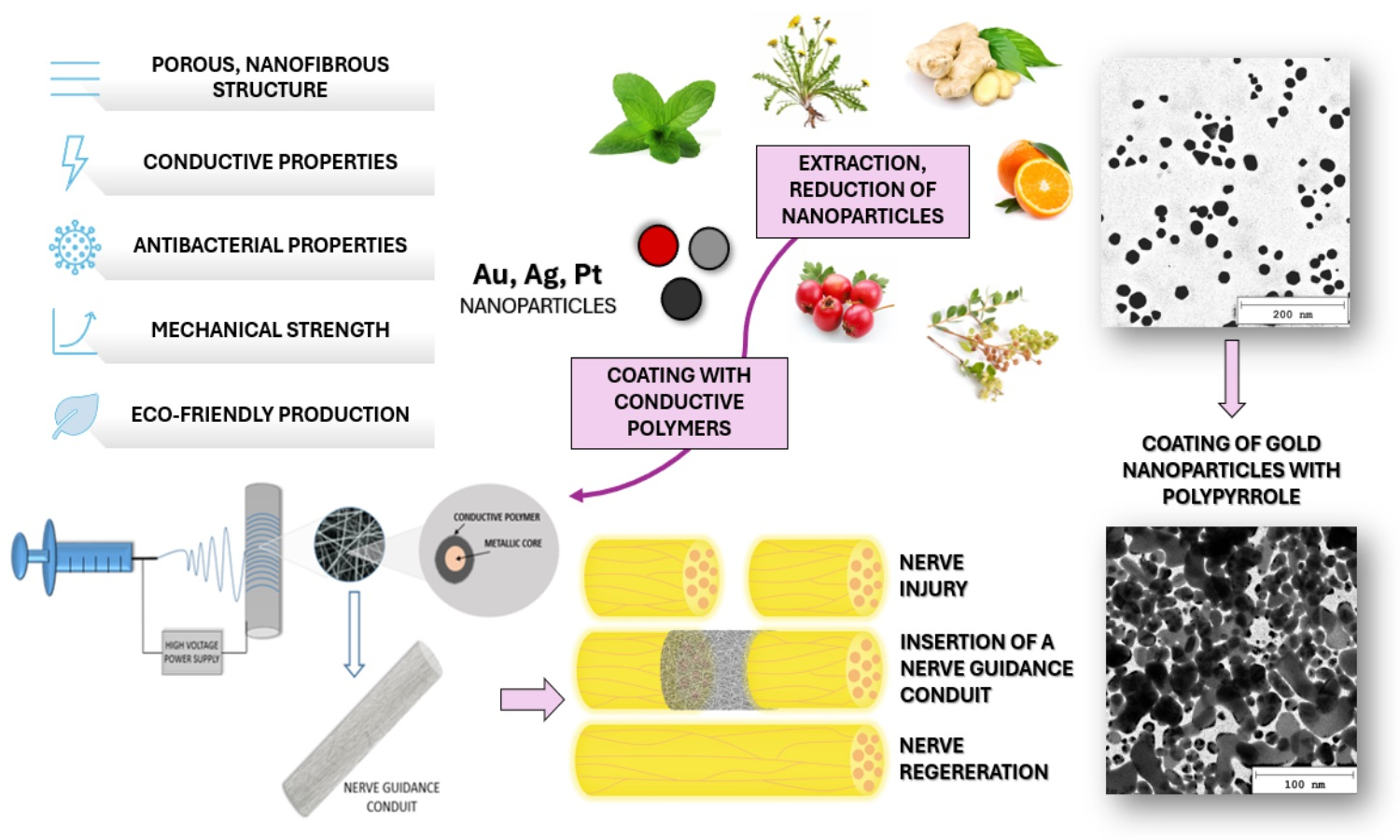

Appropriate protection and guiding are crucial during peripheral nerves repair. New generation nerve guidance conduits (NGCs) should not only provide mechanical support for the damaged nerve but also support healing processes. One of the most promising tissue regeneration applications is fibrous biomaterials since they are characterized by high porosity, flexibility, and strength. Additionally, they enable cell adhesion and proliferation. In this study, novel fibrous nanocomposites were obtained by applying the electrospinning technique, using polylactic acid (PLA) as a polymeric matrix which was further modified with metallic nanoparticles coated with conductive polymers. Such an approach resulted in the obtainment of biomaterials with a potential ability to conduct nerve impulses. The chemical structure of the obtained composites, as well as the morphology of ready products and separate nanocomponents, were investigated using Fourier-transform infrared spectroscopy (FTIR), transmission electron microscope (TEM) and scanning electron microscope (SEM) techniques. Furthermore, conductive and swelling properties in various media were determined. Finally, biomaterials were confirmed to be non-cytotoxic to L929 mouse fibroblasts and 1321N1 human glial cells. Based on the presented results, it can be concluded that nanofibrous nerve guidance conduits have all the key properties in the process of peripheral nerve regeneration and may constitute an important step in novel NGCs development.