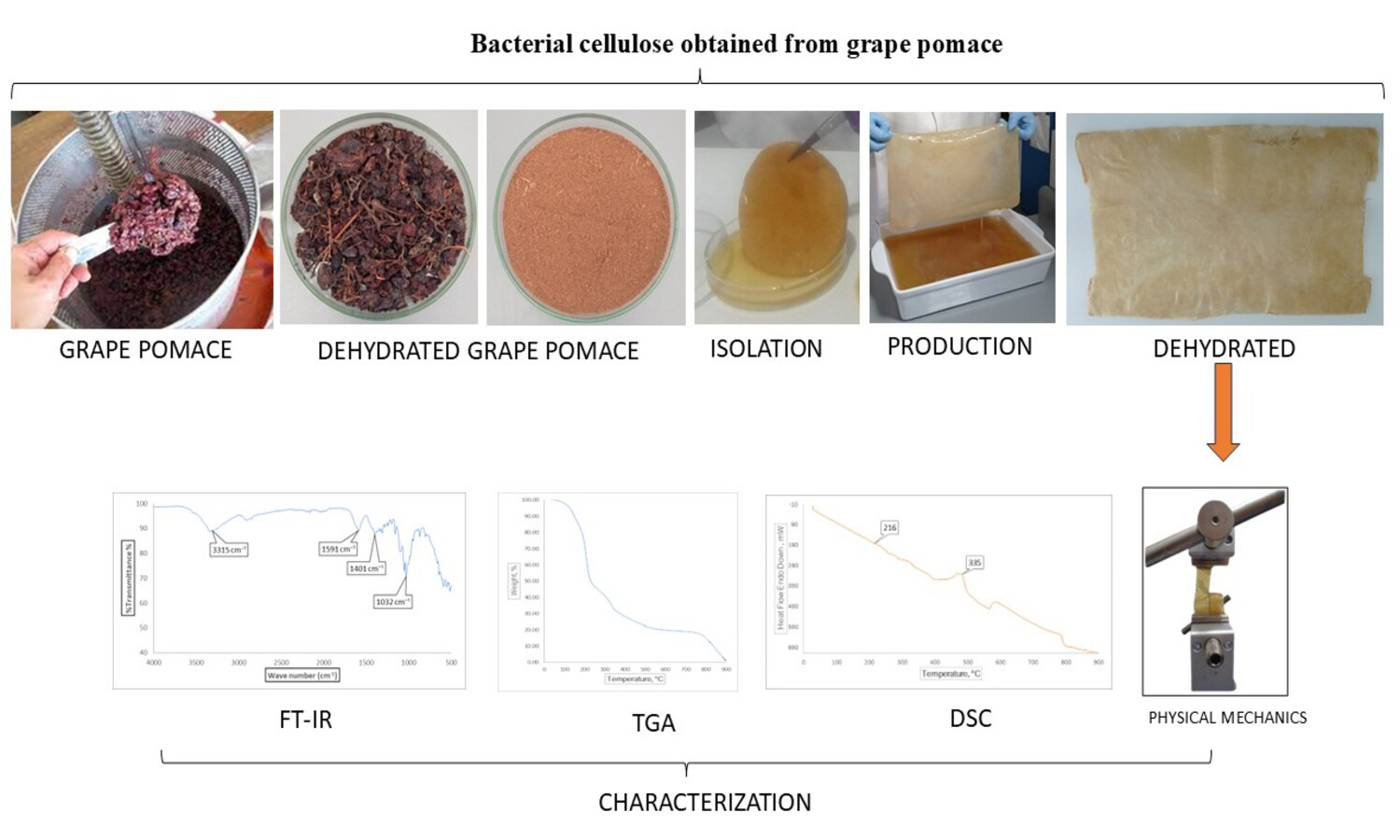

Production of bacterial cellulose by spontaneous fermentation of grape pomace and its thermal, mechanical, and spectroscopic characterization

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

DOI: 10.3144/expresspolymlett.2026.6

GRAPHICAL ABSTRACT

ABSTRACT

Bacterial cellulose (BC) is an eco-friendly biopolymer with outstanding structural and functional properties, offering promising applications in sustainable packaging and bio-based materials. In this study, we demonstrate the feasibility of producing BC via spontaneous fermentation, using grape pomace supplemented with sucrose as the sole carbon source, nutrient substrate, and microbial inoculum, without the addition of commercial strains or nitrogen supplements. Fermentation was conducted under static conditions, yielding biofilms with stable structural characteristics and BC production of up to 14.1 g/L, thereby confirming the efficiency of this low-cost, residue-based process. The films obtained exhibited well-organized polymeric networks, with thermal stability in the range of Tg ≈ 159–266 °C and mechanical resistance comparable to or higher than conventional biopolymers. Characterization confirmed reproducible chemical profiles, thermal stability, and measurable variation in mechanical performance, with a tensile strength ranging from 0.0001 to 105 MPa and an elongation at break of 15±5%. The process highlights a resource-efficient and sustainable pathway, adaptable to rural contexts and aligned with circular economic principles. While minor variations among replicates reflected the intrinsic variability of biological systems, mean values and standard deviations demonstrated reproducible physicochemical and mechanical properties. These findings demonstrate that BC derived from agro-industrial residues can be produced under simple, low-input conditions, opening opportunities for scalable valorization in functional and sustainable materials.

RELATED ARTICLES

Evangelia Balla, Panagiotis Klonos, Apostolos Kyritsis, Dimitrios Bikiaris

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

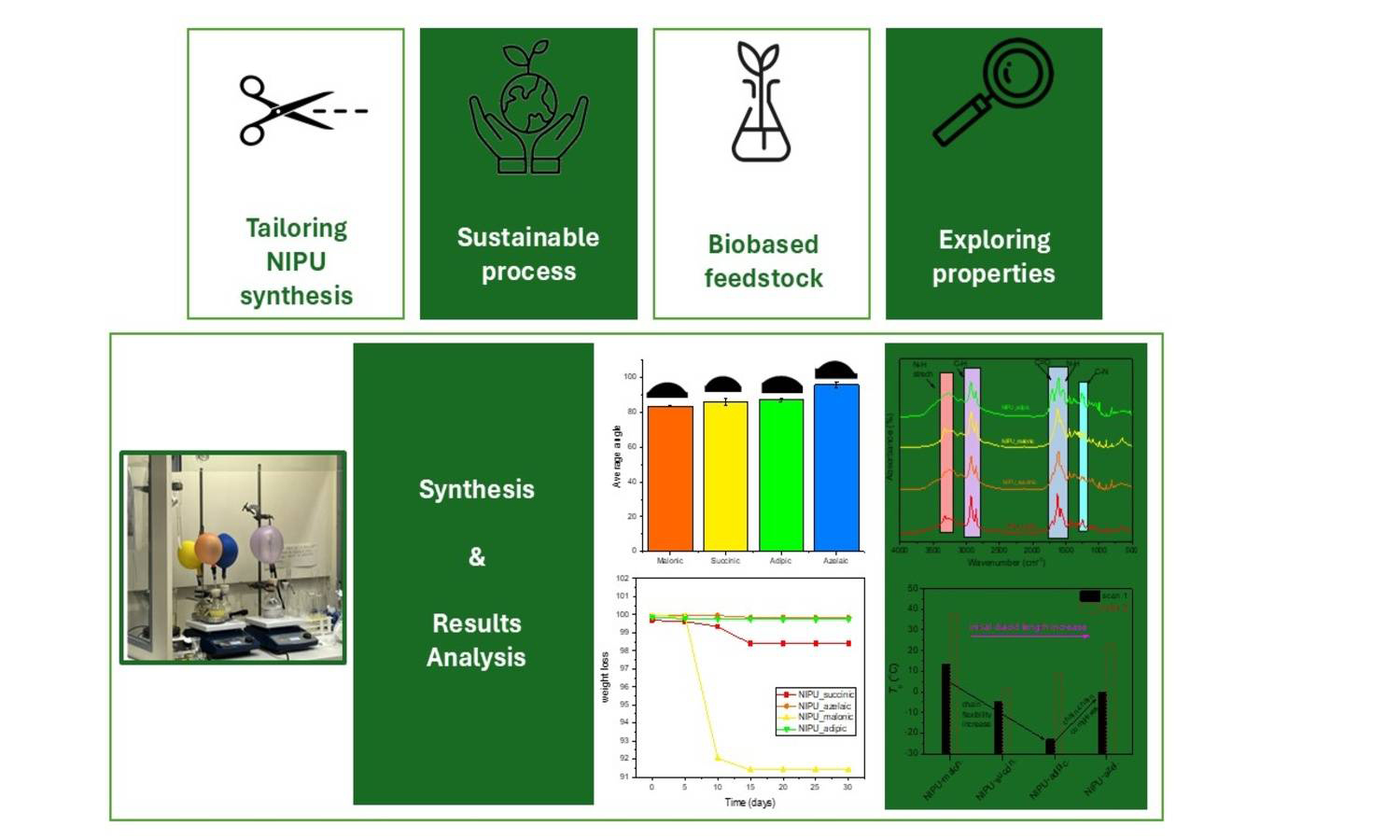

In recent decades, numerous efforts have been dedicated to the investigation of eco-friendly non-isocyanate polyurethanes (NIPUs) as alternatives to conventional polyurethanes (PUs). Since isocyanates are classified by the EU as hazardous and toxic compounds, NIPUs offer a promising route to mitigate isocyanate-related health risks as well as other environmental concerns associated with traditional PU synthesis. In the present study, we report the synthesis as well as the detailed structural and thermal characterization of a new series of fully biobased non-isocyanate polyurethanes (NIPUs) based on aliphatic dicarboxylic acids of different chain lengths. The NIPUs were prepared via a two-step polyaddition reaction involving glycerol carbonate and diamine. Their synthesis enables a sustainable pathway to tailor NIPUs’ physicochemical properties via diacid structure control. Studies of their structure, thermal behavior and trends, morphological, and hydrolytic findings confirmed strong diacid chain length dependence on glass transition temperature (Tg ~13, 0, ‒5 and –23 °C), molecular weight, surface wettability, and enzymatic degradability. Short-chain diacids yielded NIPUs with rapid hydrolytic degradation, while their longer-chain analogs were hydrophobic and thermally stable. Contact angle measurements (~75–85°) also confirm these trends. The tunable properties position these materials among strong candidates for biomedical applications.

Soni Thakur, Amal M. Sindi, Rahul Dev Bairwan, Rasha A. Mahmoud, Eman Alfayez, Nurul Fazita Mohammad Rawi, Kanchan Jha, H.P.S. Abdul Khalil

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

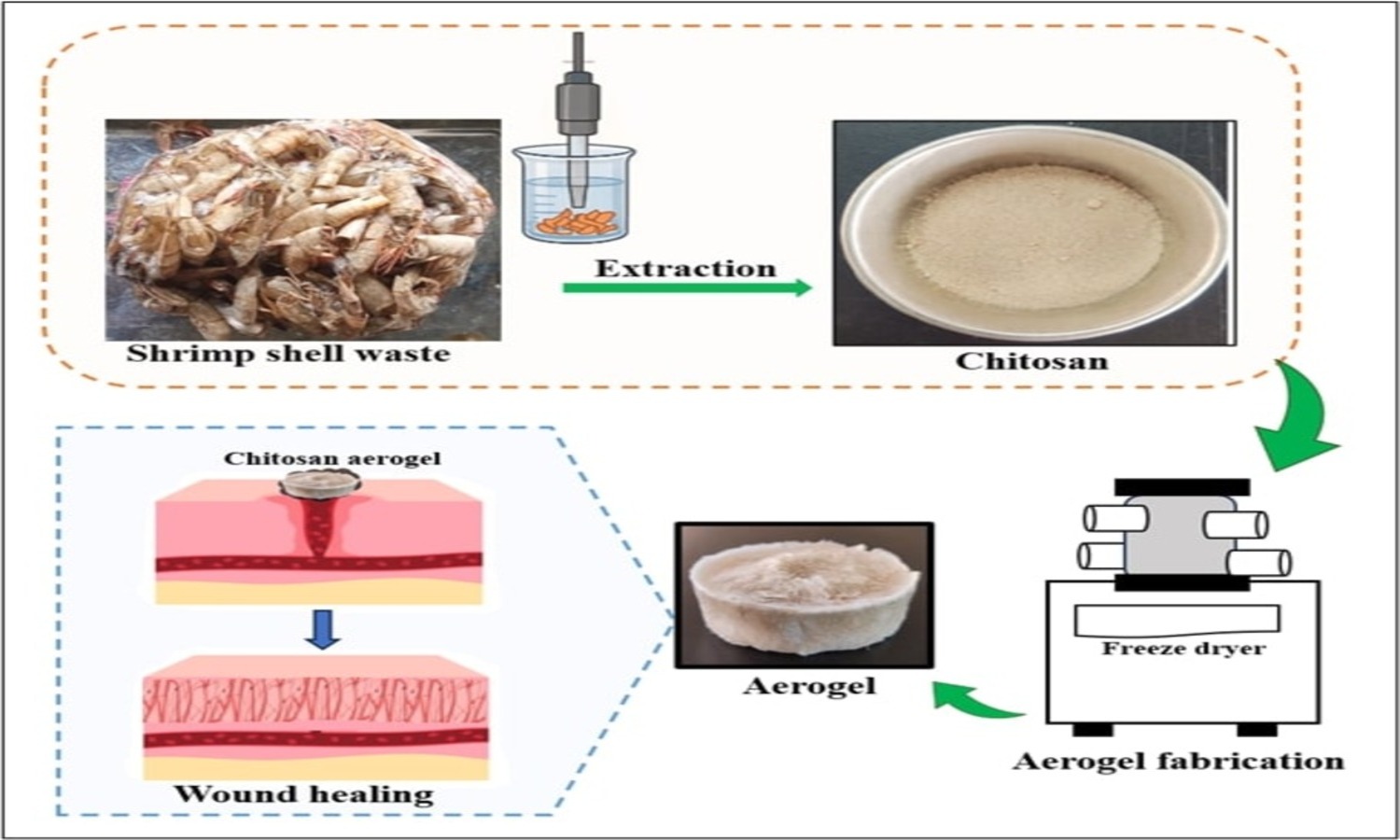

This research presents an eco-friendly approach for extracting chitosan from shrimp shell waste through ultrasound-assisted extraction (UAE) to prepare biocompatible aerogel scaffolds for biomedical applications. The study investigates the influence of various ultrasonic treatment times (10, 20, 30, 40 min) on the yield and structural and physicochemical properties of the extracted chitosan via characterization using Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Among the tested conditions, the 30 min UAE-treated chitosan aerogels showed optimal porosity and structural integrity. Biocompatibility of the aerogels was evaluated, and the results confirmed their non-cytotoxic nature. The bioactivity of the chitosan aerogels was evaluated in terms of their in vitro wound closure ability and antibacterial properties. The aerogels demonstrated a wound closure rate of around 51% after 72 h, significantly higher than the untreated control (37%). In addition, they exhibited clear antibacterial activity against Escherichia coli and Staphylococcus aureus. This sustainable extraction and fabrication method not only adds value to marine waste but also produces functional biomaterials with potential applications in wound healing, tissue engineering, and regenerative medicine, supporting global efforts toward sustainability and circular bioeconomy.

Elumalai Vengadesan, Swaminathan Muralidharan, Dhanjit Das, Thirugnanasambandam Arunkumar

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

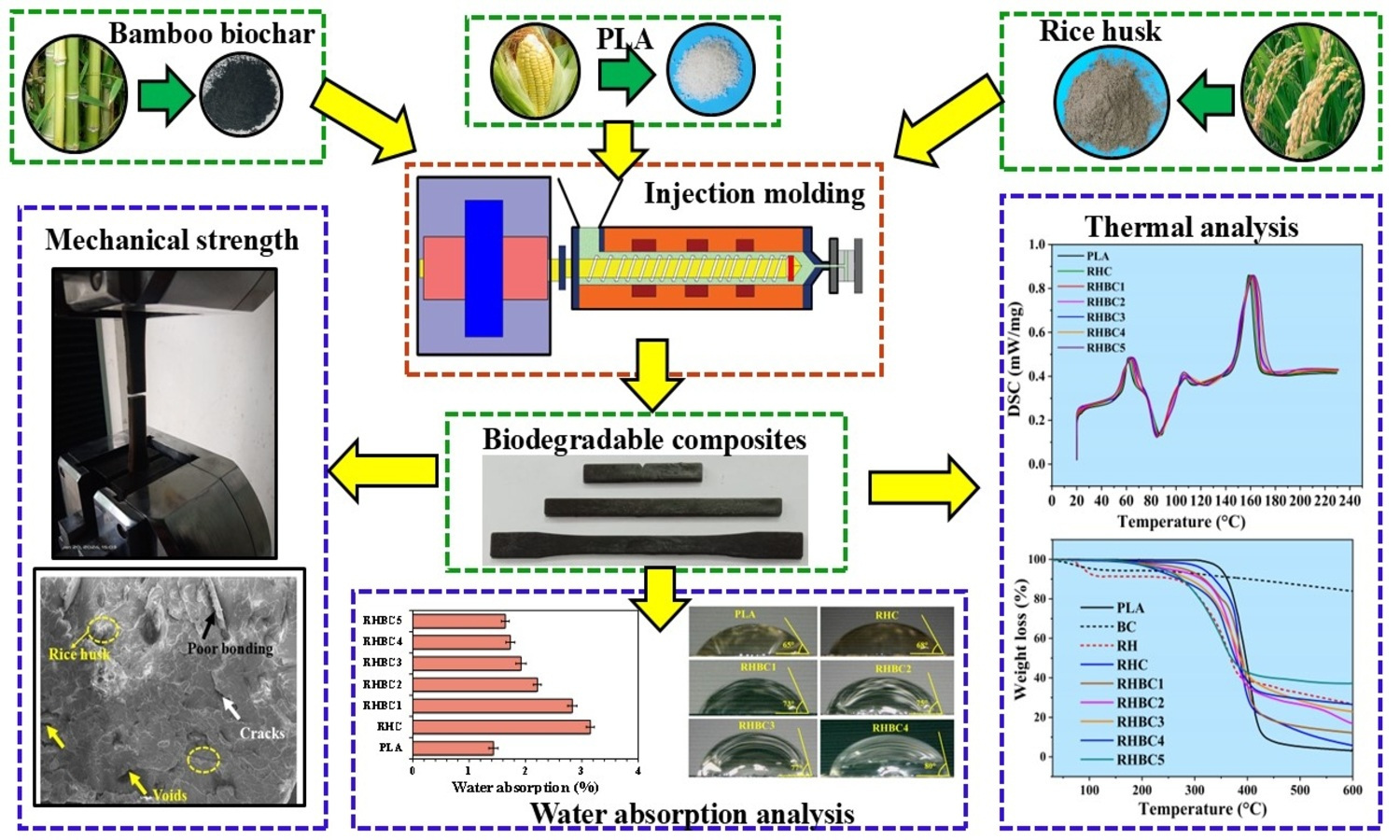

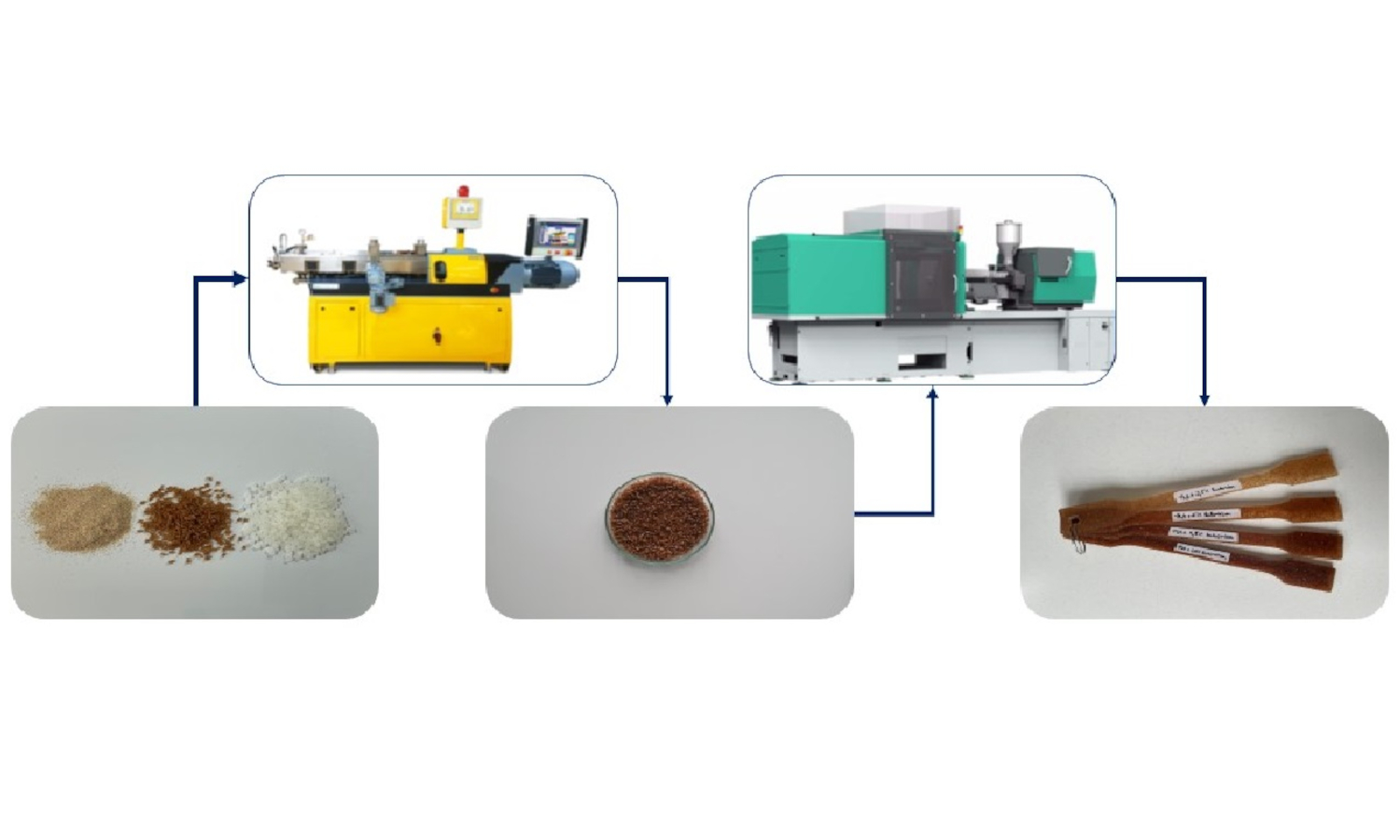

The growing need for sustainable materials has stimulated research into eco-friendly composites, with biochar emerging as an important reinforcement in polymer matrices. Biochar is a carbon-rich material produced by pyrolyzing organic biomass, offering various benefits over traditional fillers, including sustainability, waste reduction, and carbon sequestration. This study explores the effects of bamboo biochar as a hybrid reinforcement on the properties of polylactic acid (PLA)-rice husk composites. The present hybrid composites are prepared by varying the bamboo biochar from 5–25% and have better mechanical properties than PLA and its composite reinforced with a rice husk filler. The tensile, flexural, and compressive strengths of 51.5, 166.0, and 77.5 MPa are measured for the biochar percentage of 10%, representing increases of 73.1, 150.0, and 58.2% compared to PLA, and 158.2, 98.6, and 31% compared to the PLA composite with rice husk. Higher tensile and flexural moduli of 1.46 and 7.34 GPa are observed for 10 and 15%, respectively. However, the impact strength decreases with higher biochar content due to increased rigidity. The material’s hardness increases at higher biochar content due to enhanced stiffness. Thermal transition and degradation points rise due to increased crystallinity from the biochar reinforcement’s nucleation effect. Additionally, the hydrophobic biochar reinforcement reduces water absorption of PLA composite from 3.2 to 1.6%.

Guilherme Ribeiro de Carvalho, Rafael Affonso Netto, Camila Delarmelina, Marta Cristina Teixeira Duarte, Liliane Maria Ferrareso Lona

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

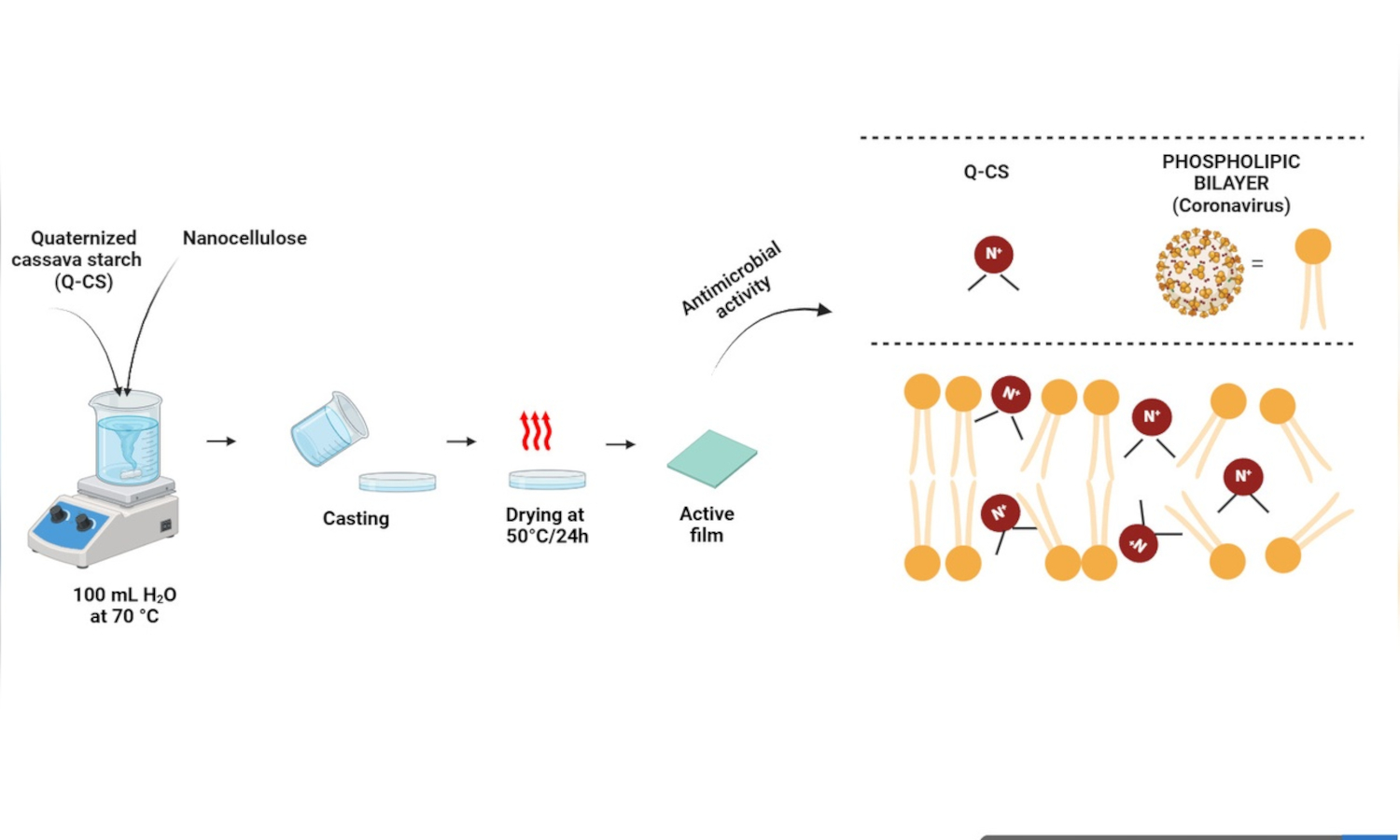

In this study, a new plastic film with antiviral and antibacterial properties was developed using modified cassava starch with glycidyltrimethylammonium chloride (GTMAC) and reinforced by crystalline nanocellulose (CNC), called Q-CS/CNC. For comparison, a control film (Q-CS) was produced without the addition of CNC. Elemental analysis revealed a degree of substitution (DS) of 0.552, indicating the replacement of the OH groups of starch by the NR4+ groups of GTMAC during the quaternization reaction. The addition of CNC resulted in significant increases (p < 0.05) of 38.9, 38.2, and 43.1% in thickness, opacity, and water vapor permeability measurements, respectively, compared to Q-CS. Incorporating CNC also contributed to an increase of 43.6% in tensile strength and 109% in stiffness but slightly decreased thermal stability. The Q-CS/CNC film demonstrated efficacy by inactivating 99% of the coronavirus in 1 min and inhibiting the growth of Staphylococcus aureus and Escherichia coli. This action is attributed to the electrostatic interaction of quaternary amino groups, grafted onto starch, with the phospholipid membrane of microorganisms, resulting in the inactivation of these microorganisms. Therefore, these results highlight the potential use of Q-CS/CNC film as antimicrobial packaging, especially against coronavirus.

Lilla Bubenkó, Násfa Németh, Sára Frey, Tamás Molnár, Károly Belina, Orsolya Viktória Semperger

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Biocomposites have recently received more attention because of raising environmental awareness and the drive toward sustainable technologies. The most common biodegradable polymer is poly(lactic acid) (PLA), which has an excellent balance of physical and rheological properties, but there is some limit to its usage. PLA properties can be improved by adding different types of fibers or fillers that come from agricultural waste. In this study, corn cob and lavender stem were used to reinforce PLA without any coupling agent, and the properties of the composites were investigated. The melt flow rate (MFR) values decreased with the corn cob content and increased with the addition of lavender stem. Mechanical tests showed that the tensile and flexural modulus of the composites increased and the strengths decreased with the reinforcement material content. The rigidness of PLA slightly decreased with the addition of fillers. There was no significant effect on the thermal properties. The unremarkable improvement of the reinforcement was due to the lack of appropriate adhesion of the two phases. The structure of the compounds was found to be homogenous on the scanning electron microscopy (SEM) micrographs. The incorporation of corn cob and lavender stem can reduce the production cost of materials.