Content

All issues / Volume 18 (2024) / Issue 1 (January)

László Mészáros

Vol. 18., No.1., Pages 1-1, 2024

DOI: 10.3144/expresspolymlett.2024.1

Vol. 18., No.1., Pages 1-1, 2024

DOI: 10.3144/expresspolymlett.2024.1

This is an editorial article. It has no abstract.

Piotr Stachak, Izabela Łukaszewska, Jan Ozimek, Konstantinos Nikolaou Raftopoulos, Artur Bukowczan, Edyta Hebda, Carlos Bujalance Calduch, Krzysztof Pielichowski

Vol. 18., No.1., Pages 2-26, 2024

DOI: 10.3144/expresspolymlett.2024.2

Vol. 18., No.1., Pages 2-26, 2024

DOI: 10.3144/expresspolymlett.2024.2

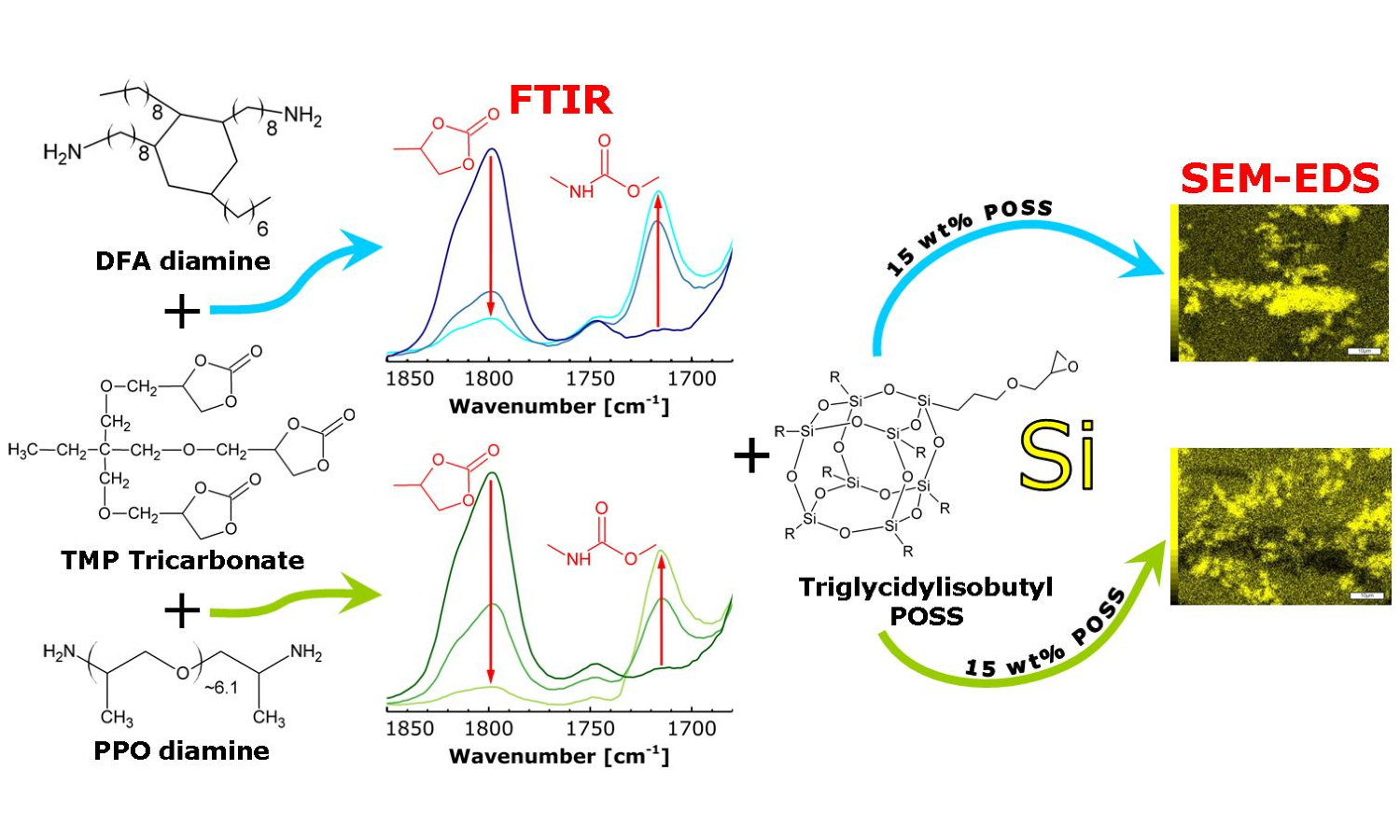

This work reports on the synthesis of non-isocyanate polyurethanes (NIPUs) obtained via the polyaddition of diamines: dimer fatty acid-derived diamine (DFA diamine) or polyether diamine (PPO diamine) with five-membered tri(cyclic carbonate) by a pre-polymerization method. The obtained NIPUs were further chemically modified by polyhedral oligomeric silsesquioxane (POSS) – glycidylisobutyl POSS (1epPOSS). The resulting reinforced composites, containing 5, 10 or 15 wt% 1epPOSS, were characterized in terms of their structure (FTIR, NMR, XRD), microstructure (SEM-EDS) and thermo-mechanical properties (DMA). FTIR confirmed the formation of polyurethanes, and NMR proved the chemical incorporation of 1epPOSS. XRD and SEM-EDS showed a uniform distribution of 1epPOSS in the matrix for low 1epPOSS concentration, with some agglomeration effects depending on the concentration of 1epPOSS. DMA indicated mechanical reinforcement of NIPUs based on DFA diamine. For NIPUs synthesized with PPO diamine, the composite with the highest 1epPOSS loading (15 wt%) exhibited superior mechanical properties in comparison to the pristine matrix, confirmed by both DMA and static stretching test.

Wannarat Chueangchayaphan, Phatchariya Nooun, Nittaya Ummarat, Narong Chueangchayaphan

Vol. 18., No.1., Pages 27-40, 2024

DOI: 10.3144/expresspolymlett.2024.3

Vol. 18., No.1., Pages 27-40, 2024

DOI: 10.3144/expresspolymlett.2024.3

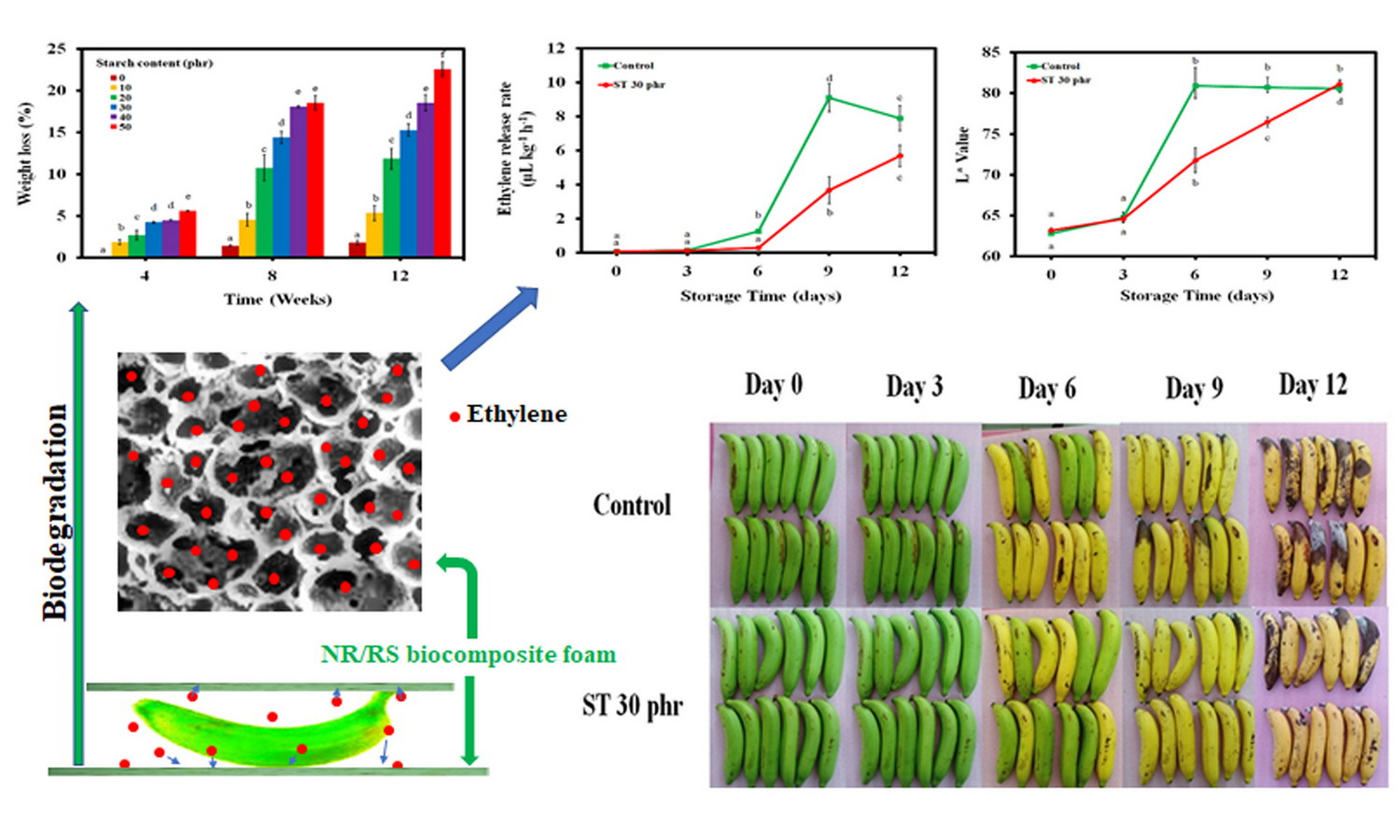

An environmental pollution problem is caused in part by packaging materials made from non-biodegradable synthetic polymers derived from petroleum. In this study, eco-friendly biofoams derived from natural rubber (NR) latex and rice starch (RS) were manufactured on a laboratory scale using the Dunlop process. Rice starch content was varied from 0 to 50 phr. The morphological, thermal, physical, mechanical, and biodegradability properties of the NR/RS biocomposite foams were characterized. Scanning electron microscopy (SEM) was used to assess the morphology of the foam cells. Dynamic mechanical thermal analysis (DMTA) and Thermogravimetric analysis (TGA) were used to investigate the thermal characteristics. When RS was present, it was discovered that the biocomposite foams had decreased thermal stability and enhanced biodegradability. Introducing RS into the NR/RS biocomposite foams also decreased tensile strength, elongation at break, and rebound resilience but increased the 100% modulus, hardness, compression force deflection (CFD), and compression set. The NR/RS biocomposite foams better preserved the banana fruit than the absence of foam, with lower ethylene accumulation, lower total soluble solids (TSS), higher pulp firmness, and good color preservation. This demonstrated that these NR/RS biocomposite foams helped to preserve banana fruit quality during storage and could be used in sustainable packaging applications.

Maria Casapu, Ion Fuiorea, Michel Arrigoni

Vol. 18., No.1., Pages 41-60, 2024

DOI: 10.3144/expresspolymlett.2024.4

Vol. 18., No.1., Pages 41-60, 2024

DOI: 10.3144/expresspolymlett.2024.4

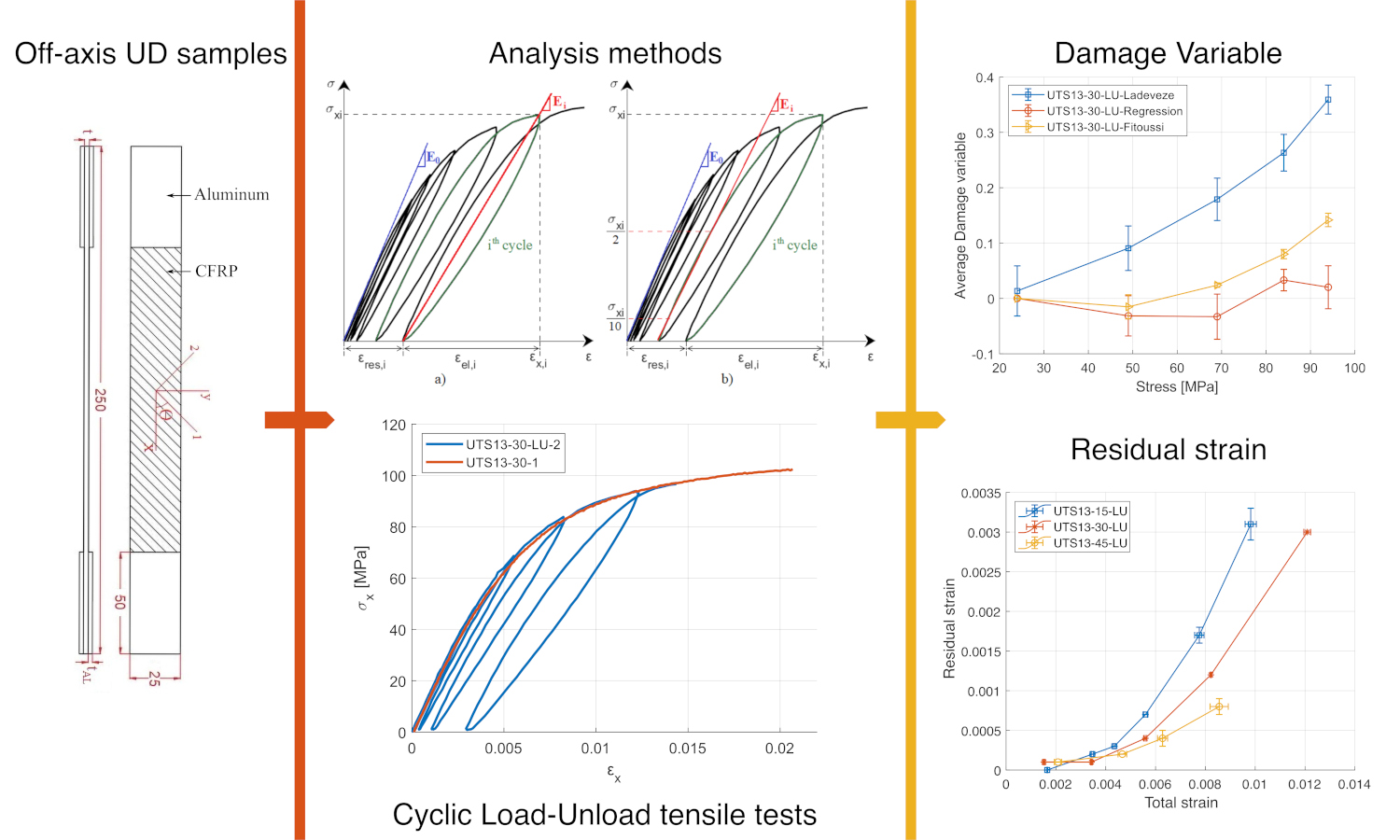

Composite materials are of increasing interest in aircraft and spacecraft structures, and carbon fiber reinforced polymers (CFRP) have emerged as materials meeting quality standards for structural applications in the aircraft industry. Despite their high mechanical properties, CFRPs are associated with high production costs. Building on recent research by the authors, this paper investigates the use of ply-level hybridization to reduce manufacturing costs while maintaining the mechanical performance of the manufactured material. Focusing on the causes of nonlinear response under off-axis tensile loading, the paper involves cyclic load-unload (LU) tensile tests conducted at off-axis angles of 15°, 30°, and 45° to predict mechanical characteristics and damage evolution. Residual strains are directly extracted from load-unload stress-strain responses. Three distinct methods for estimating cycle modulus are employed and compared for damage variable formulation. The research findings reveal dependencies of both the damage variable and residual strains on the off-axis angle. Furthermore, the method used to assess the modulus during cycling loading significantly influences the damage variable estimation. Encouragingly, the hybrid laminates exhibit reduced internal damage and matrix plasticity compared to reference counterparts, indicating a positive effect on the mechanical performances of hybridized CFRPs in addition to the cost reduction.

Mustafa Kuyumcu, Cenk Kurtulus, Mustafa Ciftci, Mehmet Atilla Tasdelen

Vol. 18., No.1., Pages 61-71, 2024

DOI: 10.3144/expresspolymlett.2024.5

Vol. 18., No.1., Pages 61-71, 2024

DOI: 10.3144/expresspolymlett.2024.5

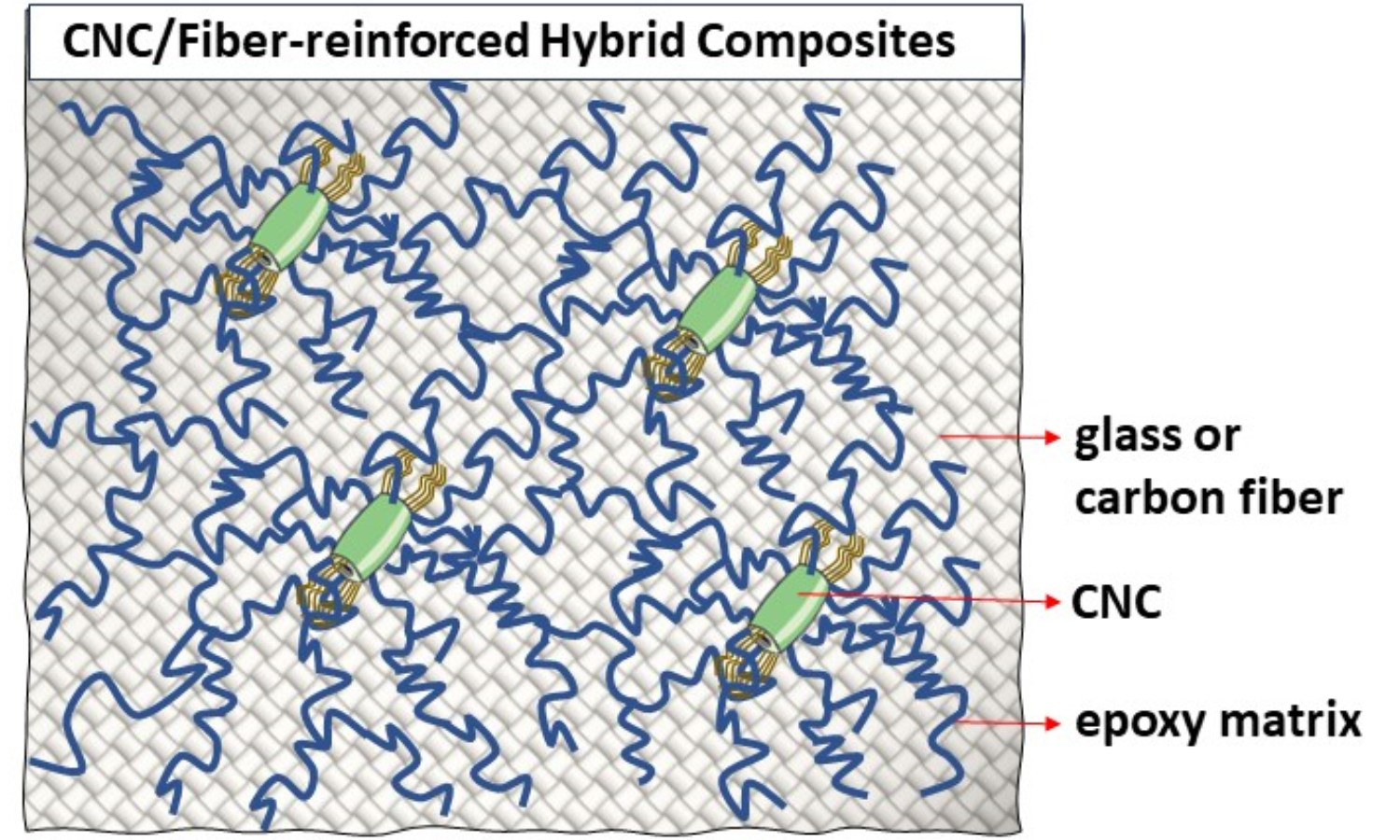

In this study, the potential use of nanocrystalline cellulose (CNC) modified epoxy nanocomposite as a matrix is investigated for both glass and carbon fiber-reinforced composites. Various amounts of CNCs (1, 2, 4, and 6 wt%) were added to bisphenol A diglycidyl ether-based epoxy resin (DGEBA), and the optimum CNC loading was determined as 4 wt% in terms of mechanical and thermal properties. Compared to the reference sample containing a neat epoxy matrix with the obtained carbon fiber/CNC-epoxy (CNC/epoxy/CF) and glass fiber/CNC-epoxy (CNC/epoxy/GF) hybrid nanocomposites, significant improvements have been determined in the in-plane shear modulus and strength, and flexural modulus, respectively. The mechanical properties improvements of CNC/epoxy/CF hybrid composites are approximately 0.9% higher than the CNC/epoxy/GF hybrid composites. Additionally, the distribution of CNC in hybrid nanocomposites is also investigated by scanning and transmission electron microscopies. It is noted that the homogenous dispersion of CNCs in the epoxy matrix and their diameters varied from 10 to 100 nm are detected at higher magnification.

Flavio Massignan, Gergő Gyulai , Kata Horváti, Szilvia Bősze, Éva Kiss

Vol. 18., No.1., Pages 72-87, 2024

DOI: 10.3144/expresspolymlett.2024.6

Vol. 18., No.1., Pages 72-87, 2024

DOI: 10.3144/expresspolymlett.2024.6

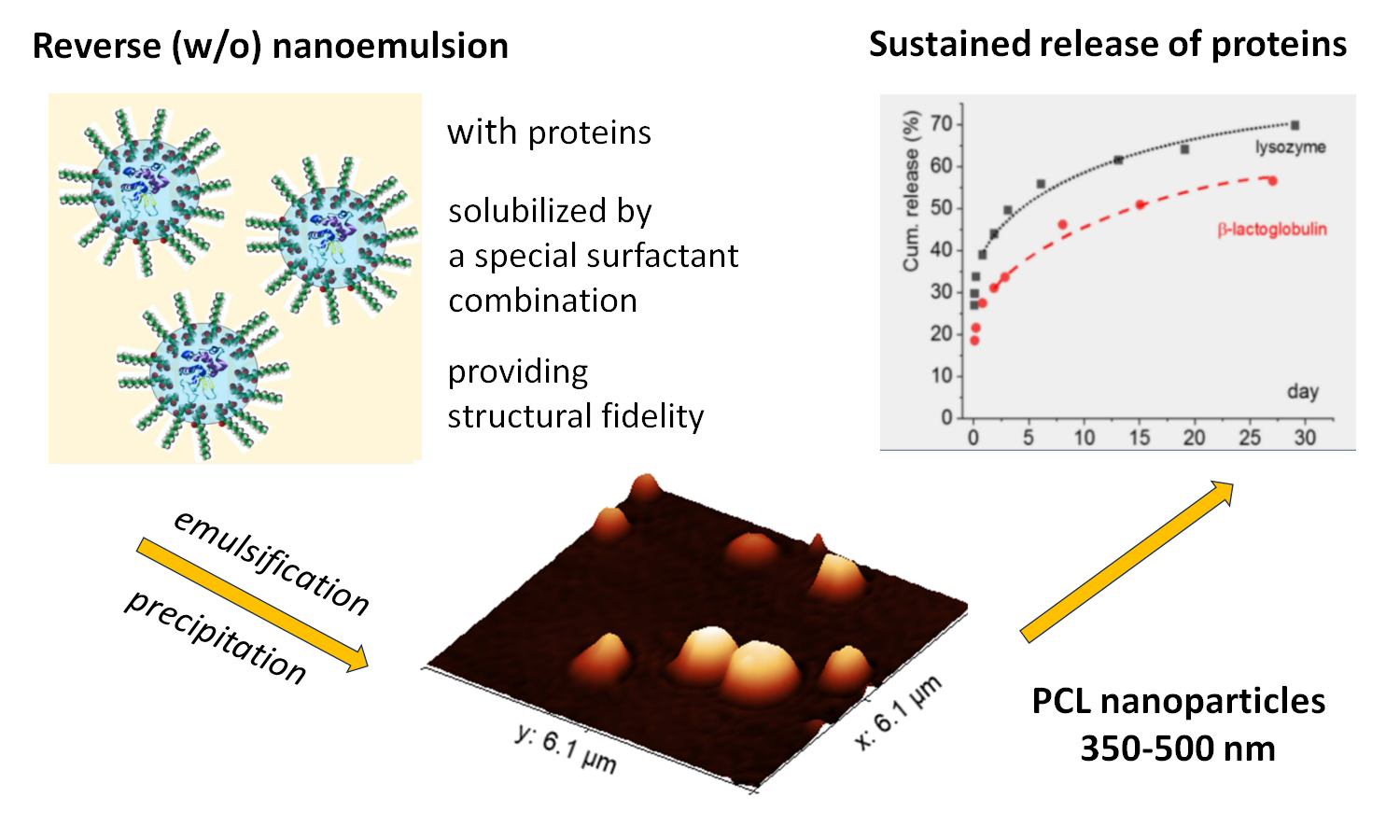

The elaboration of potent delivery systems for peptides/proteins is still a challenge but is increasingly needed in advanced therapy. In the present research, we have developed a nanoencapsulation system for peptides/proteins, which is suitable for the delivery of hydrophilic bioactive compounds. The preparation method combines the advantageous properties of reverse nanoemulsion and nanoprecipitation, resulting in the formation of nanoparticles in the size range of 350–500 nm. The polymeric coating composed of polycaprolactone allows chemical functionalization and protection while the inner microenvironment (containing 1-decanoyl-rac-glycerol and N,N-dimethyldodecylamine N-oxide surfactants) provides aqueous surrounding for the active with structural fidelity. Hen egg white lysozyme and β-lactoglobulin were successfully encapsulated, achieving protein contents of 10–60 μg/mg and encapsulation efficiencies ranging from 5–50% depending on the protein type and loading concentration. In vitro release measurement showed a biphasic sustained release profile of both proteins in the time range of one month. In vitro cytotoxicity investigation of protein-loaded nanoparticles exhibited good cell viability (above 95% at the highest treatment concentration of 0.3 mg/ml). The encapsulated membrane-active peptides have shown improved bioactivity.

Afsoon Farzan, Sedigheh Borandeh, Hossein Baniasadi, Jukka Seppälä

Vol. 18., No.1., Pages 88-101, 2024

DOI: 10.3144/expresspolymlett.2024.7

Vol. 18., No.1., Pages 88-101, 2024

DOI: 10.3144/expresspolymlett.2024.7

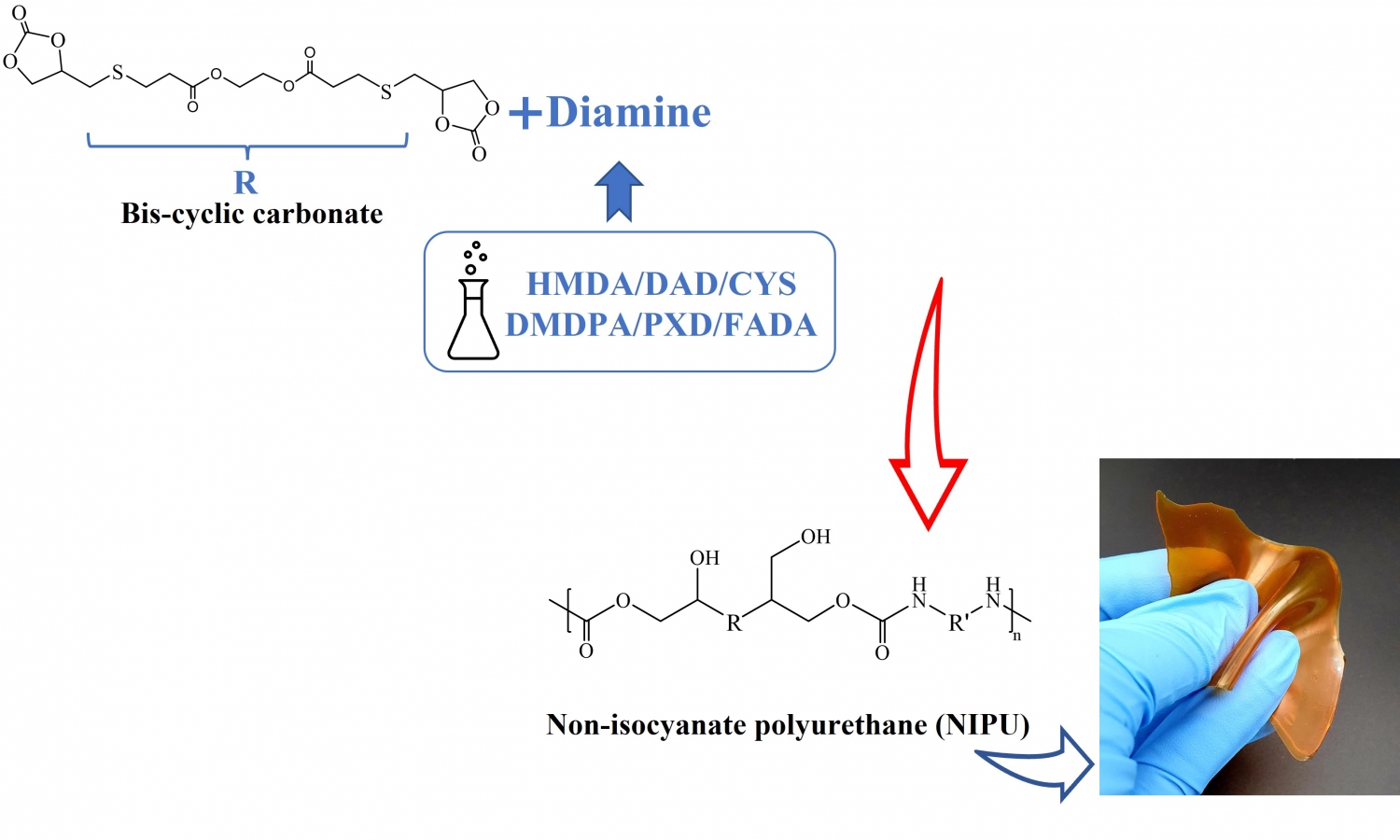

A series of environmentally friendly non-isocyanate polyurethanes (NIPUs) was synthesized through a polycondensation reaction of as-synthesized semi-bio-based bis-cyclic carbonate with diamine derivatives. The synthesis of biscyclic carbonate was realized, for the first time, from 1-thioglycerol and polyethylene glycol diacrylate via thiol-ene click and transcarbonation reaction, respectively. The impacts of using different diamine derivatives on the chemical structural, mechanical properties, thermal stability, and surface wettability of the NIPUs were determined. It was found that the NIPU containing fatty acid-based diamine decomposed at a lower temperature than that of other polymers. Besides, it demonstrated a lower Young’s modulus and a higher tensile strain at break, possibly due to its four-branched structure and greater flexibility. Meanwhile, the NIPU prepared with p-xylylenediamine provided the highest decomposition temperature, owing to an aromatic moiety in the polymer’s backbone, which improved its stiffness and thermal stability. Furthermore, it was understood that the NIPU containing diamino-N-methyldipropyl-amine exhibited a higher Young’s modulus and a lower tensile strain at break, as it had a nitrogen atom in its structure and a trigonal pyramidal configuration with the highest density of hydrogen bonds between polymer chains. Most of the developed NIPUs displayed hydrophobic surface properties, offering promising alternatives to isocyanate-based coating materials.

Shivapura Manchaiah Anush, Suchetha Naga Raju, Ballupet Honnapa Gayathri, Keresanthe Parameshwarappa Ajeya, Yarabahally Ravindranath Girish, Sanneerappa Darshan, Yelaware Puttaswamy Naveen, Kalappa Prashantha, Byrappa Krishnaiah Narendra, Aishwarya Jayaram

Vol. 18., No.1., Pages 102-115, 2024

DOI: 10.3144/expresspolymlett.2024.8

Vol. 18., No.1., Pages 102-115, 2024

DOI: 10.3144/expresspolymlett.2024.8

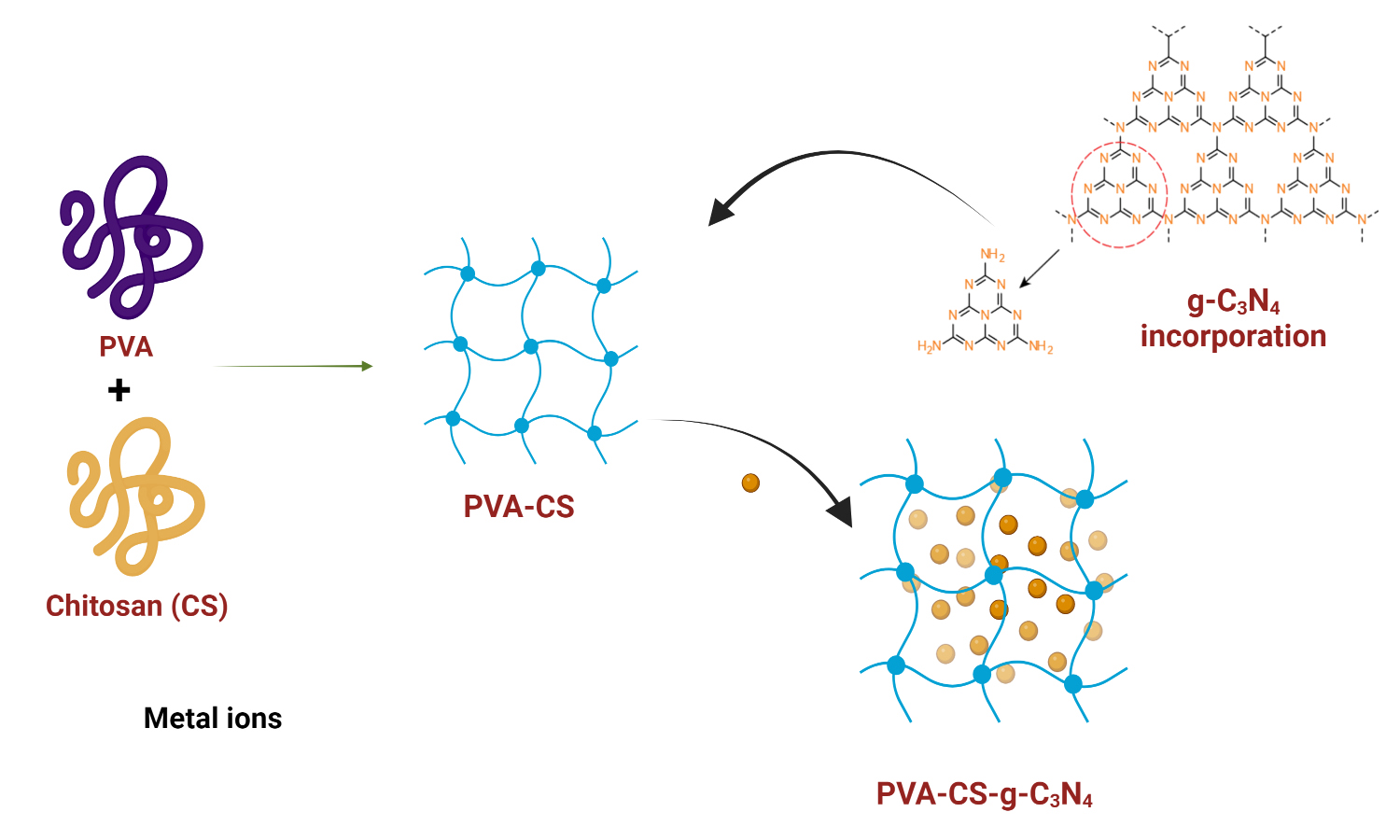

A novel adsorbent material for the effective removal of hazardous metal ions from aqueous solutions was developed through modifications to chitosan. The process involved the use of vanillin to create cross-linked chitosan, which was then combined with thiourea-based graphitic carbon nitride (g-C3N4) to form a gel matrix. The resulting composite material was thoroughly characterized using various techniques, including Fourier transform infrared spectroscopy, thermogravimetric analysis, scanning electron microscopy, energy dispersive X-ray spectroscopy, and X-ray diffractometry. To assess its efficacy, adsorption experiments were conducted to determine the capability of the synthesized compounds to adsorb Cu(II) and Cr(VI) ions. The observed results found that the adsorption process was found to follow pseudo-second-order kinetics and the Langmuir isotherm model. Through thermodynamic studies, it was revealed that the adsorption process was both endothermic and spontaneous in nature. Furthermore, desorption studies confirmed that the material could be regenerated, making it reusable. This characteristic allowed for the effective recovery of the adsorbate species and highlighted the potential for reusing the adsorbent material multiple times.