Effect of cold-resistant plasticizer with different acid chain lengths on the cold-resistant properties of PVC: Experiments and MD simulations

Vol. 19., No.9., Pages 959-976, 2025

DOI: 10.3144/expresspolymlett.2025.72

DOI: 10.3144/expresspolymlett.2025.72

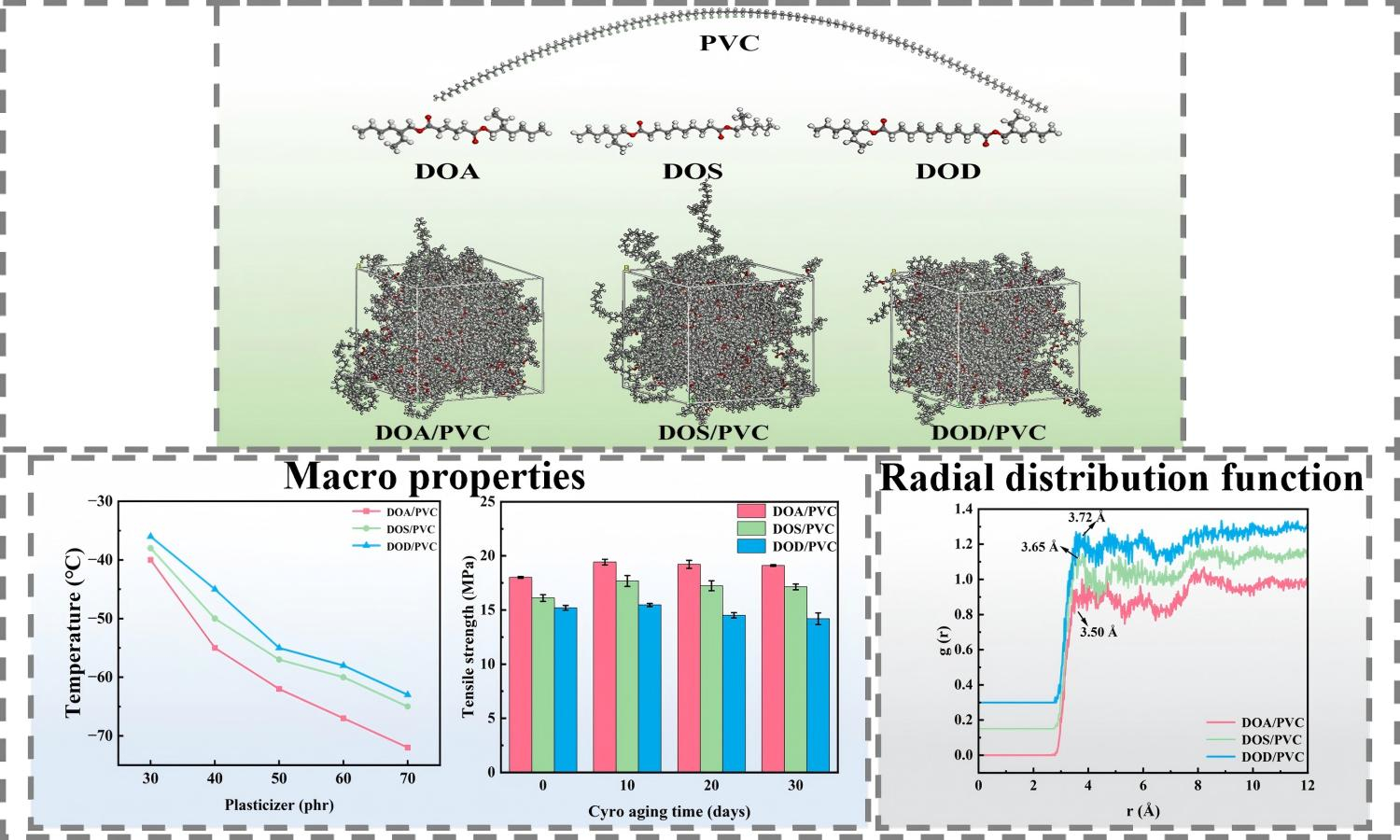

GRAPHICAL ABSTRACT

ABSTRACT

As polyvinyl chloride (PVC) films are hard and brittle in a low-temperature environment, aliphatic dibasic acid ester plasticizers with different acid chain lengths were fabricated, i.e. di(2-ethylhexyl) adipate (DOA), di(2-ethylhexyl) sebacate (DOS) and dioctyl dodecanedioate (DOD), and their effects on the cold-resistant properties of PVC were investigated using experiments and molecular dynamics (MD) simulations. The brittleness temperature and tensile properties of plasticizers/PVC are negatively related to the acid chain length of the aliphatic dibasic acid esters. The brittleness temperatures of the three systems are all below –50 °C. In-situ low-temperature tensile tests and aging tests indicate that DOA/PVC exhibits the best cold resistance and stability. MD simulations further reveal that the best compatibility between DOA and PVC is attributed to its strong binding energy and weak hydrogen bonding interactions, while van der Waals forces are dominant in DOS/PVC and DOD/PVC. This study elucidates the structure-property relationship between aliphatic dibasic acid ester plasticizers and PVC from the perspective of molecular interactions, and provides insights into the design of cold-resistant PVC plasticizers.

RELATED ARTICLES

Amanda Legnani, André Luis Marcomini, Philipe Augusto Pocidonio Silva, Ricardo Geraldo de Sousa, Anderson Júnior dos Santos, João Paulo Ferreira Santos

Vol. 20., No.4., Pages 326-341, 2026

DOI: 10.3144/expresspolymlett.2026.26

Vol. 20., No.4., Pages 326-341, 2026

DOI: 10.3144/expresspolymlett.2026.26

This work presents the development of high-performance thermoplastic polyurethane (TPU) nanocomposites reinforced with low contents of multilayer graphene (mG), aiming to improve their tribological behavior. Using twin-screw extrusion followed by hot pressing, nanocomposites containing 0.1, 0.25, 0.5, 1, and 2% mG weight were fabricated and systematically evaluated. Nanocomposites with only 0.1–0.25 wt% mG achieved a 36% reduction in friction coefficient and 87.5% reduction in wear volume compared to neat TPU. Results are rarely reported at such low filler loadings. Scanning electron microscopy (SEM) analysis revealed uniform dispersion at these optimal concentrations, while higher mG contents led to agglomeration and performance loss. Rheological studies indicated improved flow behavior, and dynamic-mechanical analysis confirmed increased energy dissipation and thermal response. These results suggest that the concentrations of 0.1% and 0.25% of multilayer graphene used in the study are promising for improving the performance of TPU nanocomposites in applications requiring high wear resistance for advanced applications in automotive, biomedical, and high-load engineering components, where durability and low friction are essential.

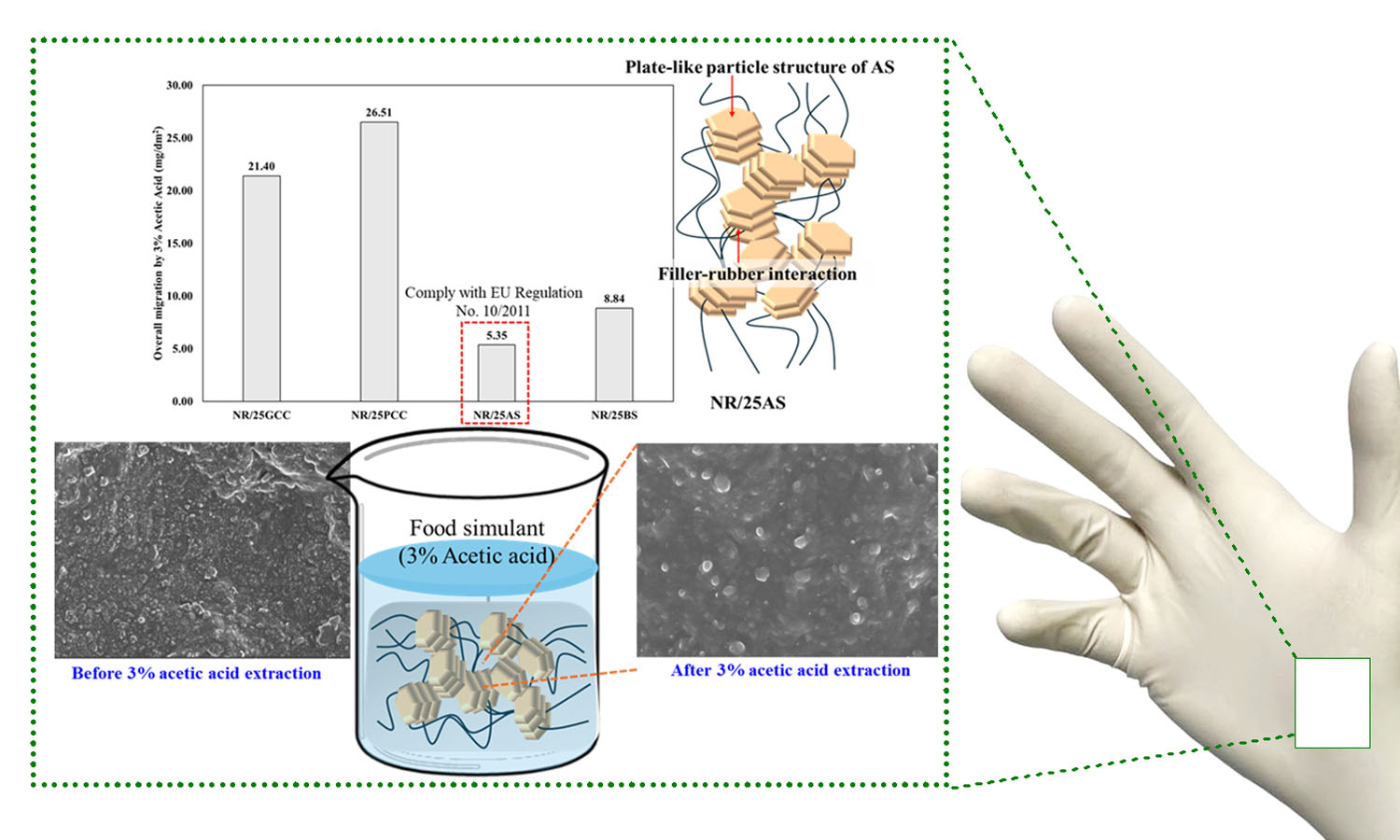

Sirithorn Kaewklum, Parisa Faibunchan, Apinya Krainoi, Banyat Cherdchim, Jutharat Intapun

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Powder-free natural rubber gloves for chemical migration resistance of food-contact grade are prepared using a variety of fillers, including ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), aluminum silicate (AS), and barium sulfate (BS)-filled natural rubber (NR), respectively. The properties of NR gloves, including mechanical, dynamic mechanical, and thermal properties, were investigated. Furthermore, the overall migration test of NR gloves was conducted according to the regulations for food contact gloves (EU Regulation No. 10/2011), using 3% acetic acid as the simulant. Among the fillers studied, the plate-like particles of AS facilitated the most effective filler-rubber interactions and reinforcement in AS-filled natural rubber (NR/AS). Consequently, the highest crosslink density, force at break, and damping properties of NR gloves were achieved by applying AS in the NR matrix. Moreover, the lowest overall migration level was observed for NR/AS with a value of 5.35 mg/dm2, which complies with EU Regulation (overall migration of food simulants shall not exceed 10 mg/dm2). Therefore, NR gloves filled with AS are suitable for food-contacting NR gloves.

Magali Castres, Aboulghit El Malki Alaoui, Camille Caisso, Martin Monloubou, Michel Arrigoni

Vol. 18., No.10., Pages 1008-1022, 2024

DOI: 10.3144/expresspolymlett.2024.77

Vol. 18., No.10., Pages 1008-1022, 2024

DOI: 10.3144/expresspolymlett.2024.77

Nowadays, ultra high molecular weight polyethylene (UHMWPE), allows the combination of lightweight, high strength and is praised for the design of severely loaded structures. It has become a good option for lightweight armour solutions. It is therefore important to characterise its mechanical behaviour. Up to now, strain rate effects on mechanical behaviour have been poorly explored. In this work, this issue is tackled by studying the strain rate influence on the in-plane deformation, in shear and tension of the Tensylon® HSBD30A, a UHMWPE dedicated to ballistic and blast protection. Two laminates of Tensylon® of respective orientation [0 °/90°]20 and [±45°]20 were subjected to static and split Hopkinson tensile bar (SHTB) tests. A new mounting system was designed, and new specimen shapes were used to match the experimental setup configurations. Digital image correlation (DIC) was used to measure the in-plane strain. A significant strain-rate dependence on the material behaviour.is evidenced. Besides, results exhibit a higher strength for the [0°/90°]20 specimen than for the [±45°]20 one. Despite some limitations, the proposed setup and measurement methods allowed visualisation of strain rate effects on the stress-strain relationship for strain rates ranging from the quasi-static regime to the dynamic one (1500 s–1).

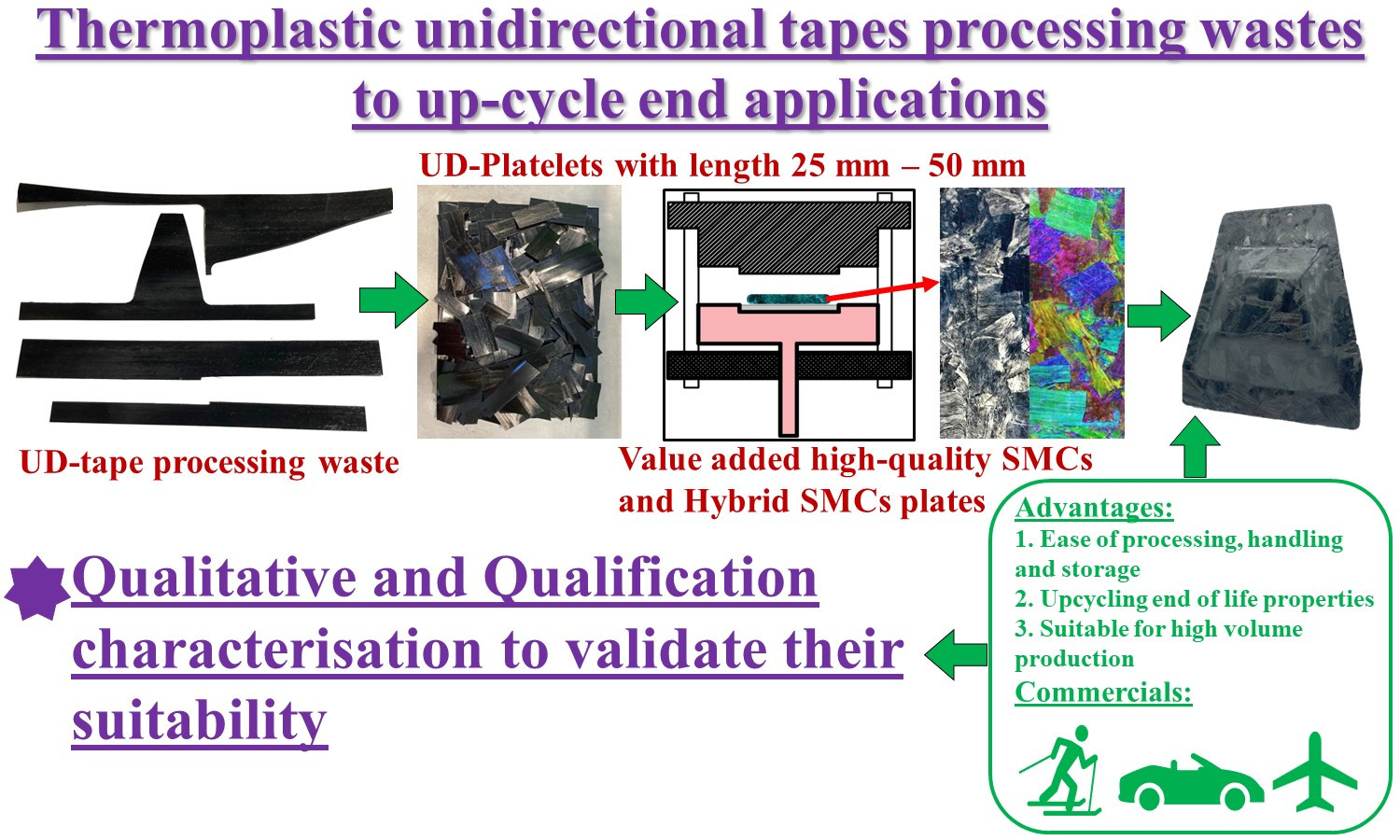

Chethan Savandaiah, Andreas Kapshammer, Bernhard Plank, Vanja Stolcer, Christian Marschik, Zoltan Major

Vol. 18., No.9., Pages 883-900, 2024

DOI: 10.3144/expresspolymlett.2024.66

Vol. 18., No.9., Pages 883-900, 2024

DOI: 10.3144/expresspolymlett.2024.66

Thermoplastic (TP) composites, known for their ease of handling, suitability for high production rates, and recyclability, are emerging as a promising alternative to thermoset-based composites. The expected growth in TP-based composites in automotive, sports, and aerospace industries may result in increased post industrial waste. To address this, we repurposed our in-house process scrapped carbon fibre-reinforced polycarbonate tapes into sheet moulding compounds (SMCs) and Hybridised SMCs (Hy-SMCs) using compression moulding. In Hy-SMCs, the top and bottom layers were unidirectional tapes, while the core section had randomly oriented platelets in a 50:50 ratio. Our evaluation included qualitative and thermo-mechanical standard tests. The incorporation of unidirectional tapes in Hy-SMCs significantly improved the tensile and flexural properties of SMCs. Specifically, these enhancements resulted in an impressive 81 to 85% increase in mechanical strength compared to the standard aluminium grade. Additionally, Hy-SMCs exhibited a 120 to 130% increase in tensile and flexural properties compared to SMCs. Fractography revealed a complex relation between fractured surfaces, with multimode failures in both SMCs and Hy-SMCs. Also, the non-destructive evaluation showed platelet reorientation during consolidation and localised voids with increased specimen thickness.

Toughness enhancement of polyamide 1012 with intermolecular hydrogen bonding with 3-pentadecylphenol

Jing Lu, Qin Ma, Jianqi Yao, Jiajie Yin, Ruiyan Zhang, Faliang Luo

Vol. 18., No.7., Pages 705-714, 2024

DOI: 10.3144/expresspolymlett.2024.52

Vol. 18., No.7., Pages 705-714, 2024

DOI: 10.3144/expresspolymlett.2024.52

In order to improve the impact toughness of polyamide 1012 (PA1012) by reducing the amount of hydrogen bonding resulting from PA1012 itself, 3-pentadecylphenol (PDP) was considered to be added into PA1012 using melting extrusion. The hydrogen bonding interaction between PA1012 and PDP was characterized by Fourier transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR). The effects of PDP on the crystallization, melting process, and mechanical behavior of PA1012 were tested in detail. The results show that the PDP can reduce the temperature of PA1012 crystallization and melting but it can significantly improve elongation at break and impact toughness. The notched impact strength of the PA1012/PDP composites containing 20 wt% PDP reached to 70.6 kJ·m–2, which is about seven times that of the neat PA1012. The effects of PDP on PA1012 properties is ascribed to hydrogen bonding interaction between hydrogen bonding between phenol hydroxyl groups and amino groups on PA1012 chains. The deduction was also verified by adding acetylated 3-pentadecylphenol (APDP) to modify PA1012. It is believed the research will open up new prospects for the wide application of PA1012 toughening.