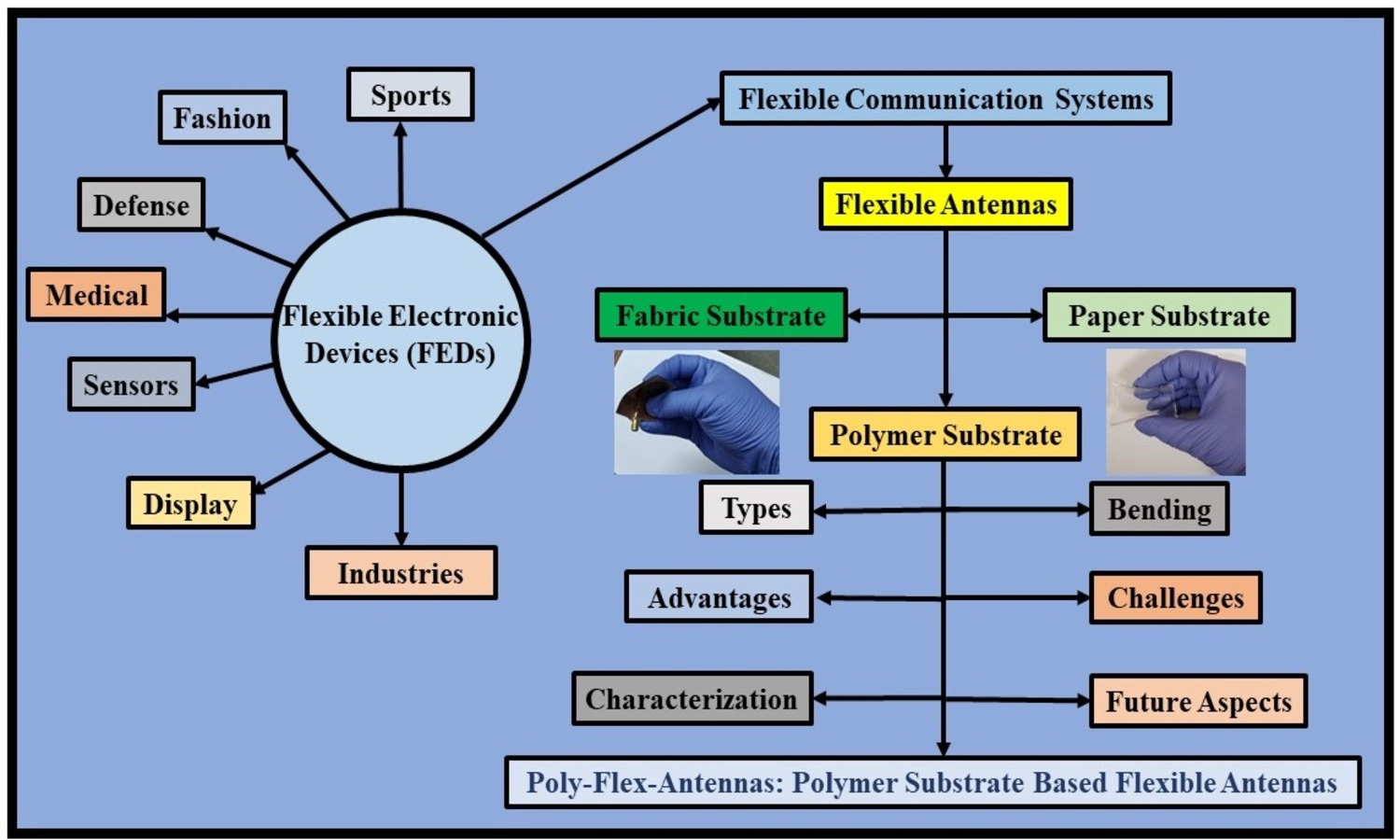

Poly-flex-antennas: Application of polymer substrates in flexible antennas

Vol. 18., No.4., Pages 371-390, 2024

DOI: 10.3144/expresspolymlett.2024.28

DOI: 10.3144/expresspolymlett.2024.28

GRAPHICAL ABSTRACT

ABSTRACT

The

proliferation of flexible electronics has entirely transformed the field of

antenna design and paved the door for cutting-edge uses in communication,

sensing, and other areas. The present research lends a succinct overview of the

intriguing advancements in flexible antenna technology, with specific emphasis

on the implementation of polymer substrates. As we refer to poly-flex antennas in

this article, they stand for the incorporation of polymer substrates in antenna

design. Polymer substrates are the optimum candidate for flexible antenna

applications as they have specific advantages, including being lightweight,

conformable, and inexpensive. The main features of poly-flex antennas, such as

their design concepts, fabrication processes, and performance characteristics,

are being explored in this proposed article. We delve into the wide variety of

polymer substrates that are appropriate for antennas, taking into account their

dielectric characteristics, flexibility, and environmental resistance. Their

dielectric characterization, bending effects, challenges, and future prospects

of this burgeoning field are also addressed. We conclude by emphasizing the

immense potential of poly-flex-antennas to shape the future of wireless

communication and sensing systems, and how the adoption of polymer substrates

is driving innovation in antenna engineering.

RELATED ARTICLES

Dam Xuan Thang, Tong Khanh Linh

Vol. 20., No.3., Pages 246-263, 2026

DOI: 10.3144/expresspolymlett.2026.20

Vol. 20., No.3., Pages 246-263, 2026

DOI: 10.3144/expresspolymlett.2026.20

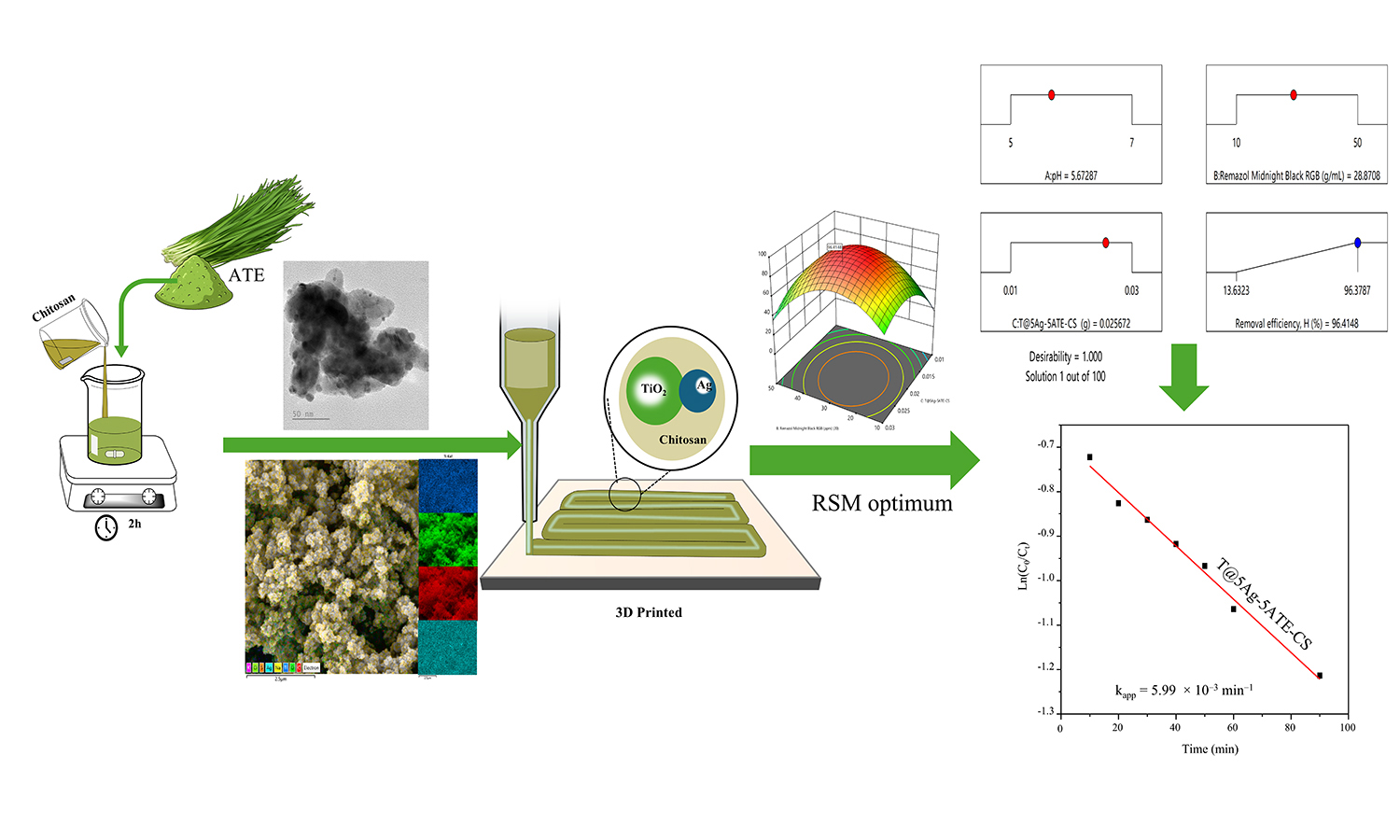

We report a green route to Ag–TiO2 nanocomposites using an Allium tuberosum extract, rich in organosulfur and polyphenolic constituents, as a dual-function biogenic reducer and stabilizer, enabling efficient Ag+→Ag0 conversion and capping of Ag–TiO2 without the use of harsh reagents. The nanocomposites are formulated into chitosan-based inks for direct ink writing (DIW) of porous, mechanically robust, reusable membranes (optimal formulation T@5Ag–5ATE–CS) with a homogeneous Ag dispersion. Multiscale characterization (SEM/TEM, XRD, FTIR, UV–vis DRS, EDS mapping) confirms metallic Ag0 uniformly decorating TiO2 and an extended visible-light response attributable to strong localized surface plasmon resonance. Under near-UV/visible irradiation, the membranes decolorize Remazol Midnight Black RGB dye with pseudo-first-order kinetics, yielding kapp up to 5.99·10–3 min–1 with R2 ≈ 0.99 and outperforming pristine TiO2. Response surface methodology identifies an optimum at pH 5.67, 28.87 mg·L–1 dye, and 0.0257 g catalyst, delivering a predicted 96.41% versus experimental 95.07% removal (validation error 1.39%) with excellent model statistics (R2 ≈ 0.995). The combined effects of Allium-tuberosum-assisted Ag plasmonics, TiO2 photocatalysis, and chitosan-enhanced adsorption underpin the high photocatalytic activity and reusability, highlighting a scalable, eco-friendly pathway to printable photocatalytic/antimicrobial membranes for wastewater treatment.

Cláudia Andréa Batista dos Santos, Bartłomiej Kryszak, Rafał Malinowski, Aleksandra Ujćič, Konrad Szustakiewicz

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

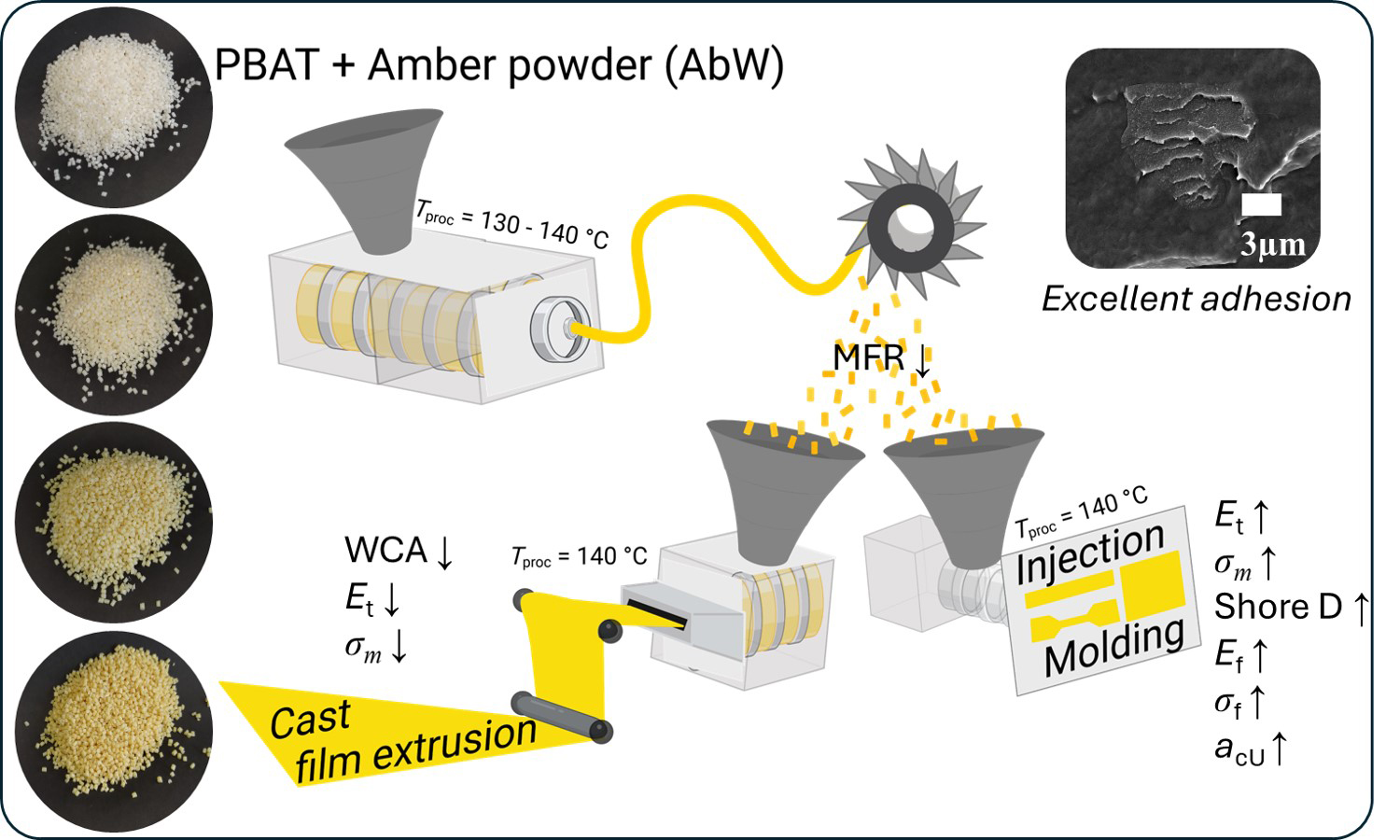

This study investigates the interaction between poly(butylene adipate-co-terephthalate) (PBAT) and amber powdered waste (AbW) from jewelry at different filler concentrations (0, 1, 2.5, and 5 wt%) obtained via melt mixing in a corotating twin screw extruder. The resulting materials were pelletized and processed using two techniques: 1) cast film extrusion and 2) injection molding. The shaped specimens exhibited excellent interfacial adhesion. Thermal behavior, as assessed by Vicat softening temperature (VST), differential scanning calorimetry (DSC), and thermogravimetric analysis (TGA), showed minimal variation among the composites. Despite similar melt flow rate (MFR) values among the samples, the incorporation of AbW affected the behavior of the polymer during cast film extrusion. Consequently, the composite films exhibited lower tensile mechanical parameters (tensile strength, Young’s modulus, stress and strain at break) compared to the neat PBAT film. In turn, the injection molded composites showed improved tensile, flexural, and impact parameters compared to their neat counterpart. Additionally, a slight decrease in water contact angle (WCA) suggested increased surface hydrophilicity of the extruded films. These findings demonstrate the potential of AbW as an additive for biopolymer composites with enhanced mechanical performance. The increased surface hydrophilicity is particularly relevant for applications targeting biocompatibility and biodegradability.

Soni Thakur, Amal M. Sindi, Rahul Dev Bairwan, Rasha A. Mahmoud, Eman Alfayez, Nurul Fazita Mohammad Rawi, Kanchan Jha, H.P.S. Abdul Khalil

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

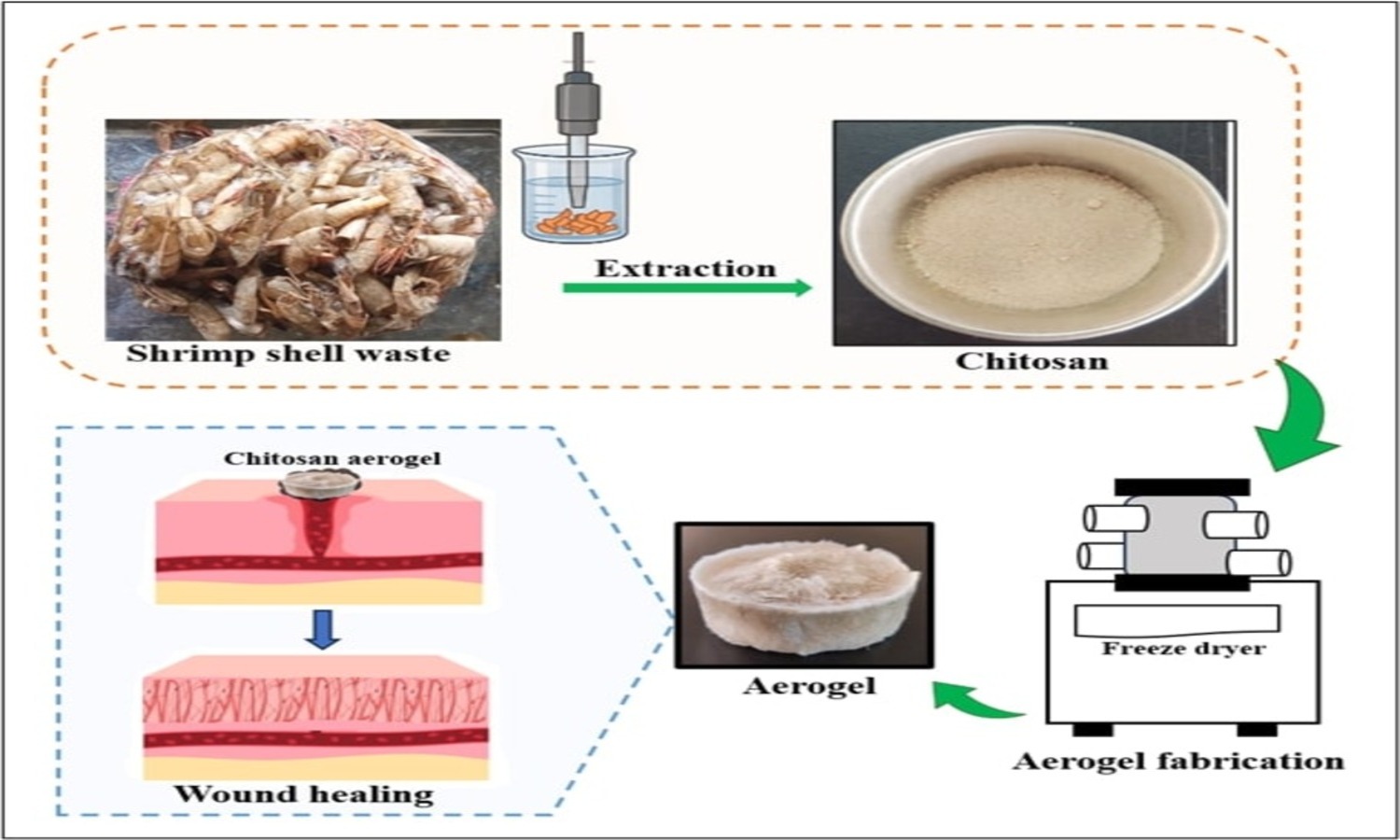

This research presents an eco-friendly approach for extracting chitosan from shrimp shell waste through ultrasound-assisted extraction (UAE) to prepare biocompatible aerogel scaffolds for biomedical applications. The study investigates the influence of various ultrasonic treatment times (10, 20, 30, 40 min) on the yield and structural and physicochemical properties of the extracted chitosan via characterization using Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Among the tested conditions, the 30 min UAE-treated chitosan aerogels showed optimal porosity and structural integrity. Biocompatibility of the aerogels was evaluated, and the results confirmed their non-cytotoxic nature. The bioactivity of the chitosan aerogels was evaluated in terms of their in vitro wound closure ability and antibacterial properties. The aerogels demonstrated a wound closure rate of around 51% after 72 h, significantly higher than the untreated control (37%). In addition, they exhibited clear antibacterial activity against Escherichia coli and Staphylococcus aureus. This sustainable extraction and fabrication method not only adds value to marine waste but also produces functional biomaterials with potential applications in wound healing, tissue engineering, and regenerative medicine, supporting global efforts toward sustainability and circular bioeconomy.

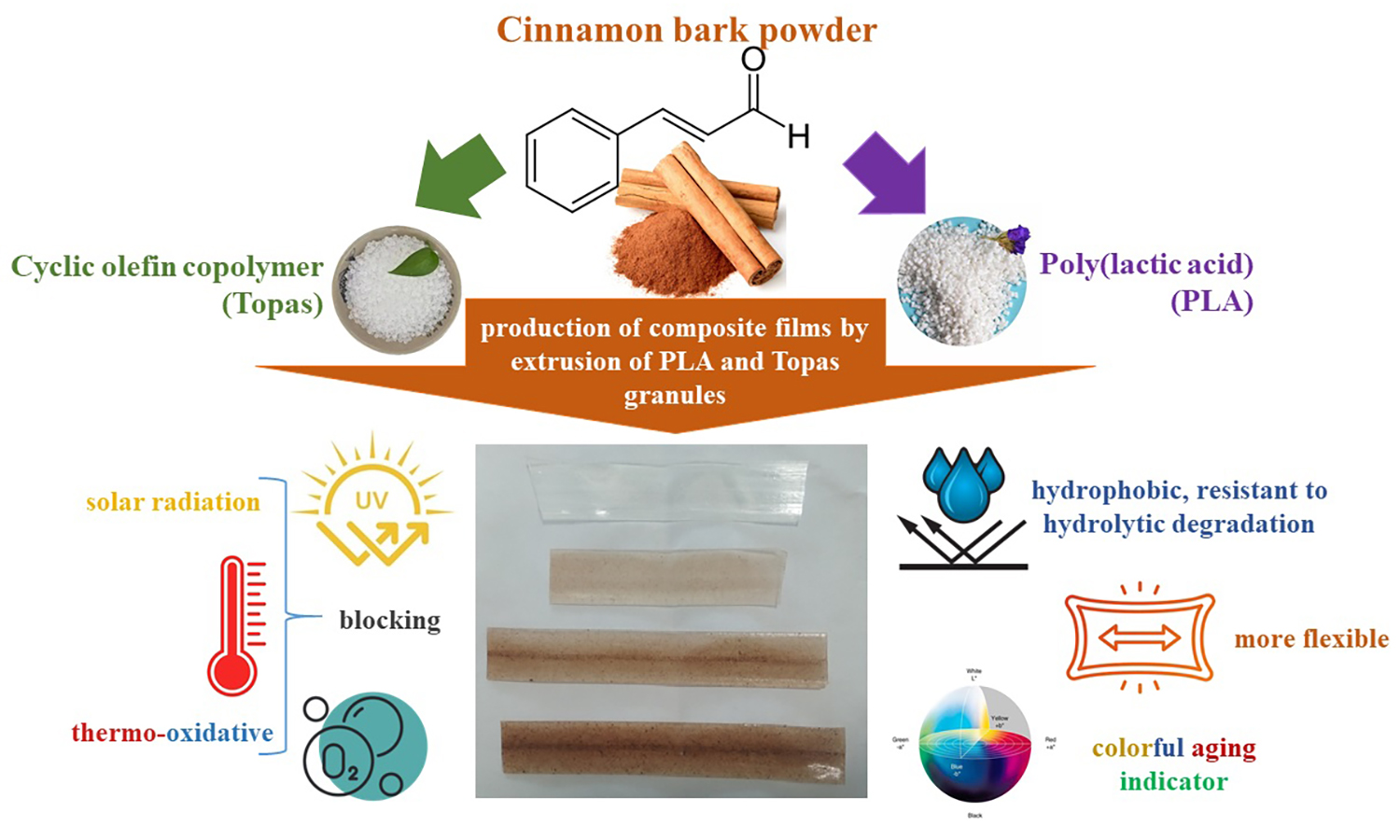

Effect of natural cinnamon extract on the stabilizing properties of biodegradable packaging polymers

Anna Kosmalska-Olańska, Anna Masek

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

The growing focus on sustainability, eco-friendly technologies, decarbonization, and reducing carbon footprints shapes current industry challenges. This article reviews the potential of cinnamon as a bio-additive for polymer stabilization in packaging. Samples were prepared from ethylene-norbornene copolymer (Topas), a cyclic olefin copolymer known for purity, transparency, and low gas permeability, and poly(lactic acid) (PLA), a bio-based alternative to petroleum plastics. Cinnamon powder was added in 0.5, 1.0, and 1.5 wt%. After solar and thermo-oxidative aging, hydrophobicity, chemical composition, mechanical, and color properties were analyzed. Results showed higher hydrophobicity and resistance to hydrolytic degradation due to reduced water penetration. PLA, normally brittle, became more flexible, with 0.5 wt% cinnamon showing optimal performance after 100 h of solar aging, similar to Topas composites. Overall, PLA and cyclic olefin copolymer (COC) films with cinnamon improved durability, extended food shelf life, and acted as natural color indicators of material aging.

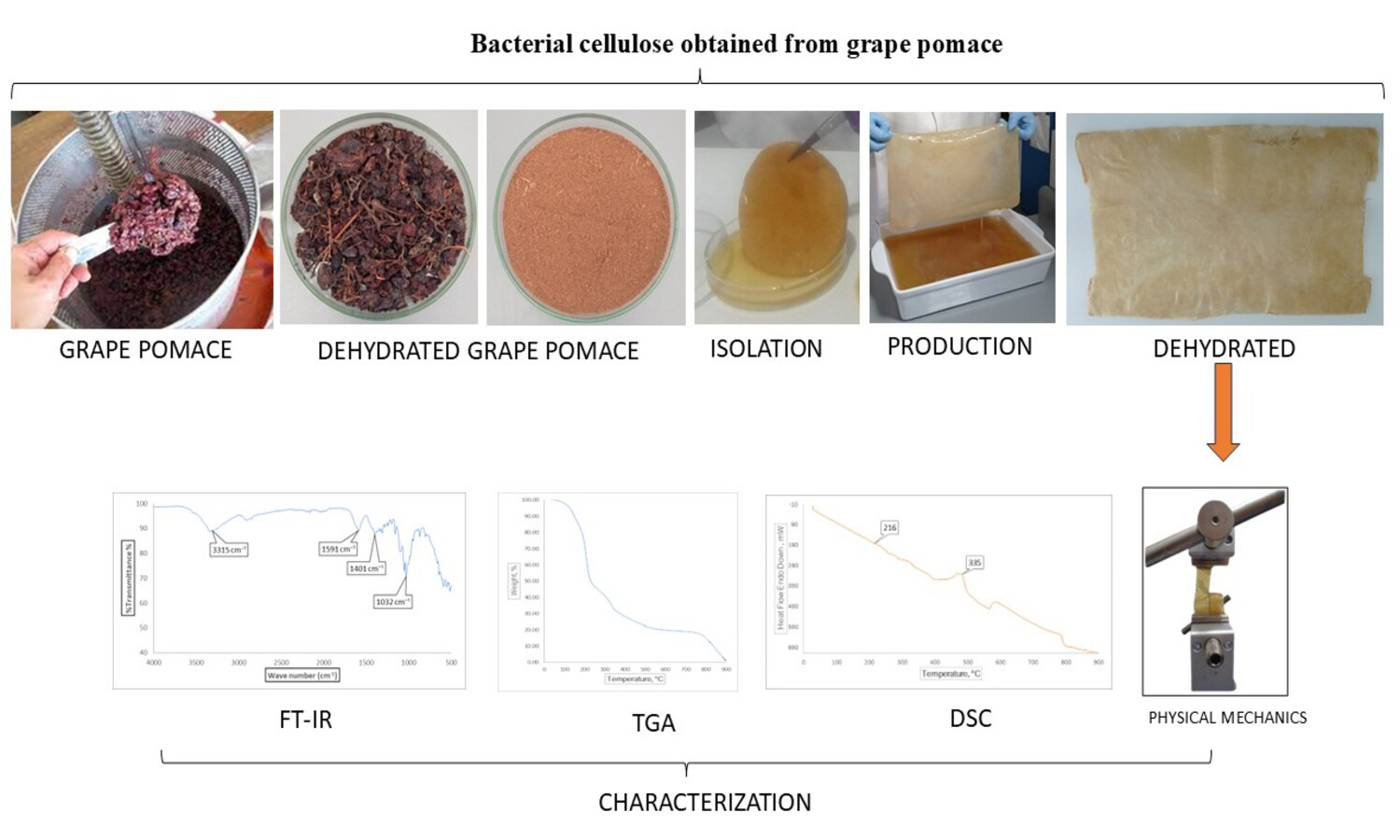

Isabel Milagros Gavilan-Figari

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Bacterial cellulose (BC) is an eco-friendly biopolymer with outstanding structural and functional properties, offering promising applications in sustainable packaging and bio-based materials. In this study, we demonstrate the feasibility of producing BC via spontaneous fermentation, using grape pomace supplemented with sucrose as the sole carbon source, nutrient substrate, and microbial inoculum, without the addition of commercial strains or nitrogen supplements. Fermentation was conducted under static conditions, yielding biofilms with stable structural characteristics and BC production of up to 14.1 g/L, thereby confirming the efficiency of this low-cost, residue-based process. The films obtained exhibited well-organized polymeric networks, with thermal stability in the range of Tg ≈ 159–266 °C and mechanical resistance comparable to or higher than conventional biopolymers. Characterization confirmed reproducible chemical profiles, thermal stability, and measurable variation in mechanical performance, with a tensile strength ranging from 0.0001 to 105 MPa and an elongation at break of 15±5%. The process highlights a resource-efficient and sustainable pathway, adaptable to rural contexts and aligned with circular economic principles. While minor variations among replicates reflected the intrinsic variability of biological systems, mean values and standard deviations demonstrated reproducible physicochemical and mechanical properties. These findings demonstrate that BC derived from agro-industrial residues can be produced under simple, low-input conditions, opening opportunities for scalable valorization in functional and sustainable materials.