Progress in devulcanization of waste tire rubber: Upcycling towards a circular economy

Zaheer ul Haq , Teng Ren, Xinyan Yue, Krzysztof Formela

, Teng Ren, Xinyan Yue, Krzysztof Formela , Denis Rodrigue

, Denis Rodrigue , Xavier Colom Fajula

, Xavier Colom Fajula , Tony McNally

, Tony McNally , Dong Dawei, Yong Zhang

, Dong Dawei, Yong Zhang , Shifeng Wang

, Shifeng Wang

, Teng Ren, Xinyan Yue, Krzysztof Formela

, Teng Ren, Xinyan Yue, Krzysztof Formela , Denis Rodrigue

, Denis Rodrigue , Xavier Colom Fajula

, Xavier Colom Fajula , Tony McNally

, Tony McNally , Dong Dawei, Yong Zhang

, Dong Dawei, Yong Zhang , Shifeng Wang

, Shifeng Wang

Vol. 19., No.3., Pages 258-293, 2025

DOI: 10.3144/expresspolymlett.2025.20

DOI: 10.3144/expresspolymlett.2025.20

GRAPHICAL ABSTRACT

ABSTRACT

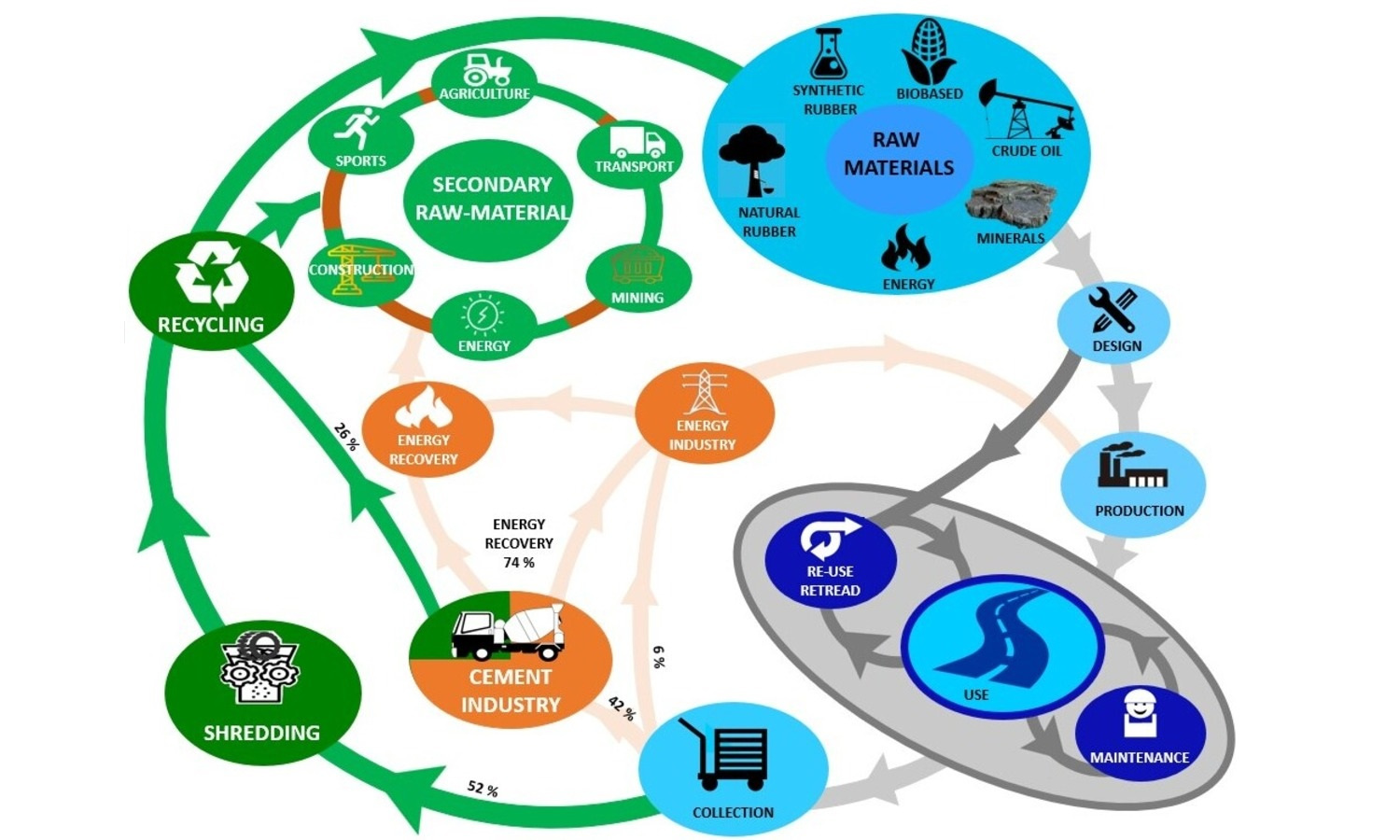

As a complex composite material, tire rubber has always presented significant environmental and waste management concerns due to its non-biodegradability and accumulation in landfills. The devulcanization of tire rubber has emerged as a historical challenge in the field of sustainable rubber engineering since Goodyear invented cross-linking in 1839. This review provides a comprehensive analysis of waste tire recycling processes, focusing on the sources, legislation, management strategies, and utilization across different regions. It explores the multifaceted challenges of devulcanizing rubber, with a specific focus on transitioning from ground tire rubber to the concept of multi-decrosslinking: sulfur bridge breakage, rubber chain depolymerization and micro-nano sized core-shell carbon black. Ideal devulcanization has restricted the release of reinforcing fillers, resulting in devulcanized rubber mainly containing dozens of micron particles, which hinder the wide usage of devulcanized rubber. This review comprehensively assesses the current state-of-the-art techniques for tire rubber devulcanization, including physical, chemical and biological methods. It explores the intricacies of ground tire rubber as a starting material, structural evolution of ground tire rubber during the devulcanization process and the associated challenges in achieving efficient devulcanization while retaining desirable mechanical properties. Furthermore, through an in-depth analysis of recent advancements, limitations and prospects, this paper offers a complete understanding of the challenges faced in tire rubber devulcanization. Considering the technical and environmental aspects of these processes, this work contributes to multi-decrosslinking, the ongoing discourse on sustainable materials development and circular economy initiatives, which pave the way for future innovations in the field of rubber recycling.

RELATED ARTICLES

Xavier Colom, Scott Martínez, Fernando Carrillo-Naverrete, Javier Cañavate

Vol. 20., No.2., Pages 114-126, 2026

DOI: 10.3144/expresspolymlett.2026.10

Vol. 20., No.2., Pages 114-126, 2026

DOI: 10.3144/expresspolymlett.2026.10

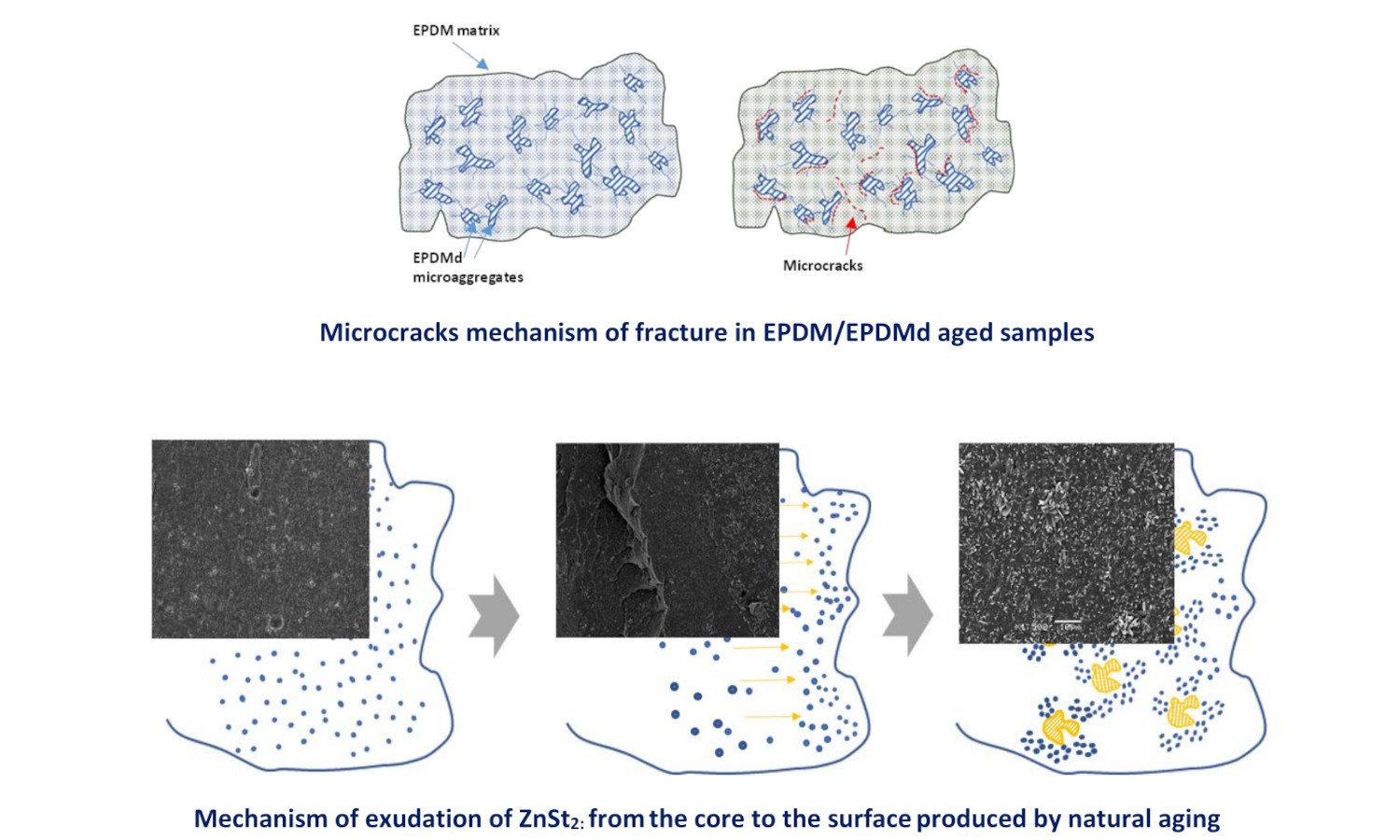

The need to recycle elastomeric waste requires studying its viability in industrial applications. This study investigates the feasibility of recycling elastomeric waste by analyzing whether virgin ethylene-propylene-diene monomer (EPDM) can be replaced by blends of virgin EPDM and thermomechanically and microwave devulcanized EPDM (EPDMd) in industrial applications from the perspective of environmental degradation. Two types of samples were examined: conventional EPDM used to roof membranes, and EPDM blended with different amounts (20, 40, and 50 phr) of EPDMd. Samples were subjected to natural aging in coastal and mountainous environments. Results show that mechanical properties decline with higher EPDMd content and, to a lesser degree, with prolonged outdoor exposure. The coastal climate proved more aggressive than the mountainous one when EPDMd content exceeded 40 phr. Zinc stearate (ZnSt2), a byproduct of vulcanization, was found to influence the evolution of the mechanical behavior. The combined analysis of scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), abrasion tests, and thermogravimetric analysis (TGA) provided insights into the degradation processes of these elastomeric blends.

Longqiang Xiao, Weijia Huang, Kaihong Lin, Shucui Han, Zuyun Luo, Linxi Hou, Yan’gen LV

Vol. 20., No.1., Pages 3-17, 2026

DOI: 10.3144/expresspolymlett.2026.2

Vol. 20., No.1., Pages 3-17, 2026

DOI: 10.3144/expresspolymlett.2026.2

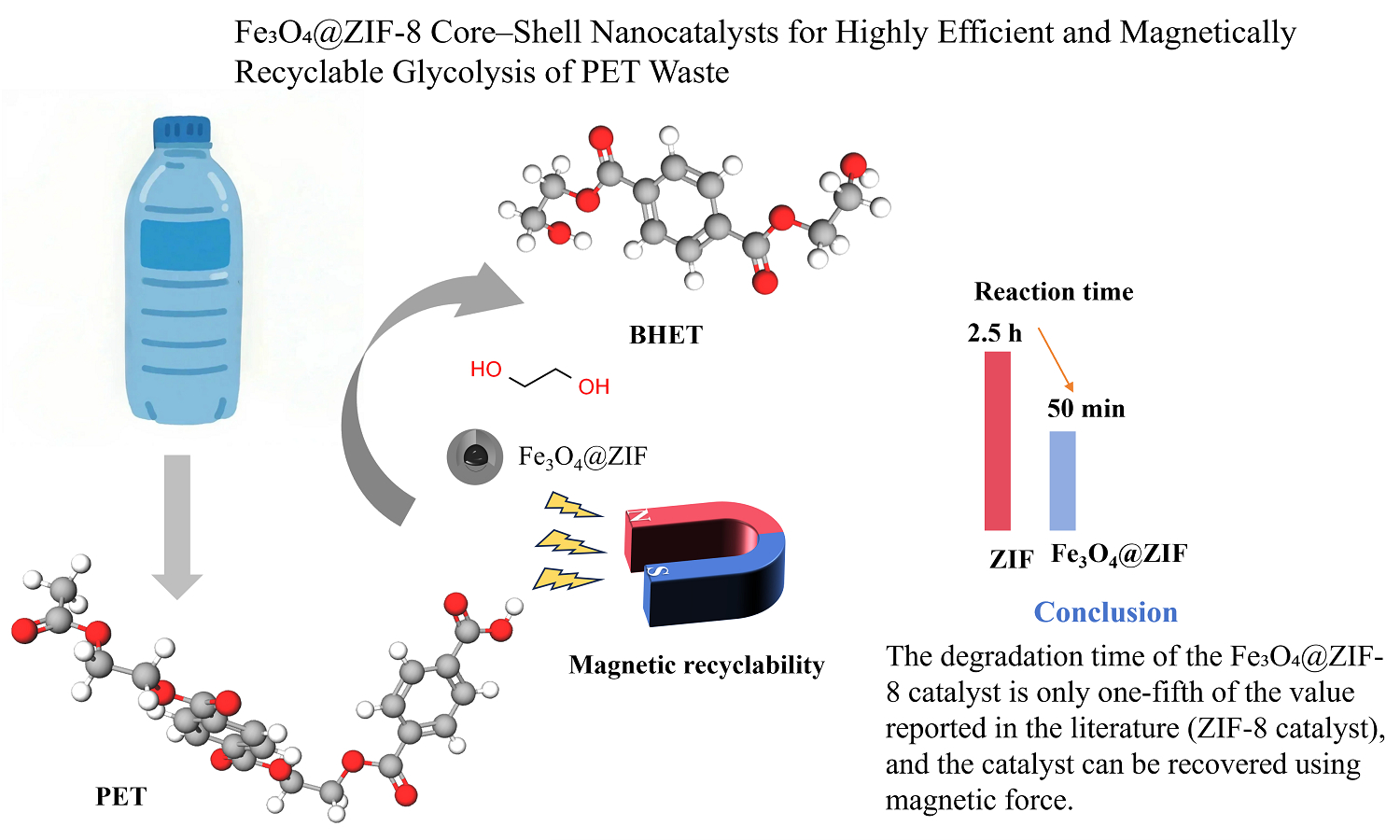

In this study, magnetic core-shell Fe3O4@ZIF-8 was synthesized via a hydrothermal method and applied to Polyethylene terephthalate(PET) degradation. The catalytic degradation of PET by Fe3O4@ZIF-8 was carried out under atmospheric pressure, yielding high-value bis(2-hydroxyethyl) terephthalate (BHET) monomers. The as-synthesized Fe3O4@ZIF-8 core-shell composites possess hierarchical porosity with tunable nanoscale cavities. SEM and TEM analyses confirmed the core-shell morphology, with nanoparticles having a size distribution of 180–280 nm. The degradation product was identified as a high-purity, colorless, and transparent monomeric BHET through 1H NMR and LC analyses. Based on a series of onefactor experiments and a Box-Behnken experimental design, the optimal process conditions were determined to be an alcoholysis temperature of 200°C, a catalyst dosage of 0.5 wt% (relative to PET mass), a reaction time of 50 min, and an ethylene glycol-to-PET mass ratio of 4.5:1. Under these conditions, the actual BHET yield reached 81.12%, closely matching the predicted value.

Katalin Bocz, Ferenc Ronkay

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

This is an editorial article. It has no abstract.

Xiaohua Li, Weiming Liu, Junlong Wang, Shanshan Shao, Weiliang Ding

Vol. 19., No.6., Pages 578-593, 2025

DOI: 10.3144/expresspolymlett.2025.44

Vol. 19., No.6., Pages 578-593, 2025

DOI: 10.3144/expresspolymlett.2025.44

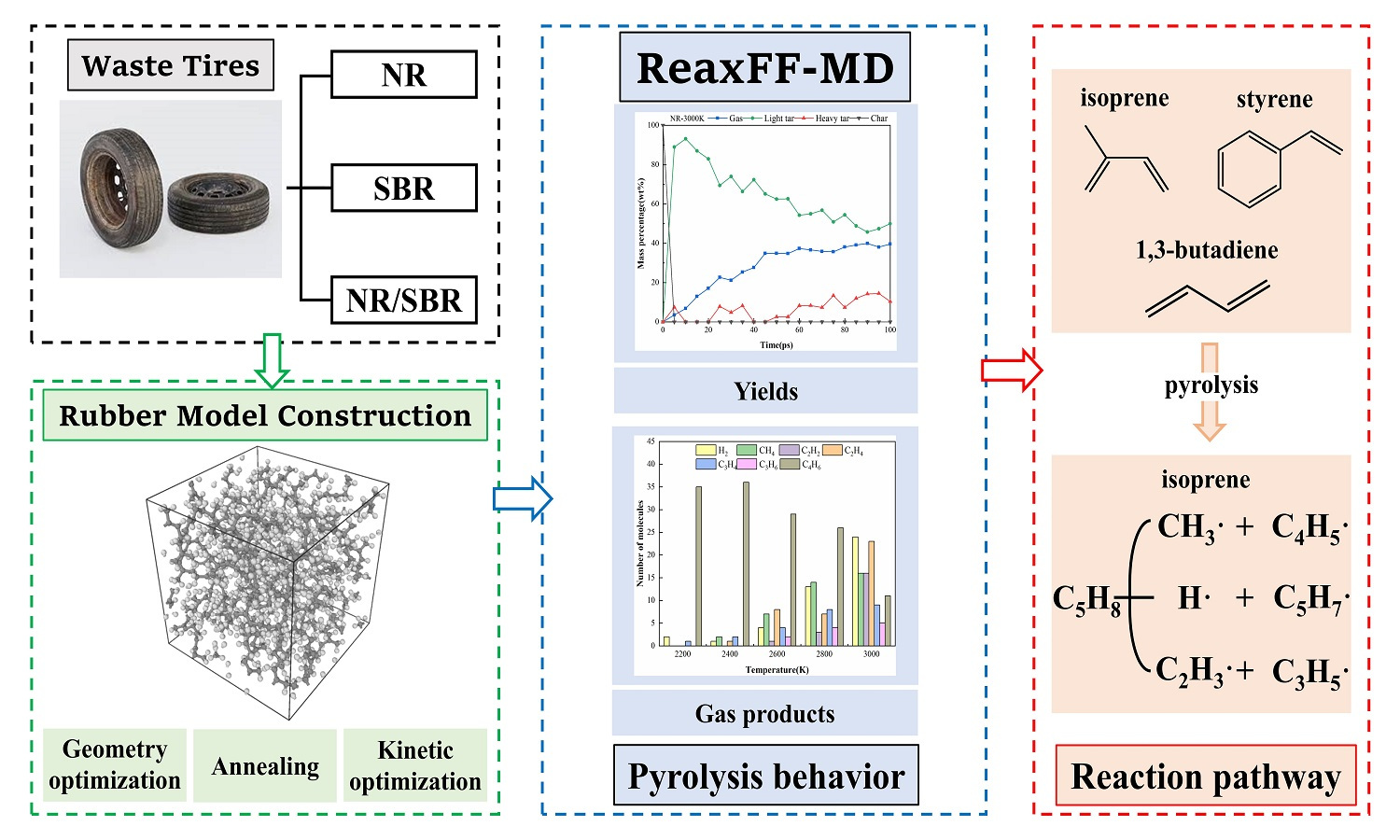

Pyrolysis is one of the effective methods for recycling waste tire rubber, and there are fewer studies on the simulation and mechanism of pyrolysis of multi-component mixed rubber. This study employs reactive force field molecular dynamics (ReaxFF-MD) simulations to analyze the pyrolysis product evolution processes of natural rubber (NR), styrene-butadiene rubber (SBR), and mixed rubber (NR/SBR). The results show that with increasing temperature, the gas yield of NR/SBR increases from 16.32% at 2000 K to 37.01% at 3000 K, and the molecular numbers of gas products such as H2 and small-molecule hydrocarbons increase with temperature. The co-pyrolysis of NR/SBR accelerates solid rubber pyrolysis time and promotes the formation of main gas products (excluding C4H6). Using simulation results, the reaction pathways of pyrolysis intermediates were analyzed: the main intermediates of NR are isoprene monomers and C10H16• short-chain radicals, while those of SBR are styrene and butadiene. The bond cleavage mechanisms of intermediates were compared through reaction energy barrier calculations. This study systematically reveals the pyrolysis product characteristics and reaction mechanisms of rubbers, providing theoretical support for the selective pyrolysis recycling of various waste rubbers.

Dániel Gere, Tamás Bárány

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

This is an editorial article. It has no abstract.