Content

All issues / Volume 19 (2025) / Issue 9 (September)

Katalin Bocz, Ferenc Ronkay

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

This is an editorial article. It has no abstract.

Alexandra Maria Cardona Loaiza, Maria Eduarda Araújo Ribeiro, Ruben J. Sanchez Rodriguez

Vol. 19., No.9., Pages 862-877, 2025

DOI: 10.3144/expresspolymlett.2025.66

Vol. 19., No.9., Pages 862-877, 2025

DOI: 10.3144/expresspolymlett.2025.66

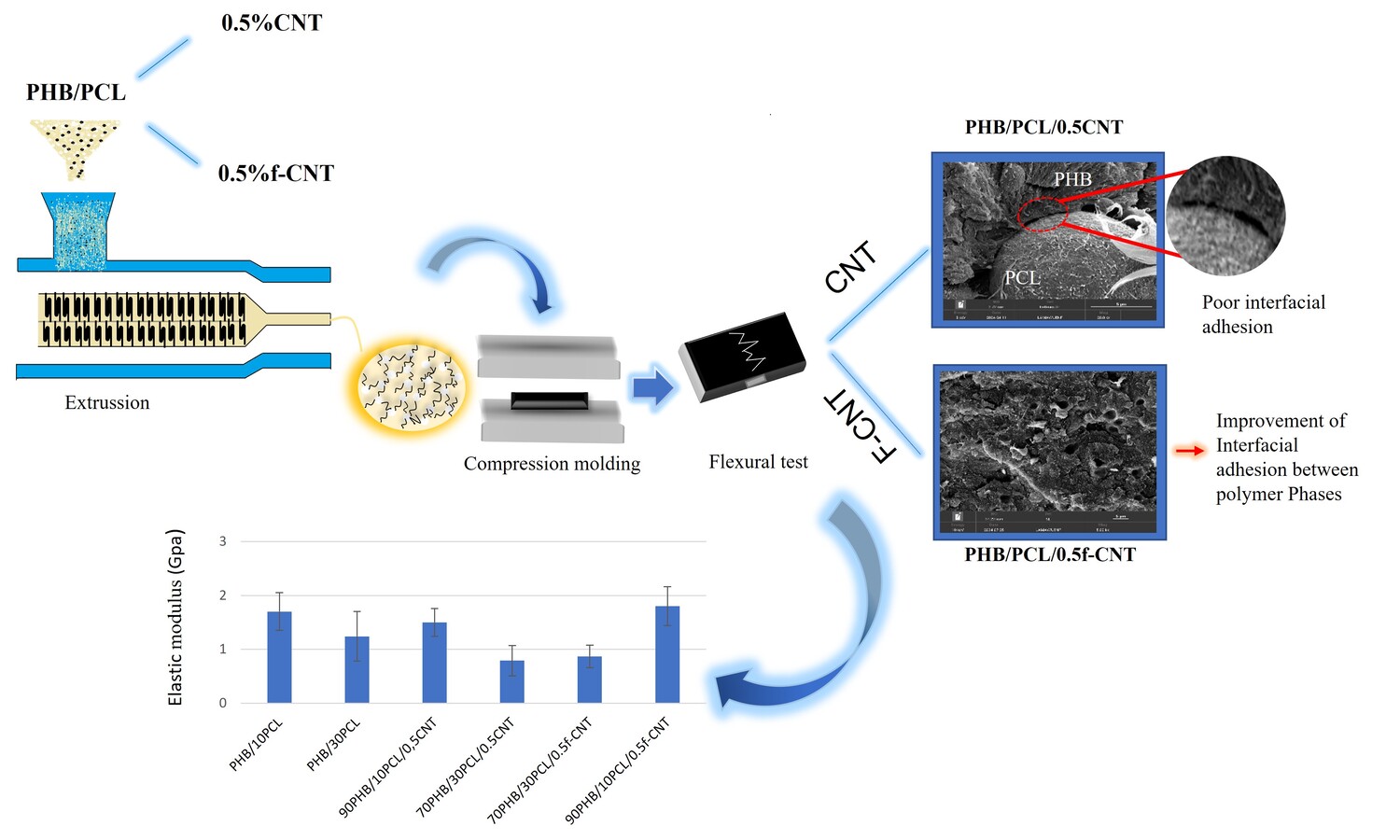

Polyhydroxybutyrate (PHB) is a polymer with great application potential; however, its brittleness and low mechanical strength restrict its use in many fields. This study investigated a strategy to overcome the mechanical limitations of PHB by blending it with polycaprolactone (PCL) and producing nanocomposites with non-functionalized carbon nanotubes (CNT) and functionalized ones (f-CNT). The effect of blend composition and the addition of f-CNT were studied in hotpressed specimens. In PHB/30PCL blends, a reduction in the overall crystallinity degree was observed, while in PHB/10PCL the crystallinity maintained close to neat PHB. In PHB/10PCL nanocomposites, no significant change was registered, but in PHB/30PCL with f-CNT, the crystallinity degree increased and achieved values comparable to PHB. Differential scanning calorimetry suggested that f-CNT had a higher impact in PCL crystallinity in formulations of PHB/30PCL. Scanning electron microscopy showed that in these formulations, f-CNT were preferably located at the interface of PHB/PCL, while in PHB/10PCL the particles were mainly located in PHB. In general, the blends suffered with a reduction in elastic modulus and strength, especially for PHB/30PCL formulation.

Paulina Wiśniewska, Natalia A. Wójcik, Józef Haponiuk, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

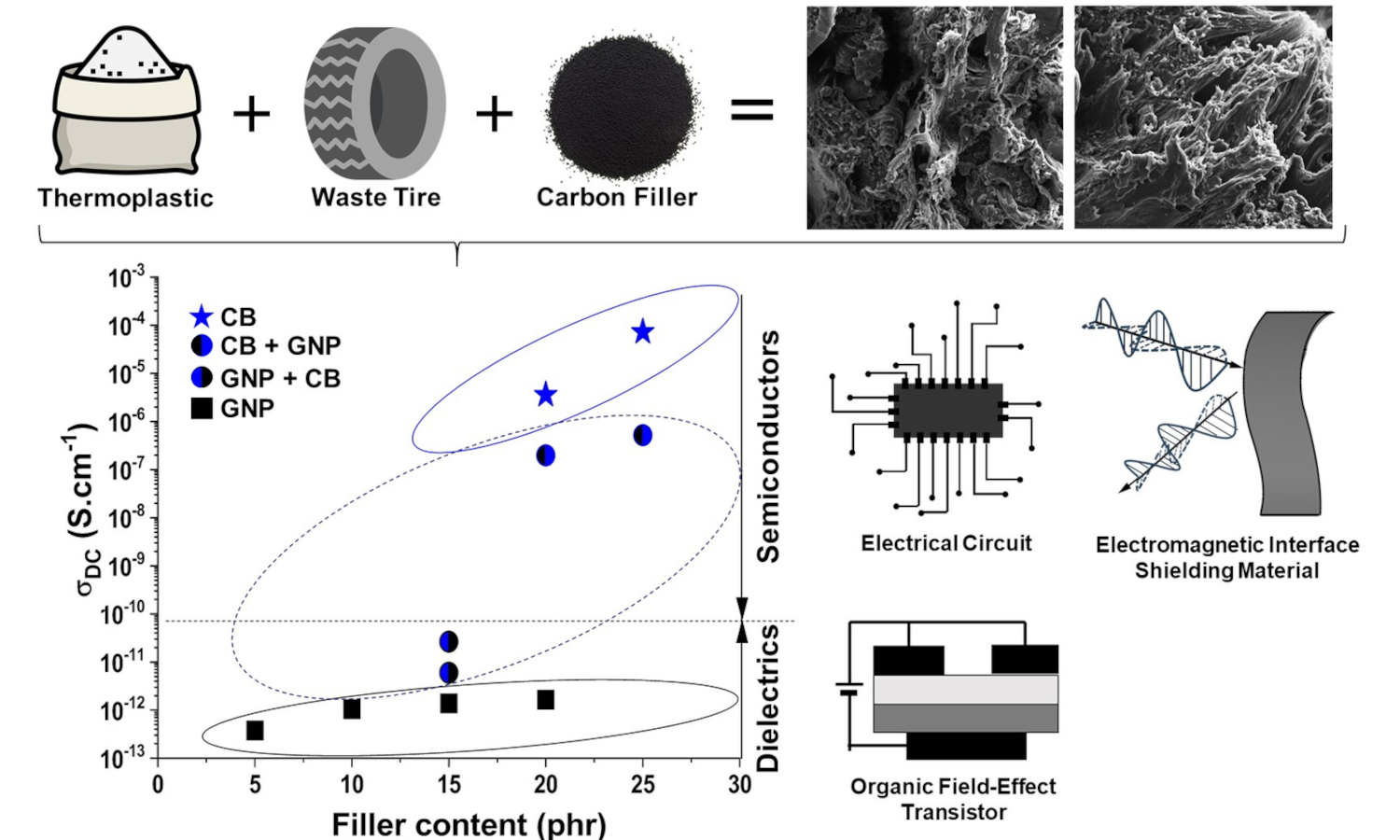

Waste rubber management through developing blends of thermoplastics with ground tire rubber (GTR) has gained significant attention for creating sustainable, high-performance materials with enhanced properties. In this work, we developed customized graphene/polymer nanocomposites applying GTR, ethylene-vinyl acetate copolymer (EVA), and graphene nanoplatelets (GNPs), taking carbon black (CB) as the reference additive. A wide range of electrical conductivity from 10–12 S/cm (dielectric) to 10–5 S/cm (semiconductor) was obtained for optimized composites containing GNPs and CB, respectively. Thermal, mechanical, and flame-retardant properties looked promising for additive manufacturing, while electrical conductivity was tailored for soft electronics. In view of processability, mechanical strength, and elasticity, GNPs-incorporated EVA/GTR composites showed an edge over their CB-aided counterparts. For example, tensile strength and elongation at break of EVA/GTR blends reinforced with 20 phr GNPs were 4.8 MPa and 681%, respectively, compared to 4.0 MPa and 651% for the composite comprising an identical amount of CB. Interestingly, combining GNPs and CB enhanced the thermal stability and flame retardancy of EVA/GTR compared to only GNPs or CB. These results were promising from both sustainability and advanced functional materials perspectives.

Mohammad Aliff Shakir, Mardiana Idayu Ahmad, Azniwati Abd Aziz, Abdul Khalil H.P.S.

Vol. 19., No.9., Pages 893-908, 2025

DOI: 10.3144/expresspolymlett.2025.68

Vol. 19., No.9., Pages 893-908, 2025

DOI: 10.3144/expresspolymlett.2025.68

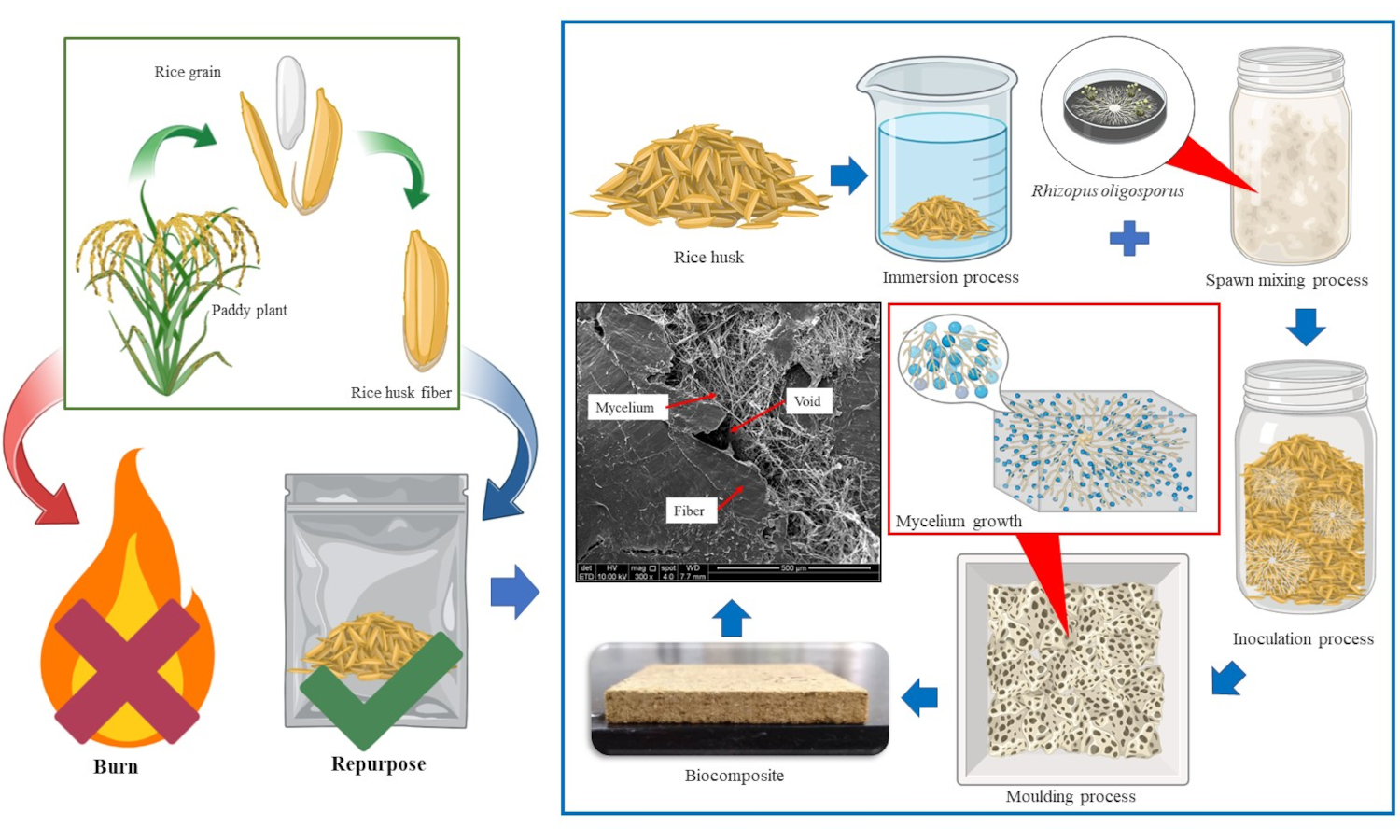

The growing demand for eco-friendly alternatives to synthetic polymers has accelerated interest in fibrous, cellulose-rich waste as a foundation for sustainable composite materials. Agricultural waste like rice husk offers abundant, renewable sources of natural polymers suitable for advanced biocomposite development. However, the integration of such materials often requires innovative bonding approaches, particularly those that are biodegradable and derived from renewable sources. This study explores the use of rice husk fibers with Rhizopus oligosporus mycelium as a bio-binder by examining how varying inoculation durations (0, 2, 4, and 6 days) affect the mechanical and physical characteristics of the composite. The prepared samples underwent hot pressing at 130°C and 5 MPa for 30 min. Visual and morphological analyses confirmed that longer inoculation periods promoted denser and more uniform mycelial growth, improving adhesion within the composite matrix. Results revealed that the composite with 4 days of inoculation exhibited the best overall physical and mechanical properties with flexural strength (5.79 MPa), tensile strength (2.59 MPa), water absorption (112.1%), contact angle (39.99°) and thickness swelling (126.33%). These findings demonstrate the feasibility of repurposing cellulose-rich agricultural waste into functional fibrous polymer composites, supporting sustainable material development and contributing to polymer recycling efforts.

Katarzyna Witt, Justyna Czajka

Vol. 19., No.9., Pages 909-928, 2025

DOI: 10.3144/expresspolymlett.2025.69

Vol. 19., No.9., Pages 909-928, 2025

DOI: 10.3144/expresspolymlett.2025.69

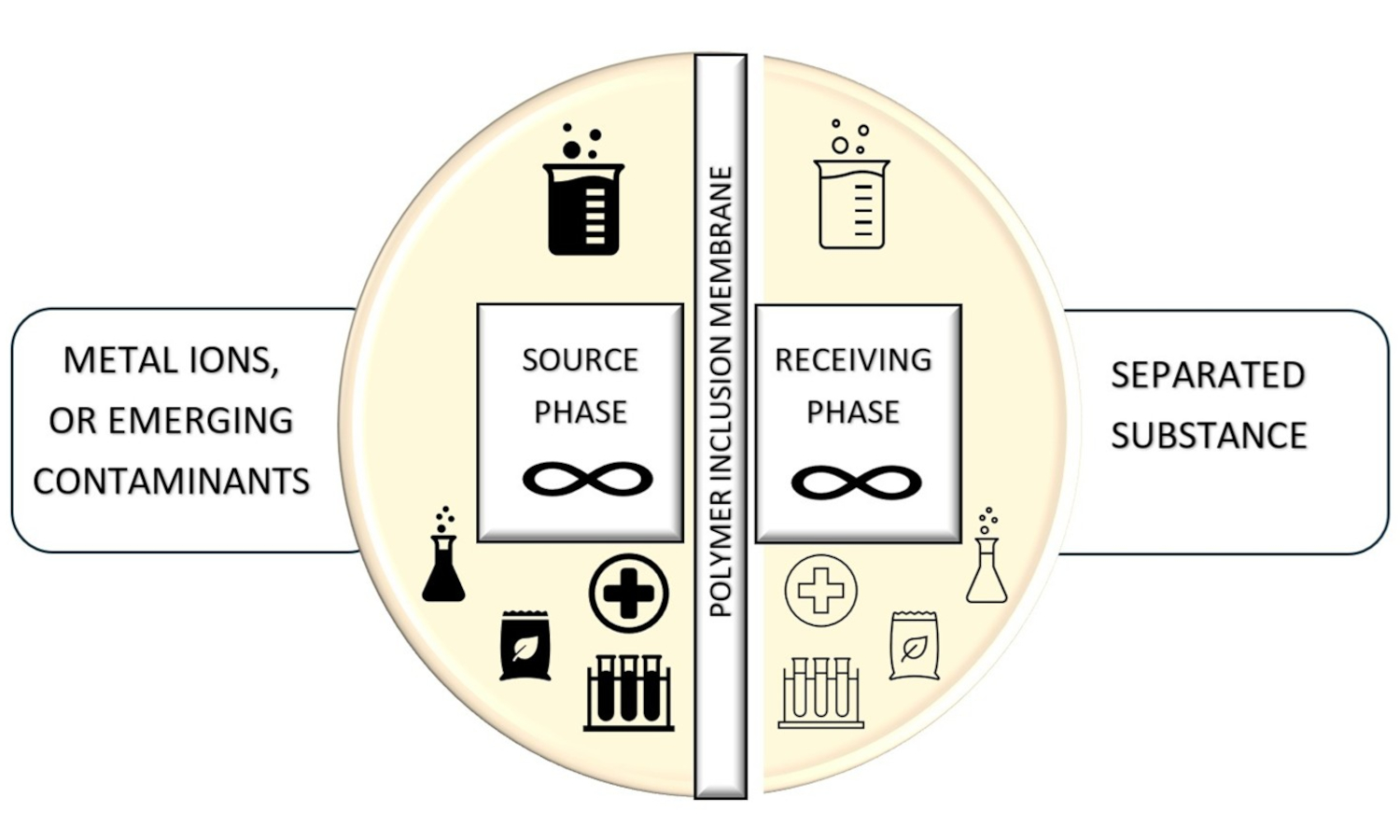

The development of membrane technologies began in the early 20th century. Since then, aspects such as the methodology of forming membranes, the materials from which they are obtained, the way they are applied, and the possibilities for their application have changed significantly. One of the types of membranes most often utilized by scientists, among others, due to their simplicity, is polymer inclusion membranes (PIMs). The modifications currently being introduced in PIMs primarily concern their composition (type of polymer, carrier/extractant, plasticizer, or presence of additional functional substances). These changes are made to help obtain the membranes that are cheaper to produce, environmentally friendly, and selective for the type of transported substance. In the presented review article, the latest achievements in the field of modification of PIMs were noticed. Described herein are selected articles published in recent years in journals important for this field of science.

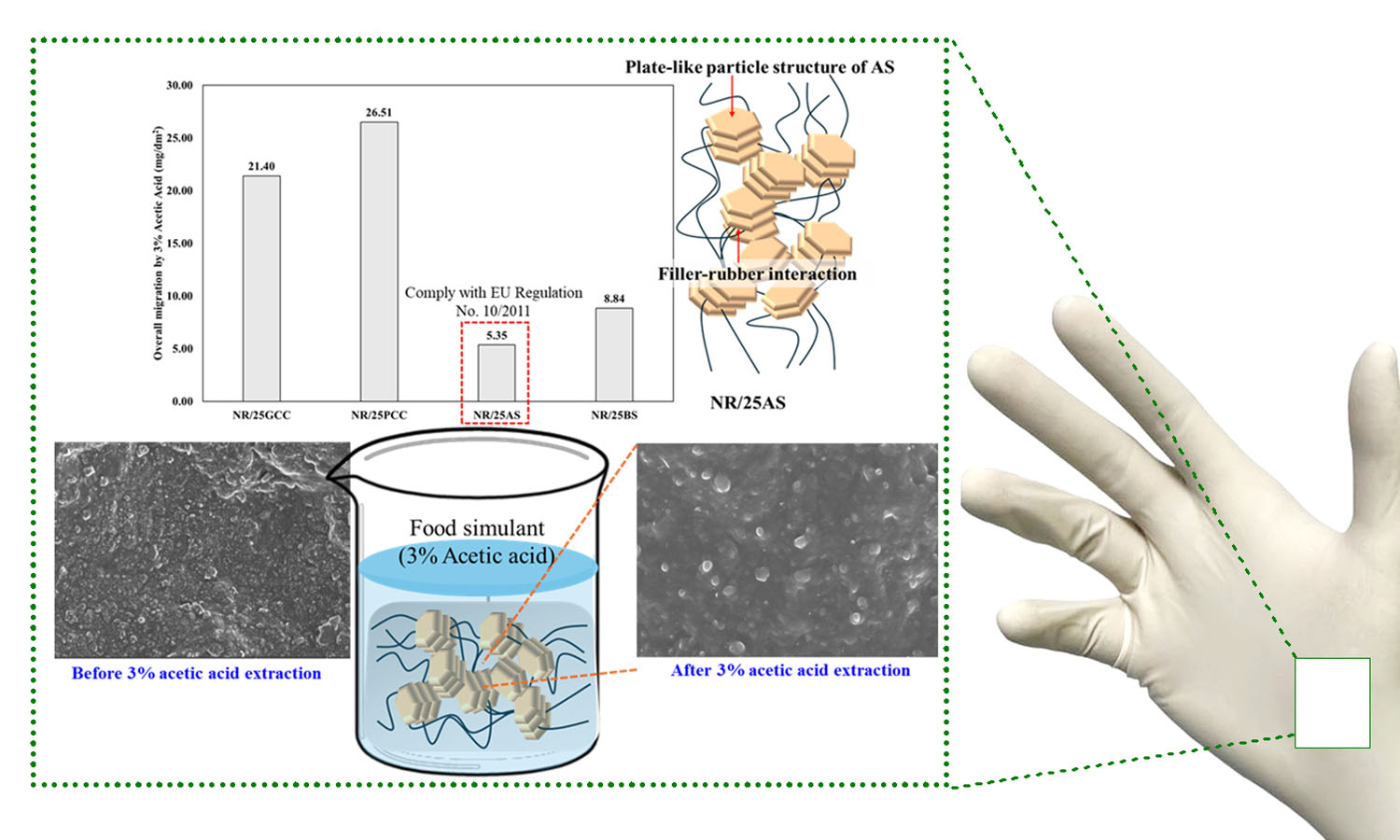

Sirithorn Kaewklum, Parisa Faibunchan, Apinya Krainoi, Banyat Cherdchim, Jutharat Intapun

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Powder-free natural rubber gloves for chemical migration resistance of food-contact grade are prepared using a variety of fillers, including ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), aluminum silicate (AS), and barium sulfate (BS)-filled natural rubber (NR), respectively. The properties of NR gloves, including mechanical, dynamic mechanical, and thermal properties, were investigated. Furthermore, the overall migration test of NR gloves was conducted according to the regulations for food contact gloves (EU Regulation No. 10/2011), using 3% acetic acid as the simulant. Among the fillers studied, the plate-like particles of AS facilitated the most effective filler-rubber interactions and reinforcement in AS-filled natural rubber (NR/AS). Consequently, the highest crosslink density, force at break, and damping properties of NR gloves were achieved by applying AS in the NR matrix. Moreover, the lowest overall migration level was observed for NR/AS with a value of 5.35 mg/dm2, which complies with EU Regulation (overall migration of food simulants shall not exceed 10 mg/dm2). Therefore, NR gloves filled with AS are suitable for food-contacting NR gloves.

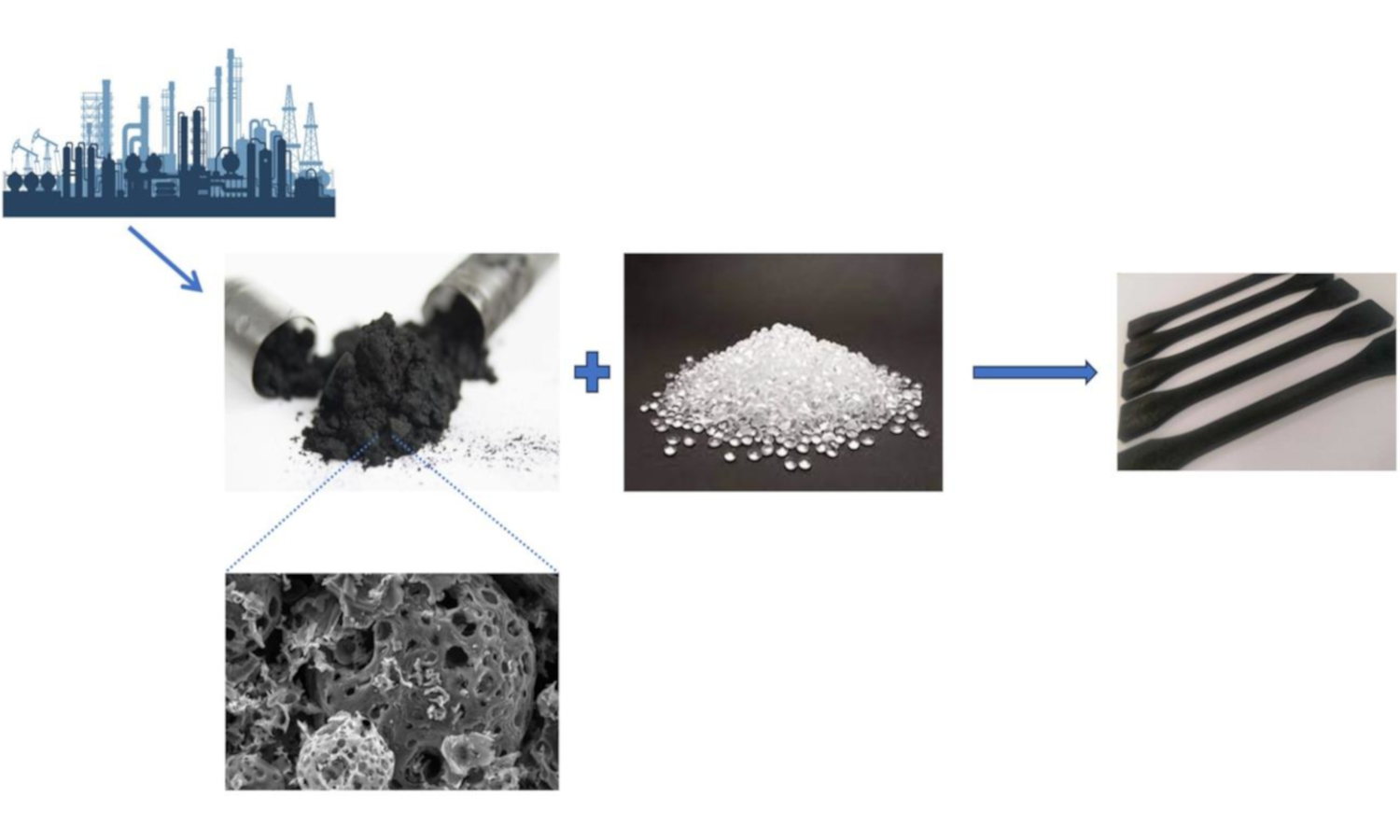

Joanna Szymańska, Wojciech H. Bednarek, Włodzimierz Urbaniak, Paweł Brzęk, Dominik Paukszta

Vol. 19., No.9., Pages 946-958, 2025

DOI: 10.3144/expresspolymlett.2025.71

Vol. 19., No.9., Pages 946-958, 2025

DOI: 10.3144/expresspolymlett.2025.71

Crude oil, a natural hydrocarbon mixture, is a key energy source and the petrochemical industry’s primary feedstock. Its large-scale processing produces heavy oil fly ash (HOFA), a solid waste that demands effective management. This study explores HOFA’s valorization as a low-cost, carbon-based filler in isotactic polypropylene (iPP) composites. Composites containing 1–20 wt% HOFA were prepared by extrusion and injection molding, then subjected to tensile, impact, and structural analyses (differential scanning calorimetry (DSC), wide angle X-ray scattering (WAXS), microscopy). Mechanical testing revealed that even small HOFA additions raised Young’s modulus proportionately to filler content, consistent with typical filled-polymer behavior. Impact strength increased by roughly 25% at both 1 and 20 wt% loadings, while tensile strength and elongation at break remained comparable to neat iPP. DSC and WAXS demonstrated that HOFA acts as a nucleating agent, promoting the β-crystalline phase, known to enhance toughness, without significantly altering the melting or crystallization temperatures.

These findings confirm that HOFA, a waste by-product, can be an effective filler for iPP, improving stiffness and impact resistance without compromising other key properties. Its use offers both economic advantages, through reduced material costs, and environmental benefits by diverting industrial waste from disposal. This approach holds promise for developing sustainable, high-performance polymer composites.

These findings confirm that HOFA, a waste by-product, can be an effective filler for iPP, improving stiffness and impact resistance without compromising other key properties. Its use offers both economic advantages, through reduced material costs, and environmental benefits by diverting industrial waste from disposal. This approach holds promise for developing sustainable, high-performance polymer composites.

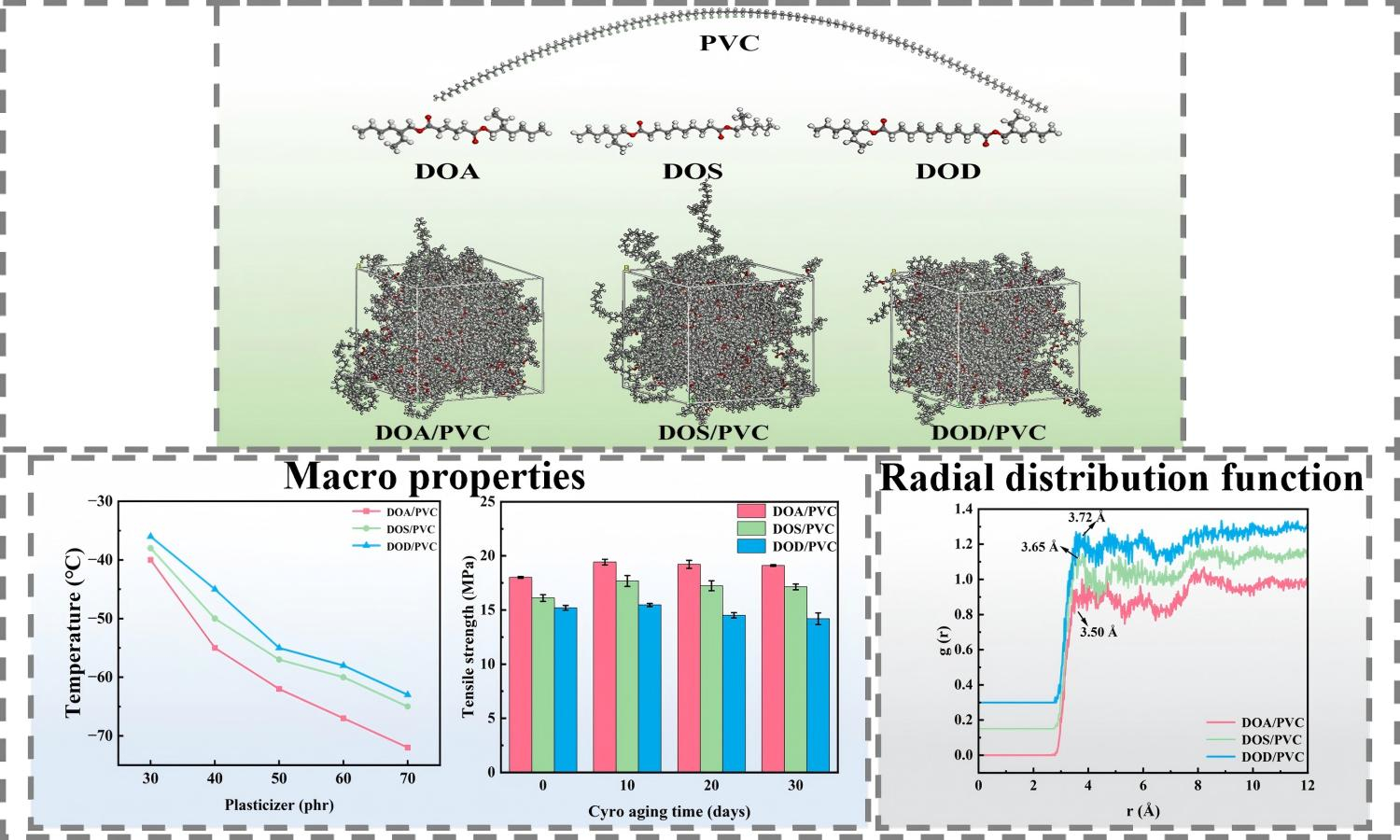

Xue Xu, Rujie Li, Li Gao, Beibei Sun, Hongming Liu, Shiai Xu

Vol. 19., No.9., Pages 959-976, 2025

DOI: 10.3144/expresspolymlett.2025.72

Vol. 19., No.9., Pages 959-976, 2025

DOI: 10.3144/expresspolymlett.2025.72

As polyvinyl chloride (PVC) films are hard and brittle in a low-temperature environment, aliphatic dibasic acid ester plasticizers with different acid chain lengths were fabricated, i.e. di(2-ethylhexyl) adipate (DOA), di(2-ethylhexyl) sebacate (DOS) and dioctyl dodecanedioate (DOD), and their effects on the cold-resistant properties of PVC were investigated using experiments and molecular dynamics (MD) simulations. The brittleness temperature and tensile properties of plasticizers/PVC are negatively related to the acid chain length of the aliphatic dibasic acid esters. The brittleness temperatures of the three systems are all below –50 °C. In-situ low-temperature tensile tests and aging tests indicate that DOA/PVC exhibits the best cold resistance and stability. MD simulations further reveal that the best compatibility between DOA and PVC is attributed to its strong binding energy and weak hydrogen bonding interactions, while van der Waals forces are dominant in DOS/PVC and DOD/PVC. This study elucidates the structure-property relationship between aliphatic dibasic acid ester plasticizers and PVC from the perspective of molecular interactions, and provides insights into the design of cold-resistant PVC plasticizers.