Thermo-mechanical characterization of PHB/PCL blend incorporated with carbon nanotubes

Vol. 19., No.9., Pages 862-877, 2025

DOI: 10.3144/expresspolymlett.2025.66

DOI: 10.3144/expresspolymlett.2025.66

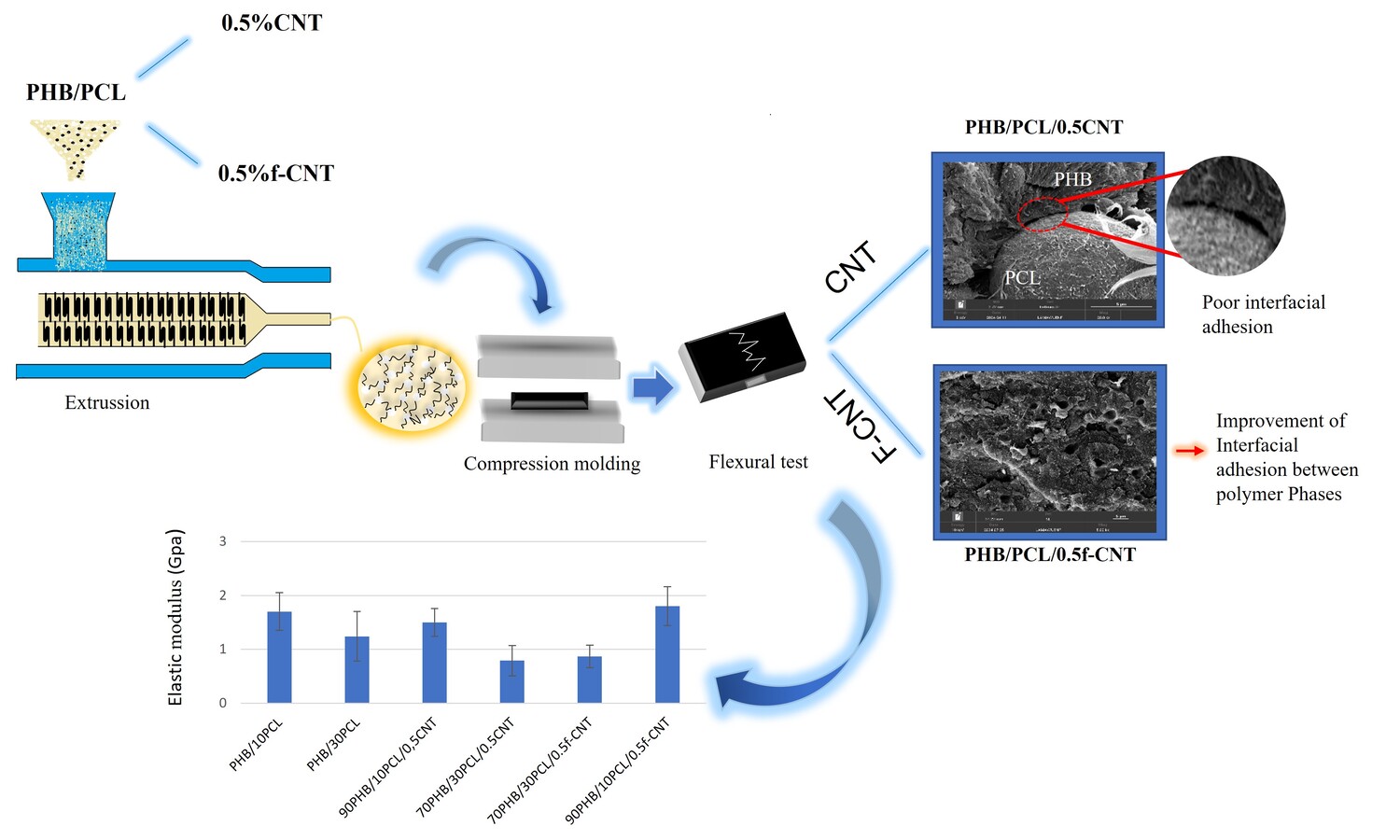

GRAPHICAL ABSTRACT

ABSTRACT

Polyhydroxybutyrate (PHB) is a polymer with great application potential; however, its brittleness and low mechanical strength restrict its use in many fields. This study investigated a strategy to overcome the mechanical limitations of PHB by blending it with polycaprolactone (PCL) and producing nanocomposites with non-functionalized carbon nanotubes (CNT) and functionalized ones (f-CNT). The effect of blend composition and the addition of f-CNT were studied in hotpressed specimens. In PHB/30PCL blends, a reduction in the overall crystallinity degree was observed, while in PHB/10PCL the crystallinity maintained close to neat PHB. In PHB/10PCL nanocomposites, no significant change was registered, but in PHB/30PCL with f-CNT, the crystallinity degree increased and achieved values comparable to PHB. Differential scanning calorimetry suggested that f-CNT had a higher impact in PCL crystallinity in formulations of PHB/30PCL. Scanning electron microscopy showed that in these formulations, f-CNT were preferably located at the interface of PHB/PCL, while in PHB/10PCL the particles were mainly located in PHB. In general, the blends suffered with a reduction in elastic modulus and strength, especially for PHB/30PCL formulation.

RELATED ARTICLES

Chin-San Wu, Shan-Shue Wang, Dung-Yi Wu, Wanwen Gu

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

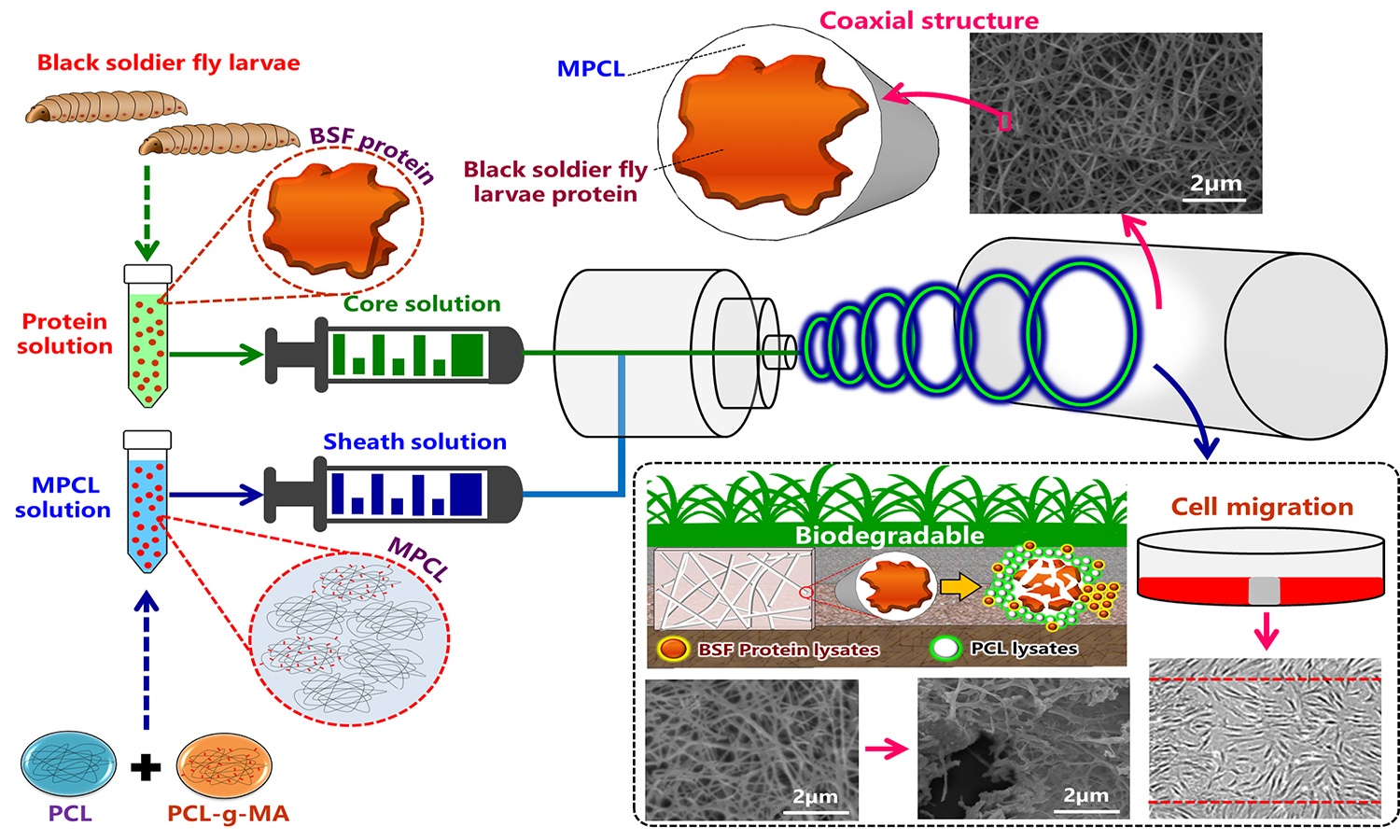

The protein from black soldier fly larvae was used as a functional ingredient of a novel green nanofiber. Larvae protein powder (LP) was blended with biodegradable poly(ε-caprolactone) (PCL) and processed in an electrospinning machine using a coaxial feeding/mixing method to produce nanofibers approximately 100–350 nm in diameter. To improve the dispersion and interface bonding of various PCL/LP nanofiber components, a homemade compatibilizer, maleic anhydridegrafted poly(ε-caprolactone) (MPCL), was added to form MPCL/LP nanofibers. The structure, morphology, mechanical properties, water absorption, cytocompatibility, wound healing, and biodegradability of PCL/LP and MPCL/LP nanofiber mats were investigated. The results showed enhanced adhesion in the MPCL/LP nanofiber mats compared to PCL/LP nanofiber mats; additionally, the MPCL/LP nanofibers exhibited increases of approximately 0.7–2.2 MPa in breaking strength and 9.0–22.8 MPa in Young’s modulus. Decomposition tests using a simulated body fluid revealed that the addition of LP enhanced the decomposition rate of both PCL/LP and MPCL/LP nanofiber mats and in vitro protein release. Cell proliferation and migration analysis indicated that PCL, MPCL, and their composites were biocompatible for fibroblast (FB) growth. Biodegradability was tested in a 30 day soil test. When the LP content was 20 wt%, the degradation rate exceeded 50%.