Disulfide bond and free radical copolymerization endow TPU with reversible cross-linking properties

Wenxin Gan, Hanyu Xue, Hongyi Lin, Renjin Gao, Yuchi Zhang, Liwei Wang, Jiuping Rao

Vol. 19., No.3., Pages 311-325, 2025

DOI: 10.3144/expresspolymlett.2025.22

DOI: 10.3144/expresspolymlett.2025.22

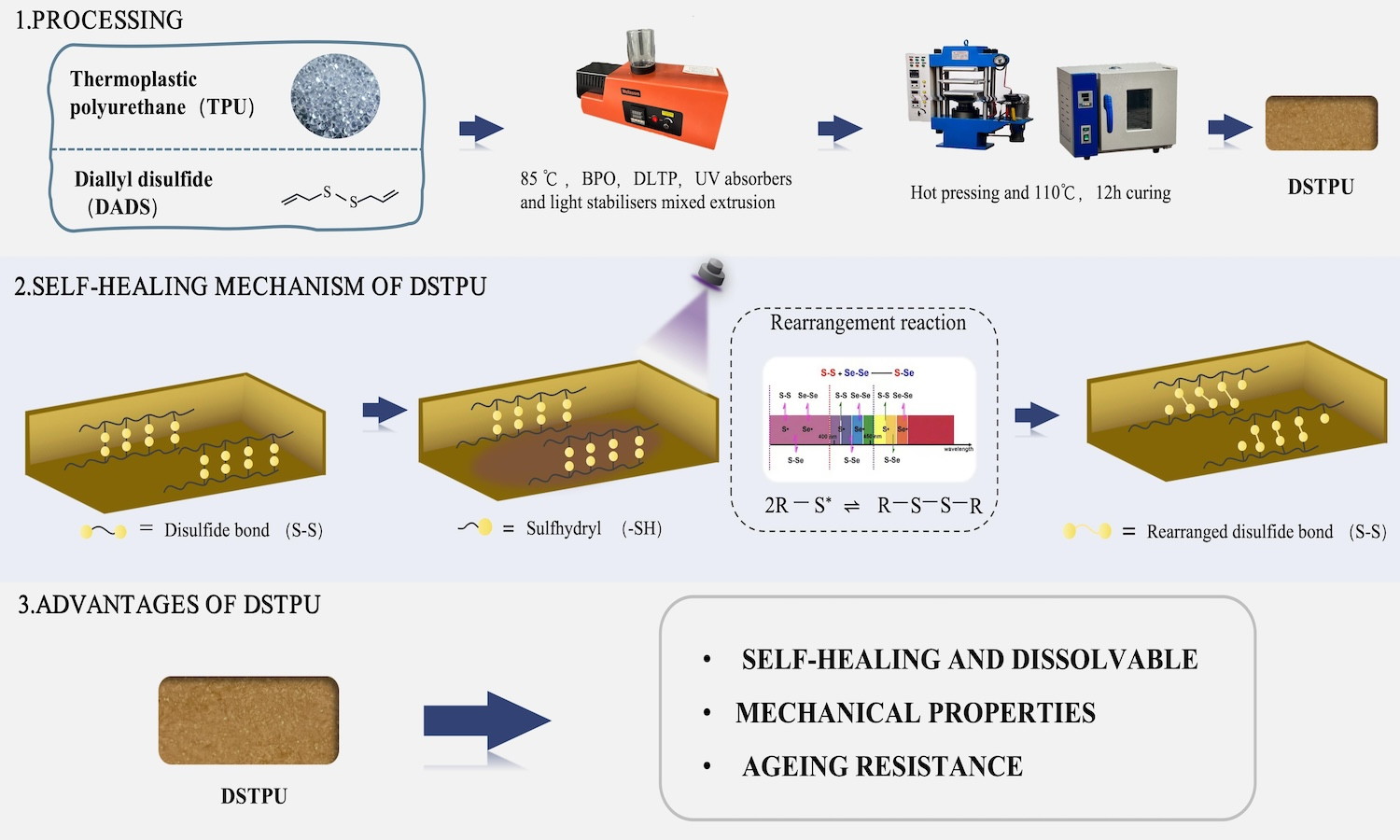

GRAPHICAL ABSTRACT

ABSTRACT

Cross-linking frequently enhanced the mechanical properties of linear polymeric materials; however, it also resulted in the transition from thermoplastic to thermosetting materials, which posed issues from an environmental perspective. Thermoplastic polyurethane (TPU) elastomers were extensively applied across various industries. To improve the mechanical properties of TPU while preserving its environmental benefits, this study integrated radical copolymerization technology to develop a reversible crosslinked TPU. Specifically, the linear polyurethane molecular chains were crosslinked using diallyl disulfide (DADS) as a functional cross-linking monomer. Through radical copolymerization reactions, reversible crosslinks formed from disulfide bonds were created between the linear polyurethane molecular chains, yielding a self-healing reversible crosslinked thermoplastic polyurethane (DSTPU). The study showed that DSTPU could self-heal and dissolve under UV light and alkaline N,N-dimethylformamide (DMF) conditions, achieving 82.2% self-healing efficiency at 3 phr DADS. It dissolved into fine particles in alkaline DMF. Disulfide bonds in DSTPU enhanced cross-linking, boosting 19% oxygen permeability, thermal conductivity (0.218 W/(m·K)), and mechanical properties like tensile stress (11.18 MPa), force (134.13 N), and elongation (548%). These bonds also enhanced aging resistance, cutting ΔYI to 6.0%.

RELATED ARTICLES

Joanna Smorawska-Kliza, Julia Habaj, Ewa Głowińska

Vol. 20., No.3., Pages 217-232, 2026

DOI: 10.3144/expresspolymlett.2026.18

Vol. 20., No.3., Pages 217-232, 2026

DOI: 10.3144/expresspolymlett.2026.18

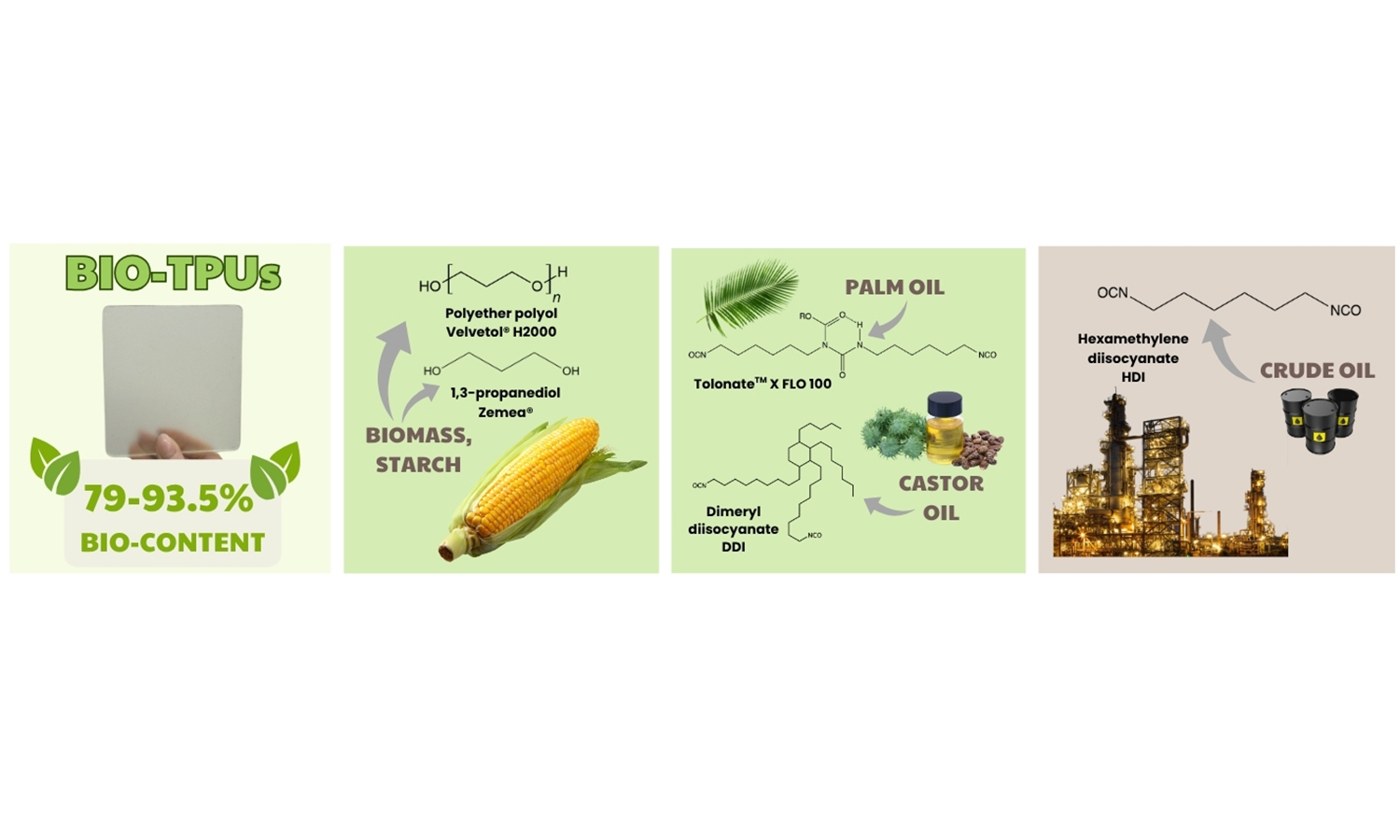

Modification of the hard segment structure in polyurethanes using isocyanate mixtures has emerged as one of the most effective strategies for developing new materials with enhanced properties and a high content of bio-based carbon. In this work, next-generation sustainable thermoplastic polyurethane elastomers (bio-TPUs) were synthesized using aliphatic isocyanate mixtures based on bio-derived diisocyanates Tolonate™ X FLO 100 and dimeryl diisocyanate (DDI) alongside hexamethylene diisocyanate (HDI). Poly(trimethylene ether) glycol (PO3G) and bio-based 1,3-propanediol served as renewable hydroxyl-terminated components. The bio-TPUs were prepared using the common ‘one-shot’ method. The resulting materials were analyzed to assess phase separation, morphology, as well as mechanical, thermal and thermomechanical properties. The results confirm the significant influence of the type of diisocyanate mixture on the properties of bio-TPU, improving their thermal stability (up to 300 °C) and reducing the melting temperature to 140 °C, which makes them suitable for low-temperature processing.

Paulina Wiśniewska, Natalia A. Wójcik, Józef Haponiuk, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

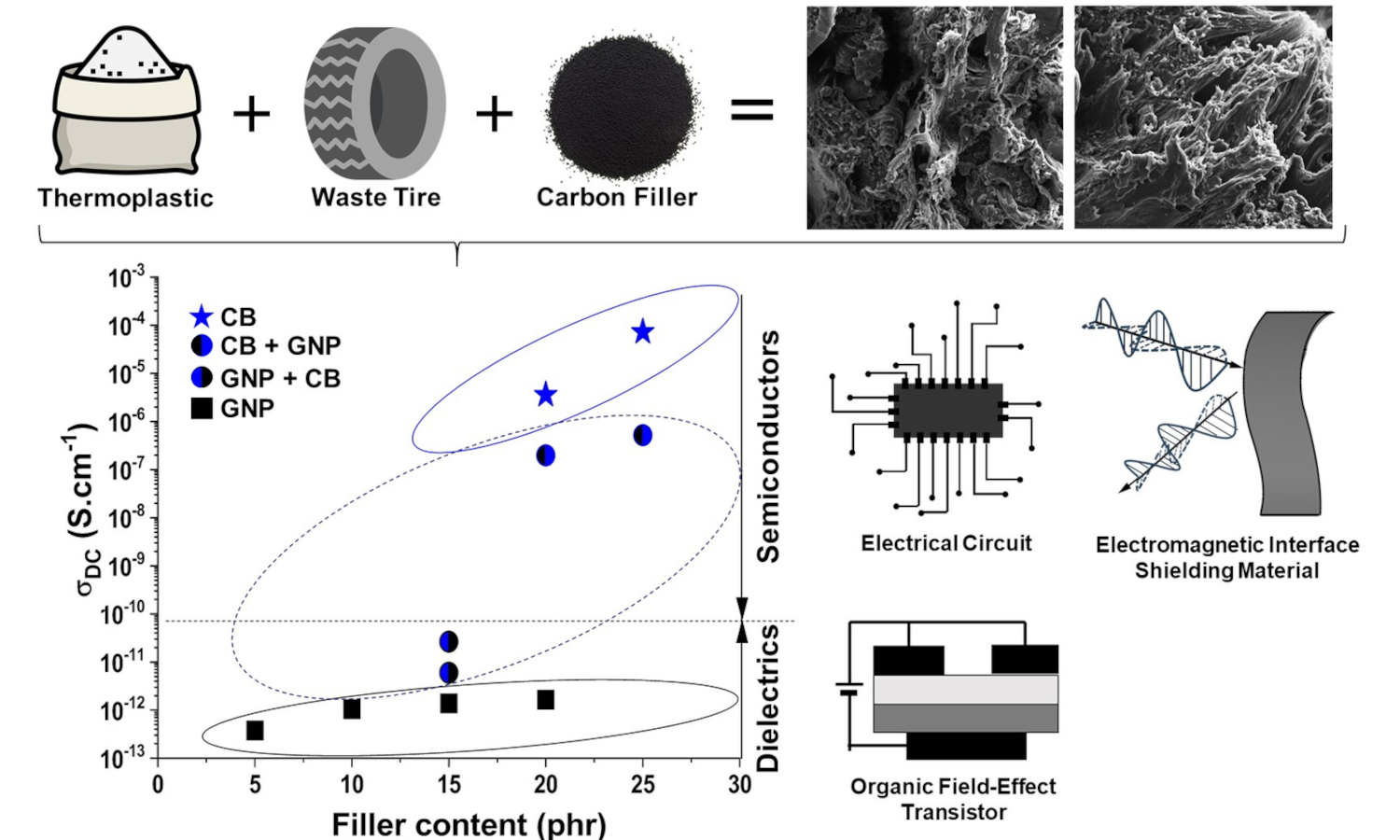

Waste rubber management through developing blends of thermoplastics with ground tire rubber (GTR) has gained significant attention for creating sustainable, high-performance materials with enhanced properties. In this work, we developed customized graphene/polymer nanocomposites applying GTR, ethylene-vinyl acetate copolymer (EVA), and graphene nanoplatelets (GNPs), taking carbon black (CB) as the reference additive. A wide range of electrical conductivity from 10–12 S/cm (dielectric) to 10–5 S/cm (semiconductor) was obtained for optimized composites containing GNPs and CB, respectively. Thermal, mechanical, and flame-retardant properties looked promising for additive manufacturing, while electrical conductivity was tailored for soft electronics. In view of processability, mechanical strength, and elasticity, GNPs-incorporated EVA/GTR composites showed an edge over their CB-aided counterparts. For example, tensile strength and elongation at break of EVA/GTR blends reinforced with 20 phr GNPs were 4.8 MPa and 681%, respectively, compared to 4.0 MPa and 651% for the composite comprising an identical amount of CB. Interestingly, combining GNPs and CB enhanced the thermal stability and flame retardancy of EVA/GTR compared to only GNPs or CB. These results were promising from both sustainability and advanced functional materials perspectives.

Katalin Bocz, Ferenc Ronkay

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

This is an editorial article. It has no abstract.

Dániel Gere, Tamás Bárány

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

This is an editorial article. It has no abstract.

Andrea Toldy

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

This is an editorial article. It has no abstract.