The kinetics of swelling and migration: A case study of plasticized polylactic acid food contact plastics tested with ethanolic food simulants

Viktor Konstantin Dragan , Noémi Petrovics

, Noémi Petrovics , Csaba Kirchkeszner

, Csaba Kirchkeszner , Tamás Tábi

, Tamás Tábi , Bálint Sámuel Szabó

, Bálint Sámuel Szabó , Zsuzsanna Eke

, Zsuzsanna Eke

, Noémi Petrovics

, Noémi Petrovics , Csaba Kirchkeszner

, Csaba Kirchkeszner , Tamás Tábi

, Tamás Tábi , Bálint Sámuel Szabó

, Bálint Sámuel Szabó , Zsuzsanna Eke

, Zsuzsanna Eke

Vol. 18., No.4., Pages 391-405, 2024

DOI: 10.3144/expresspolymlett.2024.29

DOI: 10.3144/expresspolymlett.2024.29

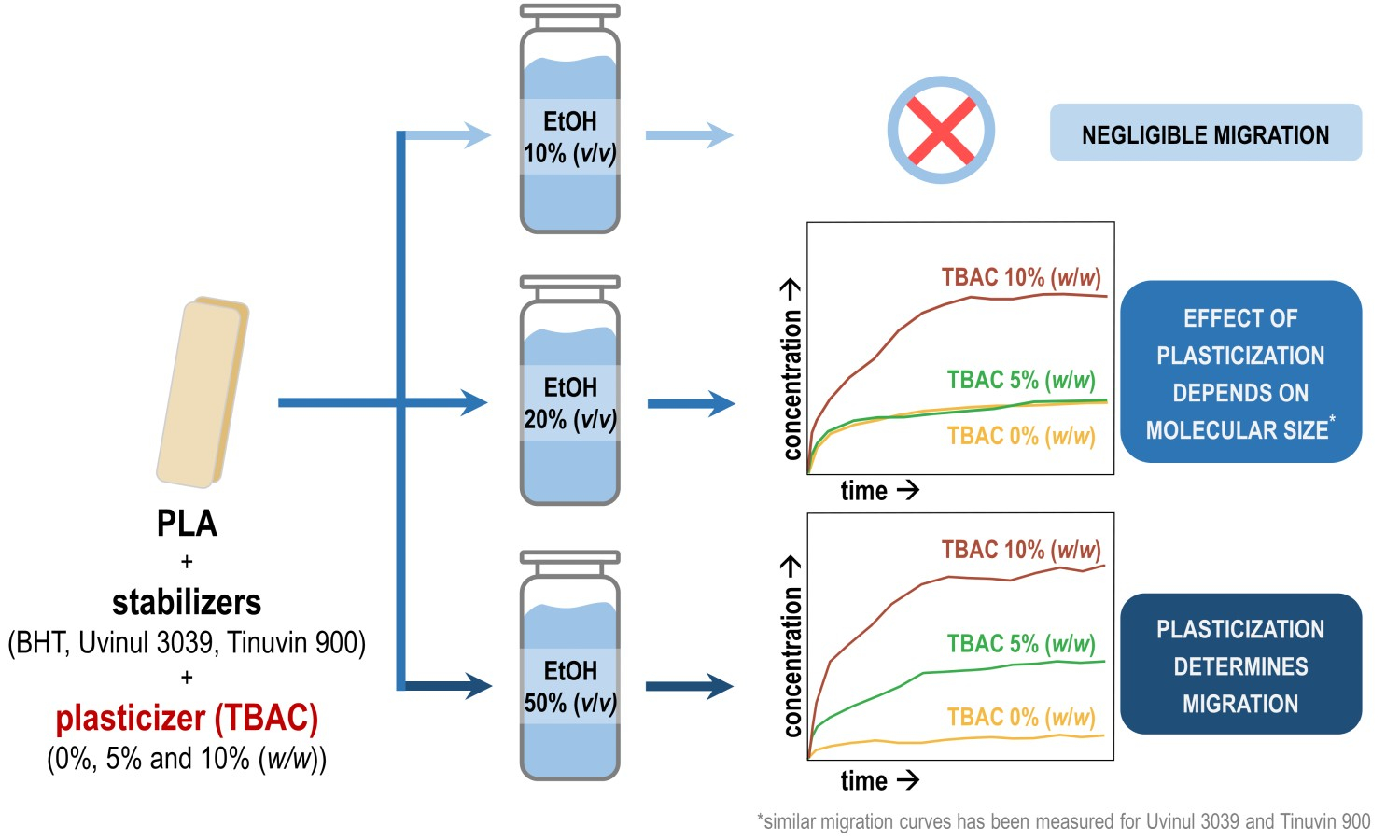

GRAPHICAL ABSTRACT

ABSTRACT

The

effect of swelling and plasticizer content of a plastic, as well as the ethanol

content of the food simulant on the migration kinetics of three stabilizer-type

additives from polylactic acid (PLA)-based food contact plastics has been

investigated. The results proved that the parameters that affect the diffusion

of substances inside the polymer matrix, i.e.,

swelling, plasticization, and the size of migrants, are the decisive factors in

the migration from PLA to ethanolic food simulants. Both swelling and migration

were negligible when ethanol 10% (v/v) was used. Contrarily, the specific

migration limits of Commission Regulation (European Union, EU) No. 10/2011 were

exceeded in ethanol 50% (v/v) for all investigated stabilizers. Migration was

promoted by plasticization, but this effect could only be observed when the

applied food simulant swelled the plastic (at least 20% (v/v) ethanol content).

The dependence of the plasticizer’s migration-enhancing effect on the swelling

has not been shown before. When the plasticization caused increased migration,

it also led to specific migration limit exceeding within a shorter period of

time. It happens even if PLA-based plastics are dedicated to the storage of

hydrophilic food, which is the most common application area of these products.

These results can support the improvement of both consumer safety and active

packaging development.

RELATED ARTICLES

Yi-jie Yang, Qiang Dou

Vol. 20., No.4., Pages 349-370, 2026

DOI: 10.3144/expresspolymlett.2026.28

Vol. 20., No.4., Pages 349-370, 2026

DOI: 10.3144/expresspolymlett.2026.28

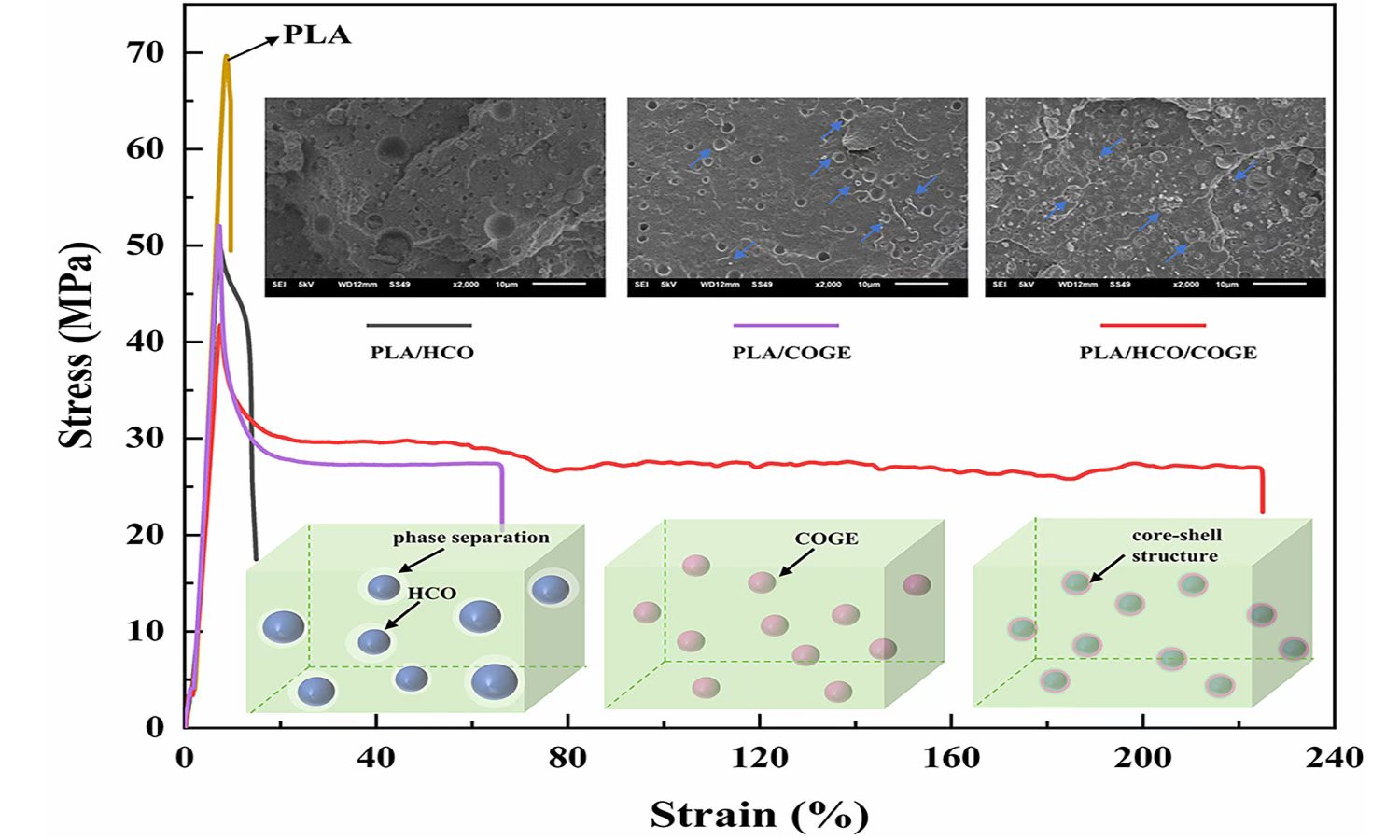

Poly(lactic acid) (PLA) has attracted much attention and shows promising applications in numerous fields. In this study, PLA was plasticized using bio-based castor oil derivatives - hydrogenated castor oil (HCO) and castor oil glycidyl ether (COGE). These eco-blends were measured using a Fourier transform infrared spectrometer, a scanning electron microscope, a contact angle test, rheology, a differential scanning calorimeter, thermogravimetry, polarized optical microscopy, and a tensile test, respectively. The findings show that a core-shell morphology of COGE-HCO encapsulation is formed in PLA matrix, and the hydrogen bonding interaction and ring-opening chemical reaction among functional groups of the components greatly improve the compatibility, ductility, cold crystallization ability, and thermostability of the eco-blends, but the melt crystallization ability is hindered. The incorporation of HCO improves the hydrophobicity and oleophobicity of the eco-blends. Due to the combined effect of HCO and COGE, the melt viscosity reduces, and the Newtonian behavior enhances; the nucleation density and spherulitic growth of PLA increase. The strain at break of the PLA/HCO/COGE (90/7.5/2.5) blend reached 221%, which is 22.6 times higher than that of the neat PLA. These eco-blends present appropriate rheological, thermal, and mechanical properties, showing application scenarios in biodegradable packaging and disposable appliances.

Paulina Bednarczyk, Kamil Rożniakowski

Vol. 20., No.3., Pages 233-245, 2026

DOI: 10.3144/expresspolymlett.2026.19

Vol. 20., No.3., Pages 233-245, 2026

DOI: 10.3144/expresspolymlett.2026.19

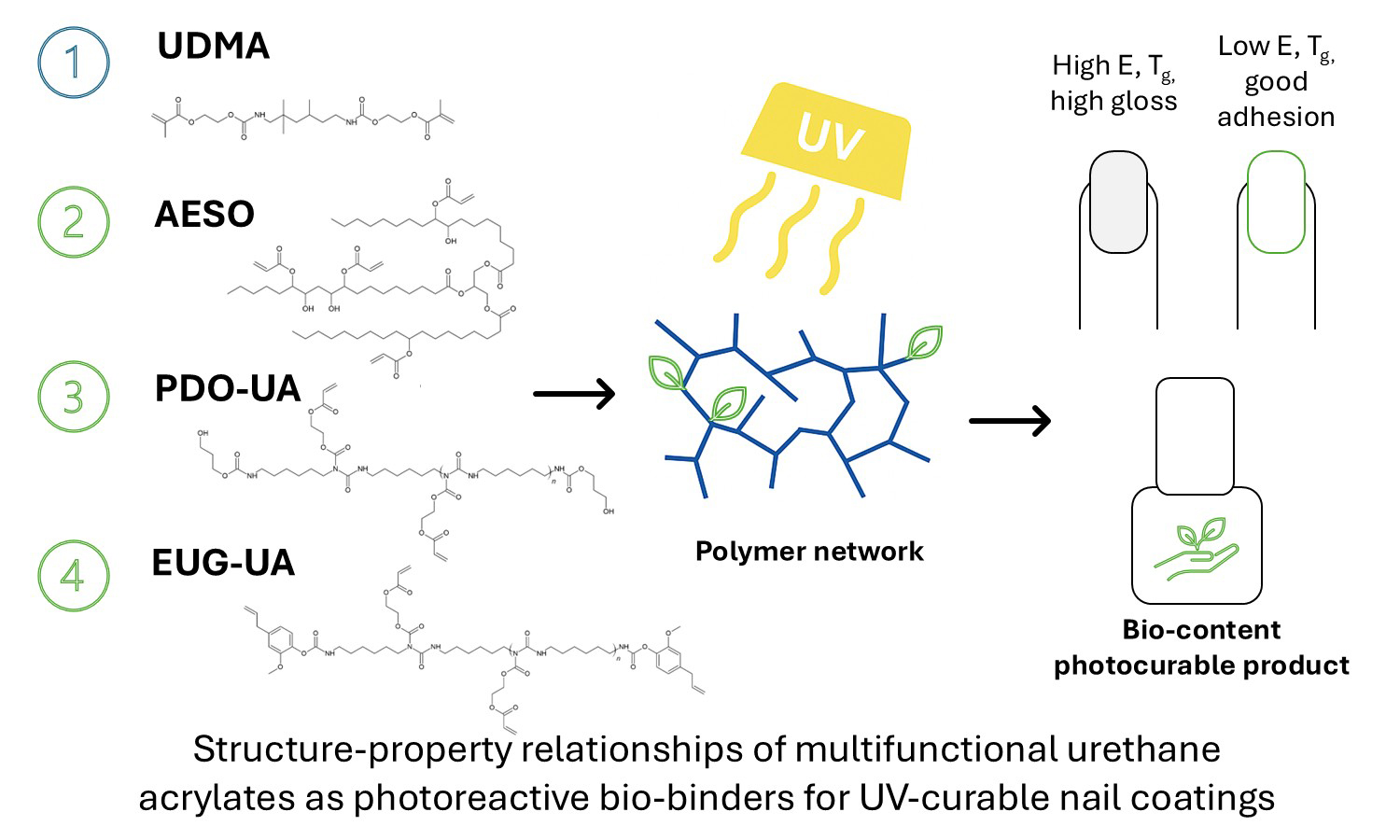

This study investigates the structure–property relationships of multi-functional urethane acrylate resins designed as photoreactive binders for UV-curable nail coatings. Four systems were examined: a commercial resin urethane dimethacrylate (UDMA), a bio-based acrylated epoxidized soybean oil (AESO), and two newly synthesized bio-based urethane acrylates derived from 1,3-propanediol (PDO–UA) and eugenol (EUG–UA). Photopolymerization kinetics were analyzed by realtime FTIR, while the properties of the cured coatings were also determined. The mechanical and thermal behavior of selfsupporting polymer films was evaluated by tensile testing and DSC analysis. The UDMA network exhibited the highest crosslink density, reflected in its high modulus (≈0.5 GPa), tensile strength (≈15 MPa), and Tg (≈60°C), making it suitable for use as a top coat. AESO showed moderate stiffness and flexibility, whereas PDO–UA and EUG–UA formed soft, low-Tg (–12 and –17°C) and highly deformable networks typical of elastomeric materials. The combined mechanical and thermal results confirmed that crosslink density strongly governs coating performance and applicability. This study demonstrates that blending UDMA with bio-based oligomers enables the design of sustainable, UV-curable nail lacquers with an optimal balance of hardness, flexibility, and adhesion to the natural nail plate.

Cláudia Andréa Batista dos Santos, Bartłomiej Kryszak, Rafał Malinowski, Aleksandra Ujćič, Konrad Szustakiewicz

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

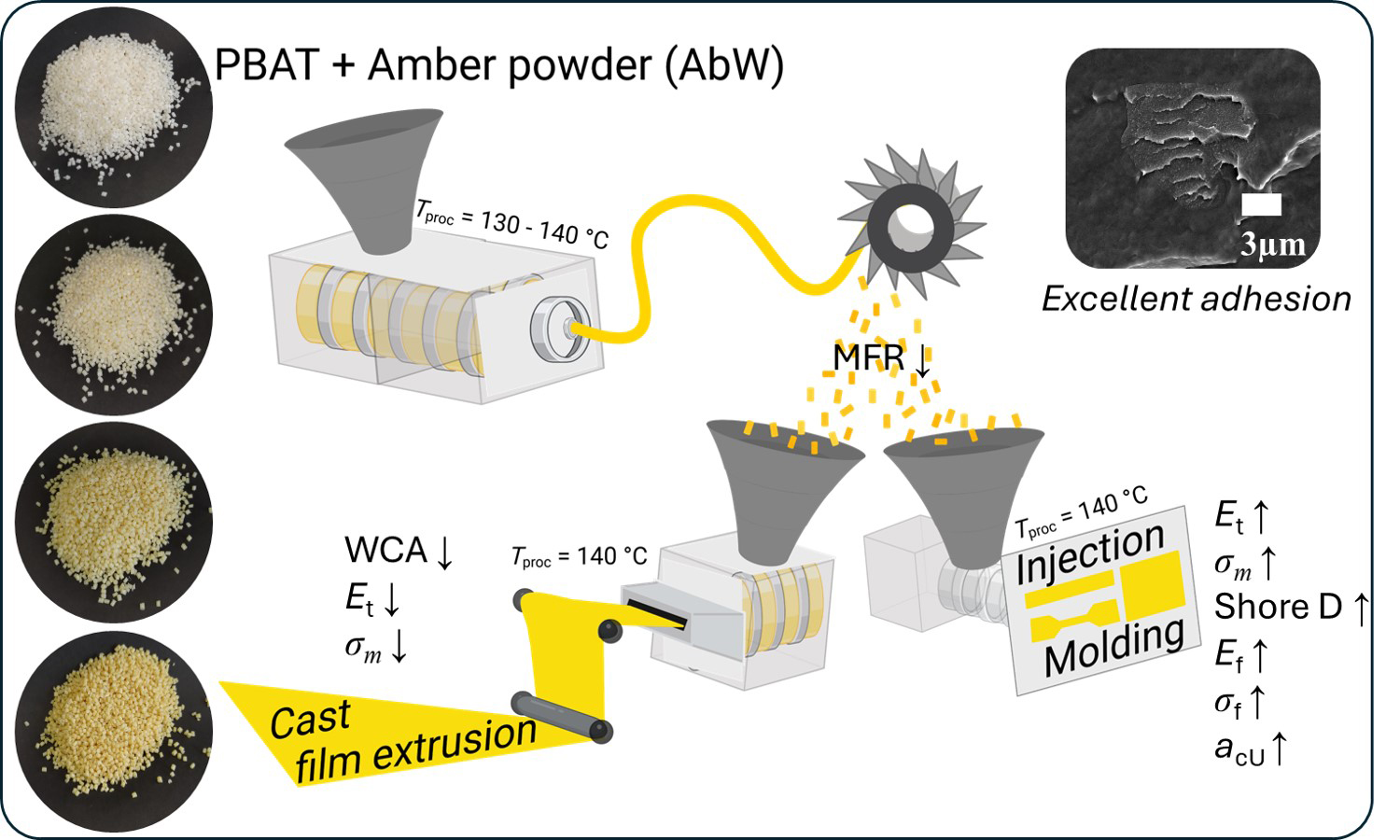

This study investigates the interaction between poly(butylene adipate-co-terephthalate) (PBAT) and amber powdered waste (AbW) from jewelry at different filler concentrations (0, 1, 2.5, and 5 wt%) obtained via melt mixing in a corotating twin screw extruder. The resulting materials were pelletized and processed using two techniques: 1) cast film extrusion and 2) injection molding. The shaped specimens exhibited excellent interfacial adhesion. Thermal behavior, as assessed by Vicat softening temperature (VST), differential scanning calorimetry (DSC), and thermogravimetric analysis (TGA), showed minimal variation among the composites. Despite similar melt flow rate (MFR) values among the samples, the incorporation of AbW affected the behavior of the polymer during cast film extrusion. Consequently, the composite films exhibited lower tensile mechanical parameters (tensile strength, Young’s modulus, stress and strain at break) compared to the neat PBAT film. In turn, the injection molded composites showed improved tensile, flexural, and impact parameters compared to their neat counterpart. Additionally, a slight decrease in water contact angle (WCA) suggested increased surface hydrophilicity of the extruded films. These findings demonstrate the potential of AbW as an additive for biopolymer composites with enhanced mechanical performance. The increased surface hydrophilicity is particularly relevant for applications targeting biocompatibility and biodegradability.

Evangelia Balla, Panagiotis Klonos, Apostolos Kyritsis, Dimitrios Bikiaris

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

In recent decades, numerous efforts have been dedicated to the investigation of eco-friendly non-isocyanate polyurethanes (NIPUs) as alternatives to conventional polyurethanes (PUs). Since isocyanates are classified by the EU as hazardous and toxic compounds, NIPUs offer a promising route to mitigate isocyanate-related health risks as well as other environmental concerns associated with traditional PU synthesis. In the present study, we report the synthesis as well as the detailed structural and thermal characterization of a new series of fully biobased non-isocyanate polyurethanes (NIPUs) based on aliphatic dicarboxylic acids of different chain lengths. The NIPUs were prepared via a two-step polyaddition reaction involving glycerol carbonate and diamine. Their synthesis enables a sustainable pathway to tailor NIPUs’ physicochemical properties via diacid structure control. Studies of their structure, thermal behavior and trends, morphological, and hydrolytic findings confirmed strong diacid chain length dependence on glass transition temperature (Tg ~13, 0, ‒5 and –23 °C), molecular weight, surface wettability, and enzymatic degradability. Short-chain diacids yielded NIPUs with rapid hydrolytic degradation, while their longer-chain analogs were hydrophobic and thermally stable. Contact angle measurements (~75–85°) also confirm these trends. The tunable properties position these materials among strong candidates for biomedical applications.

Soni Thakur, Amal M. Sindi, Rahul Dev Bairwan, Rasha A. Mahmoud, Eman Alfayez, Nurul Fazita Mohammad Rawi, Kanchan Jha, H.P.S. Abdul Khalil

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

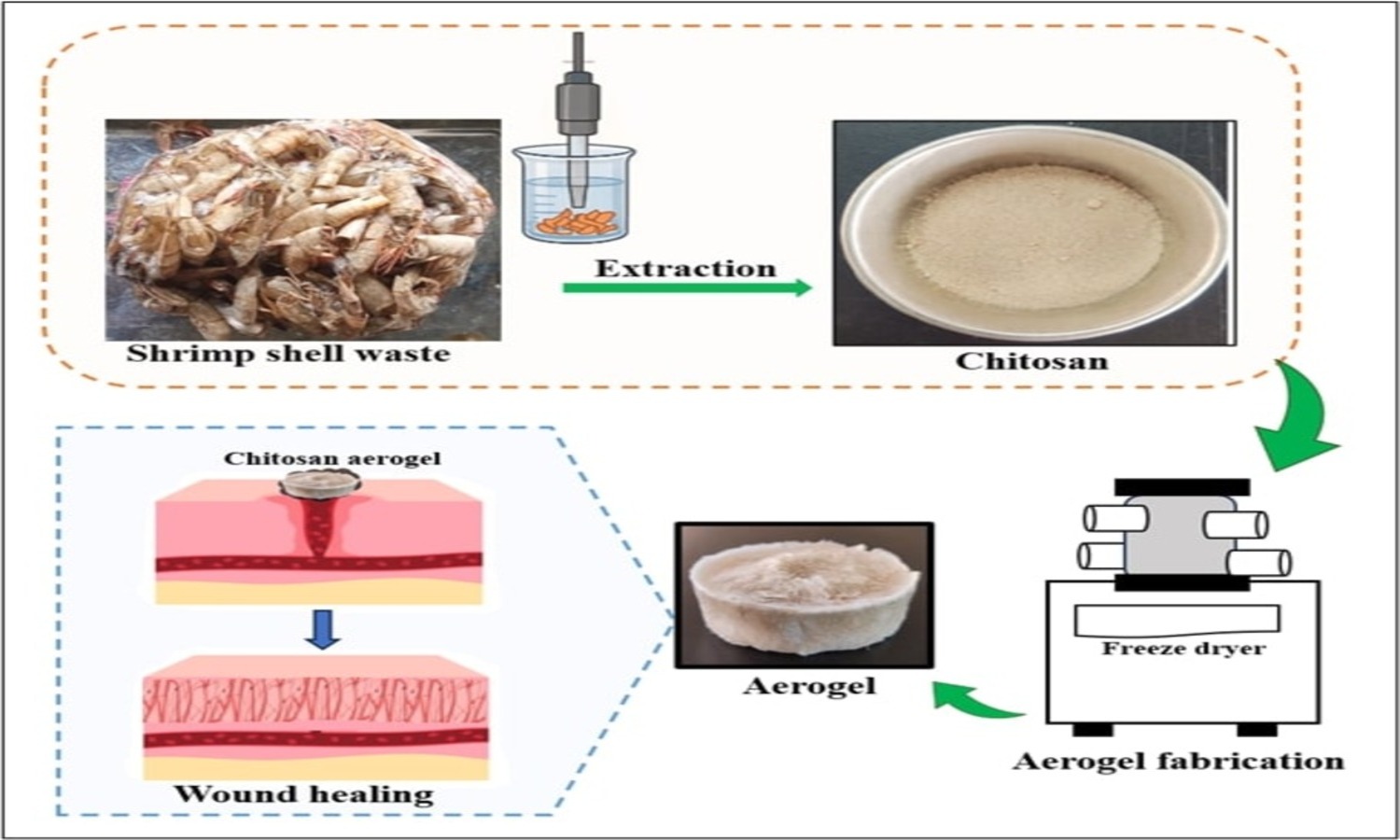

This research presents an eco-friendly approach for extracting chitosan from shrimp shell waste through ultrasound-assisted extraction (UAE) to prepare biocompatible aerogel scaffolds for biomedical applications. The study investigates the influence of various ultrasonic treatment times (10, 20, 30, 40 min) on the yield and structural and physicochemical properties of the extracted chitosan via characterization using Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Among the tested conditions, the 30 min UAE-treated chitosan aerogels showed optimal porosity and structural integrity. Biocompatibility of the aerogels was evaluated, and the results confirmed their non-cytotoxic nature. The bioactivity of the chitosan aerogels was evaluated in terms of their in vitro wound closure ability and antibacterial properties. The aerogels demonstrated a wound closure rate of around 51% after 72 h, significantly higher than the untreated control (37%). In addition, they exhibited clear antibacterial activity against Escherichia coli and Staphylococcus aureus. This sustainable extraction and fabrication method not only adds value to marine waste but also produces functional biomaterials with potential applications in wound healing, tissue engineering, and regenerative medicine, supporting global efforts toward sustainability and circular bioeconomy.