Environmental PET litter is a resource not to be wasted

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

DOI: 10.3144/expresspolymlett.2025.65

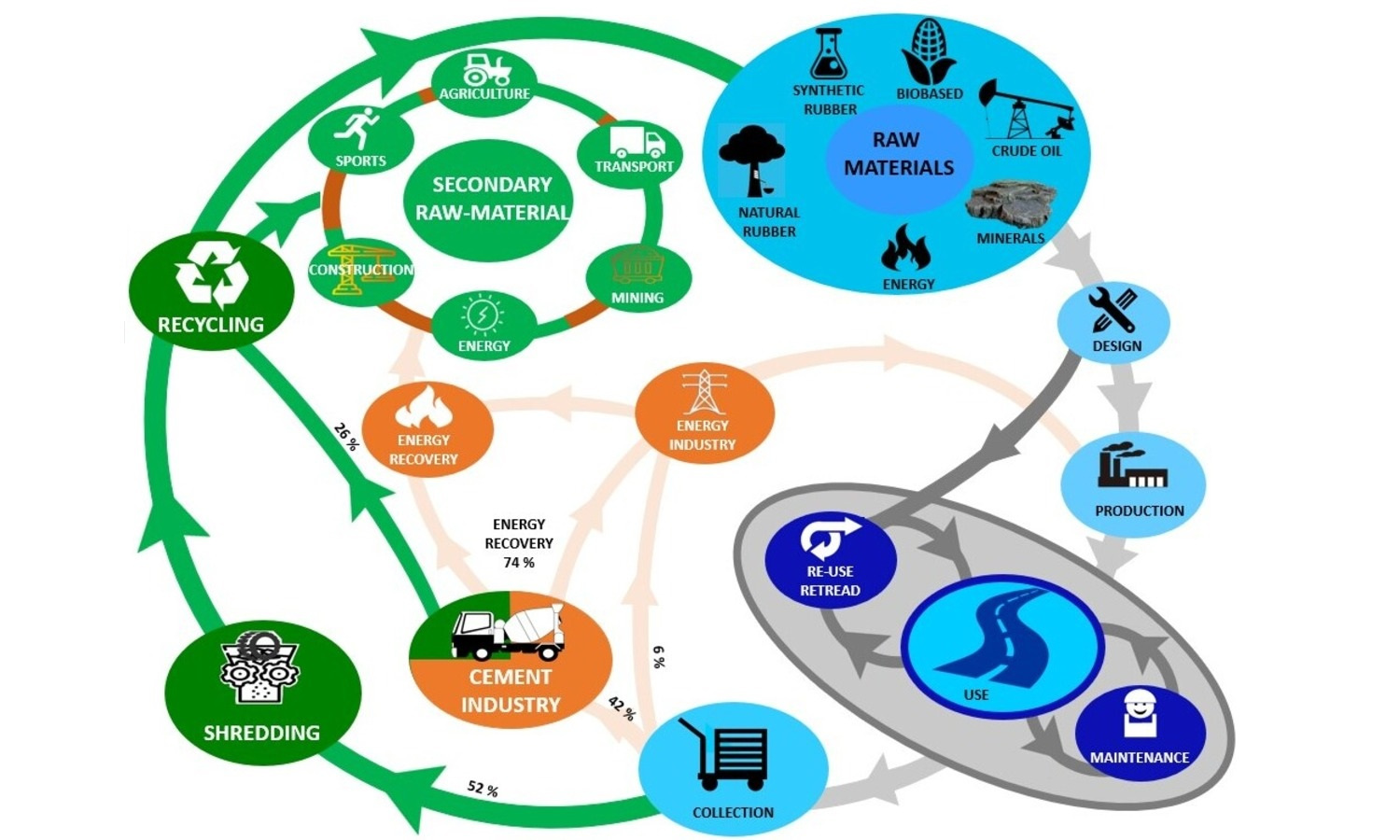

GRAPHICAL ABSTRACT

RELATED ARTICLES

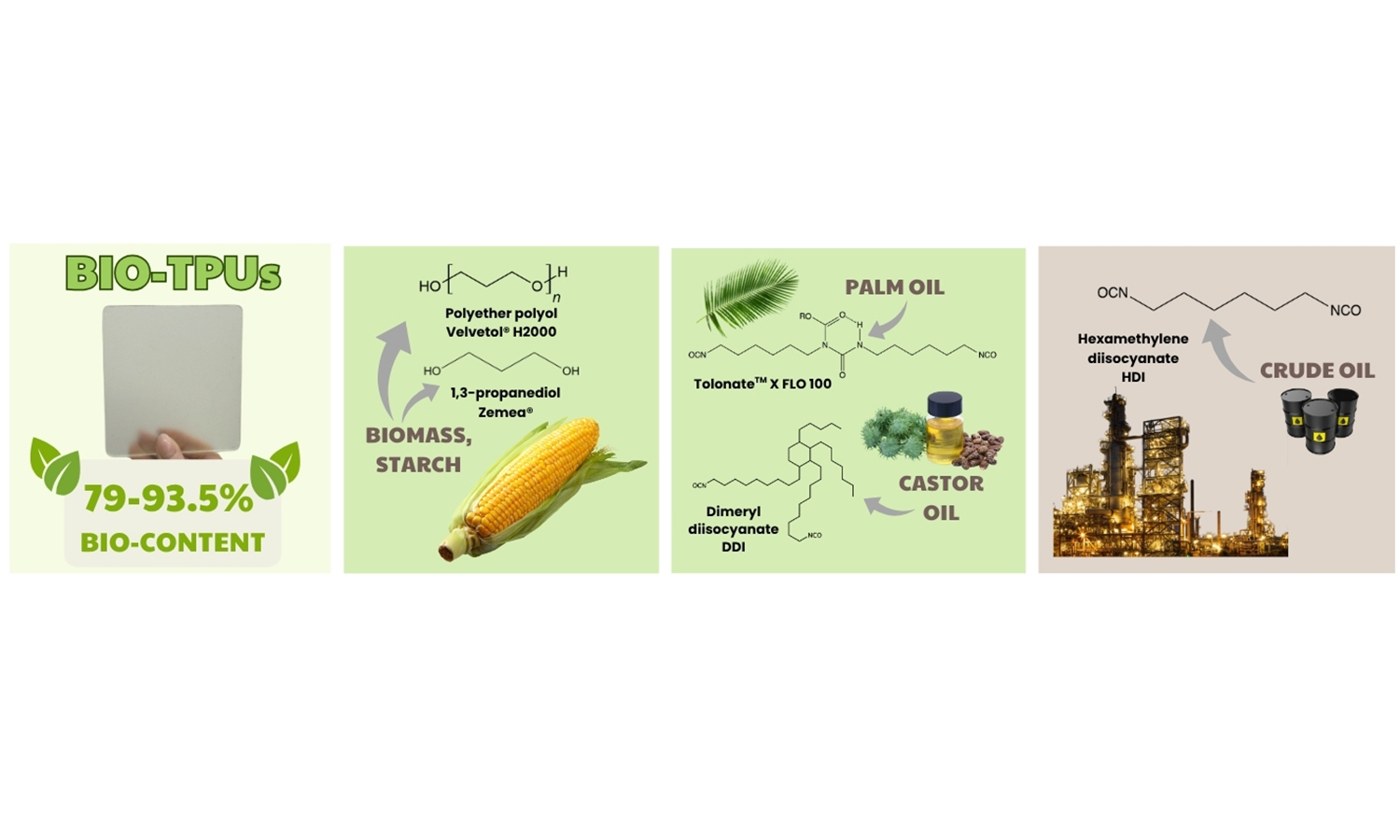

Joanna Smorawska-Kliza, Julia Habaj, Ewa Głowińska

Vol. 20., No.3., Pages 217-232, 2026

DOI: 10.3144/expresspolymlett.2026.18

Vol. 20., No.3., Pages 217-232, 2026

DOI: 10.3144/expresspolymlett.2026.18

Modification of the hard segment structure in polyurethanes using isocyanate mixtures has emerged as one of the most effective strategies for developing new materials with enhanced properties and a high content of bio-based carbon. In this work, next-generation sustainable thermoplastic polyurethane elastomers (bio-TPUs) were synthesized using aliphatic isocyanate mixtures based on bio-derived diisocyanates Tolonate™ X FLO 100 and dimeryl diisocyanate (DDI) alongside hexamethylene diisocyanate (HDI). Poly(trimethylene ether) glycol (PO3G) and bio-based 1,3-propanediol served as renewable hydroxyl-terminated components. The bio-TPUs were prepared using the common ‘one-shot’ method. The resulting materials were analyzed to assess phase separation, morphology, as well as mechanical, thermal and thermomechanical properties. The results confirm the significant influence of the type of diisocyanate mixture on the properties of bio-TPU, improving their thermal stability (up to 300 °C) and reducing the melting temperature to 140 °C, which makes them suitable for low-temperature processing.

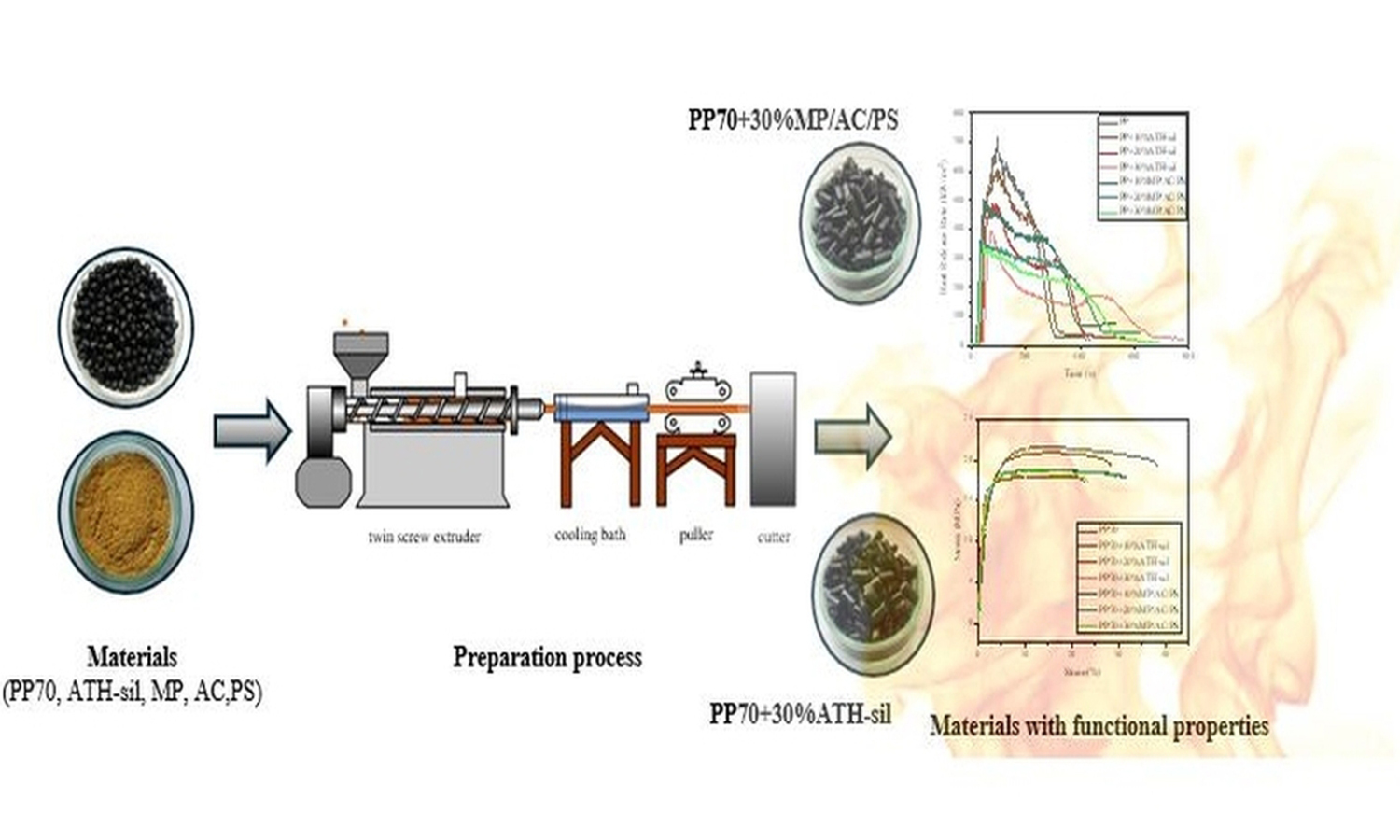

Sandra Paszkiewicz, Kamila Sałasińska, Zaida Ortega, Mateusz Barczewski, Jacek Andrzejewski, Konrad Walkowiak, Izabela Irska, Magdalena Jurczyk Kowalska, Anna Boczkowska, Marcin Borowicz, Joanna Paciorek-Sadowska, Elżbieta Piesowicz, Katarzyna Pokwicka-Croucher

Vol. 19., No.12., Pages 1286-1309, 2025

DOI: 10.3144/expresspolymlett.2025.95

Vol. 19., No.12., Pages 1286-1309, 2025

DOI: 10.3144/expresspolymlett.2025.95

Two series of polymer blends based on post-consumer polypropylene (rPP) and tire rubber crumbs (Trc) under the trademark ECOPLASTOMER® PP70 with a mutual ratio of components 70/30 wt%, containing 10, 20, and 30 wt% of flame retardants, have been prepared using a twin-screw extruder. The influence of commercially available silane-treated alumina trihydrate (ATH-sil) with the eco-friendly system based on melamine phosphate (MP), aluminum hydroxide (AC), and peanut shells (PS), used as flame retardant agents, on the mechanical, thermal, and flammability properties of polymer blends was assessed – the incorporation of ATH-sil results in the appearance of peaks related to OH groups in the Fouriertransform infrared spectroscopy (FTIR) spectra. Similar observations are made for the MP/AC/PS system. differential scanning calorimetry (DSC) analysis revealed that using the selected flame retardants did not impact the melting and crystallization temperatures of the polymer. Tensile strength experienced a minor decrease, particularly in compositions containing more than 20 wt% of the flame retardants, while hardness remained unaffected by their share. Both flame retardants reduced the flammability of the modified polypropylene/rubber powder blends, and the most favorable outcomes were achieved with ATH-sil; however, only when employed at a minimum of 30 wt%. The formulated MP/AC/PS system proved more adept at reducing flammability and smoke emissions at lower flame retardant levels (up to 20 wt%).

Dániel Gere, Tamás Bárány

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

This is an editorial article. It has no abstract.

Andrea Toldy

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

This is an editorial article. It has no abstract.

Zaheer ul Haq, Teng Ren, Xinyan Yue, Krzysztof Formela, Denis Rodrigue, Xavier Colom Fajula, Tony McNally, Dong Dawei, Yong Zhang, Shifeng Wang

Vol. 19., No.3., Pages 258-293, 2025

DOI: 10.3144/expresspolymlett.2025.20

Vol. 19., No.3., Pages 258-293, 2025

DOI: 10.3144/expresspolymlett.2025.20

As a complex composite material, tire rubber has always presented significant environmental and waste management concerns due to its non-biodegradability and accumulation in landfills. The devulcanization of tire rubber has emerged as a historical challenge in the field of sustainable rubber engineering since Goodyear invented cross-linking in 1839. This review provides a comprehensive analysis of waste tire recycling processes, focusing on the sources, legislation, management strategies, and utilization across different regions. It explores the multifaceted challenges of devulcanizing rubber, with a specific focus on transitioning from ground tire rubber to the concept of multi-decrosslinking: sulfur bridge breakage, rubber chain depolymerization and micro-nano sized core-shell carbon black. Ideal devulcanization has restricted the release of reinforcing fillers, resulting in devulcanized rubber mainly containing dozens of micron particles, which hinder the wide usage of devulcanized rubber. This review comprehensively assesses the current state-of-the-art techniques for tire rubber devulcanization, including physical, chemical and biological methods. It explores the intricacies of ground tire rubber as a starting material, structural evolution of ground tire rubber during the devulcanization process and the associated challenges in achieving efficient devulcanization while retaining desirable mechanical properties. Furthermore, through an in-depth analysis of recent advancements, limitations and prospects, this paper offers a complete understanding of the challenges faced in tire rubber devulcanization. Considering the technical and environmental aspects of these processes, this work contributes to multi-decrosslinking, the ongoing discourse on sustainable materials development and circular economy initiatives, which pave the way for future innovations in the field of rubber recycling.