From waste rubber to customized graphene/polymer nanocomposites: Thermal stability, flame retardancy and electrical conductivity

Paulina Wiśniewska, Natalia A. Wójcik, Józef Haponiuk , Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

DOI: 10.3144/expresspolymlett.2025.67

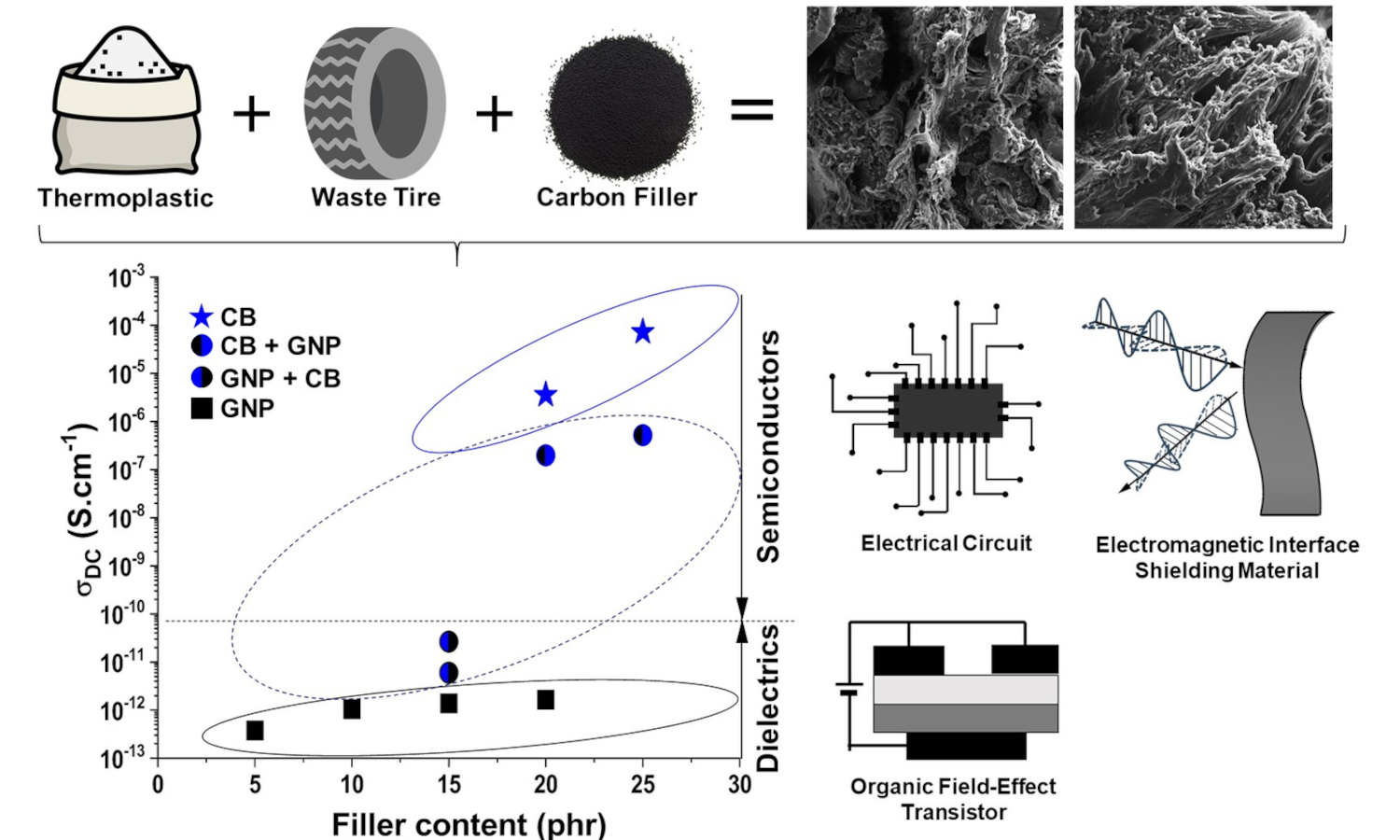

GRAPHICAL ABSTRACT

ABSTRACT

Waste rubber management through developing blends of thermoplastics with ground tire rubber (GTR) has gained significant attention for creating sustainable, high-performance materials with enhanced properties. In this work, we developed customized graphene/polymer nanocomposites applying GTR, ethylene-vinyl acetate copolymer (EVA), and graphene nanoplatelets (GNPs), taking carbon black (CB) as the reference additive. A wide range of electrical conductivity from 10–12 S/cm (dielectric) to 10–5 S/cm (semiconductor) was obtained for optimized composites containing GNPs and CB, respectively. Thermal, mechanical, and flame-retardant properties looked promising for additive manufacturing, while electrical conductivity was tailored for soft electronics. In view of processability, mechanical strength, and elasticity, GNPs-incorporated EVA/GTR composites showed an edge over their CB-aided counterparts. For example, tensile strength and elongation at break of EVA/GTR blends reinforced with 20 phr GNPs were 4.8 MPa and 681%, respectively, compared to 4.0 MPa and 651% for the composite comprising an identical amount of CB. Interestingly, combining GNPs and CB enhanced the thermal stability and flame retardancy of EVA/GTR compared to only GNPs or CB. These results were promising from both sustainability and advanced functional materials perspectives.

RELATED ARTICLES

Maja Csapó, József Gábor Kovács

Vol. 20., No.4., Pages 414-434, 2026

DOI: 10.3144/expresspolymlett.2026.32

Vol. 20., No.4., Pages 414-434, 2026

DOI: 10.3144/expresspolymlett.2026.32

The greatest obstacle to recycling post-consumer high-density polyethylene (PCR-HDPE) is typically the degradation of properties caused by impurities and heterogeneity. However, a critical analysis of the literature reveals that the real bottleneck is not the material composition, but rather rheological stability, which simultaneously determines the degradation history of the waste stream, melt behavior, and processability at the cycle level. This review proposes a new perspective: the decision among mechanical, chemical, and energetic recycling is better made based on a unified rheological stability index (RSI), which integrates carbonyl index, viscosity change after multiple instances of melting, melt flow index (MFI) instability, in-mold pressure fluctuation, and the degree of polymer incompatibility. RSI enables the prediction of the processability of PCR-HDPE and identifies which recycling path a fraction is most suitable for. The study demonstrates how an RSI-based approach can reduce quality risk, improve cycle stability, and support circular decision-making in an industrial environment.

Joanna Smorawska-Kliza, Julia Habaj, Ewa Głowińska

Vol. 20., No.3., Pages 217-232, 2026

DOI: 10.3144/expresspolymlett.2026.18

Vol. 20., No.3., Pages 217-232, 2026

DOI: 10.3144/expresspolymlett.2026.18

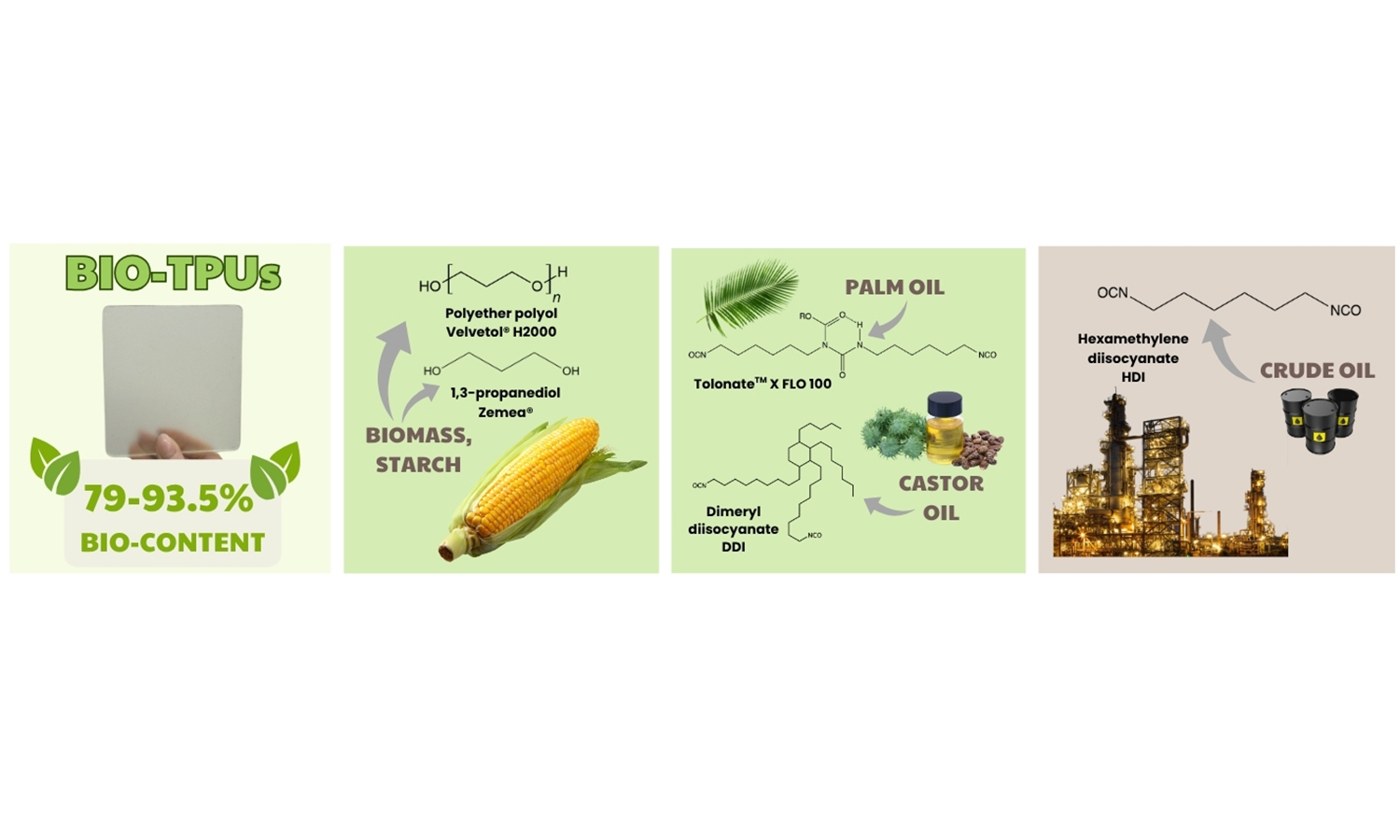

Modification of the hard segment structure in polyurethanes using isocyanate mixtures has emerged as one of the most effective strategies for developing new materials with enhanced properties and a high content of bio-based carbon. In this work, next-generation sustainable thermoplastic polyurethane elastomers (bio-TPUs) were synthesized using aliphatic isocyanate mixtures based on bio-derived diisocyanates Tolonate™ X FLO 100 and dimeryl diisocyanate (DDI) alongside hexamethylene diisocyanate (HDI). Poly(trimethylene ether) glycol (PO3G) and bio-based 1,3-propanediol served as renewable hydroxyl-terminated components. The bio-TPUs were prepared using the common ‘one-shot’ method. The resulting materials were analyzed to assess phase separation, morphology, as well as mechanical, thermal and thermomechanical properties. The results confirm the significant influence of the type of diisocyanate mixture on the properties of bio-TPU, improving their thermal stability (up to 300 °C) and reducing the melting temperature to 140 °C, which makes them suitable for low-temperature processing.

Abdulhakim Masa, Ruedee Jaratrotkamjorn

Vol. 20., No.2., Pages 186-196, 2026

DOI: 10.3144/expresspolymlett.2026.15

Vol. 20., No.2., Pages 186-196, 2026

DOI: 10.3144/expresspolymlett.2026.15

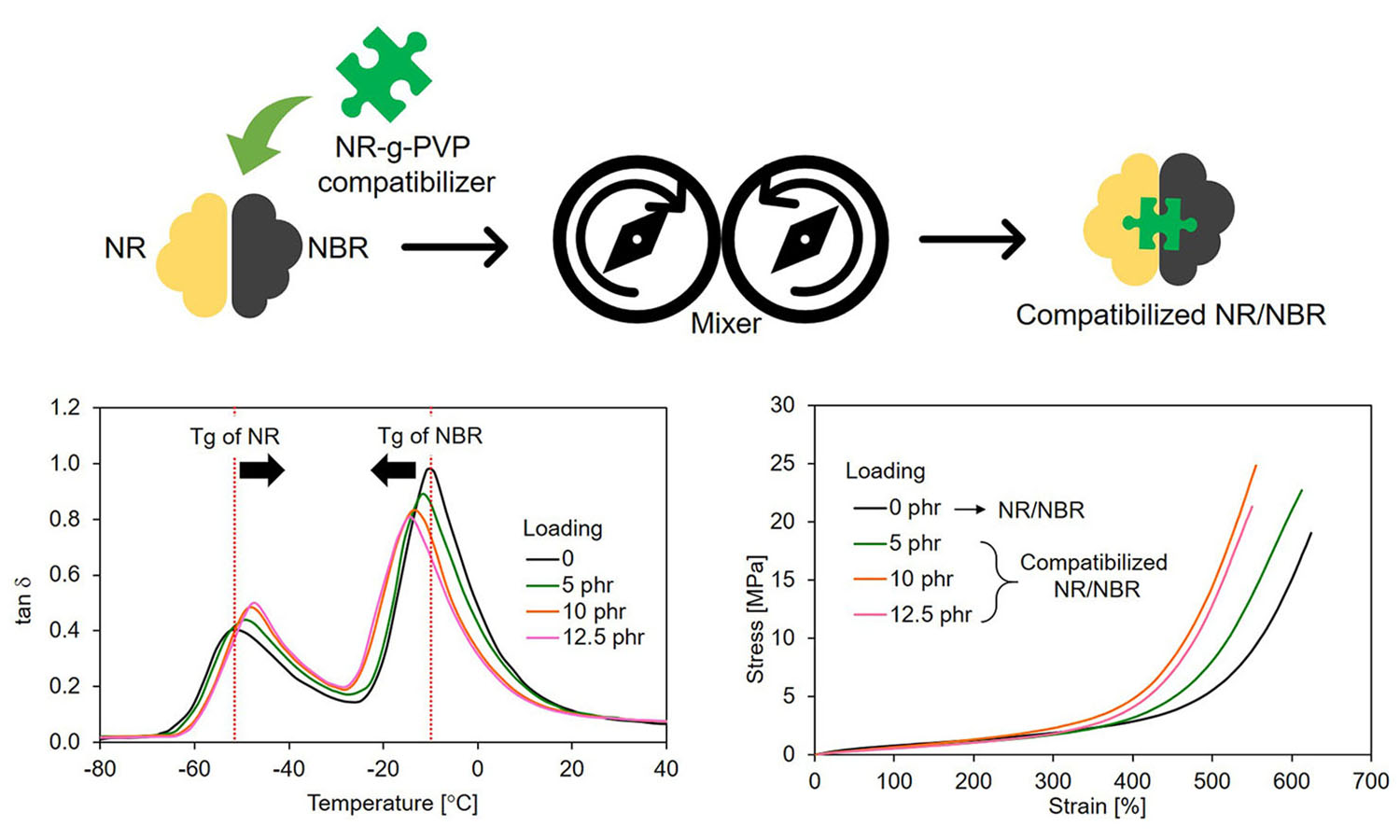

Natural rubber (NR) and acrylonitrile butadiene rubber (NBR) are typically incompatible due to differences in their polarity, which causes poor mechanical properties. In this study, a new type of compatibilizer, namely G10 or poly(vinyl propionate)-grafted natural rubber (NR-g-PVP) containing 10 wt% PVP, is employed to improve the compatibility in 50/50 blends of NR and NBR. The results show that G10 promotes the compatibility and shifts the glass transition temperatures (Tg) of NR and NBR towards each other. This indicates that G10 interacts with both NR and NBR phases. The improved compatibility resulted in a more homogeneous blend with smooth surface morphology. The mechanical properties of the blend, including 300 and 500% moduli, tensile strength, and tear resistance, increased with G10 content up to 7.5 phr. The highest tensile strength of the NR/NBR blend was achieved with 7.5 phr of G10 compatibilizer, showing an improvement of approximately 40.7% over the control sample. The results clearly revealed that NR-g-PVP can be utilized as an effective compatibilizer in NR/NBR blends.

Sandra Paszkiewicz, Kamila Sałasińska, Zaida Ortega, Mateusz Barczewski, Jacek Andrzejewski, Konrad Walkowiak, Izabela Irska, Magdalena Jurczyk Kowalska, Anna Boczkowska, Marcin Borowicz, Joanna Paciorek-Sadowska, Elżbieta Piesowicz, Katarzyna Pokwicka-Croucher

Vol. 19., No.12., Pages 1286-1309, 2025

DOI: 10.3144/expresspolymlett.2025.95

Vol. 19., No.12., Pages 1286-1309, 2025

DOI: 10.3144/expresspolymlett.2025.95

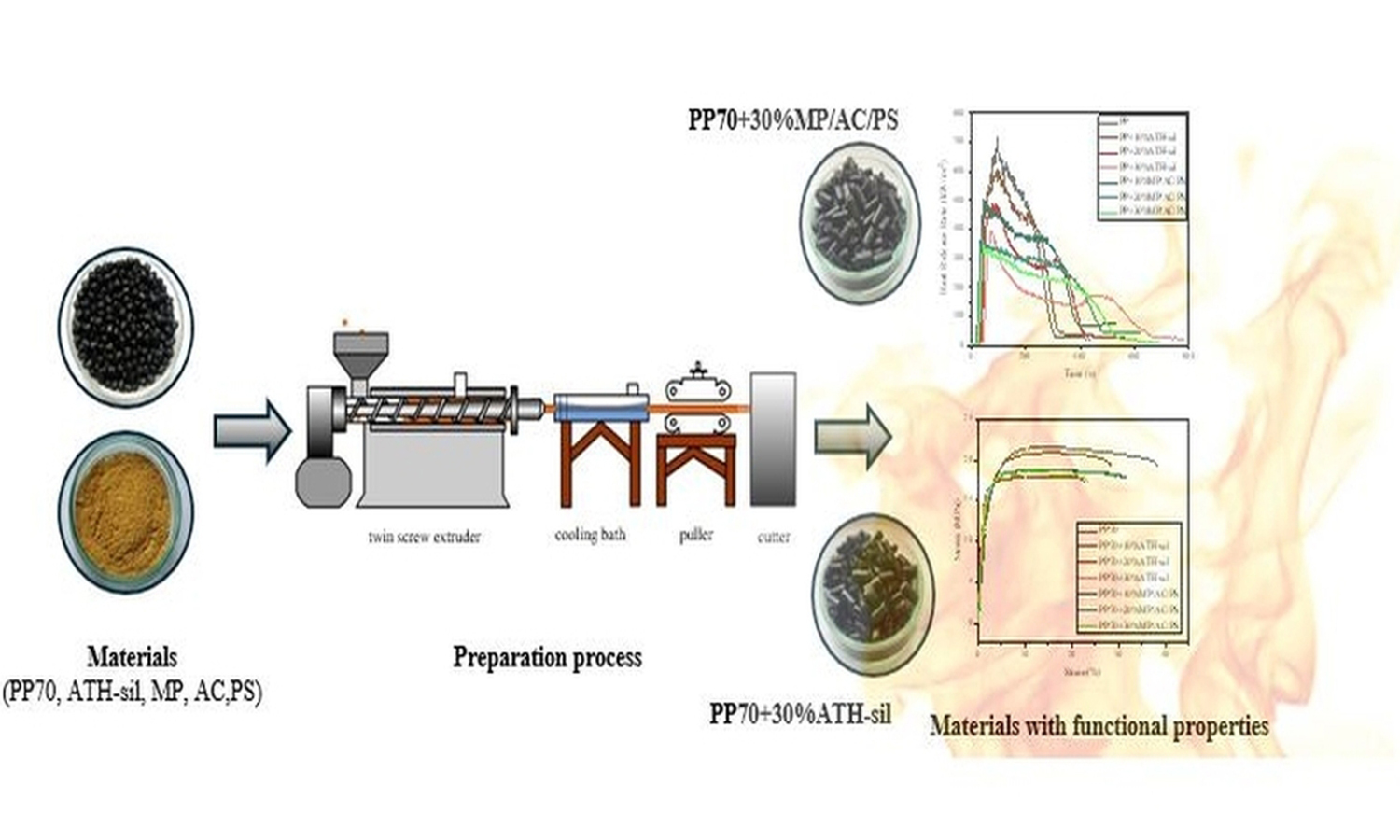

Two series of polymer blends based on post-consumer polypropylene (rPP) and tire rubber crumbs (Trc) under the trademark ECOPLASTOMER® PP70 with a mutual ratio of components 70/30 wt%, containing 10, 20, and 30 wt% of flame retardants, have been prepared using a twin-screw extruder. The influence of commercially available silane-treated alumina trihydrate (ATH-sil) with the eco-friendly system based on melamine phosphate (MP), aluminum hydroxide (AC), and peanut shells (PS), used as flame retardant agents, on the mechanical, thermal, and flammability properties of polymer blends was assessed – the incorporation of ATH-sil results in the appearance of peaks related to OH groups in the Fouriertransform infrared spectroscopy (FTIR) spectra. Similar observations are made for the MP/AC/PS system. differential scanning calorimetry (DSC) analysis revealed that using the selected flame retardants did not impact the melting and crystallization temperatures of the polymer. Tensile strength experienced a minor decrease, particularly in compositions containing more than 20 wt% of the flame retardants, while hardness remained unaffected by their share. Both flame retardants reduced the flammability of the modified polypropylene/rubber powder blends, and the most favorable outcomes were achieved with ATH-sil; however, only when employed at a minimum of 30 wt%. The formulated MP/AC/PS system proved more adept at reducing flammability and smoke emissions at lower flame retardant levels (up to 20 wt%).

Emiliano González-Rodríguez, Grecia Michelle Ramírez-Paredes, Ulises Figueroa-López, Elvia Patricia Sánchez-Rodríguez, Andrea Guevara-Morales

Vol. 19., No.11., Pages 1144-1160, 2025

DOI: 10.3144/expresspolymlett.2025.84

Vol. 19., No.11., Pages 1144-1160, 2025

DOI: 10.3144/expresspolymlett.2025.84

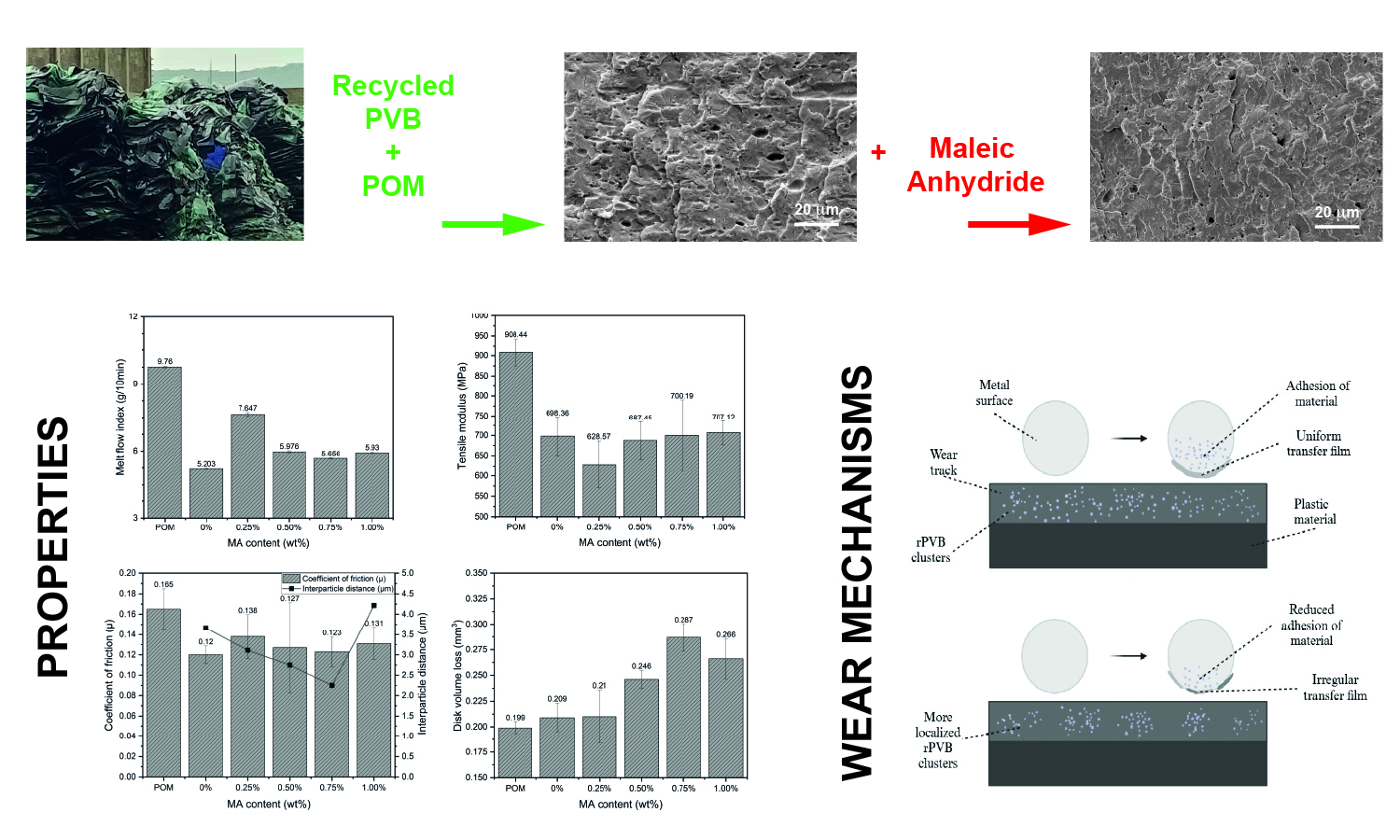

Maleic anhydride (MA) is widely used to modify plastics and as a compatibilizer in recycling. This study examines the effect of varying MA concentrations on blends of polyoxymethylene (POM) and recycled polyvinyl butyral (rPVB) from automotive windshields. Morphological analysis showed that MA contents between 0.25 and 0.75 wt% led to smaller, more closely dispersed rPVB particles, indicating enhanced phase miscibility. Rheological and thermal analyses revealed up to a 47% increase in melt flow index at lower MA concentrations, and improved interfacial interactions and crystallinity at higher levels. The tensile modulus dropped by 10% at 0.25 wt% MA but increased with further additions; tensile strength and Shore D hardness remained unaffected. Impact strength improved by up to 65% with MA addition, mainly due to increased ductility and a morphology characterized by larger rPVB domains and shorter interparticle distances at low MA contents. The coefficient of friction decreased with rPVB but increased with MA, along with higher volume loss. Microscopic wear analysis confirmed that rPVB dispersion, influenced by MA, was key to transfer film formation and surface lubrication. Thus, MA optimization enables tailored mechanical and tribological properties in POM/rPVB blends.