Influences of compatibilizer type and loading on properties of phenolic resin-crosslinked natural rubber composites filled with sepiolite

Vol. 18., No.11., Pages 1135-1148, 2024

DOI: 10.3144/expresspolymlett.2024.86

DOI: 10.3144/expresspolymlett.2024.86

GRAPHICAL ABSTRACT

ABSTRACT

Natural rubber (NR) composites reinforced with sepiolite and crosslinked with phenolic resin were prepared. Effects of compatibilizer types and contents, namely 3-aminopropyl triethoxysilane (APTES) or epoxidized NR (ENR50), on curing, tensile, strain-induced crystallization, and stress relaxation were investigated. Compared to APTES, ENR50 provided a greater compatibilizing effect in the NR composites. The ENR50 introduced strong physical and chemical interactions between sepiolite and NR, while only physical interaction was present in the APTES compatibilized composites. Stronger interaction between rubber and sepiolite improved filler dispersion, swelling resistance, and tensile strength; and delayed stress relaxation of the composite. Increased addition of ENR50 improved the modulus and tensile strength, and the greatest tensile strength was achieved at 2 phr ENR50 with a 15% improvement over composite without compatibilizer. In the case of APTES, 2 phr level enhanced tensile strength, but a further increase in APTES content degraded tensile, swelling resistance, and stress relaxation responses, due to its plasticizing effect. Moreover, ENR50 enhanced the strain-induced crystallization and delayed stress relaxation of the composites more than APTES. Weaker interaction between rubber and filler in APTES filled composites was due to having only hydrogen bonds formed between rubber and filler, in addition to crosslinks.

RELATED ARTICLES

Dibyendu Dey, Sharmistha Dhar, Barkat Aziz, Sambhu Bhadra, Sujith Nair, Kinsuk Naskar

Vol. 20., No.2., Pages 127-141, 2026

DOI: 10.3144/expresspolymlett.2026.11

Vol. 20., No.2., Pages 127-141, 2026

DOI: 10.3144/expresspolymlett.2026.11

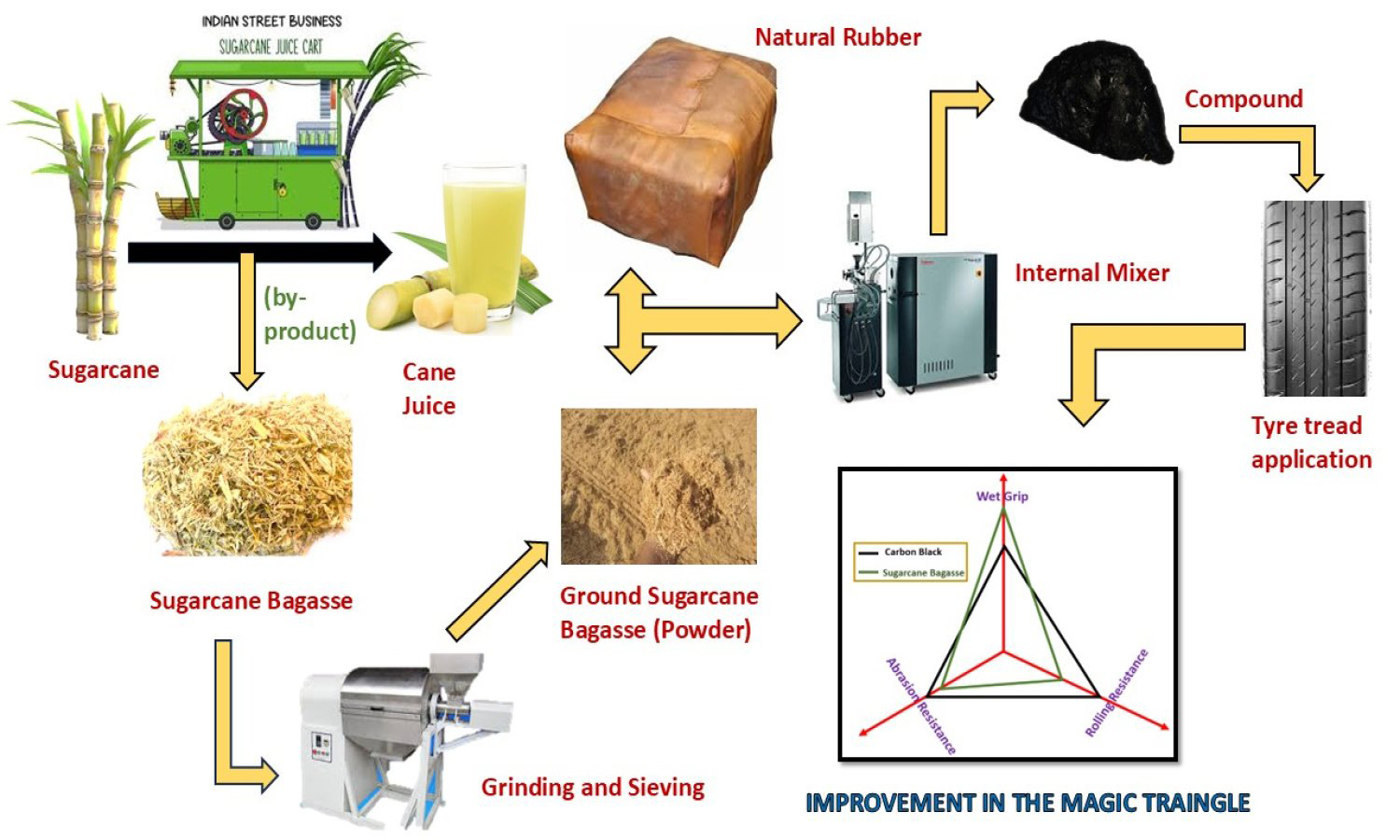

Ground sugarcane bagasse (GSB), an agro-waste rich in lignocellulosic components, was studied as a sustainable bio-filler in natural rubber (NR) tread compounds to lessen reliance on petroleum-derived carbon black (CB). A control formulation with 45 phr CB was compared to hybrid formulations with 40, 35, and 30 phr CB mixed with 5, 10, and 15 phr GSB. Tensile strength 13.1 MPa, elongation at break 700%, and hardness 67 Shore A were all optimally balanced by the compound containing 10 phr GSB (S2), while also exhibiting good cure behavior and thermal stability. Improved tire performance characteristics were confirmed by a dynamic mechanical study, which showed that tan δ at 60 °C decreased by 8.0% (resulting in lower rolling resistance) and increased by 3.9% (improving wet traction) at 0°C. The Payne effect showed improved filler dispersion as a result of GSB partially replacing CB. The results show that appropriately dispersed GSB can partially reinforce NR, enhancing energy efficiency and sustainability. However, larger GSB loadings decrease modulus, tear strength, and abrasion resistance due to lower interfacial adhesion and the presence of micro-voids. According to this study, pulverized sugarcane bagasse shows promise as an environmentally friendly filler for green tire applications, promoting the circular economy and lowering the carbon footprint of rubber compounding.

Rattanawadee Ninjan, Bencha Thongnuanchan, Phakawat Tongnuanchan, Subhan Salaeh, Jutharat Intapun, Abdulhakim Masa, Natinee Lopattananon

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

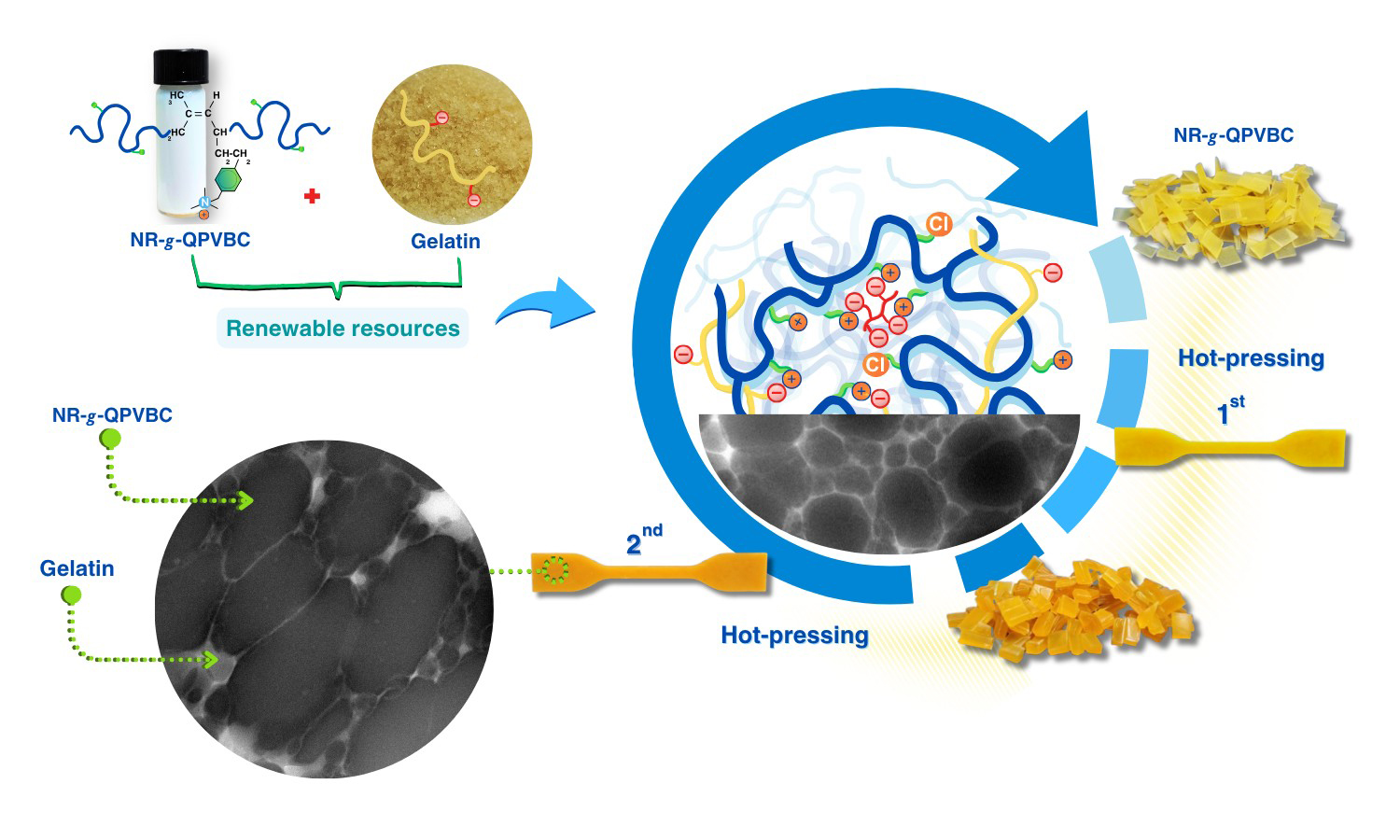

The present study has proposed a straightforward method to improve the reprocessability of modified natural rubber (NR) by blending it with gelatin (GT). The reprocessable characteristics of these blends were evaluated based on their remolding capabilities and mechanical recovery performance. In this method, poly(vinylbenzyl chloride) (PVBC) was first grafted onto NR chains to create graft copolymers known as NR-g-PVBC. The benzyl chloride groups in the graft copolymers were subsequently converted into quaternary ammonium groups, referred to as NR-g-QPVBC. This modification enabled ionic crosslinking when NR-g-QPVBC reacted with ethylenediamine tetraacetic acid. Blends were created by incorporating GT powder into the NR-g-QPVBC latex. The optimal loading level of GT was determined to be 30 wt%, as the resulting film exhibited the highest recovery of tensile properties. Initially, the film's tensile strength was measured at 15 MPa. After being remolded at 160 °C, the tensile strength decreased to 9.3 MPa, resulting in a recovery rate of 60.7% and withstanding a tensile strain of 144%. Although the NR-g-QPVBC/GT films could be remolded, their tensile properties declined with increasing remolding cycles. Therefore, this work demonstrated a practical method for producing NR-based films that could be reshaped through hot-pressing after being formed into products, increasing their reusability.

Hatay Cöcen, Nilgün Kızılcan

Vol. 20., No.1., Pages 82-96, 2026

DOI: 10.3144/expresspolymlett.2026.7

Vol. 20., No.1., Pages 82-96, 2026

DOI: 10.3144/expresspolymlett.2026.7

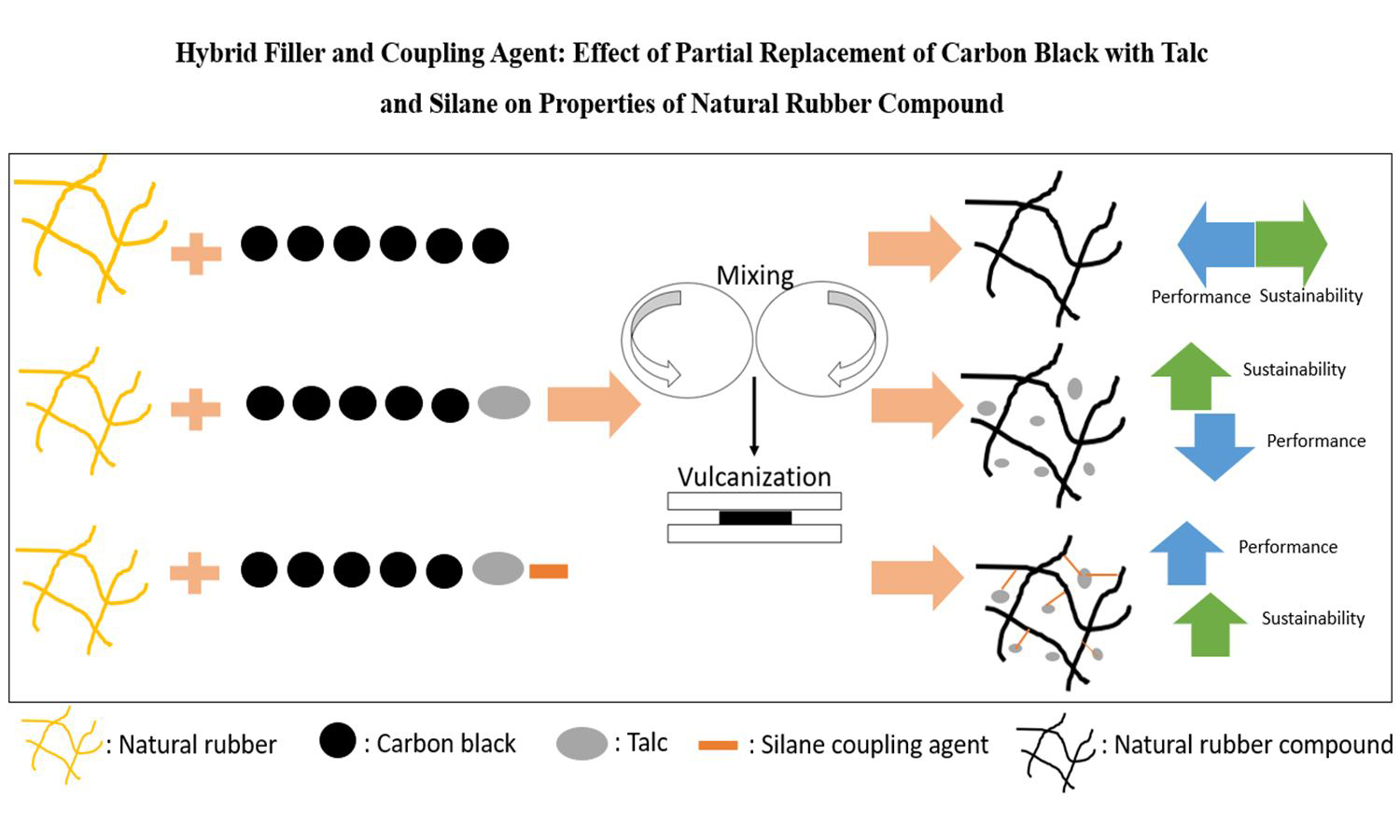

This study investigates a sustainable hybrid-filler strategy for natural rubber (NR) compound by partially replacing petroleum-based carbon black (CB) with talc and introducing a silane coupling agent to mitigate interfacial incompatibility. Compounds containing CB, CB+talc and CB+talc+increasing silane were produced via two-stage mixing and characterized for morphology (dispersion/mapping), curing and flow behavior (differential scanning calorimetry DSC/moving die rheometer, MDR/Mooney), crosslink density (Flory–Rehner), physical–mechanical properties, dynamic performance (Payne effect/heat build-up/tension–fatigue), and thermal stability (aging/thermogravimetric analysis,TGA). Talc reduced the compound viscosity, offering processing benefits. The swelling test indicated that talc decreased crosslink density, but silane recovered it, forming covalent linkages. Tensile strength and elongation at break were improved without altering hardness. Dynamically, talc increased heat build-up, whereas silane inverted the trend and reduced the temperature rise gradually from 41.5 to 29.4°C at 2 phr. Fatigue life was improved with talc (~10%), and further with silane (up to 36% at 2 phr), highlighting a favorable stiffness–fatigue balance with compatibilization. Overall, partial CB replacement by talc, in combination with silane, delivers meaningful sustainability gains with improved dynamic performance while preserving key mechanical properties of NR compounds.

Jutatip Makmanee Treitler, Diew Saijun, Kritsada Phatcharasit, Suwat Rattanapan

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

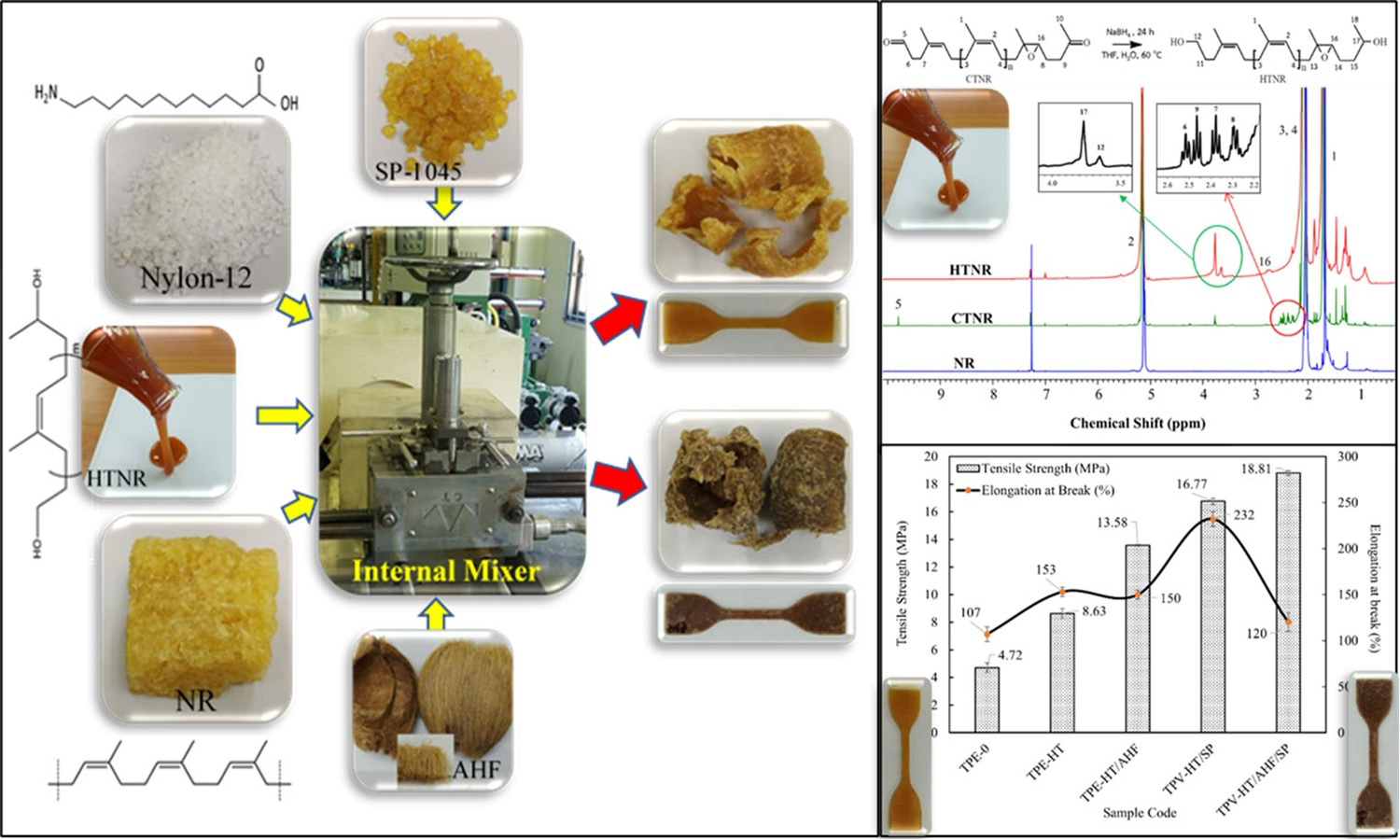

This work introduces an innovative method to enhance the compatibility of nylon-12/natural rubber thermoplastic elastomers by utilizing hydroxyl telechelic natural rubber as a reactive compatibilizer and natural fibers as reinforcement. Hydroxyl telechelic natural rubber was synthesized from natural rubber via oxidative cleavage to carbonyl telechelic natural rubber, followed by reduction with sodium borohydride. Proton nuclear magnetic resonance (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) verified the structure. Incorporating hydroxyl telechelic natural rubber into nylon-12/natural rubber (40/60 wt%) blends significantly enhanced interfacial adhesion, improving tensile strength and elongation at break compared to the uncompatibilized mix. Dynamic vulcanization using phenolic resin achieved an optimal balance of strength and ductility. The incorporation of areca husk fiber enhanced tensile strength, hardness, and solvent resistance, with a slight decrease in ductility and tear strength. Rheological analysis indicated that hydroxyl telechelic natural rubber increased melt viscosity due to improved phase interactions, while dynamic vulcanization reduced the melt flow index through network formation. Solvent uptake experiments confirmed that hydroxyl telechelic natural rubber, areca husk fiber, and SP-1045 vulcanizing agent minimized swelling in isooctane, toluene, and diesel oil.

Torfan Srisuwanno, Jobish Johns, Christopher Bascucci, Frank Clemens, Yeampon Nakaramontri

Vol. 19., No.10., Pages 1053-1072, 2025

DOI: 10.3144/expresspolymlett.2025.79

Vol. 19., No.10., Pages 1053-1072, 2025

DOI: 10.3144/expresspolymlett.2025.79

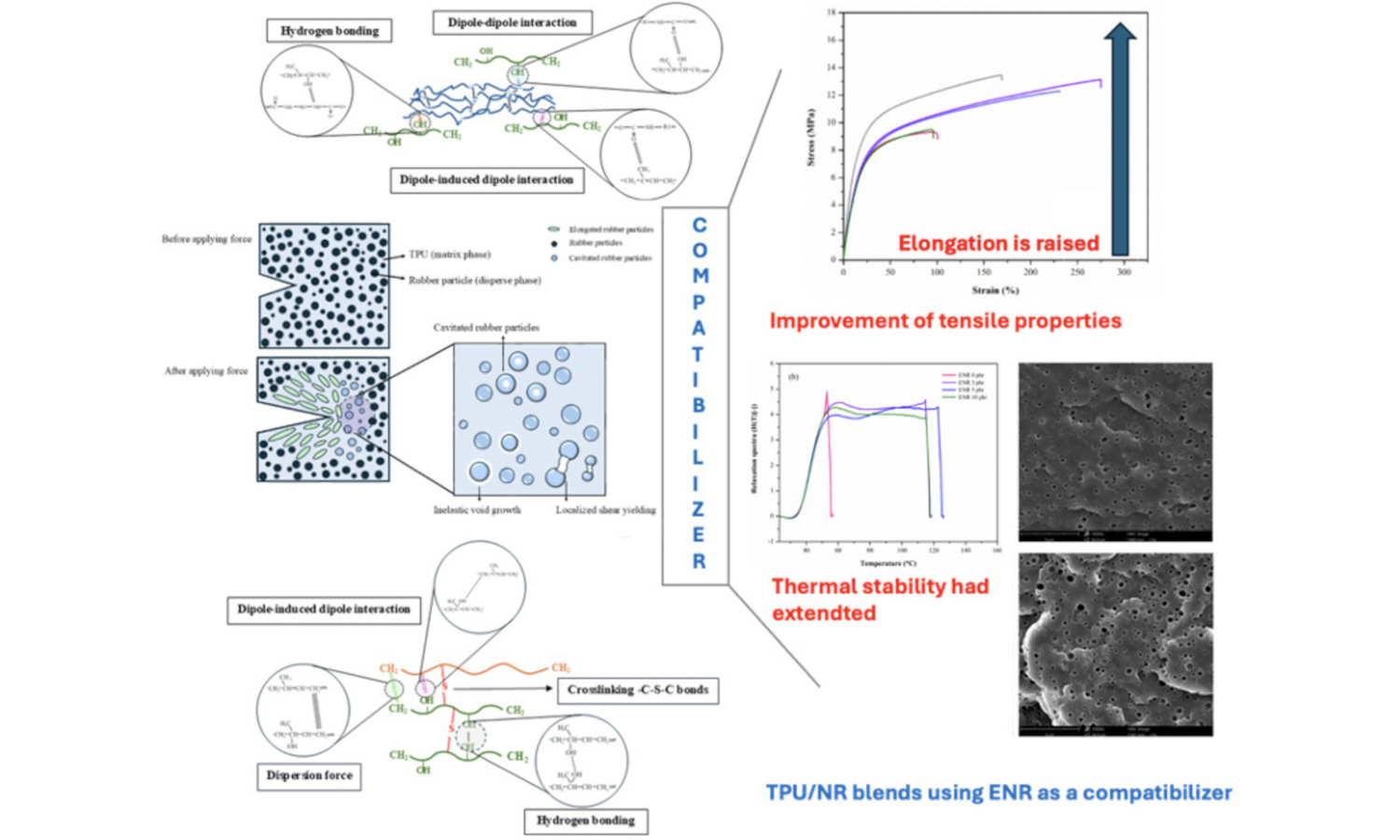

Thermoplastic natural rubber (TPNR) is widely used across industries due to its unique blend of elasticity and processability. Thermoplastic vulcanizates (TPVs) based on thermoplastic polyurethane (TPU) offer excellent mechanical properties and flexibility, yet often require enhanced elasticity and durability. Blending TPU with natural rubber (NR) is promising; however, phase incompatibility reduces mechanical strength and thermal stability. To address this, epoxidized NR (ENR) was employed as a compatibilizer in TPU/NR blends. ENR’s hydrocarbon backbone interacts with crosslinked NR, while epoxy groups enhance adhesion with TPU. Incorporating 3 phr of ENR significantly improved crosslinking, increased tensile strength by 41.1%, enhanced stress relaxation, and lowered the glass transition temperatures of both TPU and NR phases in the TPU/NR blends. These effects are attributed to improved chemical bridging between TPU and NR. However, excess ENR disrupts phase compatibility, causing polymer entanglement and reduced strength. Optimizing ENR content is essential for developing high-performance TPU/NR blends. Printability was demonstrated using the material extrusion additive manufacturing (MEx-AM) fused deposition modeling (FDM), showing potential for flexible applications like splints and medical devices.