Recycling issues with multilayer packaging

Vol. 18., No.4., Pages 348-348, 2024

DOI: 10.3144/expresspolymlett.2024.25

DOI: 10.3144/expresspolymlett.2024.25

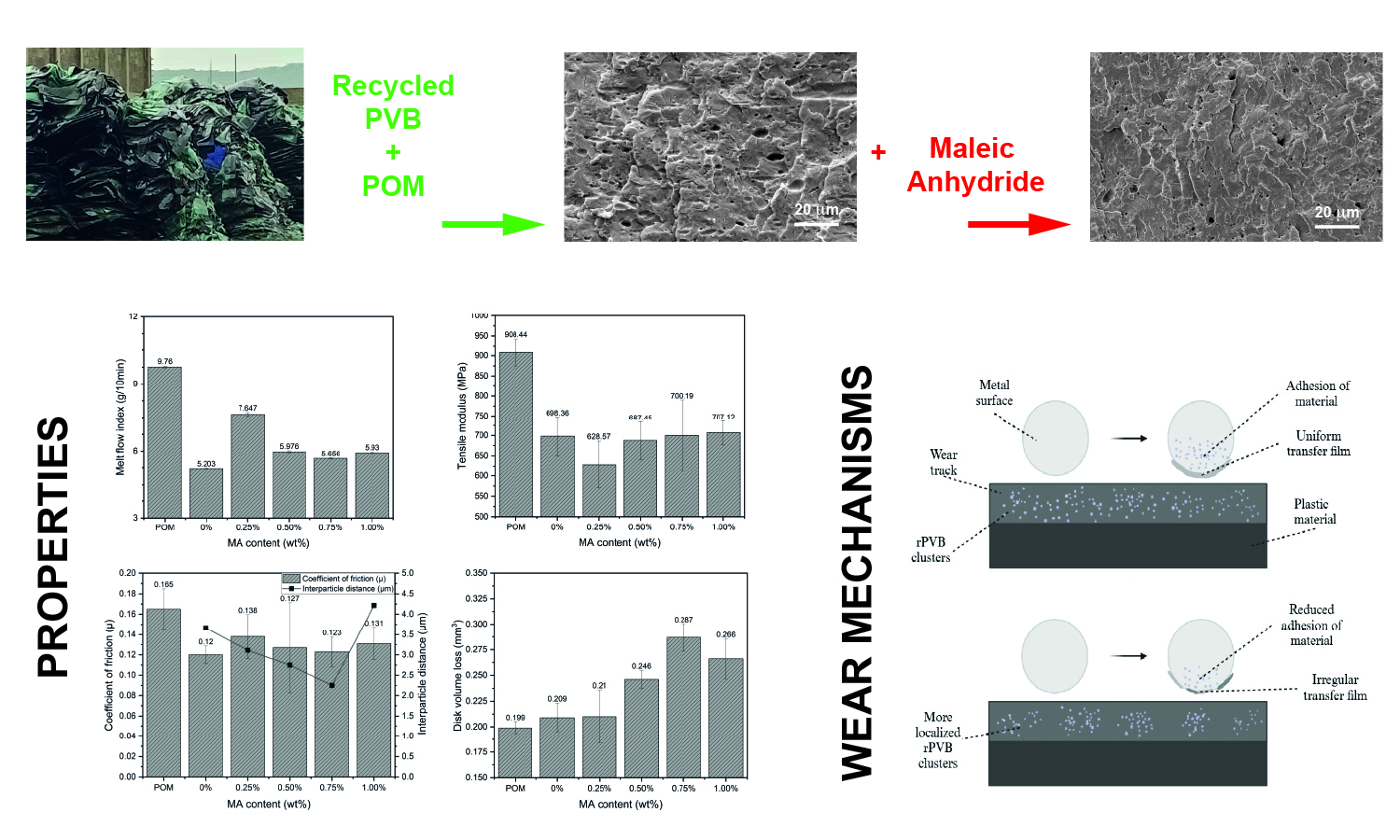

GRAPHICAL ABSTRACT

RELATED ARTICLES

Maja Csapó, József Gábor Kovács

Vol. 20., No.4., Pages 414-434, 2026

DOI: 10.3144/expresspolymlett.2026.32

Vol. 20., No.4., Pages 414-434, 2026

DOI: 10.3144/expresspolymlett.2026.32

The greatest obstacle to recycling post-consumer high-density polyethylene (PCR-HDPE) is typically the degradation of properties caused by impurities and heterogeneity. However, a critical analysis of the literature reveals that the real bottleneck is not the material composition, but rather rheological stability, which simultaneously determines the degradation history of the waste stream, melt behavior, and processability at the cycle level. This review proposes a new perspective: the decision among mechanical, chemical, and energetic recycling is better made based on a unified rheological stability index (RSI), which integrates carbonyl index, viscosity change after multiple instances of melting, melt flow index (MFI) instability, in-mold pressure fluctuation, and the degree of polymer incompatibility. RSI enables the prediction of the processability of PCR-HDPE and identifies which recycling path a fraction is most suitable for. The study demonstrates how an RSI-based approach can reduce quality risk, improve cycle stability, and support circular decision-making in an industrial environment.

Emiliano González-Rodríguez, Grecia Michelle Ramírez-Paredes, Ulises Figueroa-López, Elvia Patricia Sánchez-Rodríguez, Andrea Guevara-Morales

Vol. 19., No.11., Pages 1144-1160, 2025

DOI: 10.3144/expresspolymlett.2025.84

Vol. 19., No.11., Pages 1144-1160, 2025

DOI: 10.3144/expresspolymlett.2025.84

Maleic anhydride (MA) is widely used to modify plastics and as a compatibilizer in recycling. This study examines the effect of varying MA concentrations on blends of polyoxymethylene (POM) and recycled polyvinyl butyral (rPVB) from automotive windshields. Morphological analysis showed that MA contents between 0.25 and 0.75 wt% led to smaller, more closely dispersed rPVB particles, indicating enhanced phase miscibility. Rheological and thermal analyses revealed up to a 47% increase in melt flow index at lower MA concentrations, and improved interfacial interactions and crystallinity at higher levels. The tensile modulus dropped by 10% at 0.25 wt% MA but increased with further additions; tensile strength and Shore D hardness remained unaffected. Impact strength improved by up to 65% with MA addition, mainly due to increased ductility and a morphology characterized by larger rPVB domains and shorter interparticle distances at low MA contents. The coefficient of friction decreased with rPVB but increased with MA, along with higher volume loss. Microscopic wear analysis confirmed that rPVB dispersion, influenced by MA, was key to transfer film formation and surface lubrication. Thus, MA optimization enables tailored mechanical and tribological properties in POM/rPVB blends.