Content

All issues / Volume 20 (2026) / Issue 2 (February)

Jana Navratilova

Vol. 20., No.2., Pages 112-113, 2026

DOI: 10.3144/expresspolymlett.2026.9

Vol. 20., No.2., Pages 112-113, 2026

DOI: 10.3144/expresspolymlett.2026.9

This is an editorial article. It has no abstract.

Xavier Colom, Scott Martínez, Fernando Carrillo-Naverrete, Javier Cañavate

Vol. 20., No.2., Pages 114-126, 2026

DOI: 10.3144/expresspolymlett.2026.10

Vol. 20., No.2., Pages 114-126, 2026

DOI: 10.3144/expresspolymlett.2026.10

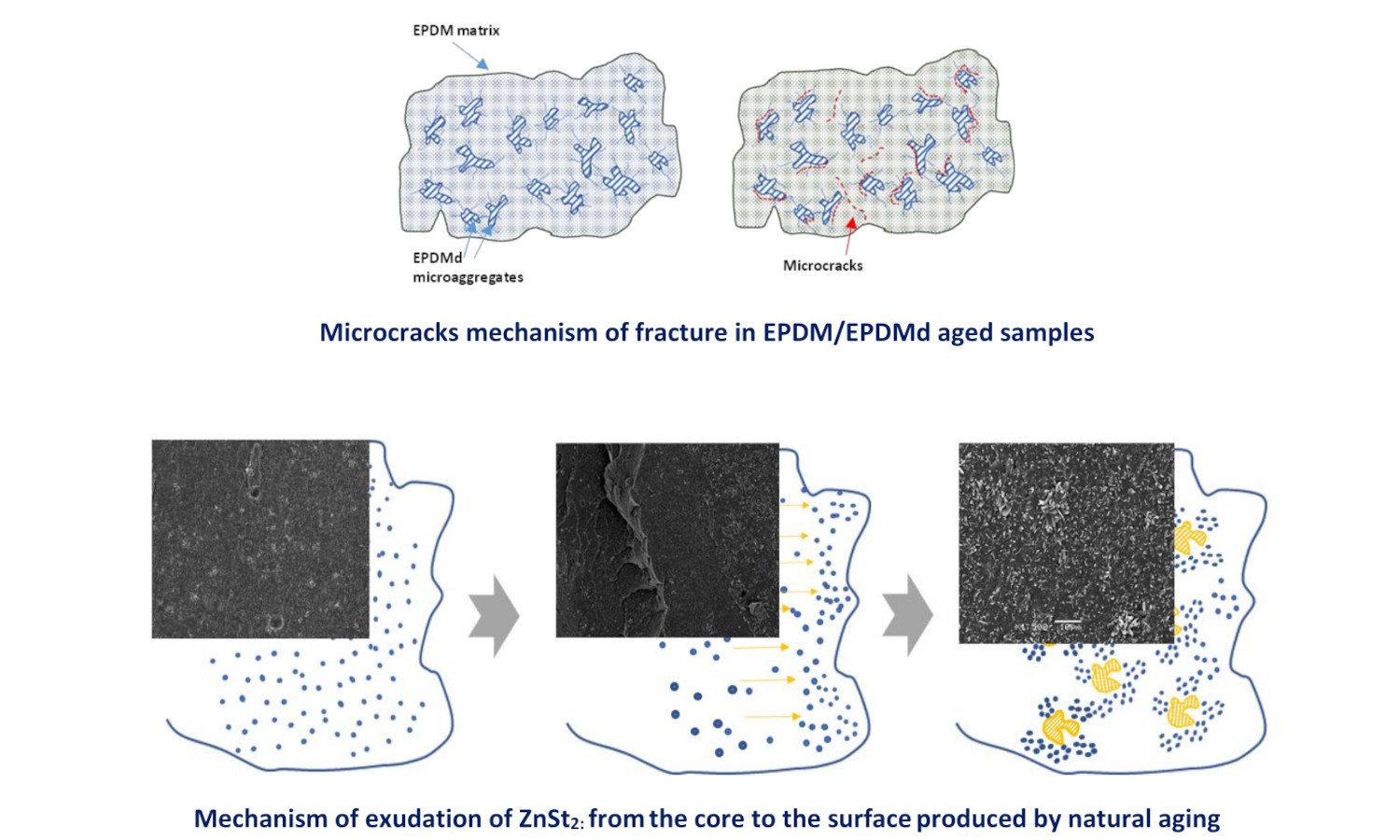

The need to recycle elastomeric waste requires studying its viability in industrial applications. This study investigates the feasibility of recycling elastomeric waste by analyzing whether virgin ethylene-propylene-diene monomer (EPDM) can be replaced by blends of virgin EPDM and thermomechanically and microwave devulcanized EPDM (EPDMd) in industrial applications from the perspective of environmental degradation. Two types of samples were examined: conventional EPDM used to roof membranes, and EPDM blended with different amounts (20, 40, and 50 phr) of EPDMd. Samples were subjected to natural aging in coastal and mountainous environments. Results show that mechanical properties decline with higher EPDMd content and, to a lesser degree, with prolonged outdoor exposure. The coastal climate proved more aggressive than the mountainous one when EPDMd content exceeded 40 phr. Zinc stearate (ZnSt2), a byproduct of vulcanization, was found to influence the evolution of the mechanical behavior. The combined analysis of scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), abrasion tests, and thermogravimetric analysis (TGA) provided insights into the degradation processes of these elastomeric blends.

Dibyendu Dey, Sharmistha Dhar, Barkat Aziz, Sambhu Bhadra, Sujith Nair, Kinsuk Naskar

Vol. 20., No.2., Pages 127-141, 2026

DOI: 10.3144/expresspolymlett.2026.11

Vol. 20., No.2., Pages 127-141, 2026

DOI: 10.3144/expresspolymlett.2026.11

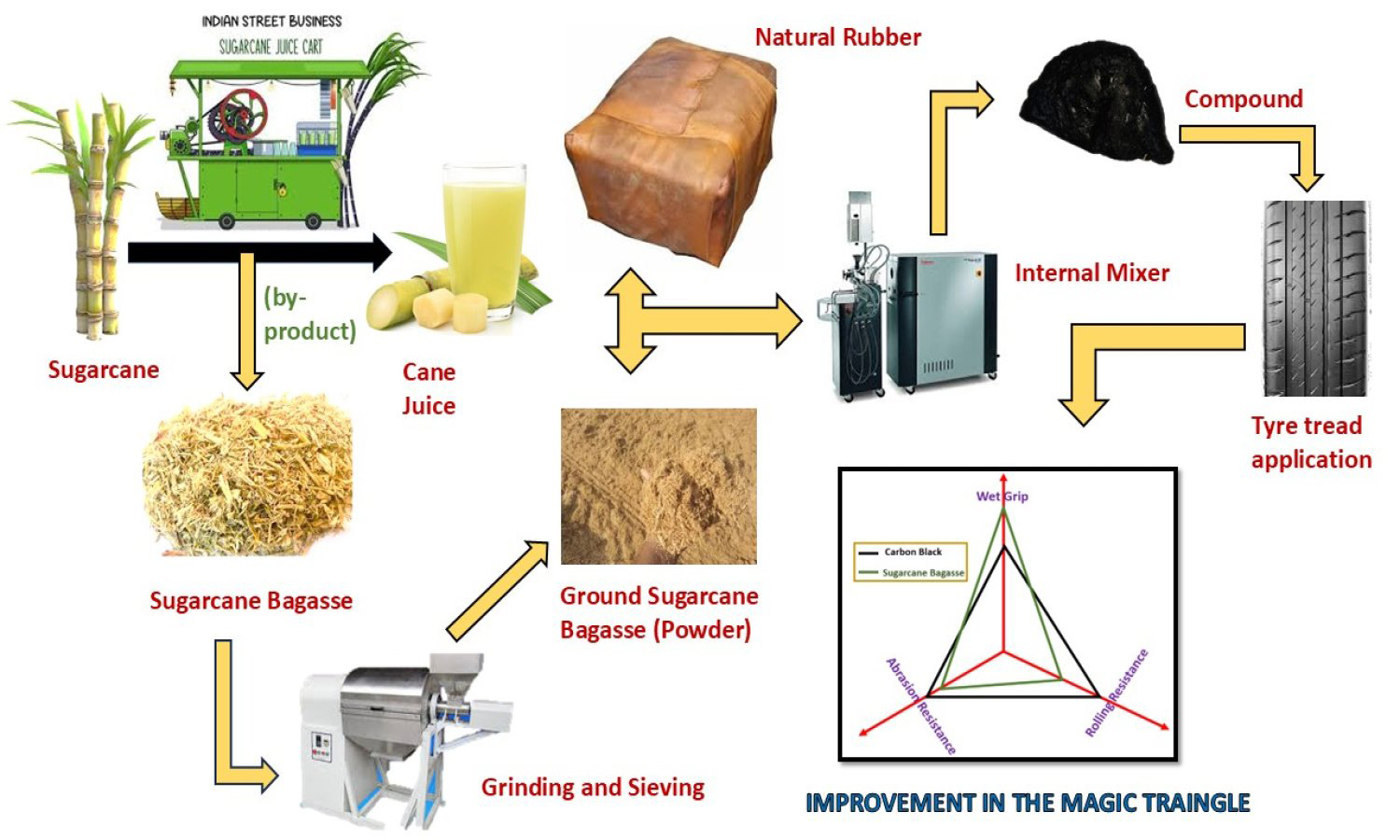

Ground sugarcane bagasse (GSB), an agro-waste rich in lignocellulosic components, was studied as a sustainable bio-filler in natural rubber (NR) tread compounds to lessen reliance on petroleum-derived carbon black (CB). A control formulation with 45 phr CB was compared to hybrid formulations with 40, 35, and 30 phr CB mixed with 5, 10, and 15 phr GSB. Tensile strength 13.1 MPa, elongation at break 700%, and hardness 67 Shore A were all optimally balanced by the compound containing 10 phr GSB (S2), while also exhibiting good cure behavior and thermal stability. Improved tire performance characteristics were confirmed by a dynamic mechanical study, which showed that tan δ at 60 °C decreased by 8.0% (resulting in lower rolling resistance) and increased by 3.9% (improving wet traction) at 0°C. The Payne effect showed improved filler dispersion as a result of GSB partially replacing CB. The results show that appropriately dispersed GSB can partially reinforce NR, enhancing energy efficiency and sustainability. However, larger GSB loadings decrease modulus, tear strength, and abrasion resistance due to lower interfacial adhesion and the presence of micro-voids. According to this study, pulverized sugarcane bagasse shows promise as an environmentally friendly filler for green tire applications, promoting the circular economy and lowering the carbon footprint of rubber compounding.

Reinforcing effect of thermo-oxidative reclaimed rubber on NR/SBR blends for tire tread applications

Yunhui Xu, Zaheer ul Haq, Junrong Li, Hui Tu, Zaixue Wang, Houluo Cong

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

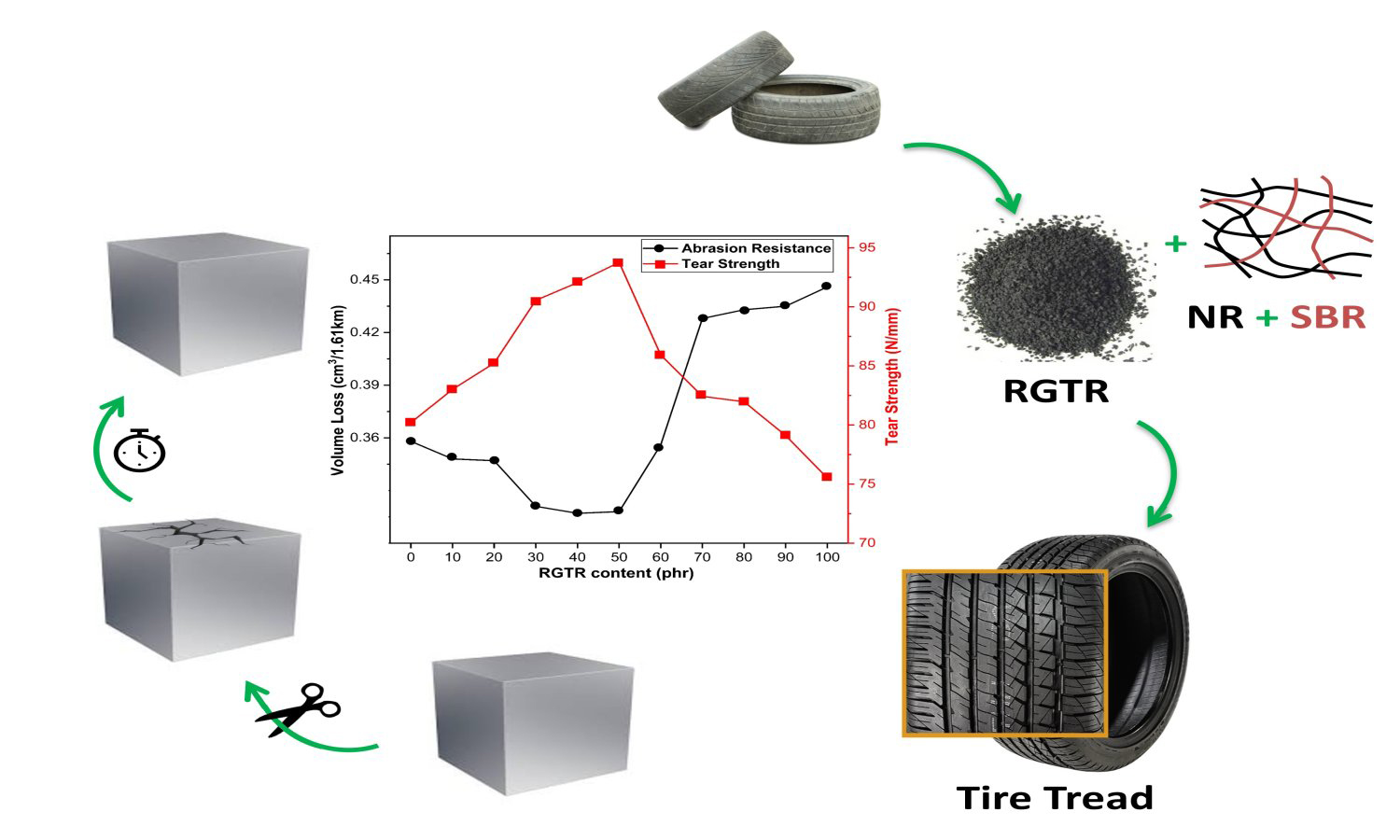

This study explores the application of thermo-oxidative reclaimed ground tire rubber (RGTR) in natural rubber (NR)/styrene butadiene rubber (SBR) composite, focusing on its impact on morphology, mechanical properties, rheological behavior, vulcanization characteristics, aging resistance, tear strength and abrasion resistance. The findings revealed that RGTR enhances the tear strength and abrasion resistance of NR/SBR composites while maintaining comparable tensile strength, elongation at break, and modulus. The incorporation of RGTR reduced Mooney viscosity of the NR/SBR composites and improved flowability. It also shortened the vulcanization time and enhanced vulcanization efficiency. The NR/SBR composites with RGTR loadings below 60 phr exhibited optimal performance, achieved a maximum tear strength of 93.77 N/mm and improved abrasion resistance. However, higher RGTR content led to increased agglomeration, as evidenced by scanning electron microscopy (SEM), which showed finer dispersion at lower RGTR contents and larger aggregates at higher loadings. These findings demonstrate the potential of RGTR as a sustainable additive for enhancing specific properties in NR/SBR composites, contributing to both performance optimization and waste tire management.

Evangelia Balla, Panagiotis Klonos, Apostolos Kyritsis, Dimitrios Bikiaris

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

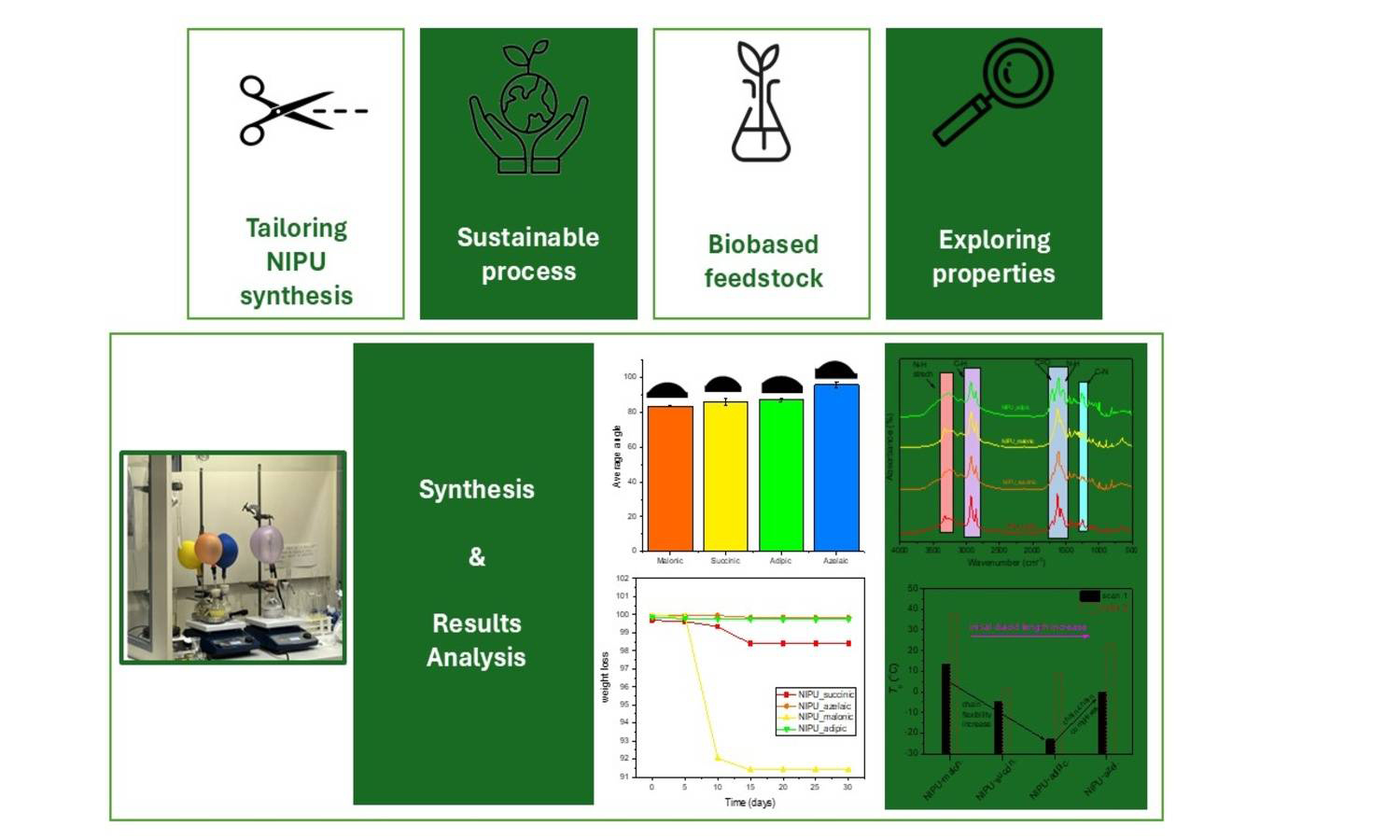

In recent decades, numerous efforts have been dedicated to the investigation of eco-friendly non-isocyanate polyurethanes (NIPUs) as alternatives to conventional polyurethanes (PUs). Since isocyanates are classified by the EU as hazardous and toxic compounds, NIPUs offer a promising route to mitigate isocyanate-related health risks as well as other environmental concerns associated with traditional PU synthesis. In the present study, we report the synthesis as well as the detailed structural and thermal characterization of a new series of fully biobased non-isocyanate polyurethanes (NIPUs) based on aliphatic dicarboxylic acids of different chain lengths. The NIPUs were prepared via a two-step polyaddition reaction involving glycerol carbonate and diamine. Their synthesis enables a sustainable pathway to tailor NIPUs’ physicochemical properties via diacid structure control. Studies of their structure, thermal behavior and trends, morphological, and hydrolytic findings confirmed strong diacid chain length dependence on glass transition temperature (Tg ~13, 0, ‒5 and –23 °C), molecular weight, surface wettability, and enzymatic degradability. Short-chain diacids yielded NIPUs with rapid hydrolytic degradation, while their longer-chain analogs were hydrophobic and thermally stable. Contact angle measurements (~75–85°) also confirm these trends. The tunable properties position these materials among strong candidates for biomedical applications.

Nikita V. Eremin, Svetlana Y. Voronina, Taisiya A. Shalygina, Valery V. Vlasov, Semyon A. Fesik, Anna A. Sukhanova

Vol. 20., No.2., Pages 168-185, 2026

DOI: 10.3144/expresspolymlett.2026.14

Vol. 20., No.2., Pages 168-185, 2026

DOI: 10.3144/expresspolymlett.2026.14

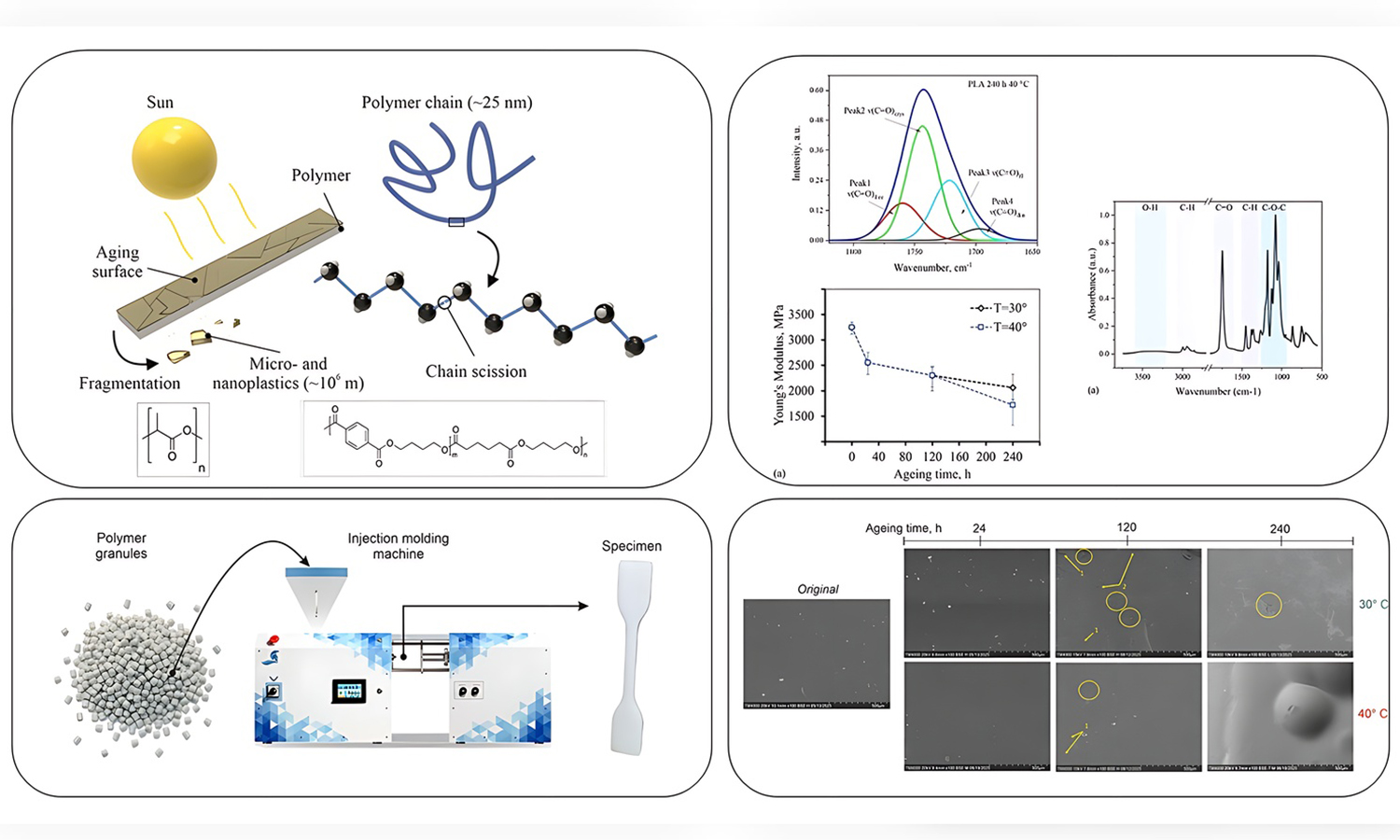

This article is devoted to the study of the degradation of two widely used biodegradable polymers, polylactic acid (PLA) and poly(butylene adipate-co-terephthalate) (PBAT), which are in demand in packaging, medicine, and agriculture. The effect of ultraviolet radiation (UV) at elevated temperatures on polymer ageing was investigated for 24, 120, and 240 h using a specially designed setup. Scanning electron microscopy, Fourier transform infrared spectroscopy, and tensile testing were employed to provide a comprehensive assessment of changes. PLA showed rapid degradation: after 120 h, its surface developed cracks and voids, and at 240 h, it became heavily damaged with cavities. PBAT degraded more gradually: at 240 h, large cracks and cavities were observed. For PLA, early ageing led to a shift and broadening of the carbonyl band, reflecting disorder and ester scission. For PBAT, a decrease in the intensity of the carbonyl shoulder and a slight shift of the main peak at elevated temperature indicated phase redistribution and the formation of new functional groups. Mechanically, PLA exhibited a sharp loss of strength and ductility in the first day of ageing, while PBAT showed greater stability, with slower reductions in stiffness and strength but a strong temperature-dependent decline in elongation. These findings are important for guiding the design of biodegradable polymers with improved durability.

Abdulhakim Masa, Ruedee Jaratrotkamjorn

Vol. 20., No.2., Pages 186-196, 2026

DOI: 10.3144/expresspolymlett.2026.15

Vol. 20., No.2., Pages 186-196, 2026

DOI: 10.3144/expresspolymlett.2026.15

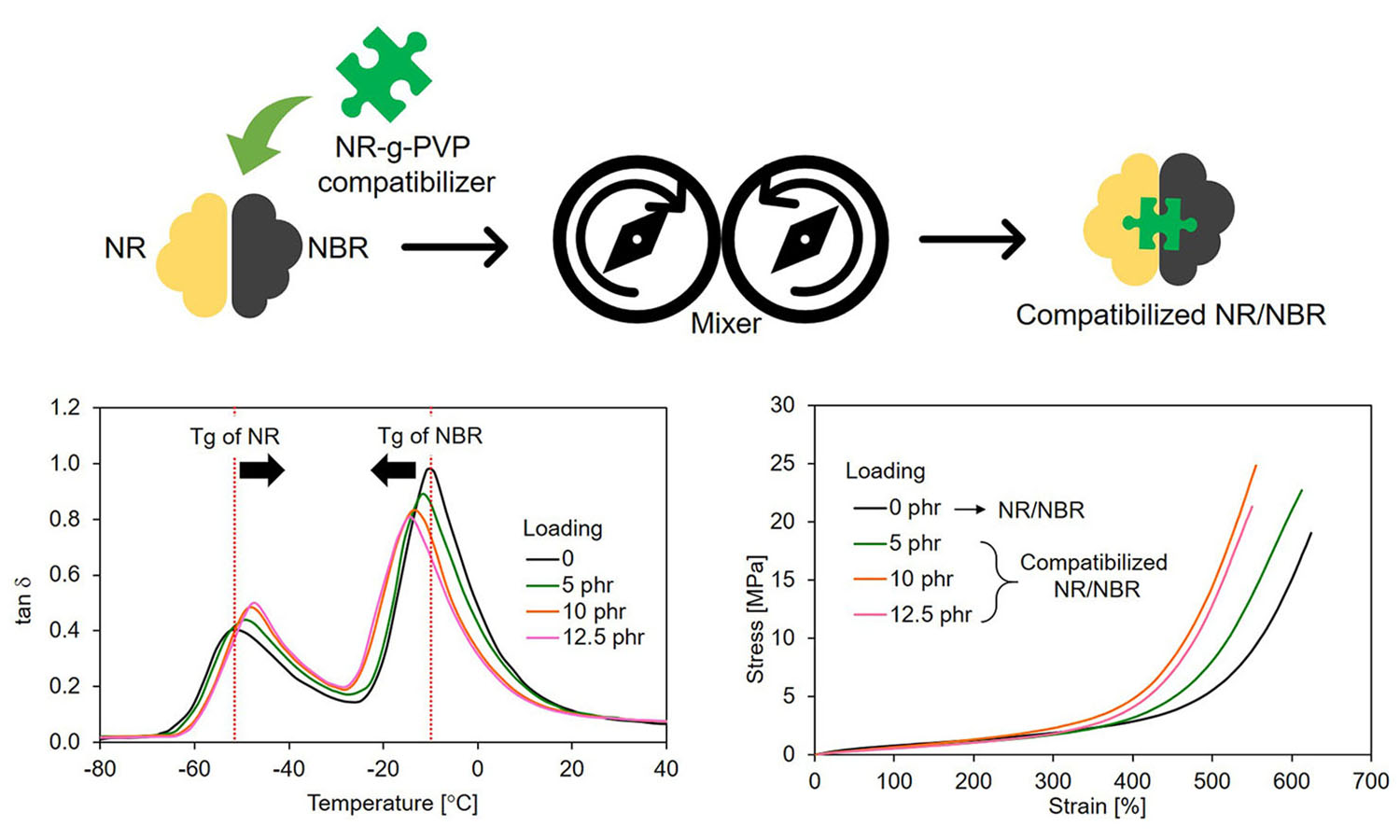

Natural rubber (NR) and acrylonitrile butadiene rubber (NBR) are typically incompatible due to differences in their polarity, which causes poor mechanical properties. In this study, a new type of compatibilizer, namely G10 or poly(vinyl propionate)-grafted natural rubber (NR-g-PVP) containing 10 wt% PVP, is employed to improve the compatibility in 50/50 blends of NR and NBR. The results show that G10 promotes the compatibility and shifts the glass transition temperatures (Tg) of NR and NBR towards each other. This indicates that G10 interacts with both NR and NBR phases. The improved compatibility resulted in a more homogeneous blend with smooth surface morphology. The mechanical properties of the blend, including 300 and 500% moduli, tensile strength, and tear resistance, increased with G10 content up to 7.5 phr. The highest tensile strength of the NR/NBR blend was achieved with 7.5 phr of G10 compatibilizer, showing an improvement of approximately 40.7% over the control sample. The results clearly revealed that NR-g-PVP can be utilized as an effective compatibilizer in NR/NBR blends.

Soni Thakur, Amal M. Sindi, Rahul Dev Bairwan, Rasha A. Mahmoud, Eman Alfayez, Nurul Fazita Mohammad Rawi, Kanchan Jha, H.P.S. Abdul Khalil

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

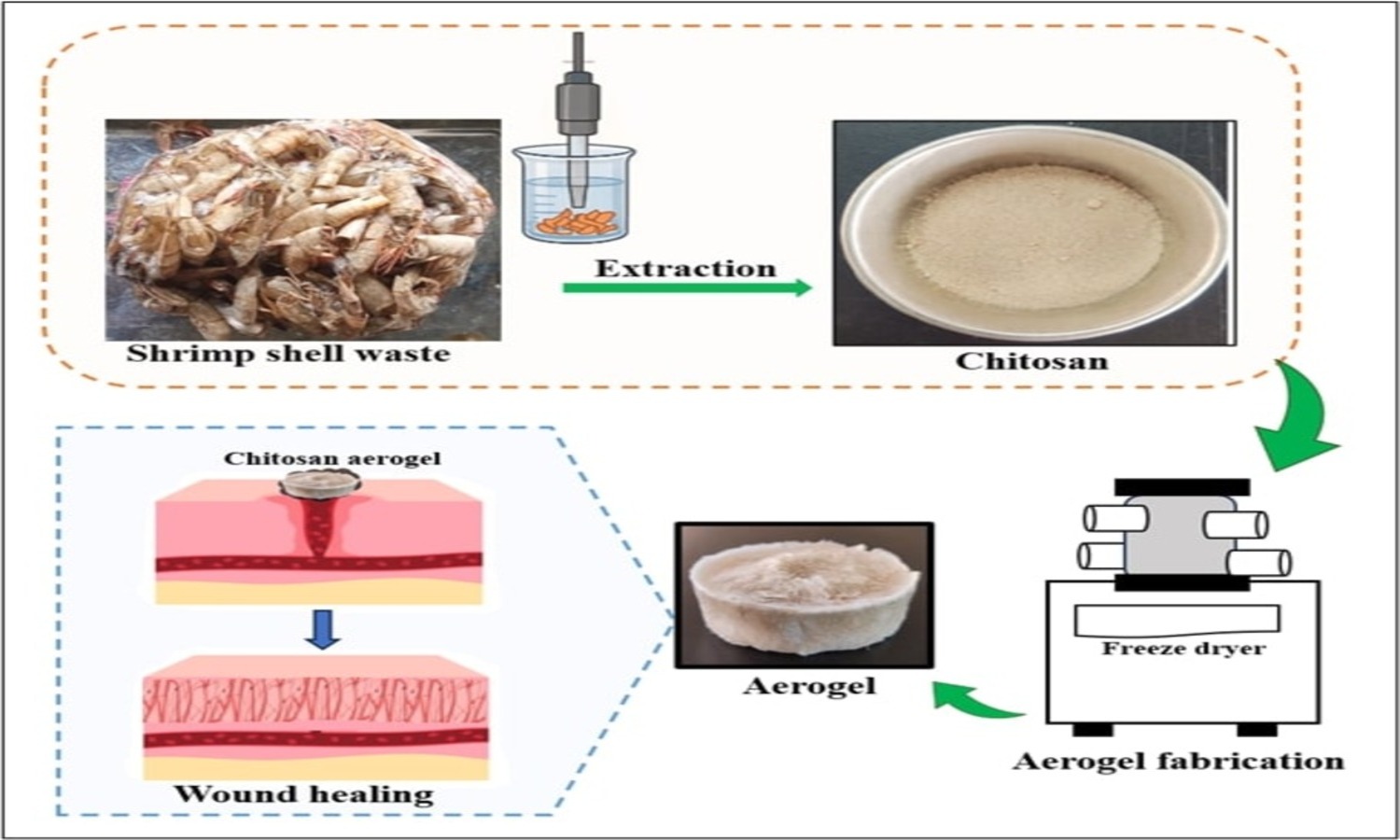

This research presents an eco-friendly approach for extracting chitosan from shrimp shell waste through ultrasound-assisted extraction (UAE) to prepare biocompatible aerogel scaffolds for biomedical applications. The study investigates the influence of various ultrasonic treatment times (10, 20, 30, 40 min) on the yield and structural and physicochemical properties of the extracted chitosan via characterization using Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Among the tested conditions, the 30 min UAE-treated chitosan aerogels showed optimal porosity and structural integrity. Biocompatibility of the aerogels was evaluated, and the results confirmed their non-cytotoxic nature. The bioactivity of the chitosan aerogels was evaluated in terms of their in vitro wound closure ability and antibacterial properties. The aerogels demonstrated a wound closure rate of around 51% after 72 h, significantly higher than the untreated control (37%). In addition, they exhibited clear antibacterial activity against Escherichia coli and Staphylococcus aureus. This sustainable extraction and fabrication method not only adds value to marine waste but also produces functional biomaterials with potential applications in wound healing, tissue engineering, and regenerative medicine, supporting global efforts toward sustainability and circular bioeconomy.