Effect of artificial UV-thermal ageing on the structural and mechanical properties of PLA and PBAT

Nikita V. Eremin , Svetlana Y. Voronina

, Svetlana Y. Voronina , Taisiya A. Shalygina

, Taisiya A. Shalygina , Valery V. Vlasov

, Valery V. Vlasov , Semyon A. Fesik

, Semyon A. Fesik , Anna A. Sukhanova

, Anna A. Sukhanova

, Svetlana Y. Voronina

, Svetlana Y. Voronina , Taisiya A. Shalygina

, Taisiya A. Shalygina , Valery V. Vlasov

, Valery V. Vlasov , Semyon A. Fesik

, Semyon A. Fesik , Anna A. Sukhanova

, Anna A. Sukhanova

Vol. 20., No.2., Pages 168-185, 2026

DOI: 10.3144/expresspolymlett.2026.14

DOI: 10.3144/expresspolymlett.2026.14

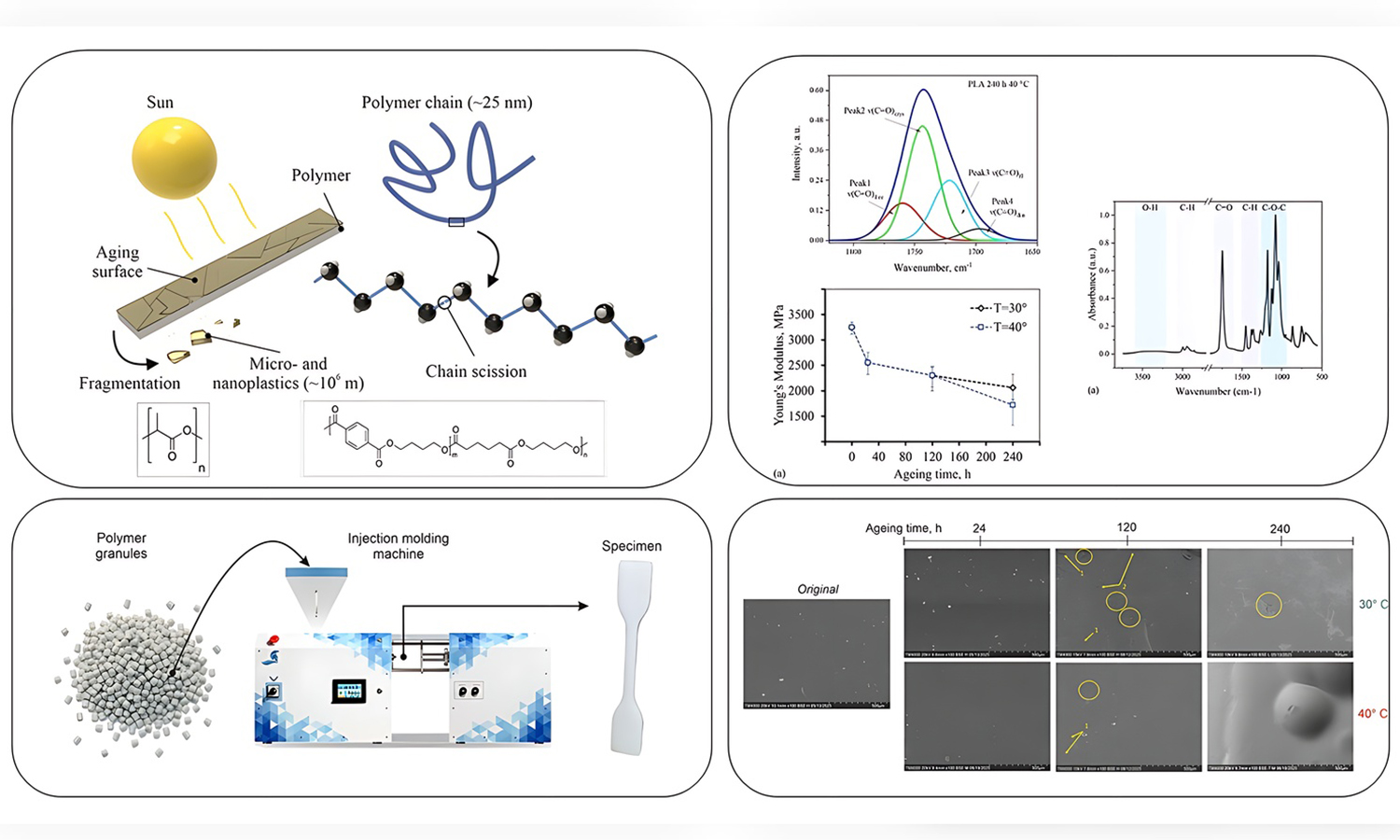

GRAPHICAL ABSTRACT

ABSTRACT

This article is devoted to the study of the degradation of two widely used biodegradable polymers, polylactic acid (PLA) and poly(butylene adipate-co-terephthalate) (PBAT), which are in demand in packaging, medicine, and agriculture. The effect of ultraviolet radiation (UV) at elevated temperatures on polymer ageing was investigated for 24, 120, and 240 h using a specially designed setup. Scanning electron microscopy, Fourier transform infrared spectroscopy, and tensile testing were employed to provide a comprehensive assessment of changes. PLA showed rapid degradation: after 120 h, its surface developed cracks and voids, and at 240 h, it became heavily damaged with cavities. PBAT degraded more gradually: at 240 h, large cracks and cavities were observed. For PLA, early ageing led to a shift and broadening of the carbonyl band, reflecting disorder and ester scission. For PBAT, a decrease in the intensity of the carbonyl shoulder and a slight shift of the main peak at elevated temperature indicated phase redistribution and the formation of new functional groups. Mechanically, PLA exhibited a sharp loss of strength and ductility in the first day of ageing, while PBAT showed greater stability, with slower reductions in stiffness and strength but a strong temperature-dependent decline in elongation. These findings are important for guiding the design of biodegradable polymers with improved durability.

RELATED ARTICLES

Mpho Phillip Motloung, Mokgaotsa Jonas Mochane

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Polylactic acid (PLA) is one of the most widely used biopolymers, and it has demonstrated a huge potential for replacing some of the conventional plastics in certain application fields. However, due to a lack of other attributes such as antimicrobial properties and slow degradation rates, it is often blended with other polymers to impart these properties. Chitosan has desirable features including antimicrobial and antioxidant properties, biodegradability and biocompatibility, and environmental friendliness. Thus, it is widely blended with PLA to generate materials that can be applied in various fields. In recent years, PLA/chitosan blend composites and nanocomposites have been produced to develop sustainable and ecofriendly materials that can be suitable in active food packaging, water treatment, air filtration, and biomedical applications. This review provides an overview of the recent advancements in the development of PLA/chitosan blend composites and nanocomposites for various applications. The processing strategies, mechanical and thermal properties, together with utilization in biomedical, air filtration, water treatment, and packaging applications, are provided.

Marcos Vinícius Basaglia, Jessica Caroline Ferreira Gimenez, Manoel Gustavo Petrucelli Homem, Sandra Andrea Cruz, Lucas Henrique Staffa, Sílvia Helena Prado Bettini

Vol. 19., No.2., Pages 124-139, 2025

DOI: 10.3144/expresspolymlett.2025.10

Vol. 19., No.2., Pages 124-139, 2025

DOI: 10.3144/expresspolymlett.2025.10

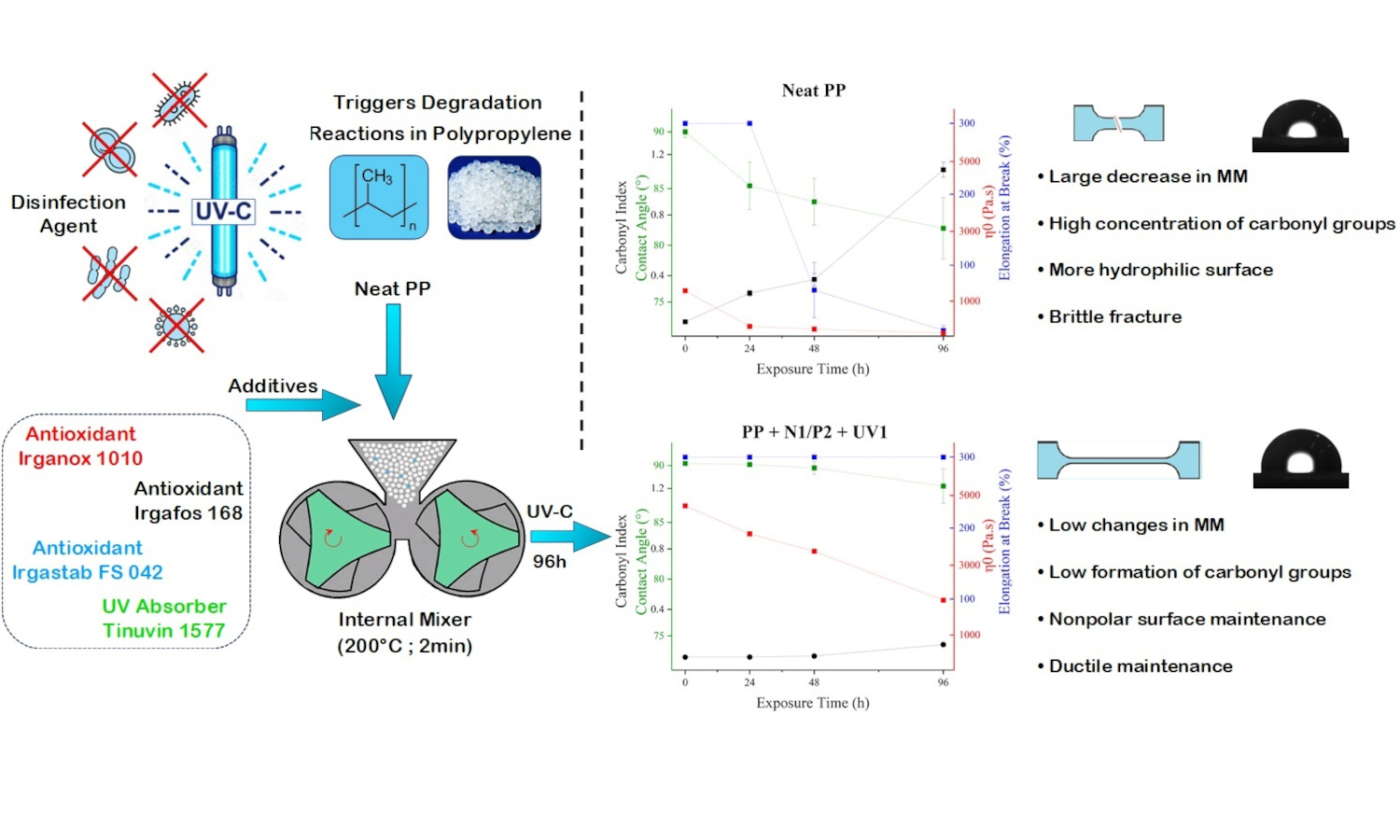

UV-C radiation (200–280 nm) is recognized for its effectiveness in disinfection, but it also induces degradation in polymeric materials such as polypropylene (PP), reducing their service life. Stabilizing additives are a viable approach to mitigating or delaying the degradation process. However, the chemical groups within these additives may adversely affect stabilization under UV-C exposure due to their potential to absorb the radiation. This study investigates the degradation of PP under UV-C radiation and evaluates the performance of stabilization systems containing phenolic antioxidants (Irganox 1010), hydroxylamine (Irgastab FS 042), and UV absorbers (Tinuvin 1577). PP films were exposed to UV-C radiation for 24, 48, and 96 h, corresponding to doses of 1000, 2000, and 4000 J/cm2. Degradation was assessed using size exclusion chromatography (SEC), parallel plate rheometry, infrared spectroscopy (FTIR), static water contact angle, and mechanical testing. The independent use of antioxidants or UV absorbers resulted in reduced carbonyl group formation relative to neat PP, but these were insufficient to prevent PP brittleness after 96 h of exposure. In contrast, the combined use of hydroxylamine or phenolic additives with UV absorbers effectively preserved PP ductility, allowing deformations exceeding 300% without fractures, indicating a synergistic effect.

Enikő Hornyák-Mester, Miklós Varga, Lilla Márta Sőrés-Tölli, Dóra Mentes, Alpár F. Hatvani-Nagy, Peter Werner Groh, Béla Viskolcz, Gábor Muránszky, Béla Fiser

Vol. 18., No.10., Pages 964-975, 2024

DOI: 10.3144/expresspolymlett.2024.74

Vol. 18., No.10., Pages 964-975, 2024

DOI: 10.3144/expresspolymlett.2024.74

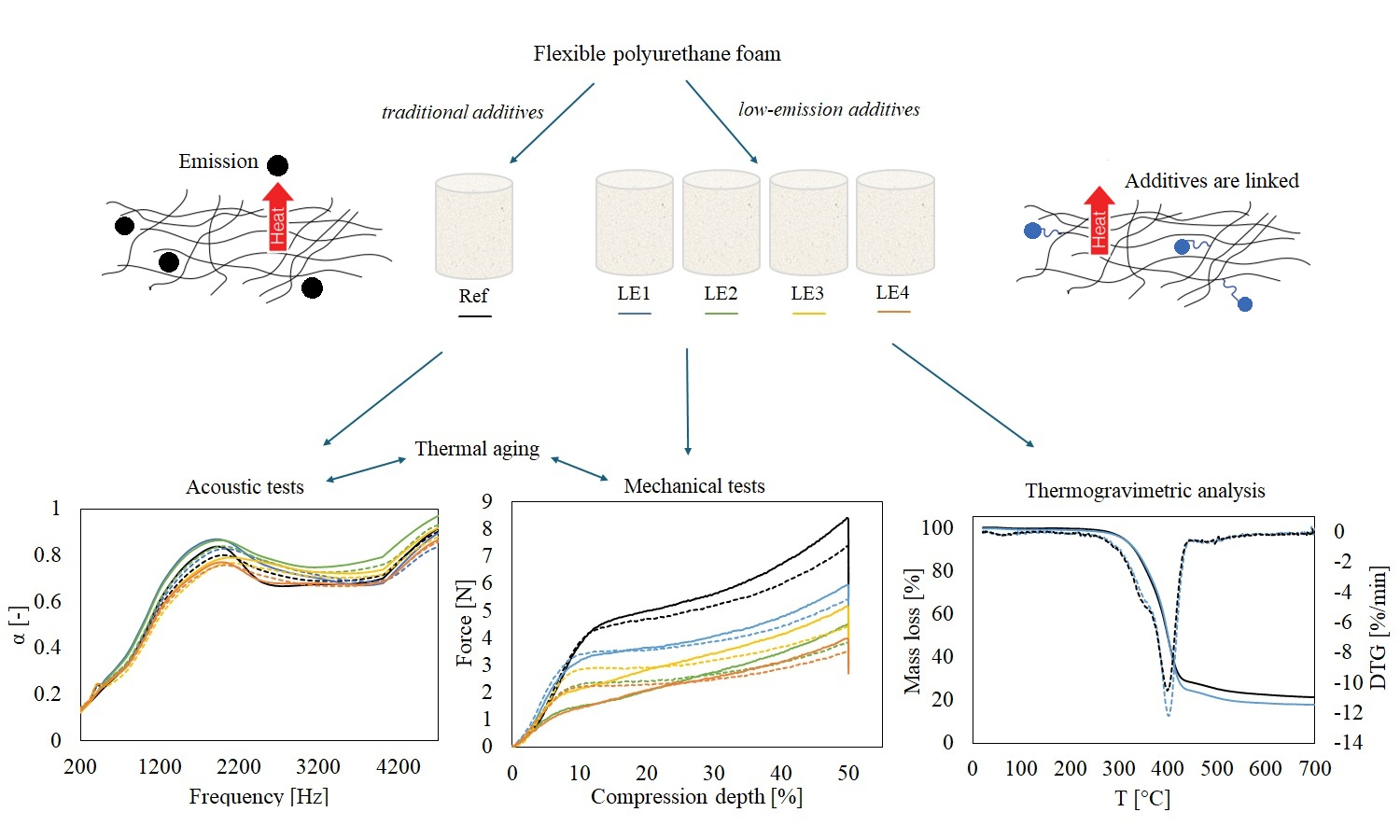

The degradation of different flexible polyurethane foams for molded application after thermal aging were compared. A reference sample using traditional higher emission additives and four samples of different composition using low-emission additives were compared. For the modified samples volatile organic compound (VOC) and semi-volatile organic compound (FOG/SVOC) contents fell well below the benchmarking limits, which indicates that the selected low-emission additives are incorporated into the polymer chain. To examine different material properties and for evaluating changes due to increased temperature exposure for a prolonged period of time mechanical and acoustic tests were carried out before and after dry heat aging. It was found that two low emission samples exhibited superior sound absorption compared to the reference sample along with less significant change after aging in the acoustic properties. The compressive strength was lower than the reference as a result of lower product densities. However, the change in compressive strength after aging was less than 15% (with one exception), which is acceptable according to the standard requirements. Thermogravimetric analysis was also performed and revealed that no significant difference can be observed between the examined samples due to heat degradation, indicating that the modifications made to reduce VOC content did not adversely affect the foam’s resistance to thermal degradation.

Marta Musioł, Joanna Rydz, Wanda Sikorska, Henryk Janeczek, Sebastian Jurczyk

Vol. 18., No.8., Pages 868-880, 2024

DOI: 10.3144/expresspolymlett.2024.64

Vol. 18., No.8., Pages 868-880, 2024

DOI: 10.3144/expresspolymlett.2024.64

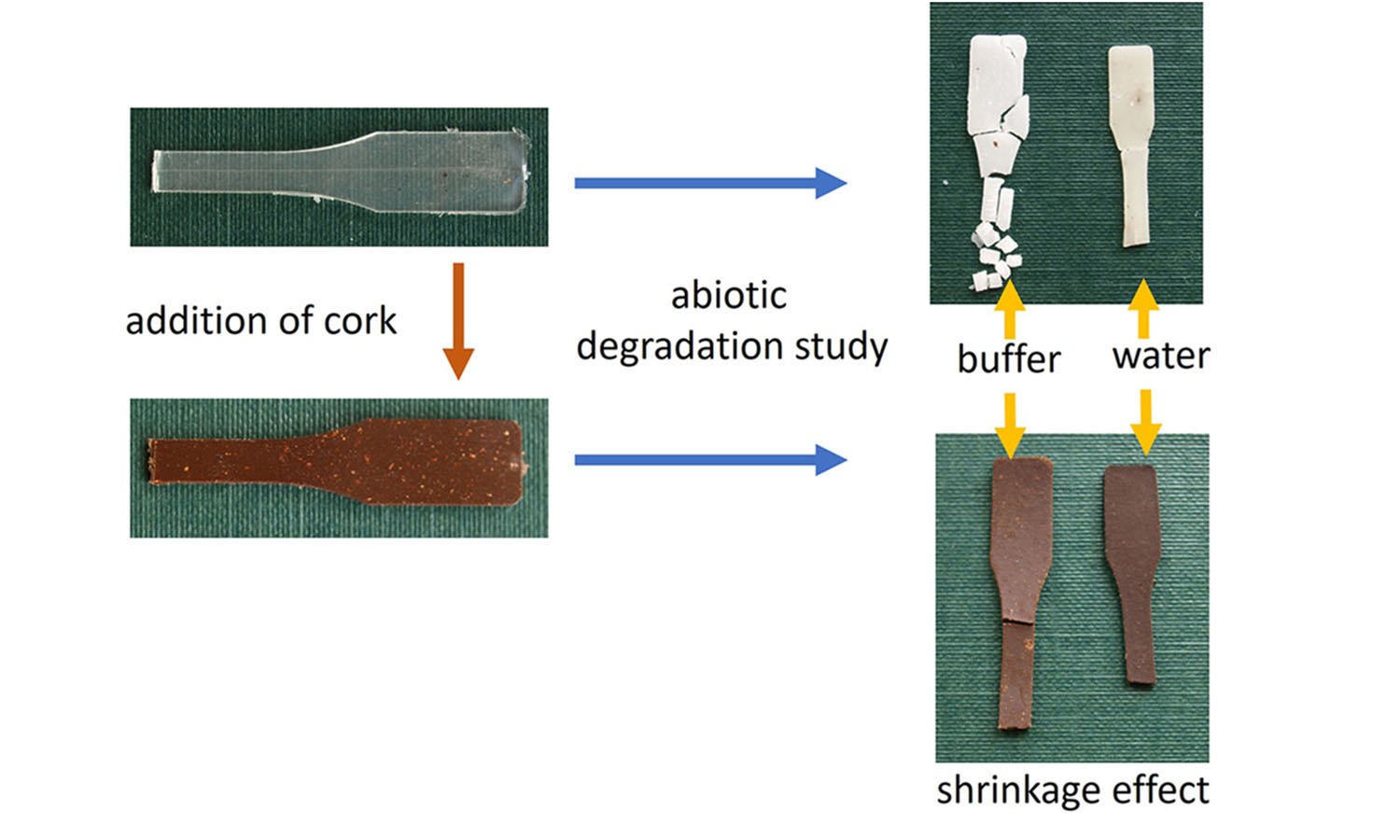

The drastic increase in the amount of packaging waste from conventional plastics, caused by improper waste management, is a serious challenge for the planet. It is therefore worth considering how we can solve this problem. Thus, it is necessary to develop new polymeric materials that retain the functional properties of traditional plastics but are susceptible to degradation with the participation of microorganisms. The development of new eco-friendly materials requires a holistic approach in terms of their disposal. Organic recycling enables the disposal of biodegradable packaging along with food remains that are difficult to remove. The article presents a study on the degradation of biocomposites of polylactide with cork in various environments (water, buffer, and compost). The obtained results indicate a clear influence of the presence of the filler and its amount on the degradation profile of the composites. In addition, the effect of sample shrinkage was observed, especially during degradation in water, where the pH decreases during the process due to the appearance of degradation products. This effect may be important not only for the degradation profile of the packaging but also during its use. Packaging distorted due to shrinkage may be a sign of improper product storage.