Organic recycling challenges of (bio)degradable packages: Degradation studies of polylactide/cork composites

Vol. 18., No.8., Pages 868-880, 2024

DOI: 10.3144/expresspolymlett.2024.64

DOI: 10.3144/expresspolymlett.2024.64

GRAPHICAL ABSTRACT

ABSTRACT

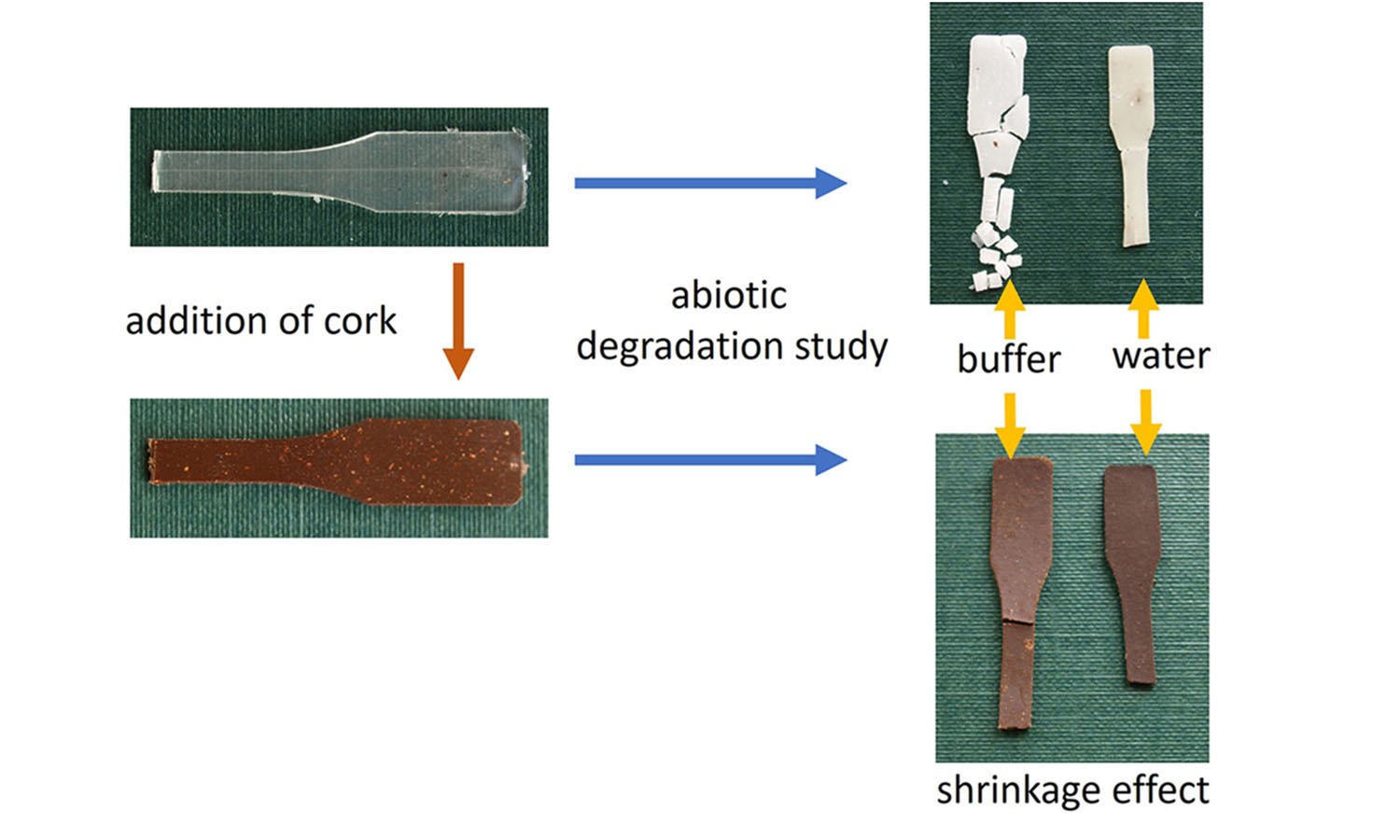

The drastic increase in the amount of packaging waste from conventional plastics, caused by improper waste management, is a serious challenge for the planet. It is therefore worth considering how we can solve this problem. Thus, it is necessary to develop new polymeric materials that retain the functional properties of traditional plastics but are susceptible to degradation with the participation of microorganisms. The development of new eco-friendly materials requires a holistic approach in terms of their disposal. Organic recycling enables the disposal of biodegradable packaging along with food remains that are difficult to remove. The article presents a study on the degradation of biocomposites of polylactide with cork in various environments (water, buffer, and compost). The obtained results indicate a clear influence of the presence of the filler and its amount on the degradation profile of the composites. In addition, the effect of sample shrinkage was observed, especially during degradation in water, where the pH decreases during the process due to the appearance of degradation products. This effect may be important not only for the degradation profile of the packaging but also during its use. Packaging distorted due to shrinkage may be a sign of improper product storage.

RELATED ARTICLES

Mpho Phillip Motloung, Mokgaotsa Jonas Mochane

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Polylactic acid (PLA) is one of the most widely used biopolymers, and it has demonstrated a huge potential for replacing some of the conventional plastics in certain application fields. However, due to a lack of other attributes such as antimicrobial properties and slow degradation rates, it is often blended with other polymers to impart these properties. Chitosan has desirable features including antimicrobial and antioxidant properties, biodegradability and biocompatibility, and environmental friendliness. Thus, it is widely blended with PLA to generate materials that can be applied in various fields. In recent years, PLA/chitosan blend composites and nanocomposites have been produced to develop sustainable and ecofriendly materials that can be suitable in active food packaging, water treatment, air filtration, and biomedical applications. This review provides an overview of the recent advancements in the development of PLA/chitosan blend composites and nanocomposites for various applications. The processing strategies, mechanical and thermal properties, together with utilization in biomedical, air filtration, water treatment, and packaging applications, are provided.

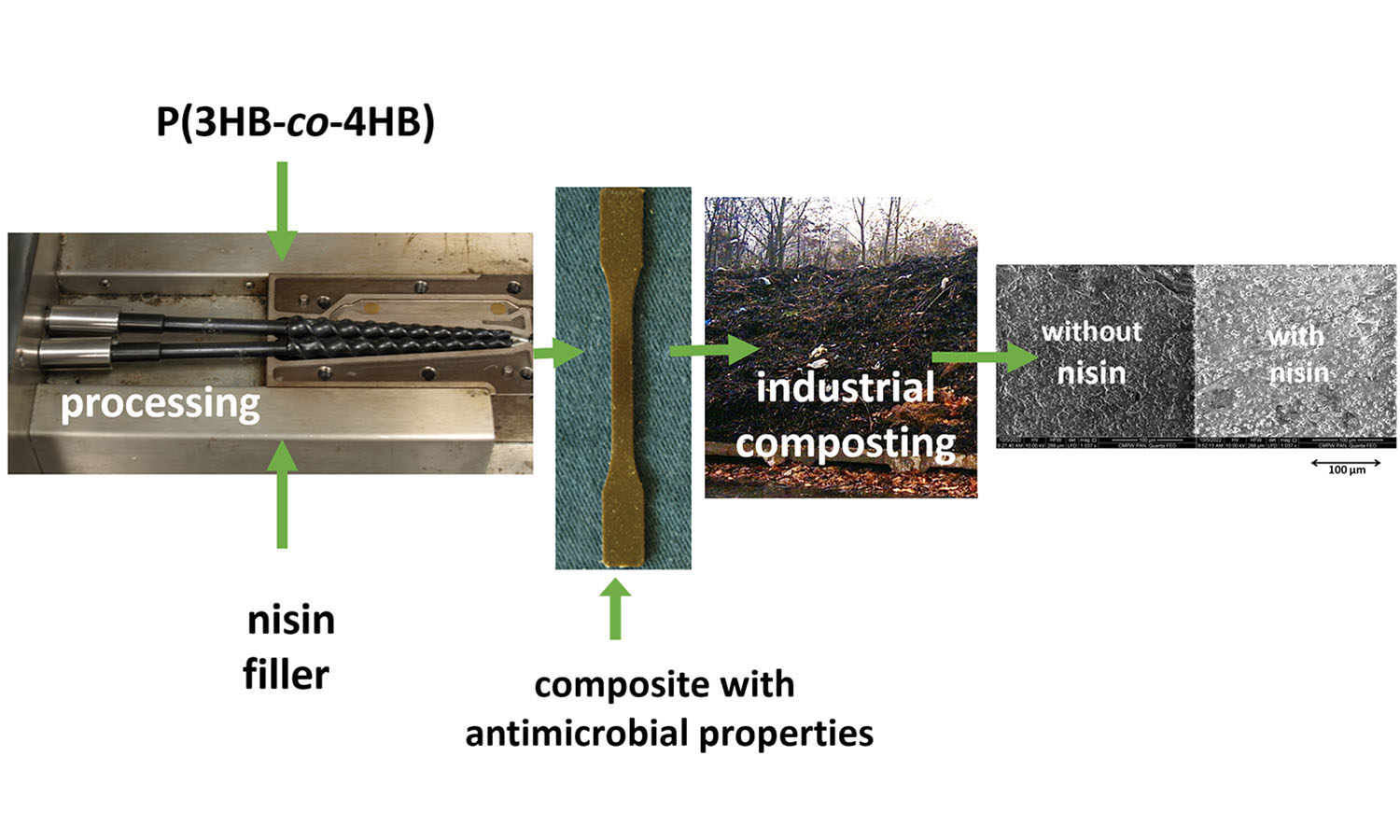

Marta Musioł, Michał Sobota, Henryk Janeczek, Anna Smola -Dmochowska, Brian Johnston, Iza Radecka

Vol. 19., No.8., Pages 773-782, 2025

DOI: 10.3144/expresspolymlett.2025.59

Vol. 19., No.8., Pages 773-782, 2025

DOI: 10.3144/expresspolymlett.2025.59

This study focused on developing compostable packaging materials possessing beneficial microbiological characteristics and evaluating their degradation process. We explore the use of nisin as a versatile antimicrobial additive in biodegradable materials. Our findings demonstrate nisin’s significant influence on the processing and degradation of composites. Nisin’s amphiphilic structure, characterized by both hydrophobic and hydrophilic components, enhances its interaction with the polymer matrix. This interaction affects smaller molar mass reduction during processing and leads to variations in degradation dynamics. The results suggest that nisin has minimal impact on the thermal stability of the matrix during processing, with less than a one-degree increase observed. Thermal stability improved for all materials during degradation, but nisin’s presence slowed this increase. Nisin’s influence on the matrix of jute fiber composites, was more pronounced, affecting the material during processing and subsequent degradation. The results indicate that samples containing nisin inhibit the growth of the gram-positive bacterium Staphylococcus aureus (S. aureus) after 24 h of incubation. The inclusion of fillers in composites elevates the microbiological activity by filler ‘antibacterial promotion’ effects in samples containing nisin. Connection with previous studies highlights the significance of polymer chain length on the composite’s antimicrobial properties.

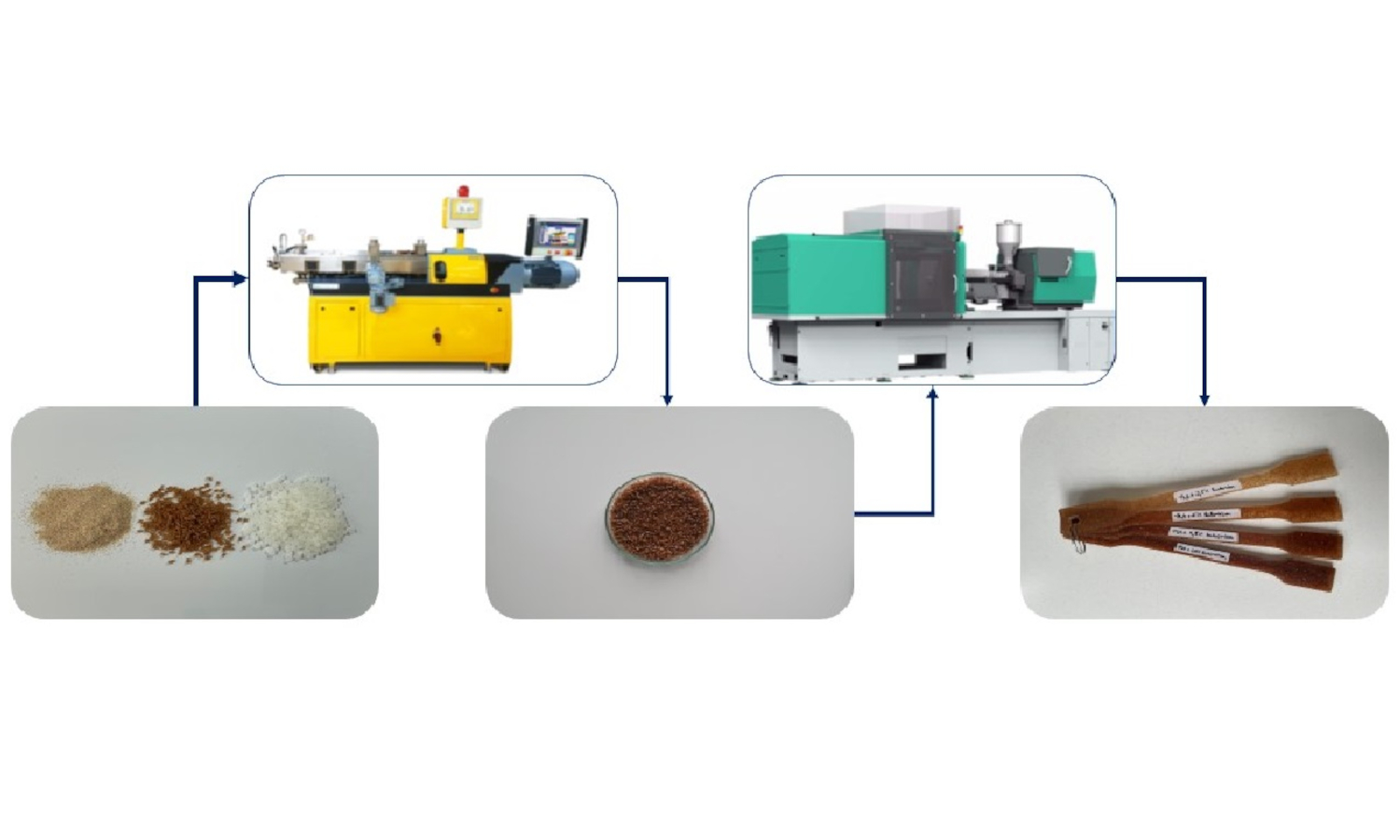

Lilla Bubenkó, Násfa Németh, Sára Frey, Tamás Molnár, Károly Belina, Orsolya Viktória Semperger

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Biocomposites have recently received more attention because of raising environmental awareness and the drive toward sustainable technologies. The most common biodegradable polymer is poly(lactic acid) (PLA), which has an excellent balance of physical and rheological properties, but there is some limit to its usage. PLA properties can be improved by adding different types of fibers or fillers that come from agricultural waste. In this study, corn cob and lavender stem were used to reinforce PLA without any coupling agent, and the properties of the composites were investigated. The melt flow rate (MFR) values decreased with the corn cob content and increased with the addition of lavender stem. Mechanical tests showed that the tensile and flexural modulus of the composites increased and the strengths decreased with the reinforcement material content. The rigidness of PLA slightly decreased with the addition of fillers. There was no significant effect on the thermal properties. The unremarkable improvement of the reinforcement was due to the lack of appropriate adhesion of the two phases. The structure of the compounds was found to be homogenous on the scanning electron microscopy (SEM) micrographs. The incorporation of corn cob and lavender stem can reduce the production cost of materials.

Katalin Litauszki, Tamás Tábi, László Mészáros

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

This is an editorial article. It has no abstract.

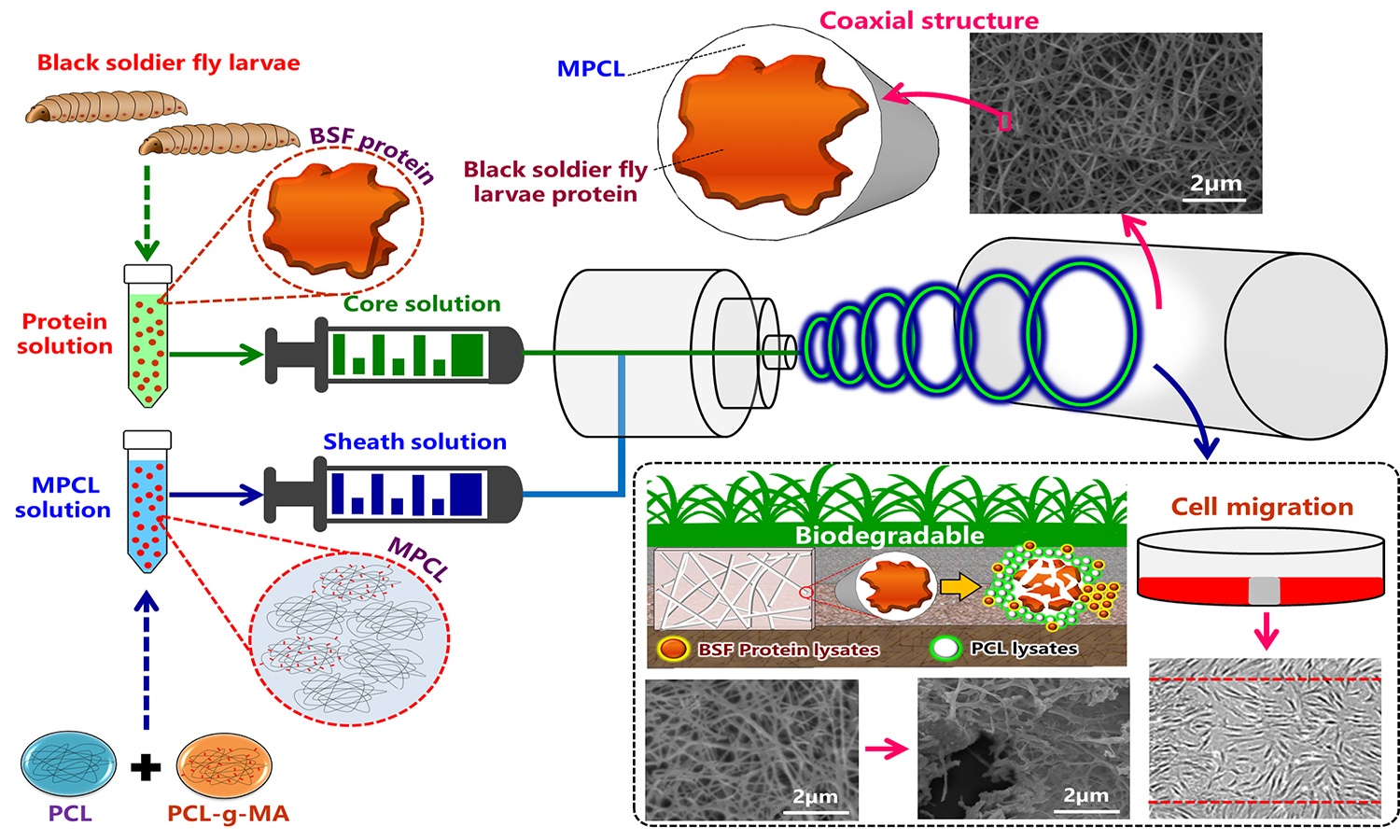

Chin-San Wu, Shan-Shue Wang, Dung-Yi Wu, Wanwen Gu

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

The protein from black soldier fly larvae was used as a functional ingredient of a novel green nanofiber. Larvae protein powder (LP) was blended with biodegradable poly(ε-caprolactone) (PCL) and processed in an electrospinning machine using a coaxial feeding/mixing method to produce nanofibers approximately 100–350 nm in diameter. To improve the dispersion and interface bonding of various PCL/LP nanofiber components, a homemade compatibilizer, maleic anhydridegrafted poly(ε-caprolactone) (MPCL), was added to form MPCL/LP nanofibers. The structure, morphology, mechanical properties, water absorption, cytocompatibility, wound healing, and biodegradability of PCL/LP and MPCL/LP nanofiber mats were investigated. The results showed enhanced adhesion in the MPCL/LP nanofiber mats compared to PCL/LP nanofiber mats; additionally, the MPCL/LP nanofibers exhibited increases of approximately 0.7–2.2 MPa in breaking strength and 9.0–22.8 MPa in Young’s modulus. Decomposition tests using a simulated body fluid revealed that the addition of LP enhanced the decomposition rate of both PCL/LP and MPCL/LP nanofiber mats and in vitro protein release. Cell proliferation and migration analysis indicated that PCL, MPCL, and their composites were biocompatible for fibroblast (FB) growth. Biodegradability was tested in a 30 day soil test. When the LP content was 20 wt%, the degradation rate exceeded 50%.