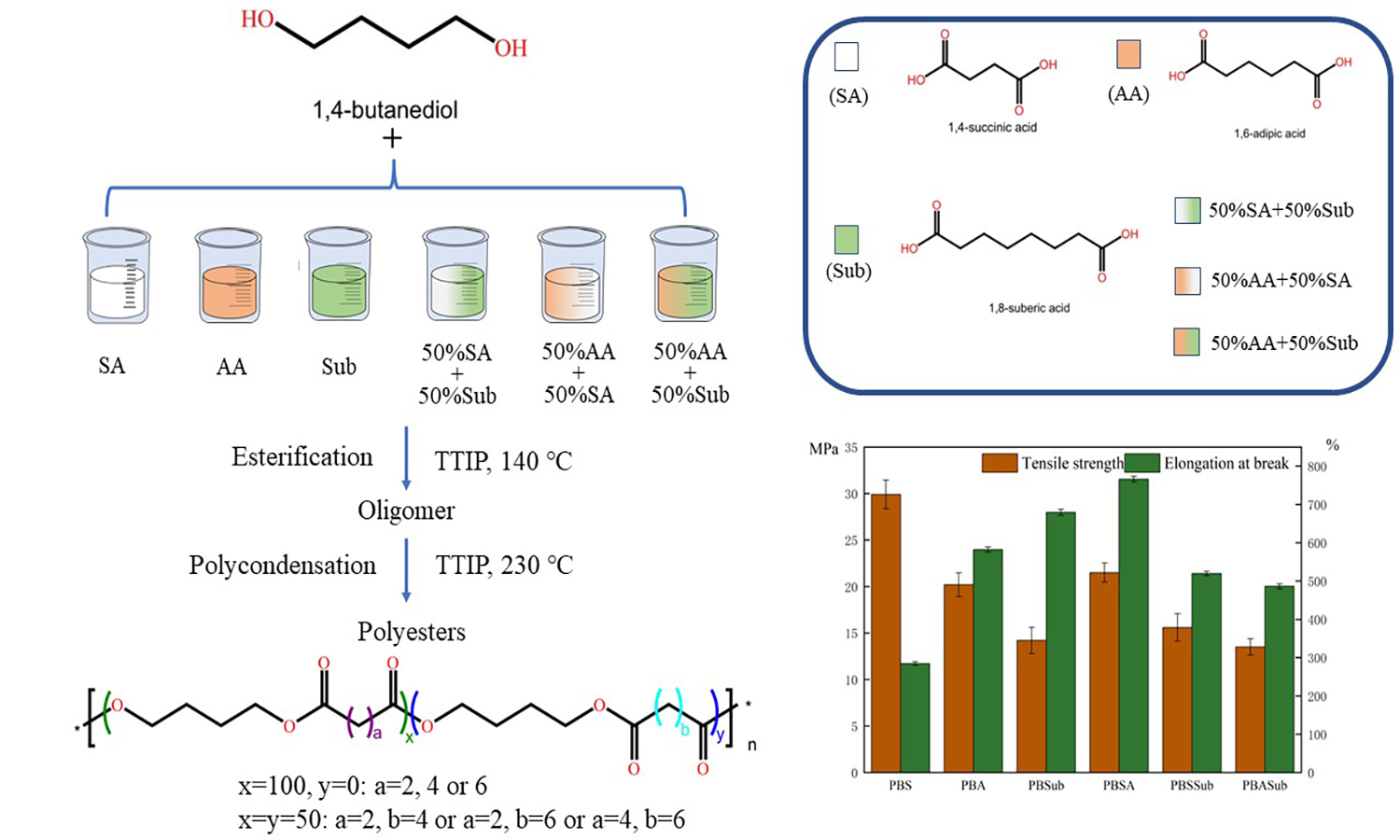

Bio-based aliphatic polyesters of 1,4-butanediol with different diacids: Effect of carbon chain lengths on mechanical properties and enzymatic hydrolysis

Vol. 18., No.12., Pages 1209-1223, 2024

DOI: 10.3144/expresspolymlett.2024.92

DOI: 10.3144/expresspolymlett.2024.92

GRAPHICAL ABSTRACT

ABSTRACT

Polybutylene succinate, polybutylene adipate, polybutylene suberate and their copolyesters were synthesized. The physical properties and biodegradability of these polyesters were controlled by adjusting the composition of carboxyl monomers. Compared with the homopolyesters, the addition of comonomer during polymerization resulted in the formation of copolyesters with lower melting temperatures and crystallinity. Among them, poly(butylene succinate-co-adipate) (PBSA) had the lowest crystallinity, and poly(butylene adipate-co-suberate) (PBASub) had the lowest melting point. The elongation at break and tensile strength of PBSA was 766.2% and 21.5 MPa, respectively. Enzymatic degradation by Fusarium solani cutinase (FsC) showed that both the crystalline and amorphous regions of the polyester were simultaneously degraded by FsC, and the crystal structure of the polyester was not disrupted. FsC preferentially got attached to the surface of polyesters, subsequently attacked the center of the films, and the water penetrated the amorphous region, leading to enhanced enzymatic hydrolysis. The biodegradability of copolyester was higher than that of homopolyesters. PBSA and poly(butylene succinate-co-suberate) (PBSSub) were completely degraded in about 10 h, and can be used in agricultural, automotive, electronics, biomedical materials, packaging, etc.

RELATED ARTICLES

Evangelia Balla, Panagiotis Klonos, Apostolos Kyritsis, Dimitrios Bikiaris

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

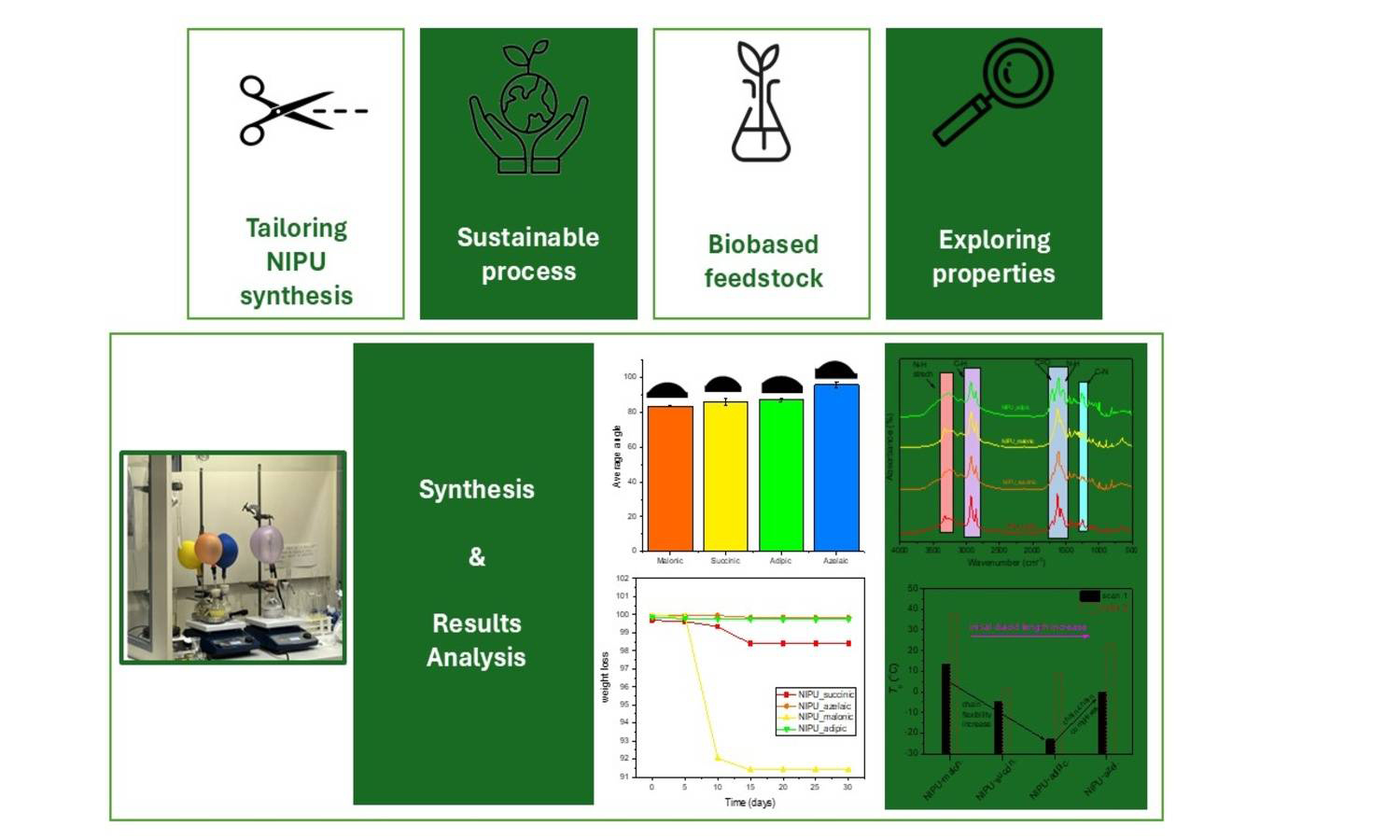

In recent decades, numerous efforts have been dedicated to the investigation of eco-friendly non-isocyanate polyurethanes (NIPUs) as alternatives to conventional polyurethanes (PUs). Since isocyanates are classified by the EU as hazardous and toxic compounds, NIPUs offer a promising route to mitigate isocyanate-related health risks as well as other environmental concerns associated with traditional PU synthesis. In the present study, we report the synthesis as well as the detailed structural and thermal characterization of a new series of fully biobased non-isocyanate polyurethanes (NIPUs) based on aliphatic dicarboxylic acids of different chain lengths. The NIPUs were prepared via a two-step polyaddition reaction involving glycerol carbonate and diamine. Their synthesis enables a sustainable pathway to tailor NIPUs’ physicochemical properties via diacid structure control. Studies of their structure, thermal behavior and trends, morphological, and hydrolytic findings confirmed strong diacid chain length dependence on glass transition temperature (Tg ~13, 0, ‒5 and –23 °C), molecular weight, surface wettability, and enzymatic degradability. Short-chain diacids yielded NIPUs with rapid hydrolytic degradation, while their longer-chain analogs were hydrophobic and thermally stable. Contact angle measurements (~75–85°) also confirm these trends. The tunable properties position these materials among strong candidates for biomedical applications.

Mpho Phillip Motloung, Mokgaotsa Jonas Mochane

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Polylactic acid (PLA) is one of the most widely used biopolymers, and it has demonstrated a huge potential for replacing some of the conventional plastics in certain application fields. However, due to a lack of other attributes such as antimicrobial properties and slow degradation rates, it is often blended with other polymers to impart these properties. Chitosan has desirable features including antimicrobial and antioxidant properties, biodegradability and biocompatibility, and environmental friendliness. Thus, it is widely blended with PLA to generate materials that can be applied in various fields. In recent years, PLA/chitosan blend composites and nanocomposites have been produced to develop sustainable and ecofriendly materials that can be suitable in active food packaging, water treatment, air filtration, and biomedical applications. This review provides an overview of the recent advancements in the development of PLA/chitosan blend composites and nanocomposites for various applications. The processing strategies, mechanical and thermal properties, together with utilization in biomedical, air filtration, water treatment, and packaging applications, are provided.

Katalin Litauszki, Tamás Tábi, László Mészáros

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

This is an editorial article. It has no abstract.