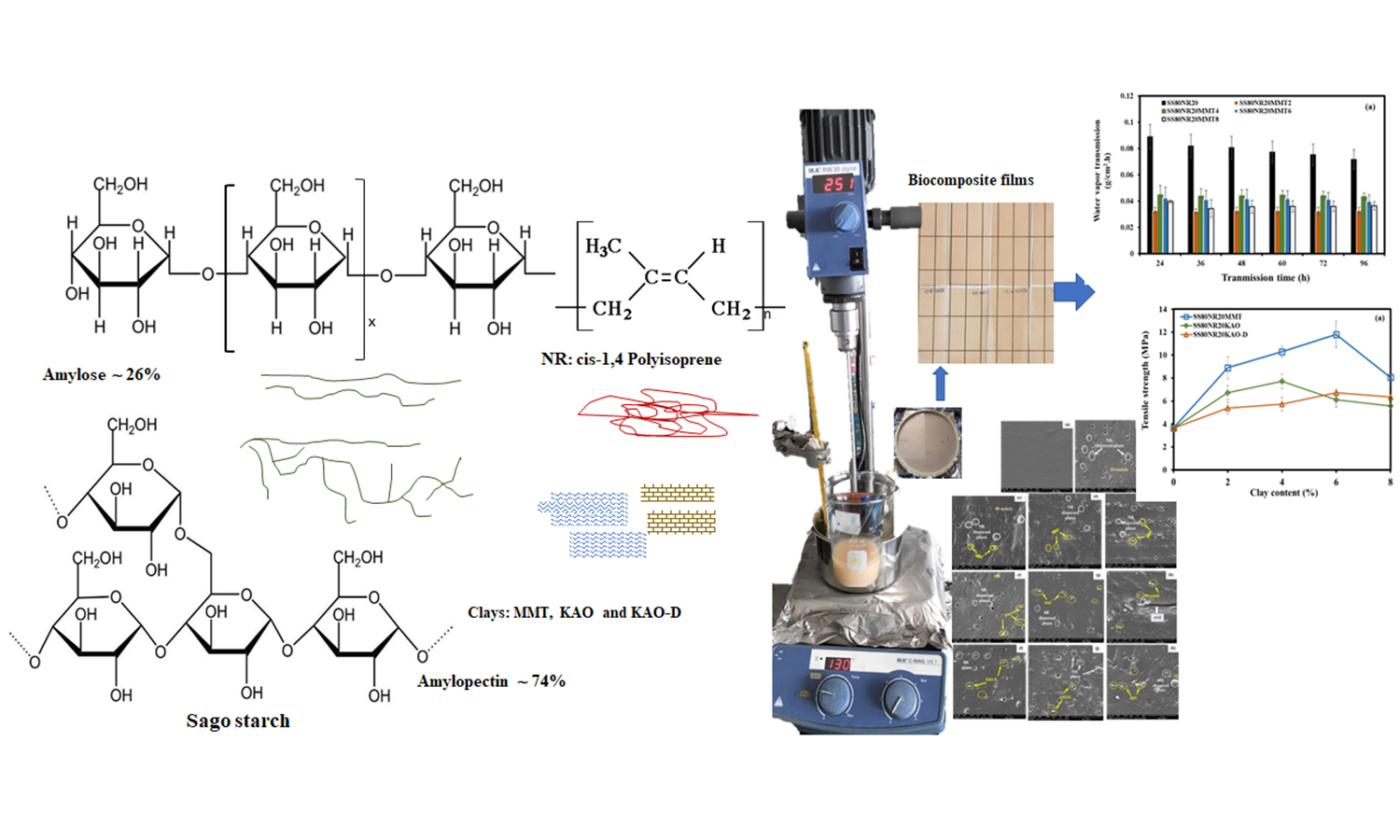

Bio-based composites of sago starch and natural rubber reinforced with nanoclays

Vol. 17., No.11., Pages 1096-1109, 2023

DOI: 10.3144/expresspolymlett.2023.83

DOI: 10.3144/expresspolymlett.2023.83

GRAPHICAL ABSTRACT

ABSTRACT

Sago

starch (SS) was blended with natural rubber (NR) using nanoclays, namely

montmorillonite (MMT), kaolinite (KAO), and kaolinite modified by dimethyl

sulfoxide (KAO-D) to enhance its physical and mechanical properties. Each nanoclay

was incorporated at 2, 4, 6, and 8 wt%, respectively. The SS80NR20 (80 wt% of

sago starch and 20 wt% of natural rubber) biocomposites were characterized by

solubility of water, water vapor transmission, mechanical and thermal

properties. The constituent interaction and morphology of the SS80NR20

biocomposites were also presented by using X-ray diffraction (XRD) technique

and scanning electron microscope (SEM). The findings demonstrated that the

inclusion of clays significantly improved both the water resistance and tensile

properties when compared to the SS80NR20 blend. In the SS80NR20 biocomposites,

MMT at 6 wt% exhibited the lowest moisture content, solubility in water, and

water vapor transmission. As the amount of nanoclay in the biocomposites

increased, their tensile strength dramatically increased whilst their strain at

break had a tendency to diminish. Strong interaction by establishing the

intercalated structure of MMT, and KAO within SS80NR20 biocomposites were

attributed to both physical and mechanical properties, while the weak

interaction at the interface of SS and NR was attributed to KAO-D.

RELATED ARTICLES

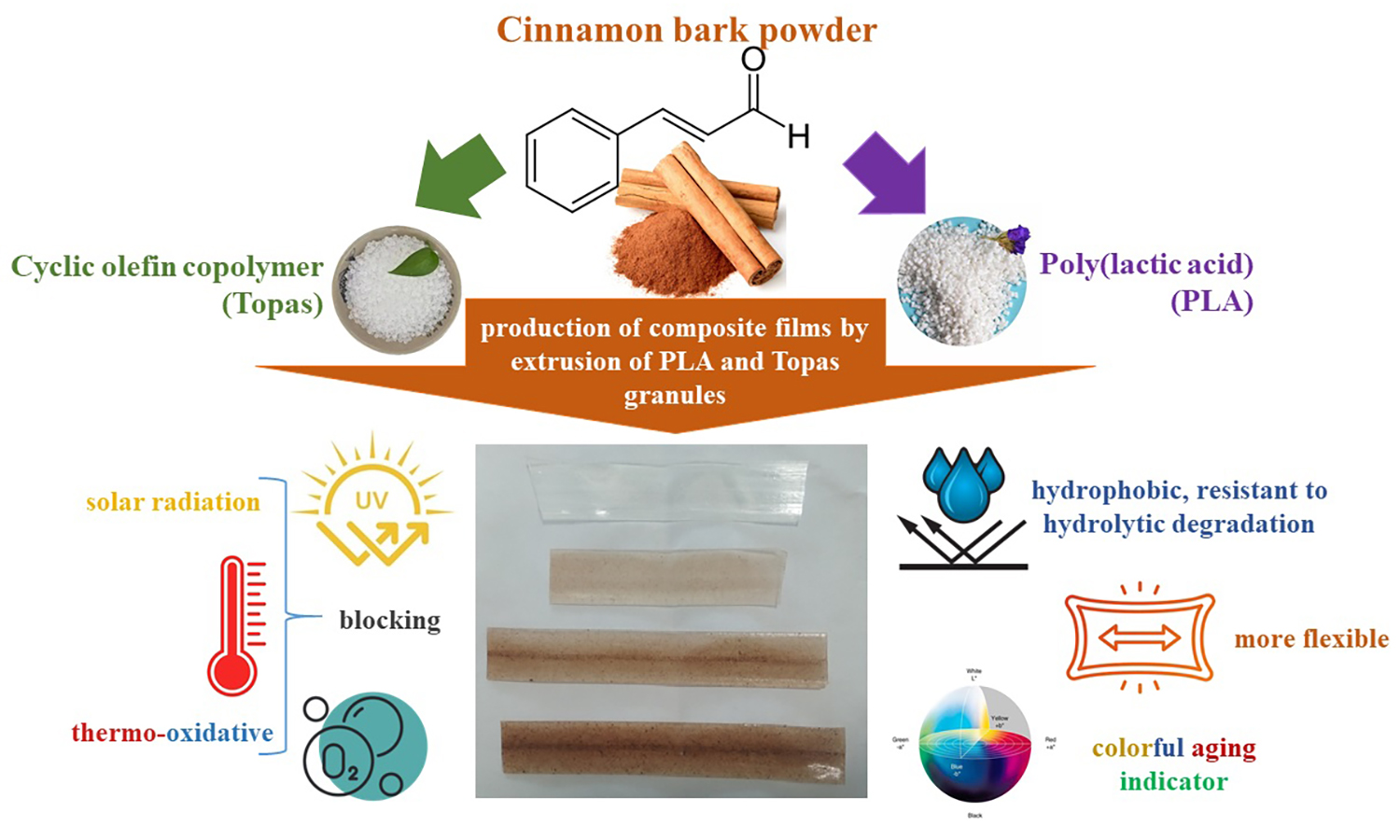

Effect of natural cinnamon extract on the stabilizing properties of biodegradable packaging polymers

Anna Kosmalska-Olańska, Anna Masek

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

The growing focus on sustainability, eco-friendly technologies, decarbonization, and reducing carbon footprints shapes current industry challenges. This article reviews the potential of cinnamon as a bio-additive for polymer stabilization in packaging. Samples were prepared from ethylene-norbornene copolymer (Topas), a cyclic olefin copolymer known for purity, transparency, and low gas permeability, and poly(lactic acid) (PLA), a bio-based alternative to petroleum plastics. Cinnamon powder was added in 0.5, 1.0, and 1.5 wt%. After solar and thermo-oxidative aging, hydrophobicity, chemical composition, mechanical, and color properties were analyzed. Results showed higher hydrophobicity and resistance to hydrolytic degradation due to reduced water penetration. PLA, normally brittle, became more flexible, with 0.5 wt% cinnamon showing optimal performance after 100 h of solar aging, similar to Topas composites. Overall, PLA and cyclic olefin copolymer (COC) films with cinnamon improved durability, extended food shelf life, and acted as natural color indicators of material aging.

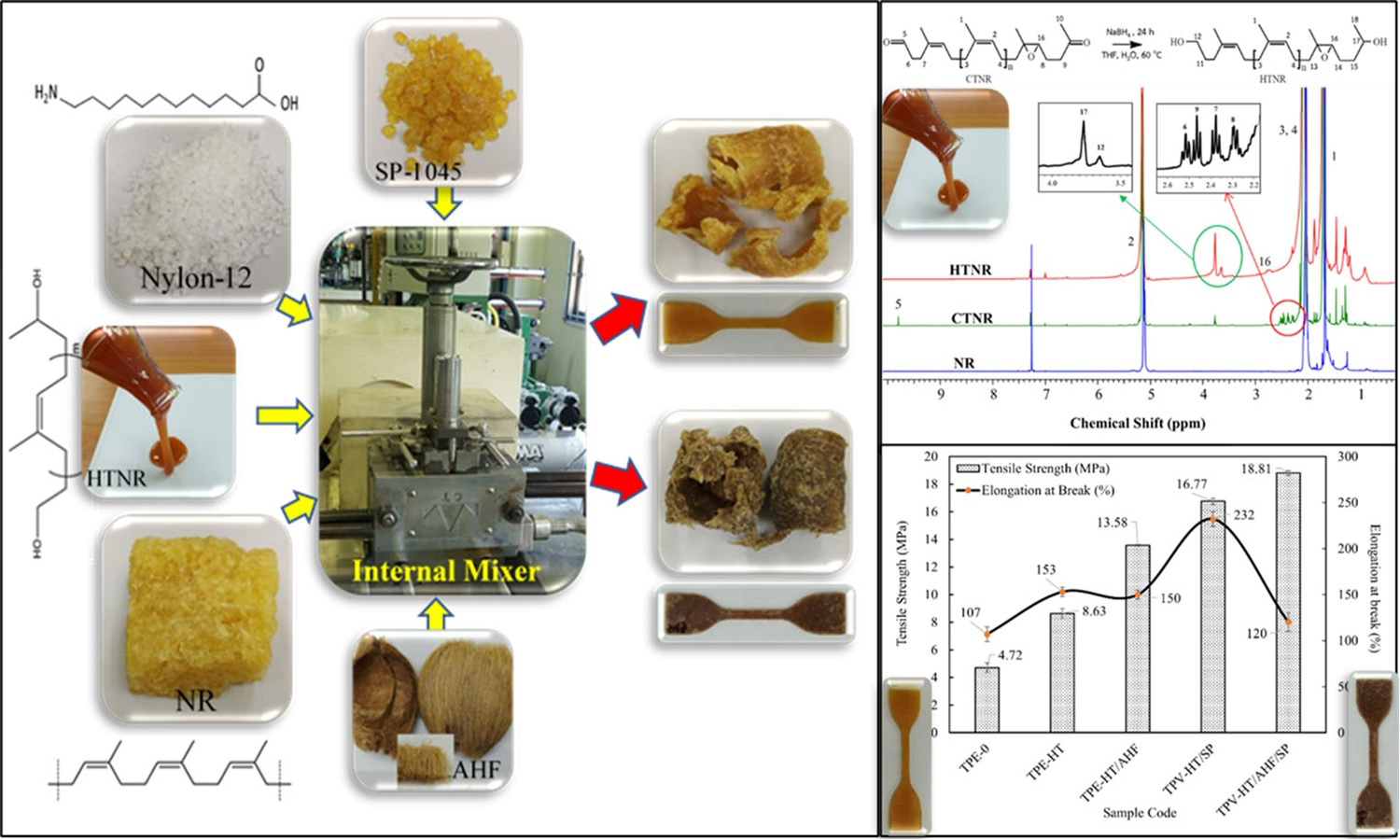

Jutatip Makmanee Treitler, Diew Saijun, Kritsada Phatcharasit, Suwat Rattanapan

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

This work introduces an innovative method to enhance the compatibility of nylon-12/natural rubber thermoplastic elastomers by utilizing hydroxyl telechelic natural rubber as a reactive compatibilizer and natural fibers as reinforcement. Hydroxyl telechelic natural rubber was synthesized from natural rubber via oxidative cleavage to carbonyl telechelic natural rubber, followed by reduction with sodium borohydride. Proton nuclear magnetic resonance (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) verified the structure. Incorporating hydroxyl telechelic natural rubber into nylon-12/natural rubber (40/60 wt%) blends significantly enhanced interfacial adhesion, improving tensile strength and elongation at break compared to the uncompatibilized mix. Dynamic vulcanization using phenolic resin achieved an optimal balance of strength and ductility. The incorporation of areca husk fiber enhanced tensile strength, hardness, and solvent resistance, with a slight decrease in ductility and tear strength. Rheological analysis indicated that hydroxyl telechelic natural rubber increased melt viscosity due to improved phase interactions, while dynamic vulcanization reduced the melt flow index through network formation. Solvent uptake experiments confirmed that hydroxyl telechelic natural rubber, areca husk fiber, and SP-1045 vulcanizing agent minimized swelling in isooctane, toluene, and diesel oil.

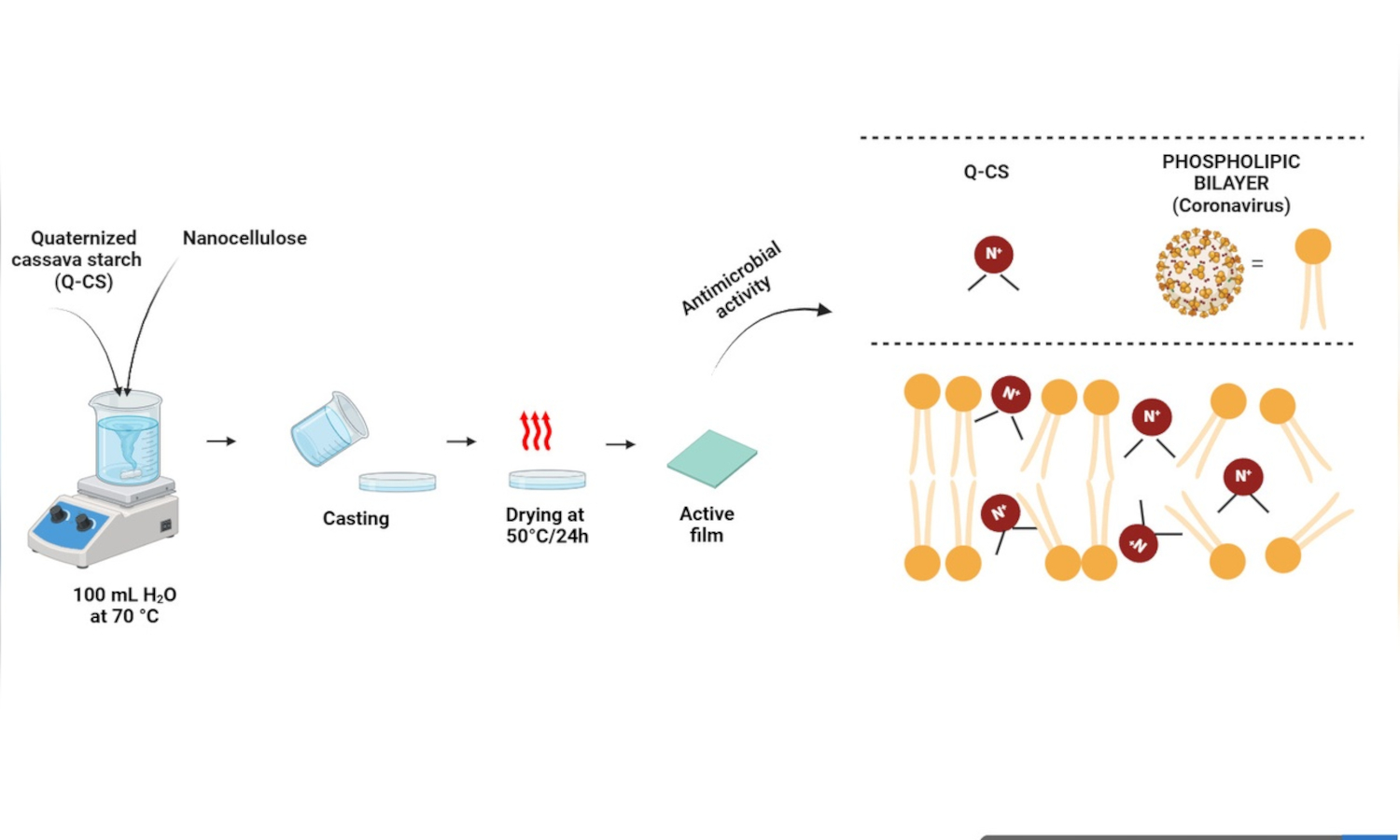

Guilherme Ribeiro de Carvalho, Rafael Affonso Netto, Camila Delarmelina, Marta Cristina Teixeira Duarte, Liliane Maria Ferrareso Lona

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

In this study, a new plastic film with antiviral and antibacterial properties was developed using modified cassava starch with glycidyltrimethylammonium chloride (GTMAC) and reinforced by crystalline nanocellulose (CNC), called Q-CS/CNC. For comparison, a control film (Q-CS) was produced without the addition of CNC. Elemental analysis revealed a degree of substitution (DS) of 0.552, indicating the replacement of the OH groups of starch by the NR4+ groups of GTMAC during the quaternization reaction. The addition of CNC resulted in significant increases (p < 0.05) of 38.9, 38.2, and 43.1% in thickness, opacity, and water vapor permeability measurements, respectively, compared to Q-CS. Incorporating CNC also contributed to an increase of 43.6% in tensile strength and 109% in stiffness but slightly decreased thermal stability. The Q-CS/CNC film demonstrated efficacy by inactivating 99% of the coronavirus in 1 min and inhibiting the growth of Staphylococcus aureus and Escherichia coli. This action is attributed to the electrostatic interaction of quaternary amino groups, grafted onto starch, with the phospholipid membrane of microorganisms, resulting in the inactivation of these microorganisms. Therefore, these results highlight the potential use of Q-CS/CNC film as antimicrobial packaging, especially against coronavirus.

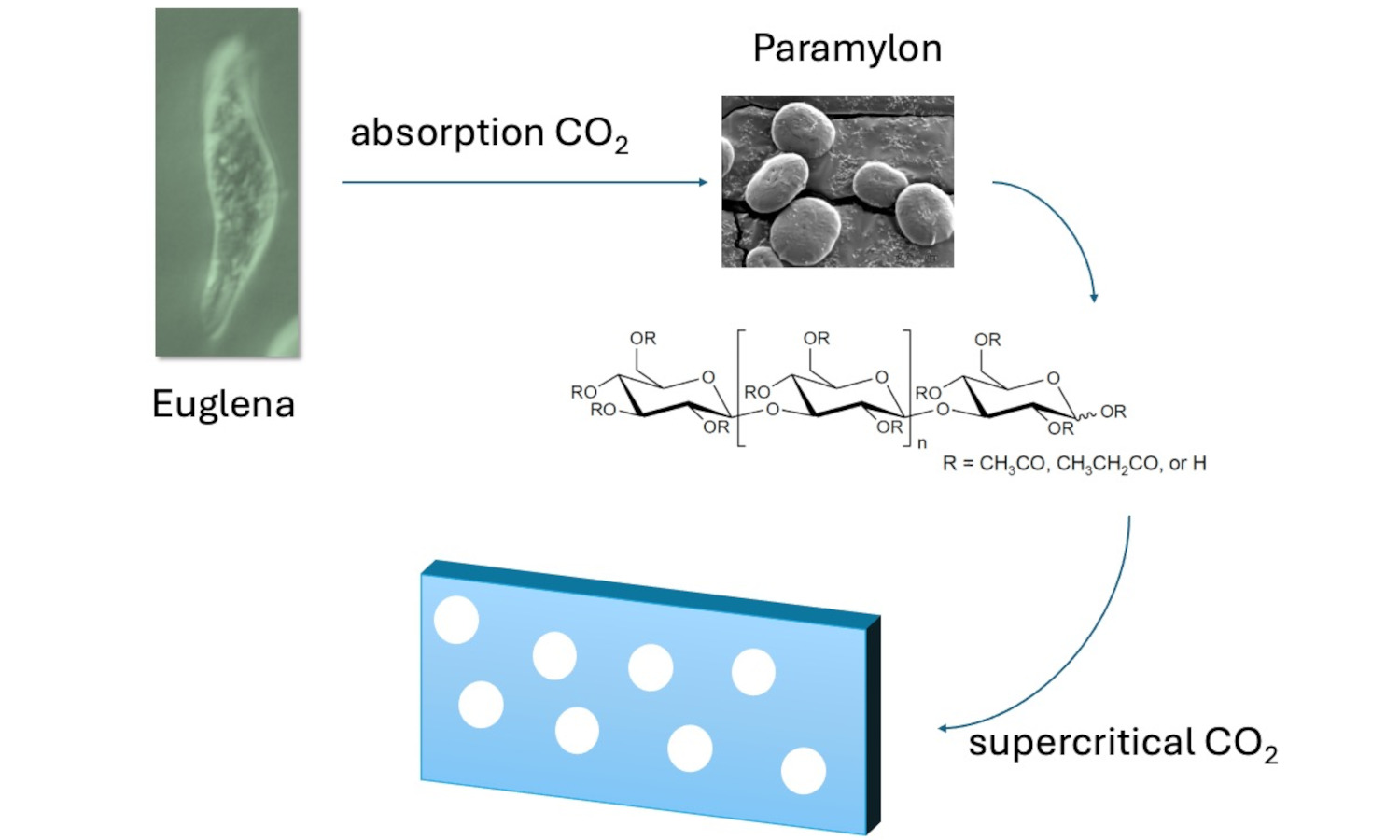

Seisuke Ata, Takumi Ono, Motonari Shibakami

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

This study demonstrated, for the first time, the successful formation of porous paramylon esters, which were made from euglenoid polysaccharide known as paramylon and short-chain fatty acids, through supercritical CO2 processing. By maintaining a constant ester functional group attached to the paramylon and varying its proportion, distinct porous structures were selectively produced. Solubility parameter estimations indicated that changes in esterification had no significant effect on the solubility of the paramylon esters used in the experiment. Thus, these structural differences are likely attributed to variations in the viscoelastic properties of paramylon esters under supercritical CO2 conditions. Furthermore, thermal conductivity measurements revealed reductions of up to 20%. Intriguingly, substantial decreases in thermal conductivity were observed even at low foaming ratios, achieved through precise control of the porous structure.

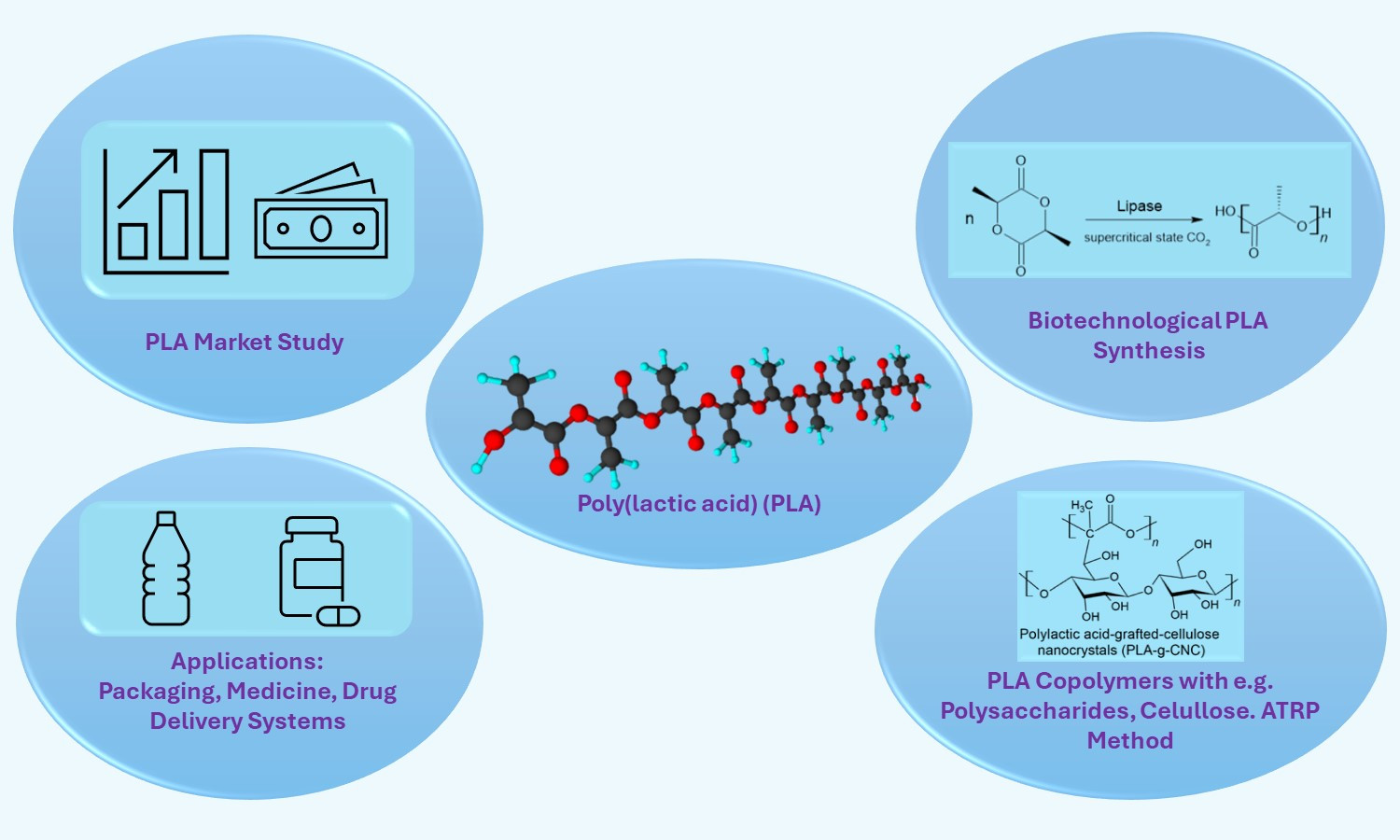

Konrad Stefaniak, Anna Masek

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

This review is focused on recent achievements in poly(lactic acid) (PLA) synthesis and copolymerization with special regard to biotechnological routes of PLA synthesis, which use bacteria/enzymes (e.g., enzymatic ring opening polymerization (eROP)). Besides PLA, also lactic acid (LA) synthesis is described and an emphasis is put on the biotechnological methods. Having regard to PLA copolymerization, this paper attempts to describe different types of PLA copolymers (such as block copolymers, PLA copolymers with polysaccharides, PLA-cellulose copolymer composites, and PLA polymer brushes). A detailed overview of the recent accomplishments in the field of PLA copolymers is presented. Various enhanced properties and applications of presented PLA copolymers are discussed. The attention is placed mainly on applications in the field of tissue engineering, drug delivery systems, and the packaging sector. Furthermore, a PLA market study and its economic forecast are presented. Eventually possible directions for future research in the field of PLA synthesis and copolymerization are indicated.