Synthesis and characteristics of α-carboxylic, ω-hydroxyl natural rubber toughened poly(lactic acid)

Abdulhakim Masa, Varaporn Tanrattanakul, Ruedee Jaratrotkamjorn

Vol. 17., No.11., Pages 1121-1134, 2023

DOI: 10.3144/expresspolymlett.2023.85

DOI: 10.3144/expresspolymlett.2023.85

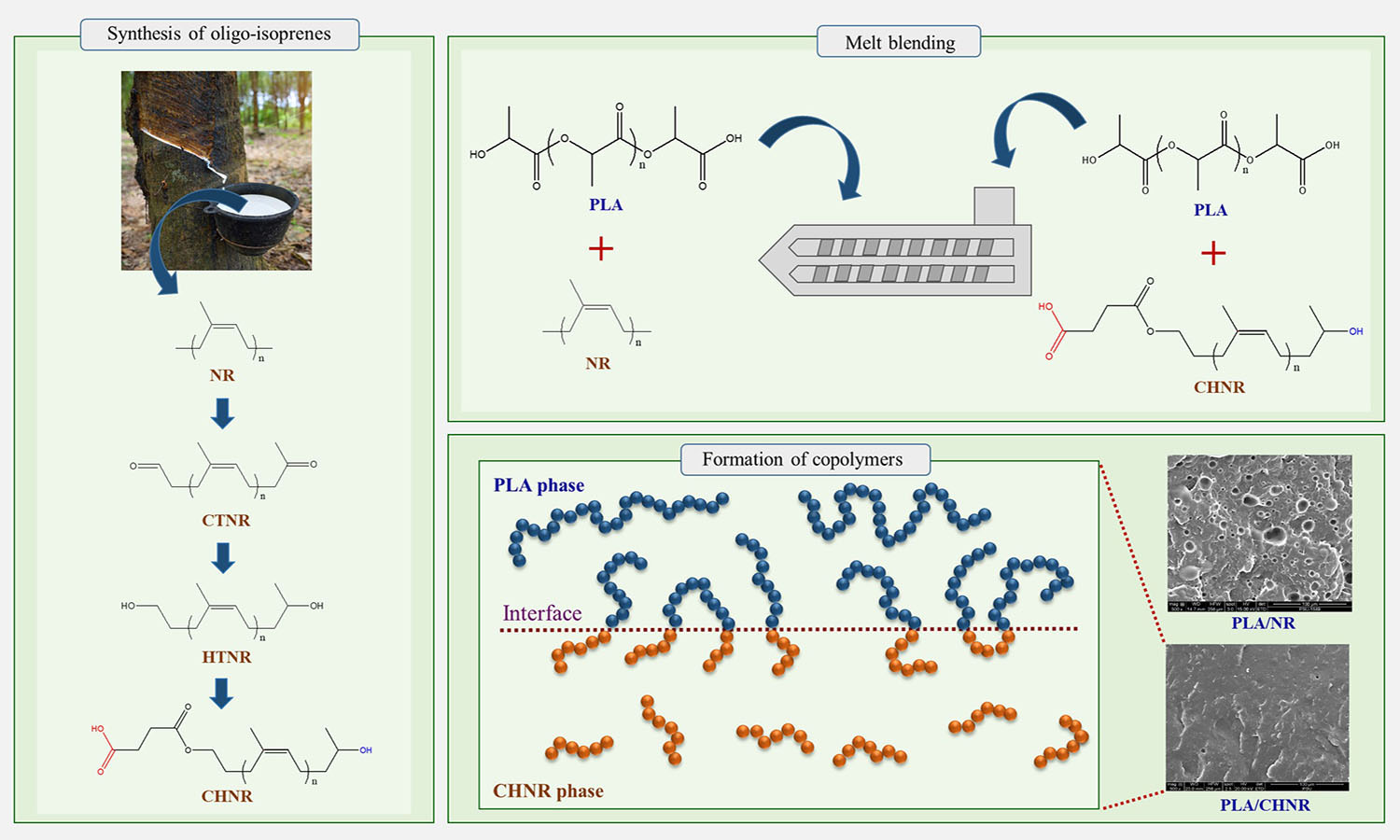

GRAPHICAL ABSTRACT

ABSTRACT

This work presented the synthesis of α-carboxyl, ω-hydroxyl natural rubber (CHNR) for use as an alternative toughening agent for poly(lactic acid) (PLA). The proton nuclear magnetic resonance spectroscopy (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) analyses verified the chemical structure of CHNR consisting of the hydroxyl and carboxyl end groups. The molecular weights of CHNR were set from 5000 to 15 000 g·mol–1 which were determined by gel permeation chromatography (GPC) and 1H-NMR. The PLA and CHNR were prepared by reactive blending using a twinscrew extruder. It was found that the reaction between PLA and CHNR proceeded through transesterification without a catalyst. The formation of copolymer (PLA-co-CHNR) at the interface of PLA and CHNR increased the interfacial adhesion between the two phases. Differential scanning calorimetry (DSC) analysis revealed that CHNR was more compatible with PLA than natural rubber (NR). The compatibilization affected the blend morphology by reducing the interfacial tension. It resulted in a reduction of rubber particle size. The CHNR with a molecular weight of 5000 g·mol–1 showed the greatest improvement in the toughness and ductility of PLA.

RELATED ARTICLES

Yashpal Singh, Raj Kumar, Nikhil Chauhan, Tejas Pramod Naik, Inderdeep Singh

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

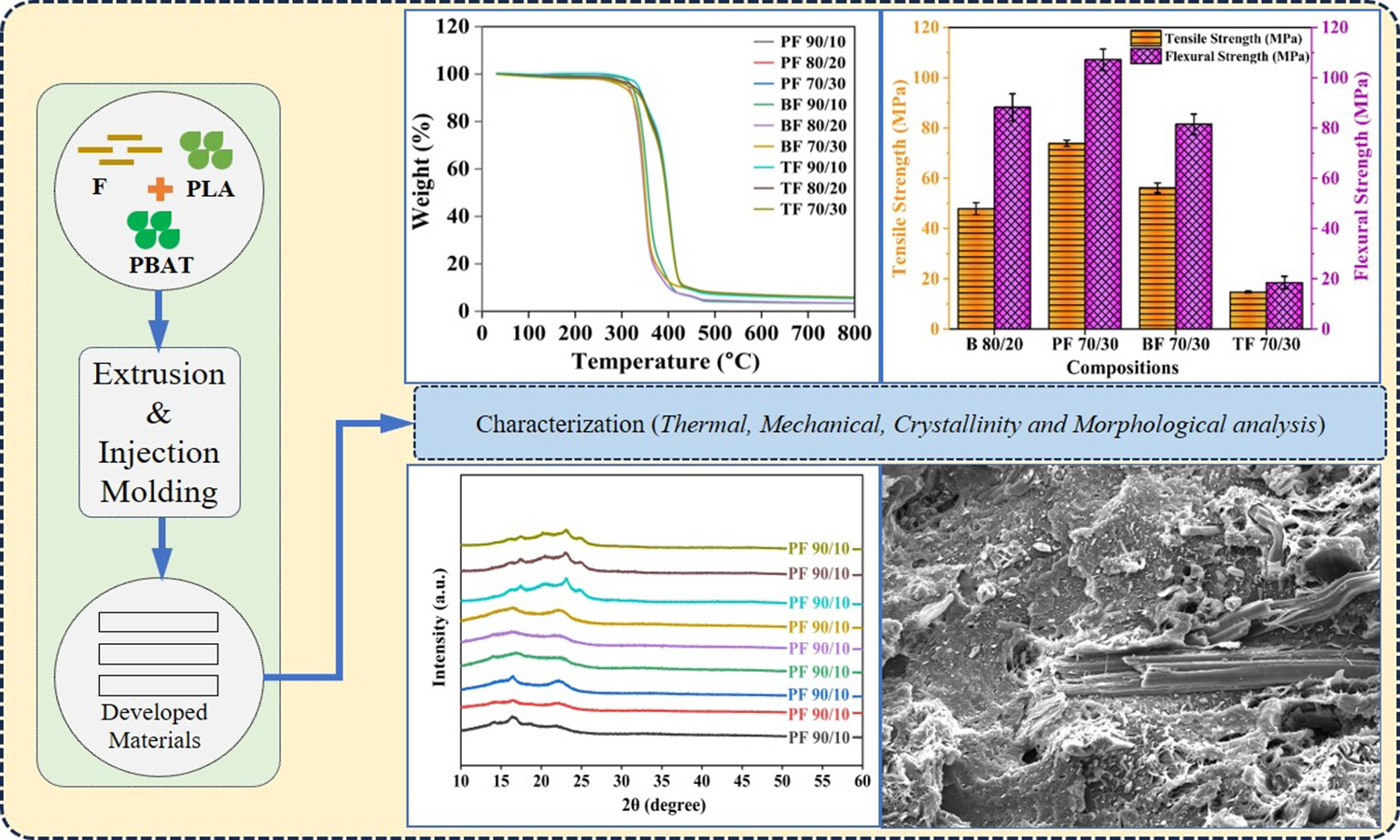

The current experimental investigation presents a comparative evaluation of selected biodegradable polymer blends and their composites, focusing on their material properties. Two biopolymers, polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), along with pineapple fibers (F), as bio-reinforcement were taken for the analysis, which was conducted in two stages: During first stage, PBAT was melt-blended with PLA in varying weight fractions (10, 20, 30, 40, and 50 wt%) to produce PLA/PBAT blend (B) and in second stage, PLA, PBAT, B 80/20 blend were reinforced with pineapple fiber (10, 20, and 30 wt%). The samples were fabricated using extrusion-injection molding. The samples were characterized for density, thermal degradation, crystallinity, and mechanical behaviour. Among the blends, the optimal B 80/20 combination exhibited tensile strength, flexural strength, and elongation at break of 47.9±2.4, 88.2±5.4 MPa, and 330.6±10.47%, respectively. Results indicate that the PLA-based composites (PF) exhibit significantly better density, tensile strength, and flexural strength as compared to neat polymers, blends, blend-based composites (BF), and PBAT-based composites (TF). Among the PF composites, the PF 70/30 composite demonstrated superior performance, with maximum tensile and flexural strength values of 73.9±1.3 and 107.1±4.3 MPa, respectively.

Syaifullah Muhammad, Rahul Dev Bairwan, H.P.S. Abdul Khalil, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

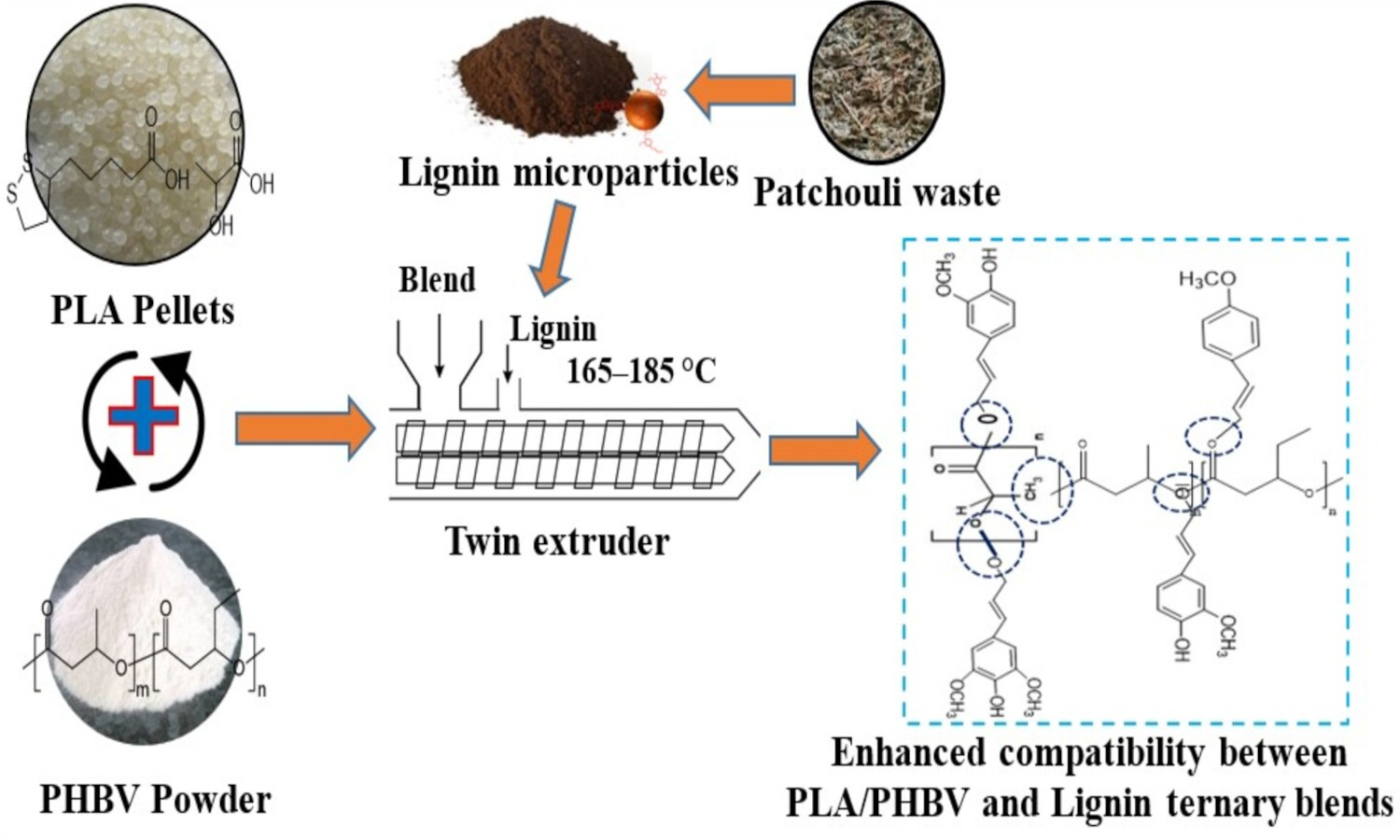

The study investigates a ternary biopolymer blend composed of biopolymers polylactic acid (PLA), polyhydroxybutyrate- co-valerate (PHBV), and lignin extracted from patchouli fiber waste for sustainable packaging applications. A PLA: PHBV blend (70:30) was enhanced by incorporating hydrophobic lignin as a filler in varying loadings of 0, 3, 6, 9, and 12 wt%. The ternary blend was prepared using twin-screw extrusion process, pelletized, and compression-molded into specimens. Comprehensive characterization of the ternary blend included evaluations of water barrier, mechanical, functional, thermal, and morphological properties. Results demonstrated that lignin addition notably improved the compatibility between PLA and PHBV, leading to enhanced barrier performance, mechanical strength, and thermal stability. SEM morphology confirmed improved interfacial adhesion due to hydrophobic nature of lignin, which facilitated better dispersion at lower filler loadings. However, at 12 wt% lignin, property reductions were observed, attributed to lignin agglomeration and poor dispersion. Optimal performance was achieved at 9 wt% lignin loading, offering a balance of improved properties without compromising processability or structural integrity. This study highlights the potential of the PLA/PHBV/lignin ternary blend as a viable, eco-friendly material for sustainable packaging, showcasing improved functionality and environmental compatibility compared to conventional polymers.

Waleed Y. Rizg, Amerh Aiad Alahmadi, Mohammed Baradwan, Rahul Dev Bairwan, Marwan M, Ahmed K. Mohamed, Sherif El Saadany, CK Abdullah, H.P.S. Abdul Khalil

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

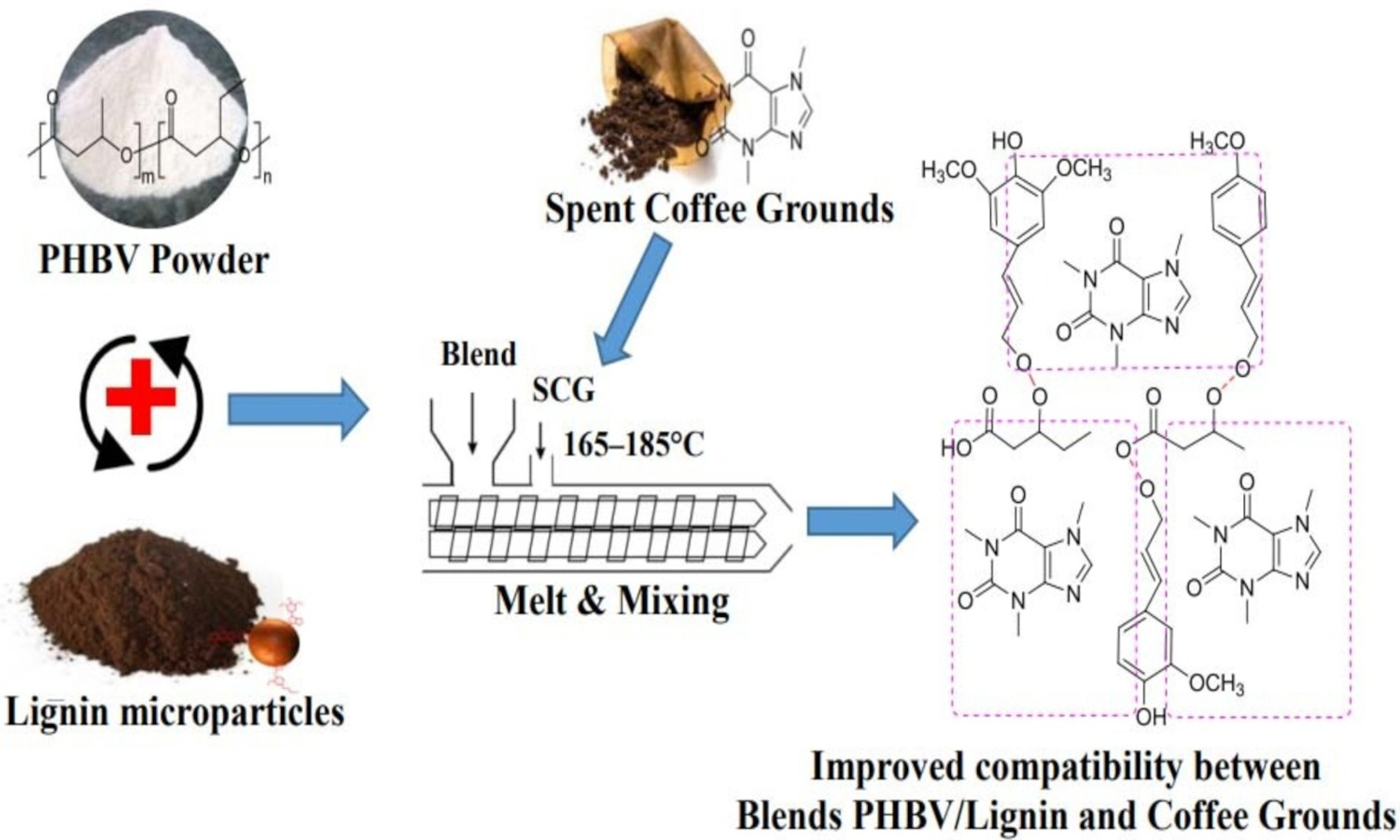

This study investigated the development of thermoplastic composites by incorporating crude lignin extracted from coir fiber waste, into poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), a biodegradable polymer. The extracted crude lignin was blended with PHBV as a matrix, and spent coffee grounds (SCG) were used as biofillers. SCG were chemically modified through sodium hydroxide (NaOH) treatment and maleic anhydride (MA) grafting to enhance their compatibility with the PHBV/lignin blend. Raw and modified SCG were characterized for their functional, morphological, and thermal properties before being incorporated. Thermoplastic biocomposites were prepared via melt compounding and compression molding and evaluated for water barrier, morphological, mechanical, and thermal properties. Results showed that MA-grafted SCG significantly enhanced PHBV-lignin properties, increasing tensile strength by 23.7% and thermal stability by 11.9% compared to the control matrix. Optimal performance was observed at 5% MA-grafted SCG filler loading. However, higher SCG concentrations (7%) led to filler agglomeration, negatively affecting the material properties. This research demonstrated the potential of utilizing agricultural and food waste to create high-performance thermoplastic composites for future applications in biodegradable packaging, contributing to the advancement of a circular economy and environmental sustainability.

Emir Avcioglu

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

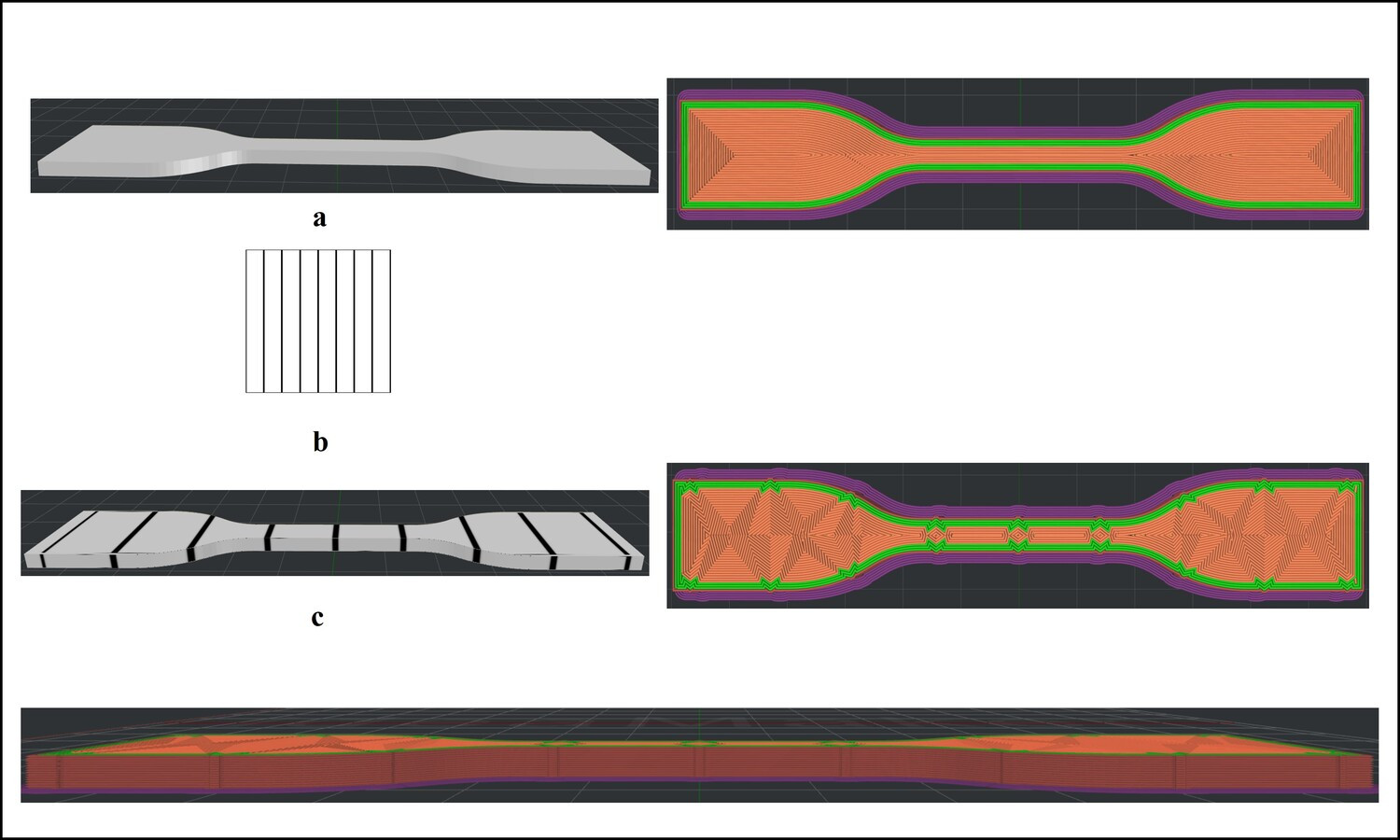

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.

Tamás Tábi

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

This is an editorial article. It has no abstract.