Content

All issues / Volume 18 (2024) / Issue 6 (June)

Ming Qiu Zhang

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

This is an editorial article. It has no abstract.

Rogerio Ramos de Sousa Junior, Guilherme Elias Saltarelli Garcia, Leonardo Dalseno Antonino, Júlia Rocha Gouveia, Demetrio Jackson dos Santos, Danilo Justino Carastan

Vol. 18., No.6., Pages 561-574, 2024

DOI: 10.3144/expresspolymlett.2024.42

Vol. 18., No.6., Pages 561-574, 2024

DOI: 10.3144/expresspolymlett.2024.42

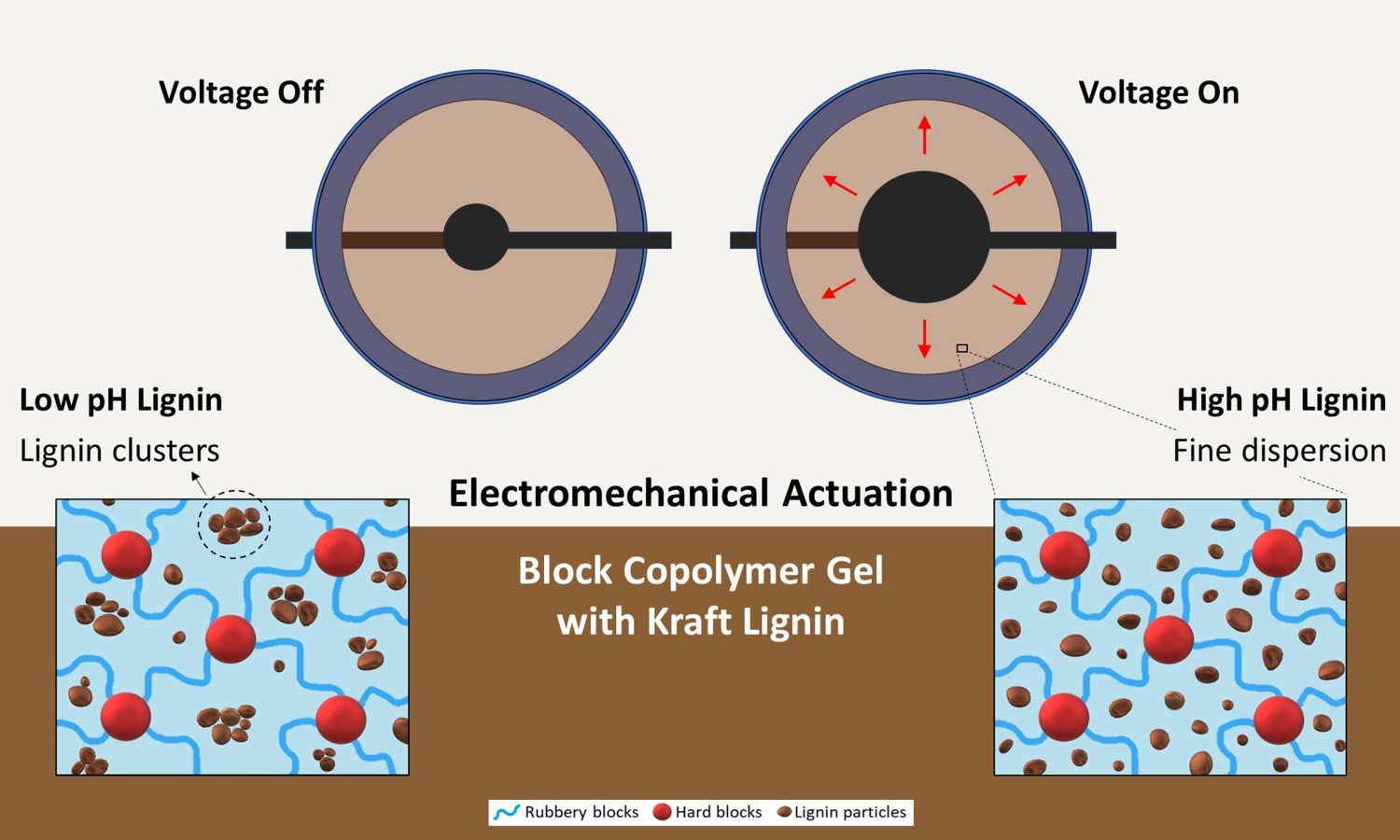

Thermoplastic

elastomer gels based on styrenic triblock copolymers have been increasingly

used as dielectric elastomers, particularly due to the possibility of tailoring

their properties based on their composition. However, these materials have a

low relative permittivity, primarily attributed to their low dipole moment.

Consequently, this characteristic poses a challenge for their application as

dielectric elastomers. In this work, we aim to assess the impact of adding

kraft lignin on the dielectric properties of thermoplastic elastomer gels.

Additionally, we investigate the effects of kraft lignin dispersion on their

viscoelastic and mechanical properties. For this purpose, we used two types of

kraft lignin: acidic and alkaline (ac-KL and alk-KL). The alk-KL demonstrated

higher dispersibility in the polymer, mainly attributed to the deprotonation of

its structure during its production process. As a result, the dielectric

elastomer with alk-KL showed a 50% increase in relative permittivity compared

to the pristine polymer without compromising its mechanical and viscoelastic

properties. Moreover, these samples demonstrated a greater actuation strain

capability in response to an electrical stimulus. Thus, the incorporation of

lignin demonstrates promise as a valuable reinforcement in the development of

advanced dielectric materials, enhancing their electro-mechanical performance.

Xianli Sun, Jiahao Xu, Xiaoke Zhi, Jingpeng Zhang, Kangwei Hou, Yuhan Bian, Xiaolin Li, Li Wang, Guangchuan Liang

Vol. 18., No.6., Pages 575-591, 2024

DOI: 10.3144/expresspolymlett.2024.43

Vol. 18., No.6., Pages 575-591, 2024

DOI: 10.3144/expresspolymlett.2024.43

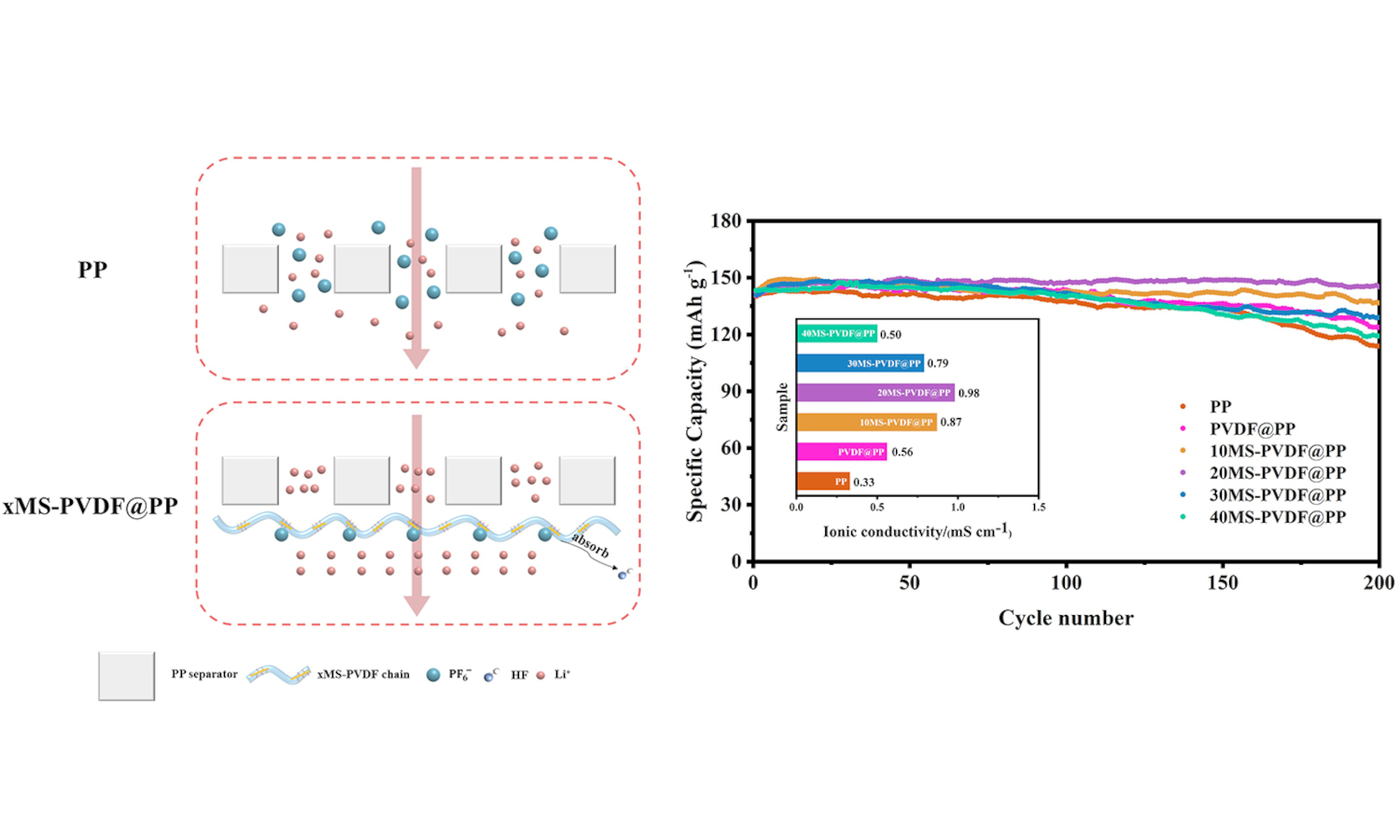

As a key component of lithium-ion batteries, a separator with excellent electrolyte wettability and good thermal stability has an important impact on the overall performance of lithium-ion batteries. Herein, a PVDF/sepiolite electrospun layer was coated on one side of the PP separator via electrospinning technology to prepare the composite separator (xMS-PVDF@PP) with sepiolite nanofibers modified with vinyltriethoxysilane (VTES) to ameliorate their dispersibility and compatibility with PVDF polymer matrix. The effect of modified sepiolite addition amounts on the physical and electrochemical properties of composite separator was intensively studied. It is found that the as-prepared xMS-PVDF@PP composite separator displays enhanced porosity, electrolyte uptake, thermal stability and Li+ ion transport kinetics than pristine PP separator. Specifically, Li|LiFePO4 battery with 20MS-PVDF@PP as separator shows the best rate and cycling performance, with a specific discharge capacity of 115.3 mAh·g–1 at 10C rate and a capacity retention rate of 97.06% after 200 cycles at 1C rate. The sepiolite in the electrospun layer can immobilize PF6– anion to facilitate the uniform distribution of Li+ ions and then inhibit the lithium dendrite growth, as well as absorb HF to alleviate Fe2+ dissolution from LiFePO4 cathode, thereby further improving the electrochemical performance of LiFePO4 battery.

Forough Abbasi Shahir, Zahed Ahmadi, Sayed Mahmood Rezaee Darvishi

Vol. 18., No.6., Pages 592-606, 2024

DOI: 10.3144/expresspolymlett.2024.44

Vol. 18., No.6., Pages 592-606, 2024

DOI: 10.3144/expresspolymlett.2024.44

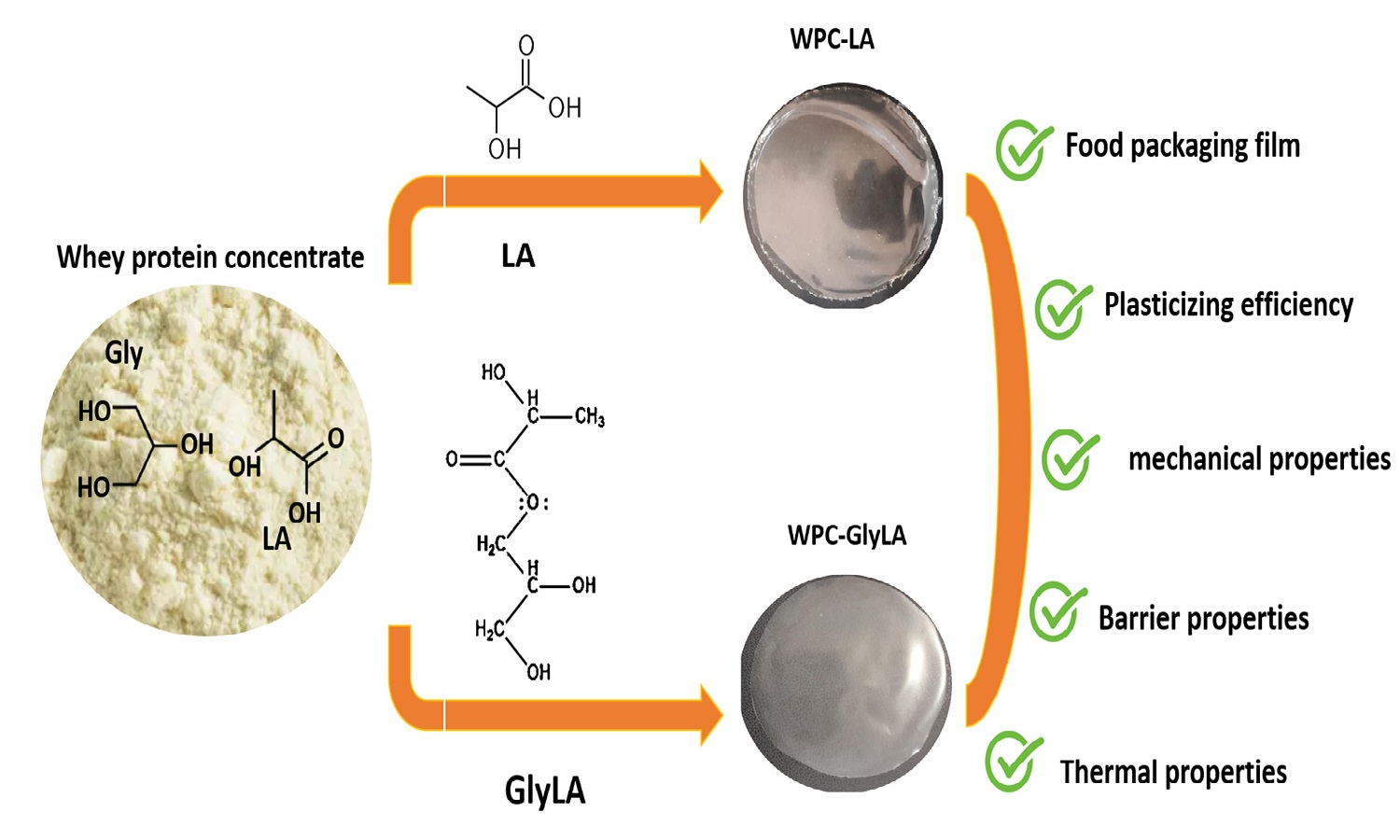

Glyceryl lactate (GlyLA) was synthesized through the esterification of glycerol (Gly) and lactic acid (LA) to plasticize whey protein concentrate (WPC) films with three different ratios of WPC to plasticizer (85, 90, and 100% w/w). LA was also introduced as a new plasticizer of whey protein films and compared in similar contents. Gly-plasticized films were also used as control groups. The synthesized GlyLA, including compatible esterification degree with WPC, was characterized by Fourier transform infrared Spectroscopy (FTIR) and hydrogen nuclear magnetic resonance spectroscopy (H-NMR) analyses. Then, the plasticizing effect of different types of plasticizers on the optical, thermal, mechanical, and water resistivity properties of the prepared films was evaluated. FTIR in attenuated total reflectance (ATR), Differential Scanning Calorimetry (DSC), tensile measurements, and cup method were also employed to examine the molecular structure, transition temperatures, mechanical resistivity, and water vapor permeability (WVP) of the modified films. The results showed a lower glasstransition temperature (Tg) and better ductility. By Increasing plasticizer content, solubility and WVP were increased in all groups. Furthermore, WPC-based films plasticized with 80 or 90% w/w of LA and GlyLA exhibited not only higher tensile strength and flexibility but also remarkably lower WVP than Gly plasticized films, turning them into potential alternatives for application as food packaging.

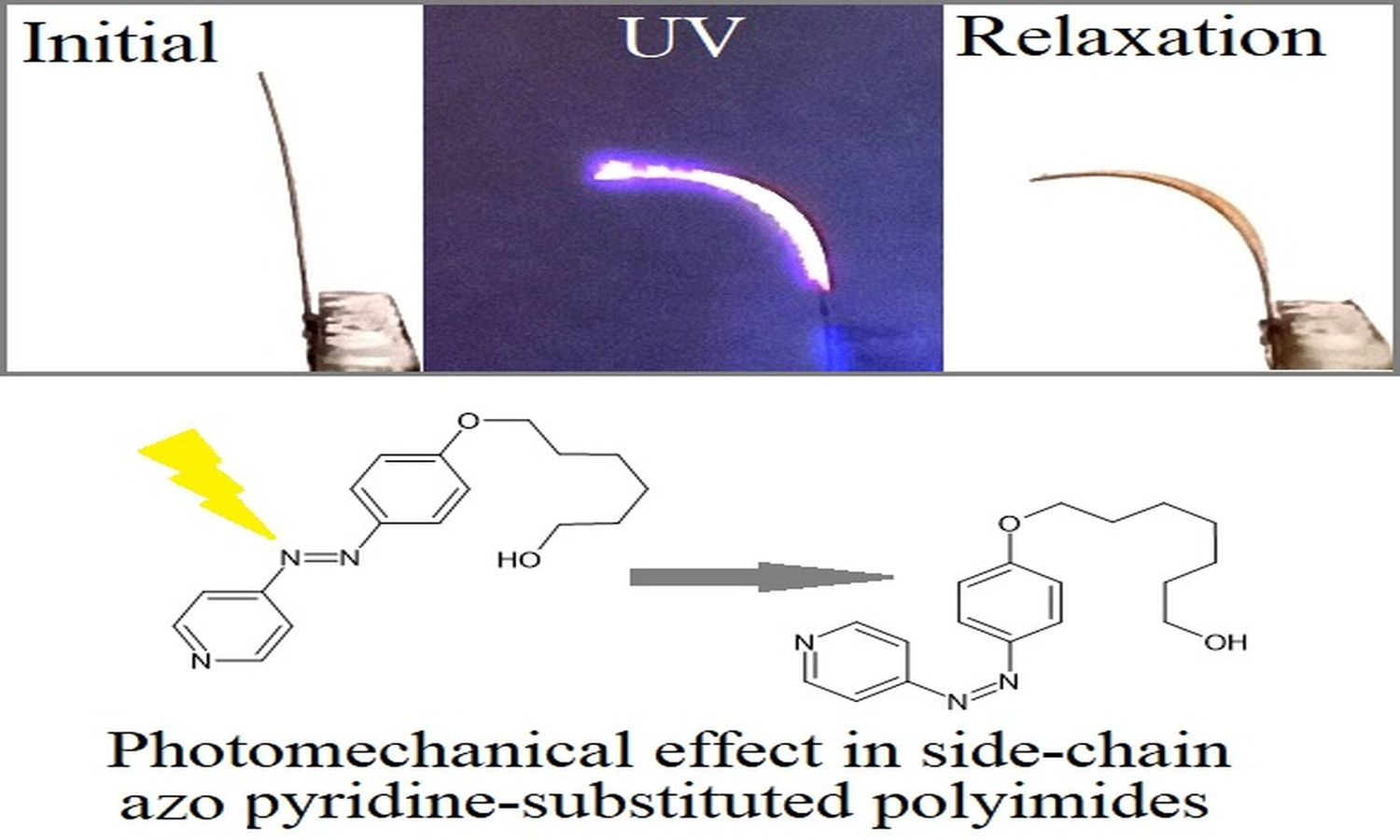

Jolanta Konieczkowska, Klaudia Nocoń-Szmajda, Agnieszka Ciemięga

Vol. 18., No.6., Pages 607-622, 2024

DOI: 10.3144/expresspolymlett.2024.45

Vol. 18., No.6., Pages 607-622, 2024

DOI: 10.3144/expresspolymlett.2024.45

The paper presents the photomechanical effect generated in new azo side-chain polyimides synthesized through a post-functionalization strategy involving the Mitsunobu reaction. Prepared azo polyimide foils were irradiated by a 405 nm diode-laser beam (intensity, I = 100 mW/cm2; polarization, Eǀǀx) for the generation of the photomechanical effect. Despite the low content of azo chromophore (substitution of the hydroxyl group was in the range of 7–35%) and thick cantilevers (thickness ~35 μm), bending angles were in the range of 30–40°. Thermal unbending was not observed for 12 months after turning off the excitation light. Our investigation showed that, despite the low content of azo chromophore, it is possible to achieve photodeformation under polarized light. To the best of our knowledge, this is the first example of the photomechanical response of azo pyridine polymers.

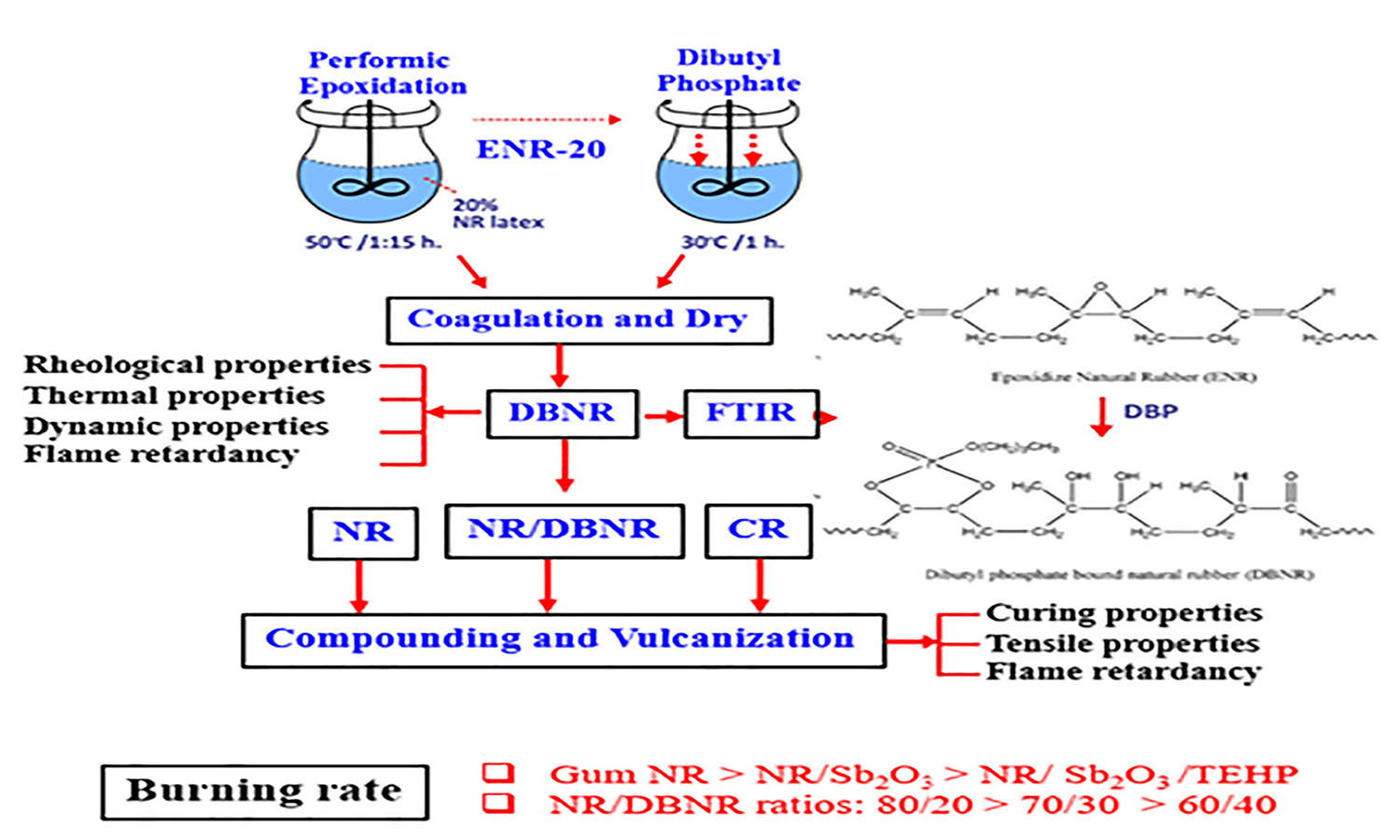

Azizon Kaesaman, Suwit Chiponbarn, Charoen Nakason

Vol. 18., No.6., Pages 623-637, 2024

DOI: 10.3144/expresspolymlett.2024.46

Vol. 18., No.6., Pages 623-637, 2024

DOI: 10.3144/expresspolymlett.2024.46

Dibutyl phosphate-bound natural rubber (DBNR) was prepared by reacting epoxidized natural rubber with 20 mol% (ENR-20) with dibutyl phosphate in a latex medium. Fourier transform infrared spectroscopy (FTIR) was used to confirm the molecular structures of ENR-20 and DBNR and to quantify the epoxide contents. The shear flows and thermal properties of DBNR were then characterized and compared with ENR-20 and natural rubber (NR). The DBNR exhibited the lowest viscosity curves, but it depicted the highest glass transition temperature (Tg) and residue from thermogravimetric evaluation, indicating higher thermal resistance. Subsequently, different NR/DBNR blend ratios were compounded, with and without flame resistance additives, compared with unmodified NR and chloroprene rubber (CR) compounds. We found that all natural rubber compounds exhibited reversion behavior due to the breakage of newly formed sulfidic bonds. However, chloroprene rubber showed marching cured curves, as evidenced by the increasing torque with prolonged testing time. Additionally, antimony trioxide retarded the curing reaction of NR, while tris(2-ethylhexyl) phosphate accelerated it. Therefore, the combination of these additives synergists with the intrinsic flame retardant properties of DBNR. The study revealed that the burning rate of NR/DBNR blends, exhibited very high flame resistance capability compared to gum NR and NR compounded with flame resistance additives.

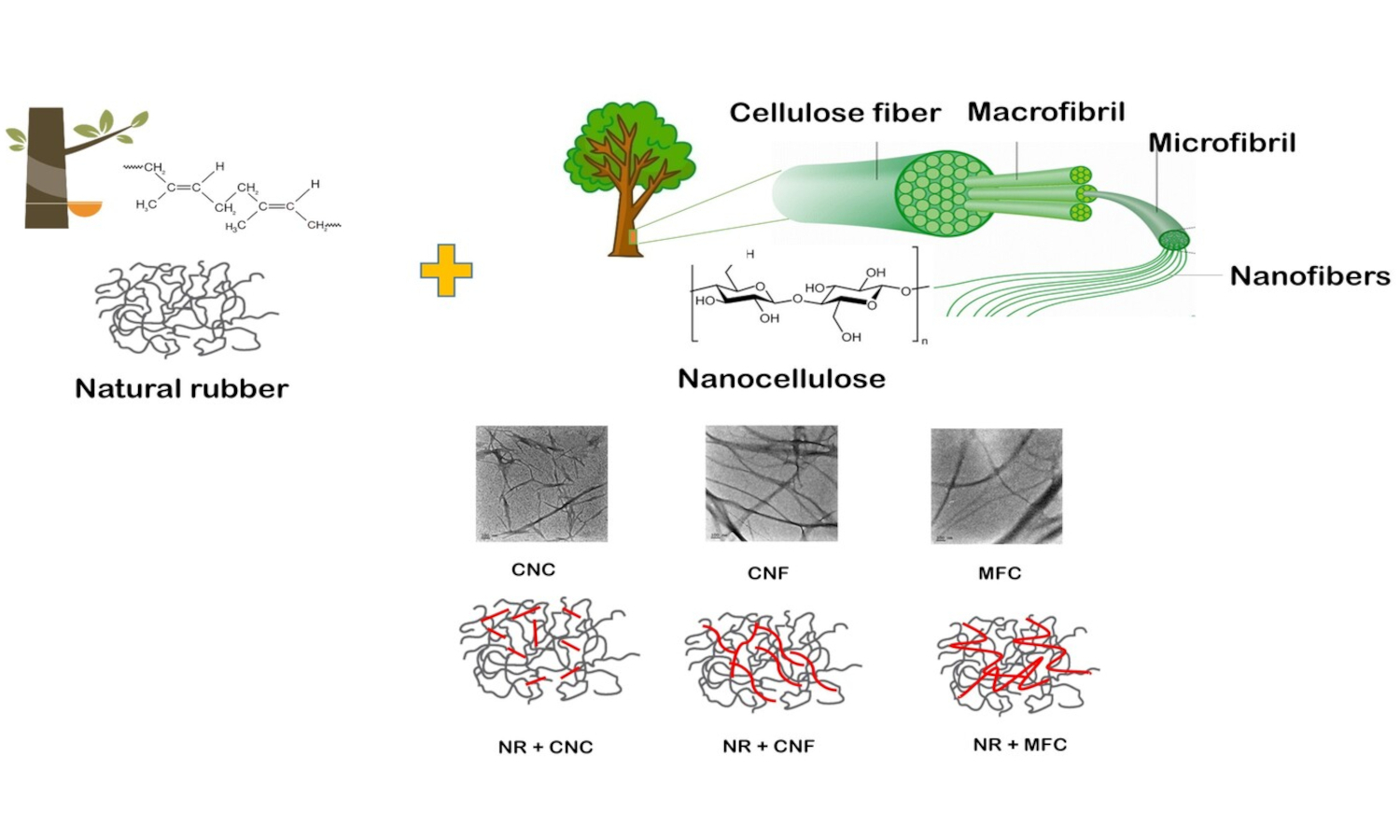

Milanta Tom, Sabu Thomas, Bastien Seantier, Yves Grohens, Mohamed Pulikaparambil Kochaidrew, Ramakrishnan Subramanian, Tapas Ranjan Mohanty, Henri Vahabi, Hanna Joseph Maria, Jibin Keloth Paduvilan, Martin George Thomas

Vol. 18., No.6., Pages 638-655, 2024

DOI: 10.3144/expresspolymlett.2024.47

Vol. 18., No.6., Pages 638-655, 2024

DOI: 10.3144/expresspolymlett.2024.47

The augmented demand for

sustainable nanocomposites has paved the way to explore naturally derived

materials. Nanocellulose, with its bountiful sources and inherent properties,

ranks top in the list of biofillers with a perspective of reducing the carbon

footprint. A systematic study is required to understand the reinforcing effect

of various types of nanocellulose. In the present work, we selected three types

of nanocellulose, i.e.,

cellulose nanocrystal (CNC), cellulose nanofiber (CNF) and microfibrillated

cellulose (MFC), to investigate the effect of geometrical structure on the

properties of unvulcanized natural rubber (NR). Incorporating these fillers

improved the tensile strength and modulus of natural rubber films significantly

through reinforcement via filler network structure. The reinforcing effect of

CNF was found to be higher compared to CNC and MFC, where an increase of 3.85

MPa in tensile strength from the neat sample was obtained. More uniform

dispersion was evident through transmission electron microscopy, atomic force

microscopy and Raman imaging for CNF in the rubber matrix. The structural

properties were determined using Raman spectra and X-ray diffraction. The rheological

studies revealed a good interaction between filler and NR. The work presented

comprehensively compares different types of nanocellulose as reinforcing filler

in NR matrix, which will help the researchers select an ideal type for their

specific application and, thus, the proper usage of renewable resources,

leading to sustainability and a circular economy.

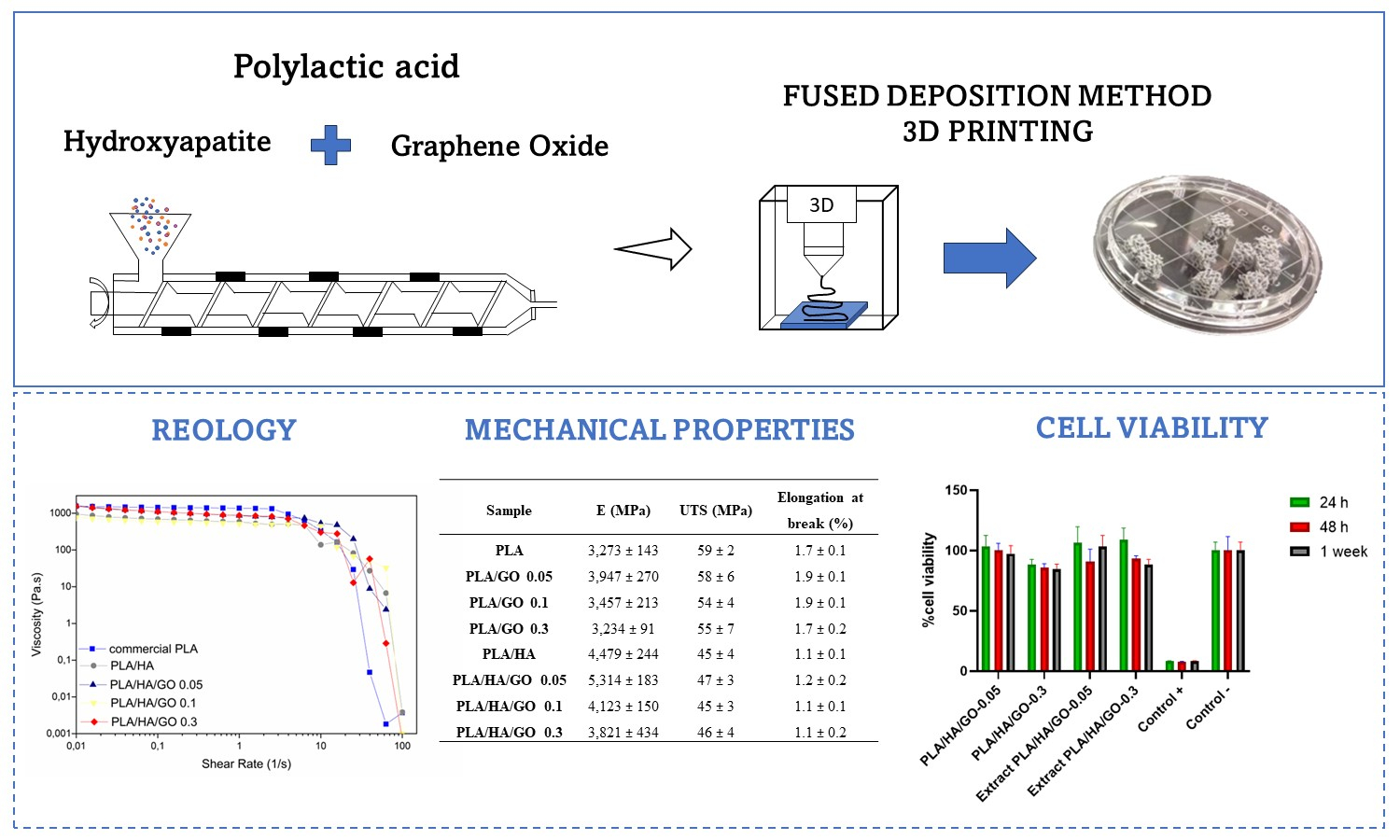

André da Silva Siqueira, Natália Ferreira Braga, Pablo Andrés Riveros Muñoz, Lucas Freitas de Freitas, Aryel Heitor Ferreira, Guilhermino Jose Macêdo Fechine

Vol. 18., No.6., Pages 656-672, 2024

DOI: 10.3144/expresspolymlett.2024.48

Vol. 18., No.6., Pages 656-672, 2024

DOI: 10.3144/expresspolymlett.2024.48

Extensive research and practical applications have been conducted within the biomaterials domain, focusing on polylactic acid (PLA) based composite. These composites have been explored for their favorable attributes, such as excellent processability, biodegradability, and bioactivity properties, but still lack mechanical properties. In this work, PLA-based nanocomposites were prepared by incorporating hydroxyapatite (HA) and graphene oxide (GO) via melt mixing (extruder). Filaments were obtained to develop scaffolds through 3D printing, utilizing the fused deposition method (FDM). The GO was produced using Hummer’s method and characterized by X-ray diffraction (XRD), thermogravimetric analysis (TGA), and Raman Spectroscopy. The composites were analyzed using Fourier-transform infrared spectroscopy (FTIR), molecular weight, contact angle measurements, and thermal, mechanical, and rheological analysis. Adding only 0.05 wt% of GO to both PLA and PLA/HA resulted in enhancements in mechanical properties, particularly tensile strength, and significantly modified the surface properties of the materials studied. Specifically, formulation involving PLA/HA/GO was the only one to exhibit rheological properties compatible with the scaffold production process via FDM. These specific formulations were also investigated regarding cytotoxicity, and the presence of GO induces good cytocompatibility in mouse osteoblast cells (MC3T3). These results suggest that FDM technology can be used to fabricate higher-performance (mechanical and biological) scaffolds for tissue engineering.