Content

All issues / Volume 18 (2024) / Issue 2 (February)

György Marosi, Katalin Bocz

Vol. 18., No.2., Pages 116-117, 2024

DOI: 10.3144/expresspolymlett.2024.9

Vol. 18., No.2., Pages 116-117, 2024

DOI: 10.3144/expresspolymlett.2024.9

This is an editorial article. It has no abstract.

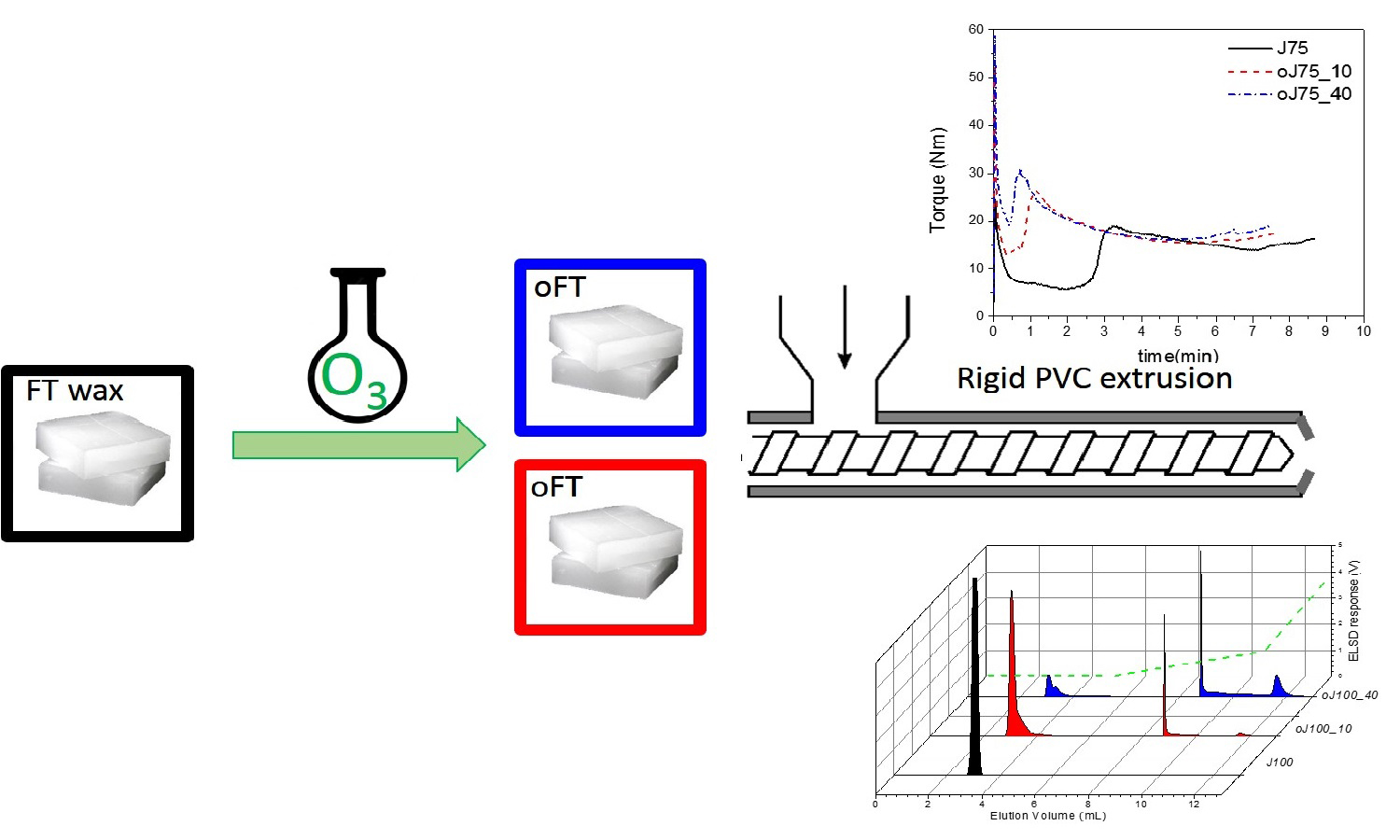

Johannes Lodewiekus Barnard, Divann Dale Robertson, Albert Johannes van Reenen

Vol. 18., No.2., Pages 118-132, 2024

DOI: 10.3144/expresspolymlett.2024.10

Vol. 18., No.2., Pages 118-132, 2024

DOI: 10.3144/expresspolymlett.2024.10

A set of linear Fischer-Tropsch (FT) waxes were oxidized to various degrees by utilizing an ozonolysis method. These waxes were comprehensively characterized in terms of their chemical composition, thermal behaviour, molecular weight distributions, and overall polarity using various analytical techniques, including Fourier transform infrared spectroscopy (FTIR), nuclear magnetic resonance spectroscopy (NMR), differential scanning calorimetry (DSC), high temperature size exclusion chromatography (HT-SEC) along with normal and reverse-phase high temperature solvent gradient interaction chromatography (HT-SGIC). Application-based studies were performed by evaluating the behaviour of these waxes in unplasticized polyvinyl chloride (uPVC) formulations. Analyses included hot melt mixing, single screw extrusion, scanning electron microscopy coupled with energy dispersive X-ray spectroscopy (SEM-EDS), and torque rheometry. Through a combination of these techniques, the lubrication mechanism of these waxes could be explained by the Rabinovitch model. It was found that a combination of molecular size and degree of polarity play a vital role in the migration of the waxes and therefore ultimately impacts the fusion behaviour of the overall polyvinyl chloride (PVC) formulation. Results indicate that fusion times can greatly be altered when using oxidised waxes, and this could be promising for the development of multifunctional lubricant systems.

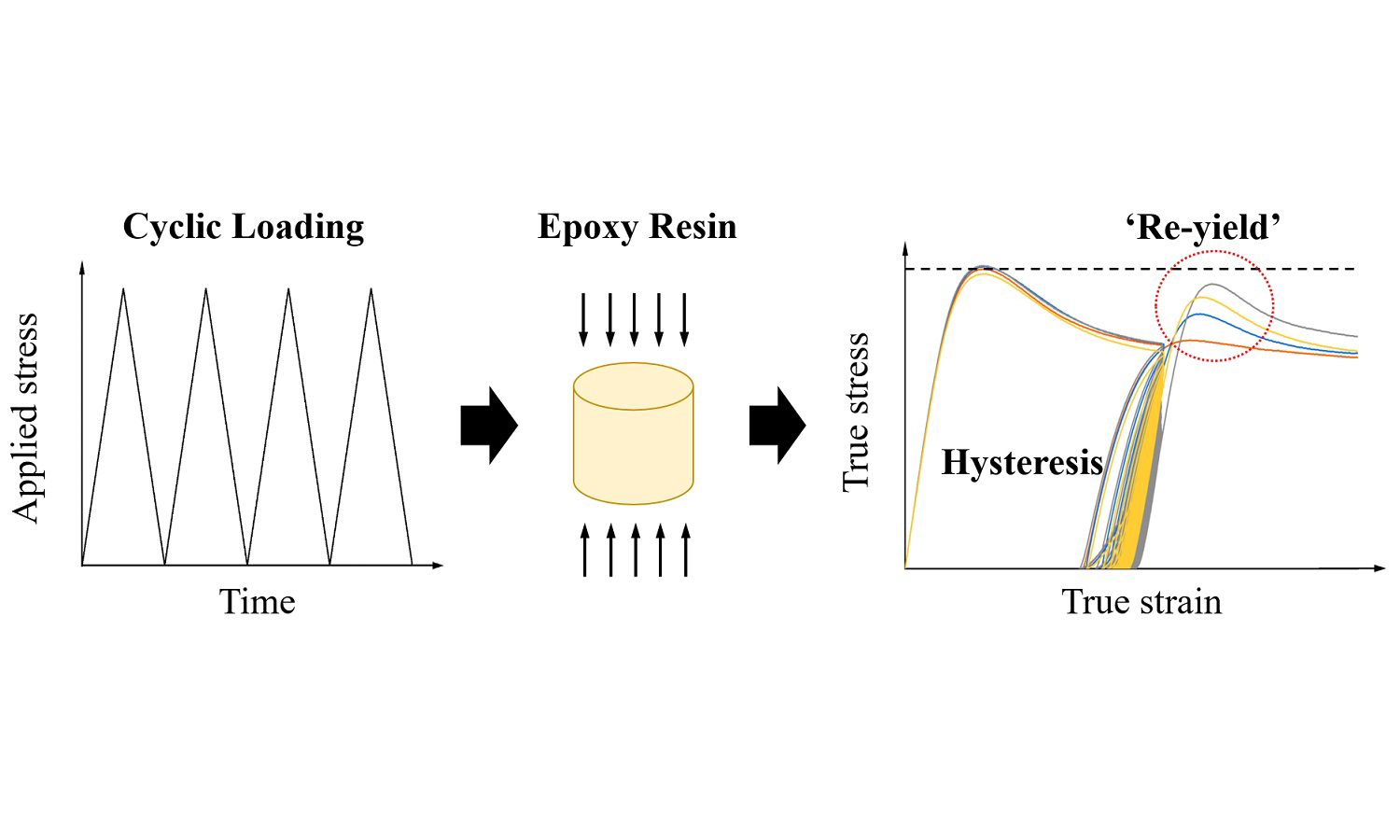

Jingwei Yu, Christian Breite, Frederik Van Loock, Thomas Pardoen, Yentl Swolfs

Vol. 18., No.2., Pages 133-143, 2024

DOI: 10.3144/expresspolymlett.2024.11

Vol. 18., No.2., Pages 133-143, 2024

DOI: 10.3144/expresspolymlett.2024.11

High-performance polymers are extensively used in various applications undergoing long-term cyclic loadings. The deformation behaviour of an amorphous thermoset epoxy resin undergoing cyclic compressive loading is investigated for a range of applied deformation levels. The measurements indicate significant hysteresis upon repeated loading and unloading cycles with progressive accumulation of plastic strain. Cyclic damage leads to a reduction of the stress needed to reach the peak strain per cycle, while cyclic stiffening corresponding to an increase of elastic modulus with increasing number of cycles is observed, attributed to chain orientation effects. The dissipated energy asymptotically decreases to zero under strain-controlled cycling conditions. Interestingly, when monotonically loaded after cycling, the epoxy exhibits an increase in yield strength. This ‘re-yield’ stress level is closely related to the selected value of the peak (unloading) strain level and increases with increasing number of loading cycles.

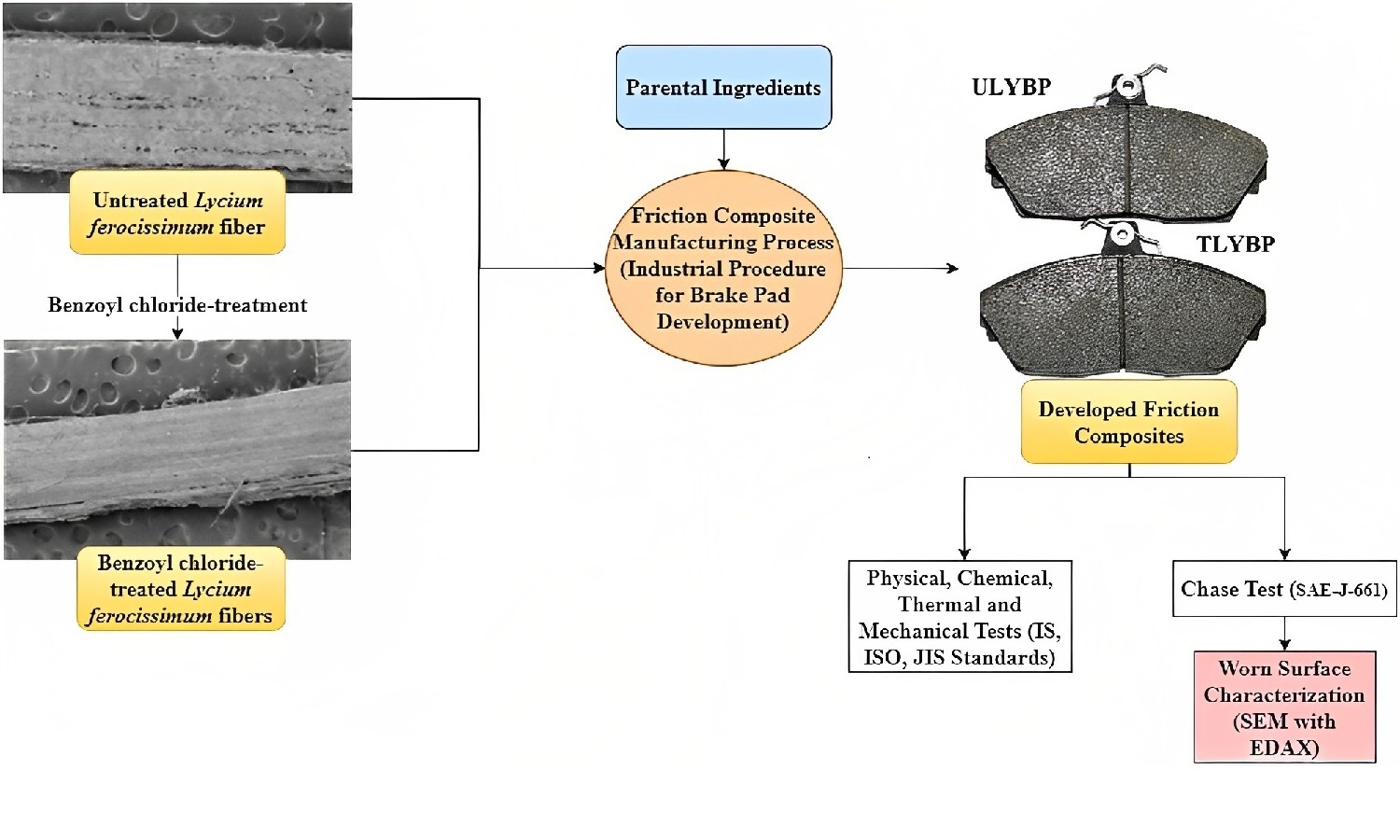

Saikrishnan Ganesh, Jayakumari Lakshmanan Saraswathy, Vijay Raghunathan, Vinod Ayyappan, Sundarrajan Dharmakrishnan, Sanjay Mavinkere Rangappa, Suchart Sienghcin

Vol. 18., No.2., Pages 144-159, 2024

DOI: 10.3144/expresspolymlett.2024.12

Vol. 18., No.2., Pages 144-159, 2024

DOI: 10.3144/expresspolymlett.2024.12

The increase in environmental consciousness and waste-to-wealth concepts in the automobile sector has led to the use of natural fibers in desirable quantities. The current study deals with the extraction, treatment, and utilization of Lycium ferocissimum stem fibers for friction composite in braking applications. The fibers of Lycium ferocissimum were extracted through manual retting and subsequently treated with benzoyl chloride. Both the benzoyl chloride treated and untreated fibers of Lycium ferocissimum were employed as reinforcements in the formulation of a friction composite, following the standard practices of the industry, and the comparison was made using commercially available friction composite. The developed friction composites were tested for original equipment manufacturer quality requirements following industrial Standards. The friction composite’s tribological behavior was analyzed using the Chase test following the Society of Automotive Engineers standards. The worn surface characteristics were analyzed using scanning electron microscope. The test results elucidated that benzoyl chloride-treated Lycium ferocissimum fibers-based friction composites showed good frictional properties with better wear resistance compared to others, having a weight loss of 5.4%.

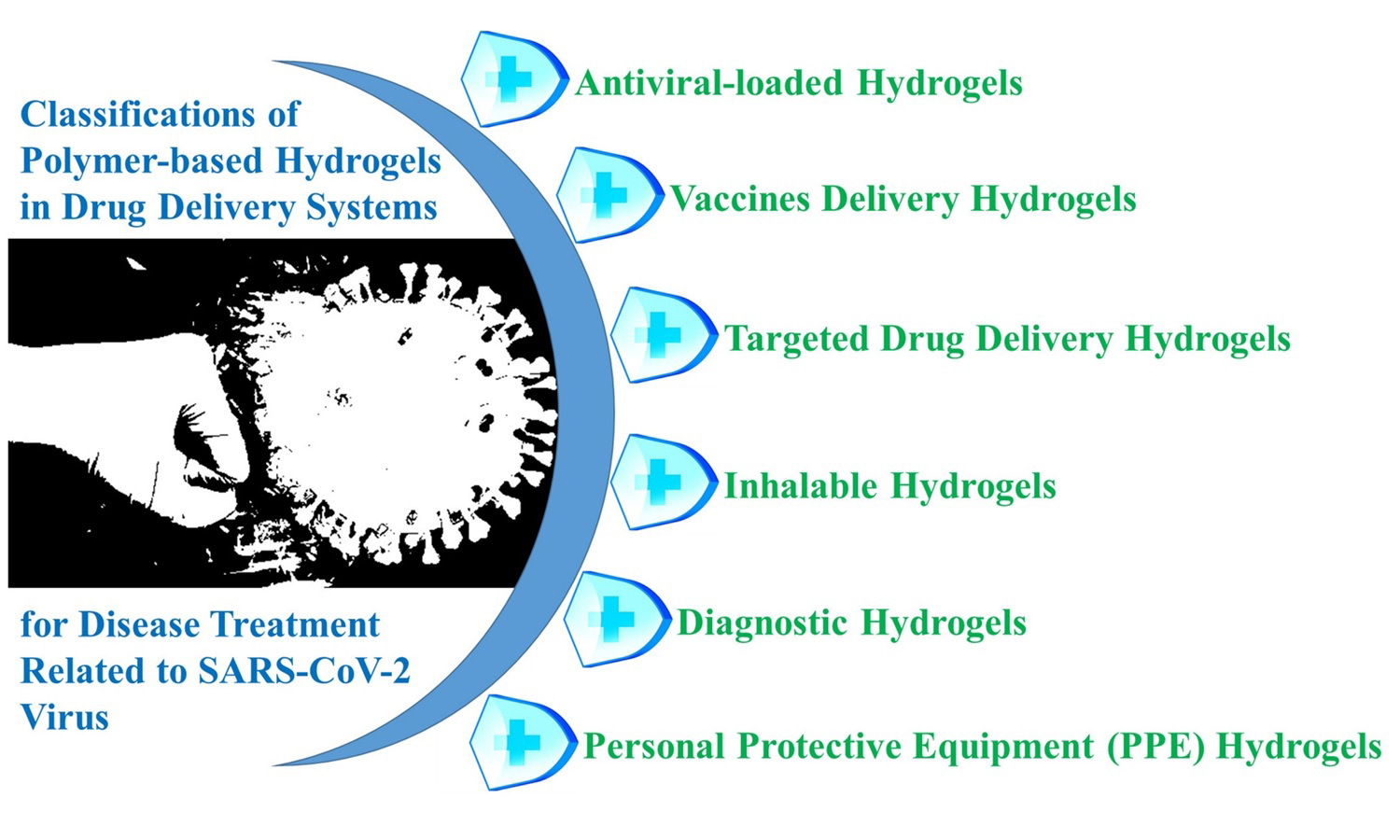

Nguyen Hoc Thang, Nguyen Van Phuc, Tran Thi Tu Nhi, Dang Xuan Cuong, Do Quang Minh

Vol. 18., No.2., Pages 160-192, 2024

DOI: 10.3144/expresspolymlett.2024.13

Vol. 18., No.2., Pages 160-192, 2024

DOI: 10.3144/expresspolymlett.2024.13

Polymer-based hydrogels are hydrophilic polymer networks with a remarkable capacity to absorb substantial amounts of water and biological fluids, rendering them highly attractive for drug delivery applications. The COVID-19 pandemic has acted as a catalyst for research and innovation in the realm of polymer-based hydrogels for drug delivery, with a particular emphasis on antiviral therapeutics, vaccines, diagnostics, and precision delivery to the respiratory system. The distinctive attributes of hydrogels, such as their biocompatibility, customizable drug release profiles, and ease of functionalization, establish them as versatile platforms for the development of advanced drug delivery systems to combat not only COVID-19 but also a spectrum of other infectious diseases. This study is dedicated to scruti-nizing and evaluating the characteristics of polymer-based hydrogels employed in drug delivery for the treatment of diseases associated with the SARS-CoV-2 virus. Furthermore, the investigation introduces a novel classification system for polymer-based hydrogels deployed in drug delivery for SARS-CoV-2-related diseases. Additionally, the paper provides an up-to-date evaluation of the latest developed hydrogels utilized in drug delivery for the treatment of dis-eases linked to the SARS-CoV-2 virus, based on research conducted through the recent months of 2023.

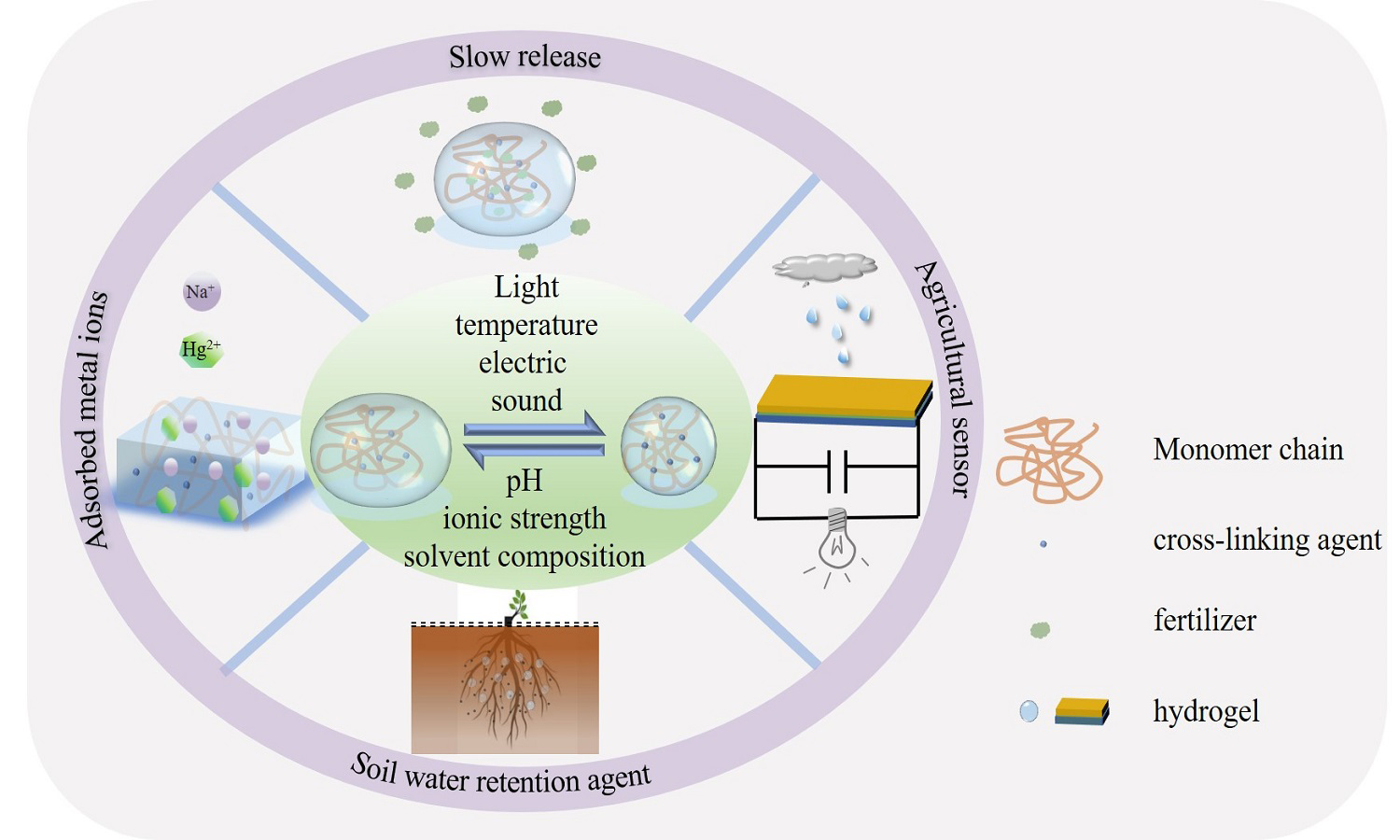

Wenxu Zhang, Xuyang Mu, Yan Xu, Guofu Ma, Ziqiang Lei

Vol. 18., No.2., Pages 193-213, 2024

DOI: 10.3144/expresspolymlett.2024.14

Vol. 18., No.2., Pages 193-213, 2024

DOI: 10.3144/expresspolymlett.2024.14

Environment-responsive hydrogels are environmentally friendly polymeric materials that rapidly respond to their environment by changing their volume or strength when the external environment, such as temperature, pH, light, and magnetism, changes. As environment-responsive hydrogels, they are uniquely flexible and sensitive, enabling them to be used in various applications, and are now at the forefront of polymer science research. Scholars have reviewed more environmentresponsive hydrogels in biomedicine, detection sensors, and drug release. We present a detailed description of the reaction mechanism and preparation process of environment-responsive hydrogels, taking temperature-responsive, pH-responsive, and light-responsive hydrogels as examples. Finally, a summary is given at the end: 1) the application of environmentally responsive hydrogels in agriculture, and 2) the problems and future trends of their application in agriculture.

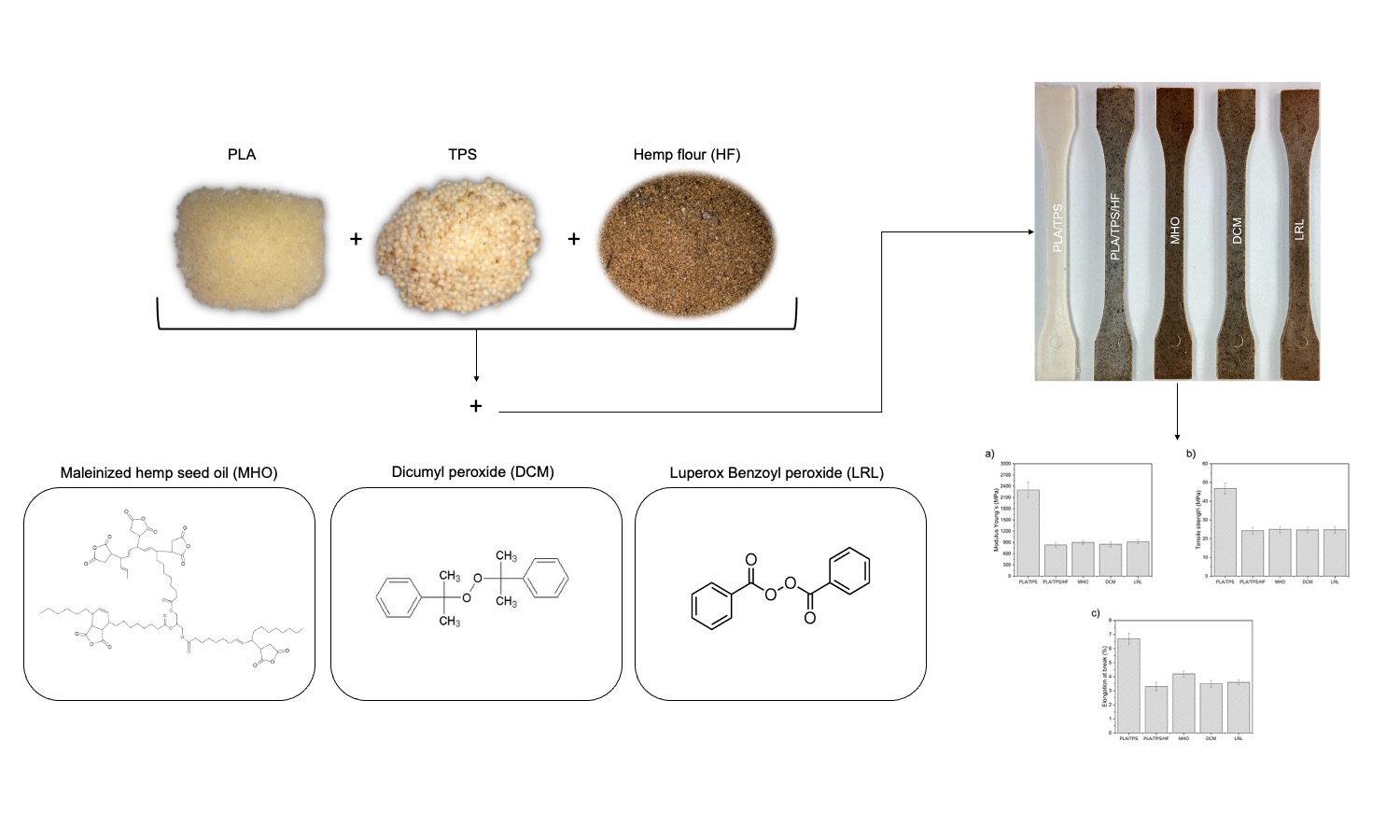

Alejandro Lerma-Canto, Ivan Dominguez-Candela, Jaume Gomez-Caturla, Vicent Fombuena, Daniel Garcia-Garcia

Vol. 18., No.2., Pages 214-228, 2024

DOI: 10.3144/expresspolymlett.2024.15

Vol. 18., No.2., Pages 214-228, 2024

DOI: 10.3144/expresspolymlett.2024.15

In a blend of poly(lactic acid) (PLA) and thermoplastic starch (TPS), a 15% load of hemp seed lignocellulosic filler (HF) was incorporated. Additionally, separate petrochemical-based compatibilizers, such as dicumyl peroxide (DCM) and benzoyl peroxide (LRL), as well as a bio-based compatibilizer, maleinized hemp seed oil (MHO), were introduced. Adding HF to the PLA/TPS blend reduced tensile mechanical properties due to the stress concentration phenomenon arising from the lack of interaction between components, yielding a more brittle material. This issue was mitigated by adding compatibilizers, notably the incorporation of MHO into the PLA/TPS/HF blend this increased elongation at break by enhancing compatibility among the blend components and providing a plasticizing effect. Moreover, regarding thermal properties, it was observed that the inclusion of HF led to a decrease in the glass transition temperature (Tg), cold crystallization temperature (Tcc), and melting temperature (Tm). Conversely, adding MHO to this blend increased all these values compared to the PLA/TPS/HF mixture, attributed to the plasticizing effect imparted by the modified oil. Additionally, following fracture in Charpy impact testing, the samples were subjected to field emission scanning electron microscopy (FESEM) analysis to examine the fractured surface of the various samples.

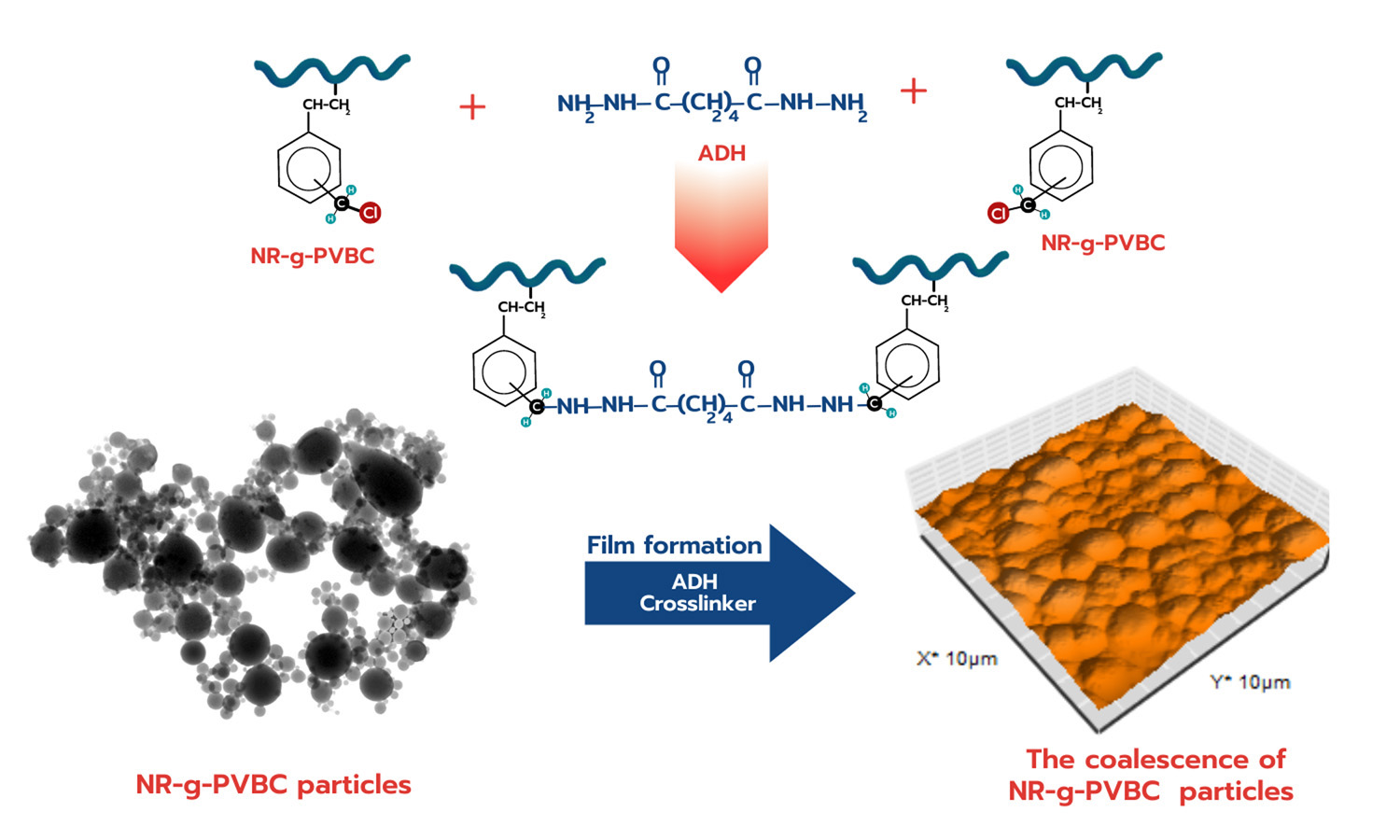

Accelerator and zinc-free prevulcanized latex based on natural rubber-bearing benzyl chloride groups

Anchisa Bunsanong, Bencha Thongnuanchan, Rattanawadee Ninjan, Subhan Salaeh, Natinee Lopattananon, Abdulhakim Masa

Vol. 18., No.2., Pages 229-242, 2024

DOI: 10.3144/expresspolymlett.2024.16

Vol. 18., No.2., Pages 229-242, 2024

DOI: 10.3144/expresspolymlett.2024.16

The present study aimed to prepare prevulcanized latex from modified natural rubber (NR) latex, graft copolymers of natural rubber and poly(vinylbenzyl chloride), NR-g-PVBC. The prevulcanized latex was prepared by heating NR-g-PVBC latex in the presence of adipic acid dihydrazide (ADH). The study showed that the tensile strength of the NR-g-PVBC films with ADH was significantly higher than that without ADH. Interactions of NR-g-PVBC with ADH were further investigated using X-ray photoelectron spectroscopy (XPS). Higher storage modulus (E′) in the rubbery plateau region was also observed for the films with ADH than that without ADH. These results corroborated that the crosslinking reaction occurred in the film with the addition of ADH. It was found that the optimal prevulcanization time was 20 min at 55 °C. After that, the effect of storage on the tensile properties of the prevulcanized latex was studied. Atomic force microscopy (AFM) analysis was performed to follow changes in the surface morphology of films obtained from the prevulcanized latex. A zeta potential value of –37.83 was observed for the prevulcanized latex after being stored for 60 days. Therefore, the present study demonstrated that grafting poly(vinylbenzyl chloride) onto NR particles offered an opportunity to prepare a new type of prevulcanized latex. This new system was accelerator-free and zinc-free, considered more environment-friendly than a sulfur-prevulcanization system.