Content

All issues / Volume 17 (2023) / Issue 4 (April)

Alessandro Pegoretti

Vol. 17., No.4., Pages 352-352, 2023

DOI: 10.3144/expresspolymlett.2023.25

Vol. 17., No.4., Pages 352-352, 2023

DOI: 10.3144/expresspolymlett.2023.25

This is an editorial article. It has no abstract.

Sangilimuthukumar Jeyaguru, Senthil Muthu Kumar Thiagamani, Sanjay Mavinkere Rangappa, Suchart Siengchin

Vol. 17., No.4., Pages 353-372, 2023

DOI: 10.3144/expresspolymlett.2023.26

Vol. 17., No.4., Pages 353-372, 2023

DOI: 10.3144/expresspolymlett.2023.26

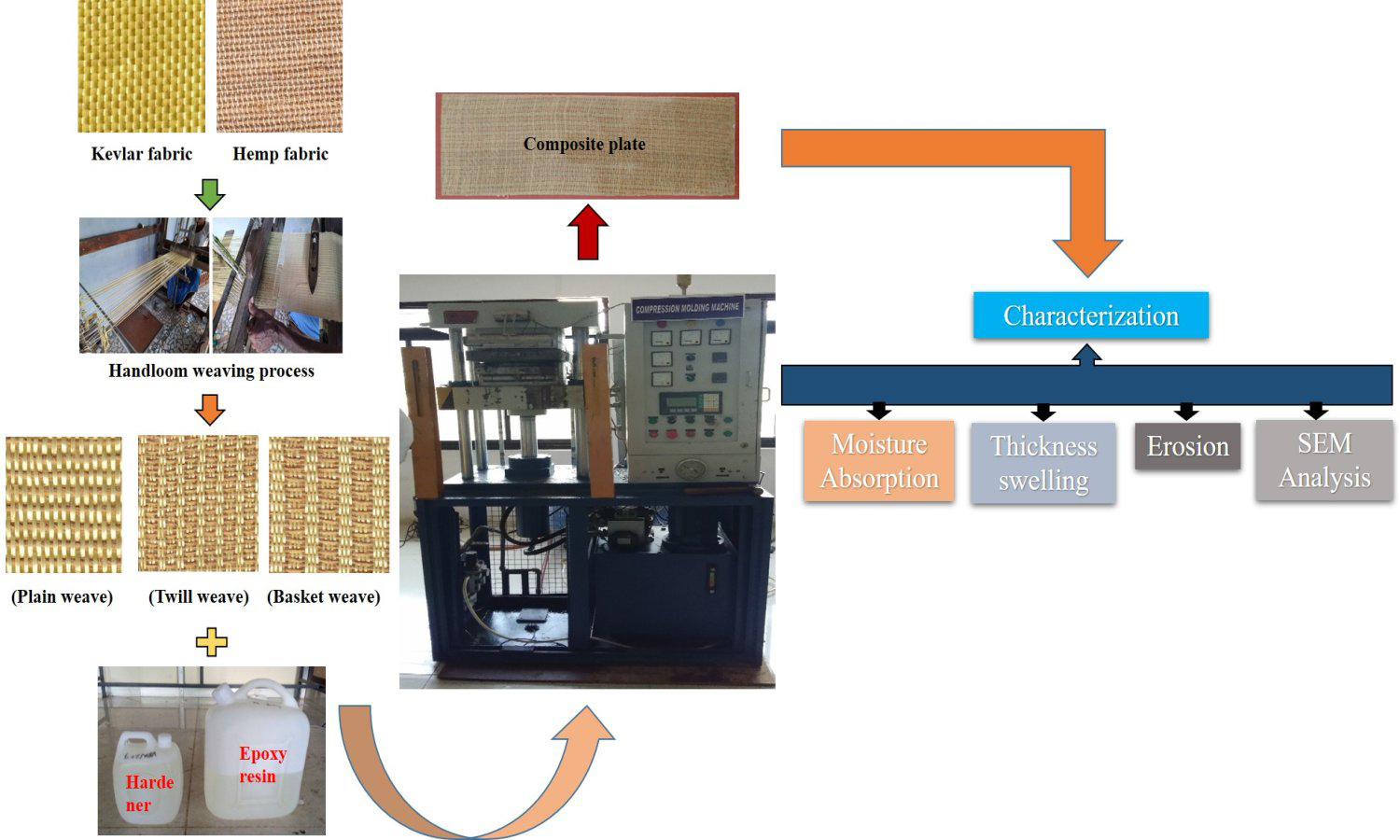

Hybridization of natural and synthetic fibers in a single composite material can be made by several means, and one of the best methods is the intra-ply in which both fibers are woven within a single layer. Through hybridization, the advantages of one type of fiber can improve the limitations of the other. Further the blending of natural and synthetic fibers leads to the fabrication of composites with higher mechanical performance. Hence, this work focuses on the fabrication of intra-ply Kevlar and hemp fiber reinforced epoxy hybrid composites with different weaving patterns such as plain weave, basket weave, and twill weave type. Yarns were woven by handloom technique to make intra-ply Kevlar and hemp fiber mats, and the composites were fabricated by compression molding. The water absorption, thickness swelling, and solid particle erosion characteristics of the composites were examined. The results of the experiments showed that the hemp fiber composites exhibited the least resistance (8.45% change in absorption and 4.34% change in thickness) towards the absorption and swelling, whereas pure epoxy (0.67% change in absorption and 0.31% change in thickness) and Kevlar (2.67% change in absorption and 1.67% change in thickness) composites possessed higher resistance. The absorption and swelling performance of all other hybrids was found to be in between the hemp and Kevlar composites hence proving the effectiveness of the hybridization. Further, Taguchi’s experimental design results indicated that the basket weave type hybrid composites had a minimal erosion rate for 2 minutes of exposure duration and an impact angle of 90°. The morphological analysis of the eroded surfaces of composites revealed the presence of micro cavities, broken fibers, crater formation, and microcracks.

Hosein Pouriman, Richard Lin, Kevin Graham, Krishnan Jayaraman

Vol. 17., No.4., Pages 373-389, 2023

DOI: 10.3144/expresspolymlett.2023.27

Vol. 17., No.4., Pages 373-389, 2023

DOI: 10.3144/expresspolymlett.2023.27

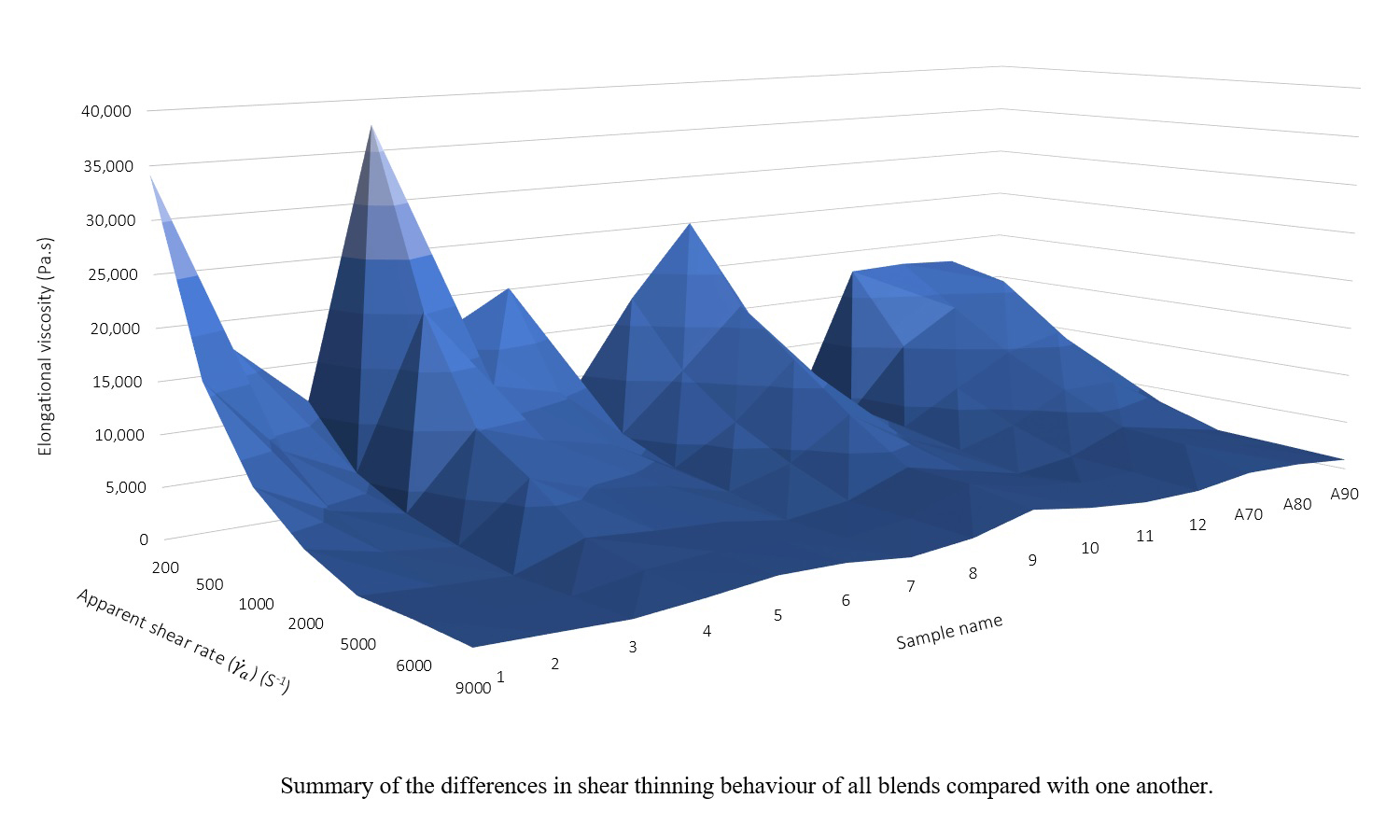

A mathematical Design of Experiments (DOE) was structured to consider the interactive effects of poly(lactic acid) (PLA), poly(3-hydroxybutyrate-co-hydroxyvalerate) (PHBV), triethyl citrate (TC) plasticiser, and epoxy functionalised styrene acrylate (ESA) within the synergistic elongational region of the PLA-PHBV blend (PLA/PHBV of 70/30 to 90/10 ratios). Twelve blends were prepared via twin screw extrusion process. Mixture design showed that PLA and TC content has the highest and ESA content has the lowest total effectiveness. The optimal values for the lowest cost and highest elongation at break and the elongational viscosity were reached at PLA/PHBV/plasticiser/ESA content of 0.574/0.3/0.113/0.012 wt%. Rheological studies showed the blends with the highest elongational viscosity were suitable for blown film extrusion.

Mohit Sood, Chang-Mou Wu

Vol. 17., No.4., Pages 390-405, 2023

DOI: 10.3144/expresspolymlett.2023.28

Vol. 17., No.4., Pages 390-405, 2023

DOI: 10.3144/expresspolymlett.2023.28

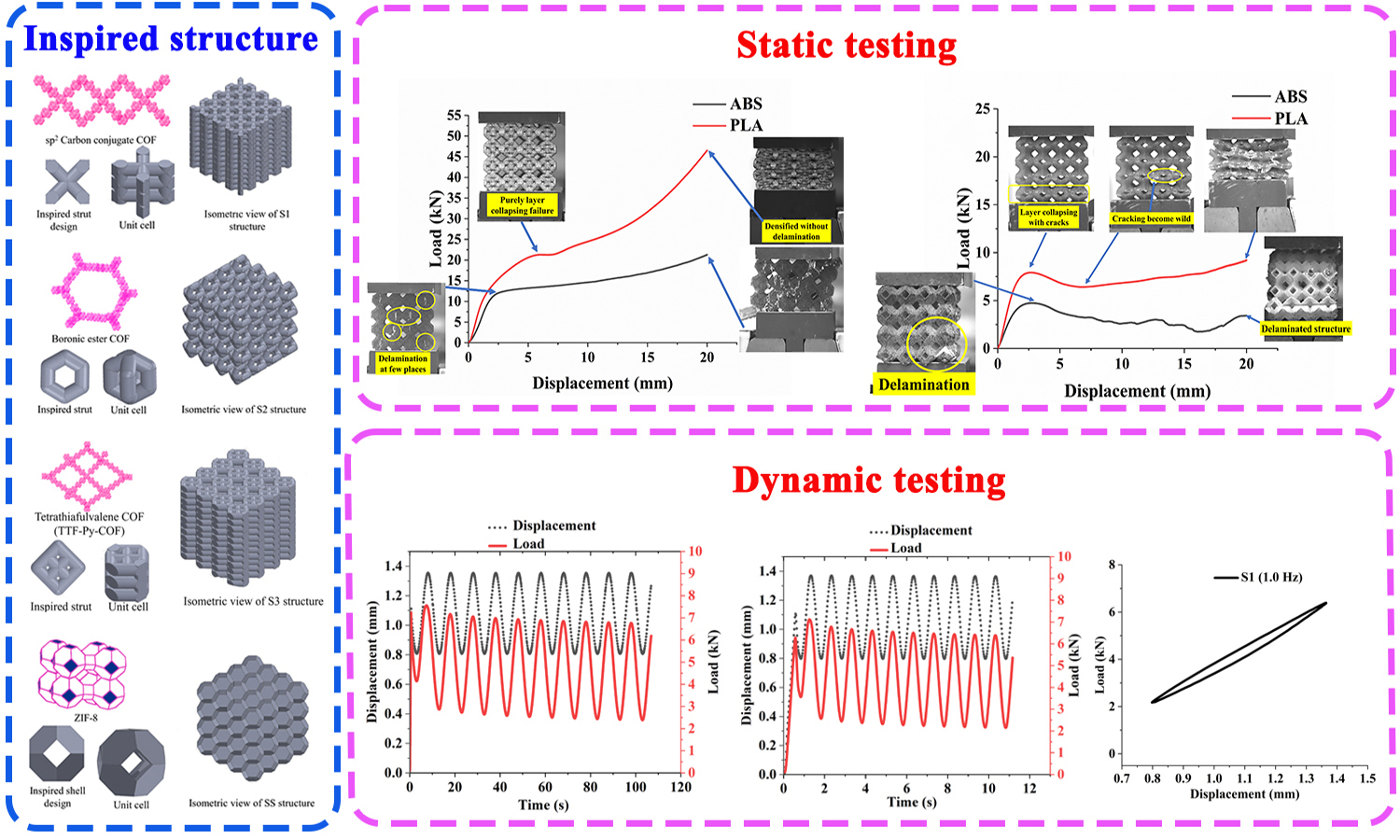

Structural change can alter the energy absorption ability of constituent materials. Carbon organic framework (COF)-inspired structures printed with fusion deposition modeling (FDM) using polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS) polymers are used to analyze the structural effect. Structures were characterized for specific energy absorption under static compression. The best structures from the static testing results were further characterized for dynamic compression using sinusoidal displacement to calculate the dynamic elastic recovery (DER), hysteresis work, and tan δ. Based on the results, the bending-dominated structure absorbed the highest energy, and the surface structure provided the best DER. The structure which failed by the pure collapsing of the layer showed the best specific values. The delamination of printed layers during loading reduced the performance of structures despite of the materials.

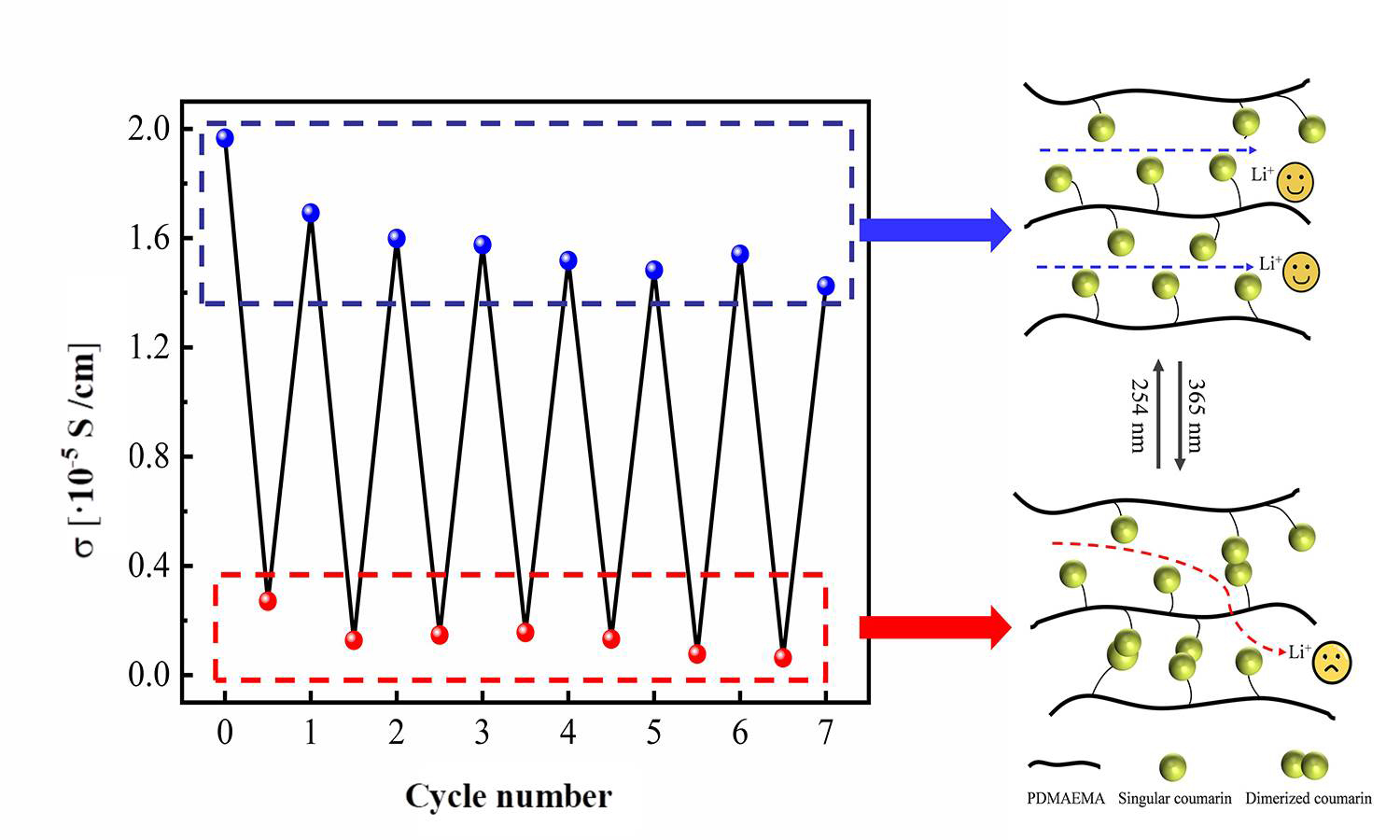

Wangjie Xu, Ming Zhang, Yijun Chen, Qinghua Tian, Xianjing Zhou, Li Zhang, Xinping Wang, Wei Zhang

Vol. 17., No.4., Pages 406-416, 2023

DOI: 10.3144/expresspolymlett.2023.29

Vol. 17., No.4., Pages 406-416, 2023

DOI: 10.3144/expresspolymlett.2023.29

Poly(ionic liquid)s (PILs) are promising candidates used as solid electrolytes because of their excellent electrochemical properties and improved processability. Introducing light-sensitive groups to PILs appears as an attractive strategy for developing novel smart PIL-based electronic devices. In this work, a new photoresponsive PIL-based solid electrolyte was prepared by blending PILs containing coumarin groups (COU-PILs) with polyvinylidene fluoride hexafluoropropylene. It was found that the ionic conductivity of COU-PIL solid electrolytes (COU-PIL SEs) can be reversibly modulated upon alternative 365 and 254 nm light irradiation. In particular, the COU-PIL SEs exhibit a highly reversible and repeatable manipulation of ionic conductivity with a maximum conductivity modulation of 95%. This reversible control over ionic conductivity is attributed to the photodimerization/photocleavage behavior of the coumarin groups.

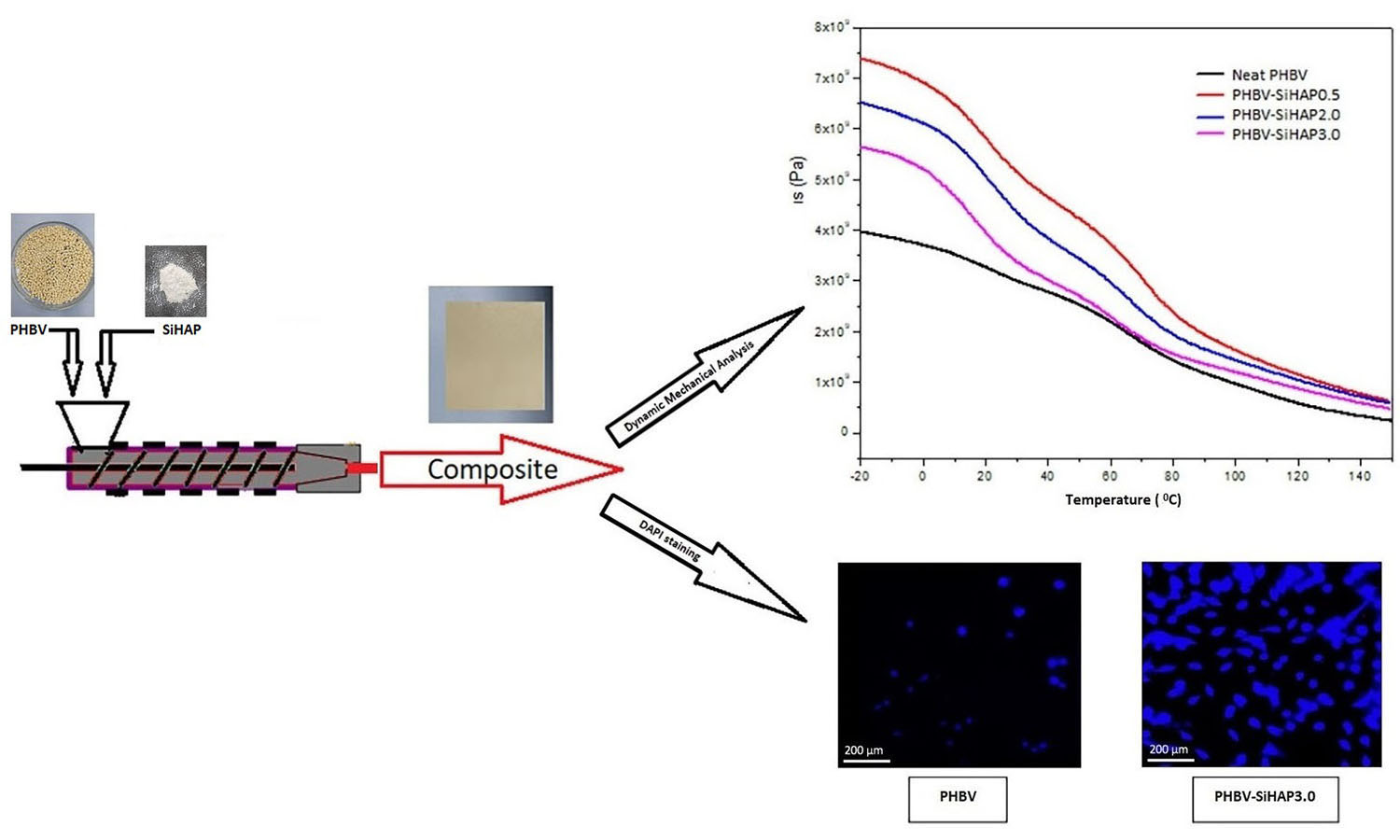

Mualla Öner, Semra Kirboga, Emrah Sefik Abamor, Kubra Karadas, Zeynep Kral

Vol. 17., No.4., Pages 417-433, 2023

DOI: 10.3144/expresspolymlett.2023.30

Vol. 17., No.4., Pages 417-433, 2023

DOI: 10.3144/expresspolymlett.2023.30

In this study, silicon-doped hydroxyapatite (SiHAP) nanoparticles and poly(hydroxybutyrate-co-3-hydroxyvalerate, PHBV) were used to develop biodegradable ‘green’ composites due to their intrinsic biodegradability and biocompatibility properties. The novel bionanocomposites were prepared by melt compounding with 0.5, 2, and 3 wt% of SiHAP content. The fracture surface of the bionanocomposites samples from scanning electron microscopy (SEM) exhibited good dispersion of SiHAP in the PHBV matrix at 0.5 wt%. X-ray diffraction (XRD) measurements showed an enhancement of the crystallinity of the PHBV matrix, thereby acting as a nucleating agent, increasing polymer crystallinity from 50 to up to 73% at 3 wt% loadings. Dynamic mechanical analysis (DMA) was used to measure the composite and neat samples’ storage modulus, loss modulus, and damping factor under an oscillating load. DMA analysis showed an increase in storage modulus of 80% at 20 °C and 0.5 wt% SiHAP loadings. Thermal gravimetric analysis (TGA) results showed that the thermal stability of PHBV is slightly decreased by adding 2 and 3 wt% SiHAP. 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) Assay and 4′,6-diamidine-2′-phenylindole dihydrochloride (DAPI) staining experiments have demonstrated that PHBV/SiHAP composites exhibit good in vitro bioactivity due to the silicon-doped hydroxyapatite nanoparticles. It is concluded that the addition of SiHAP can be a viable strategy for obtaining novel bioactive and biodegradable nanocomposites with improved mechanical and biological properties for potential medical application.

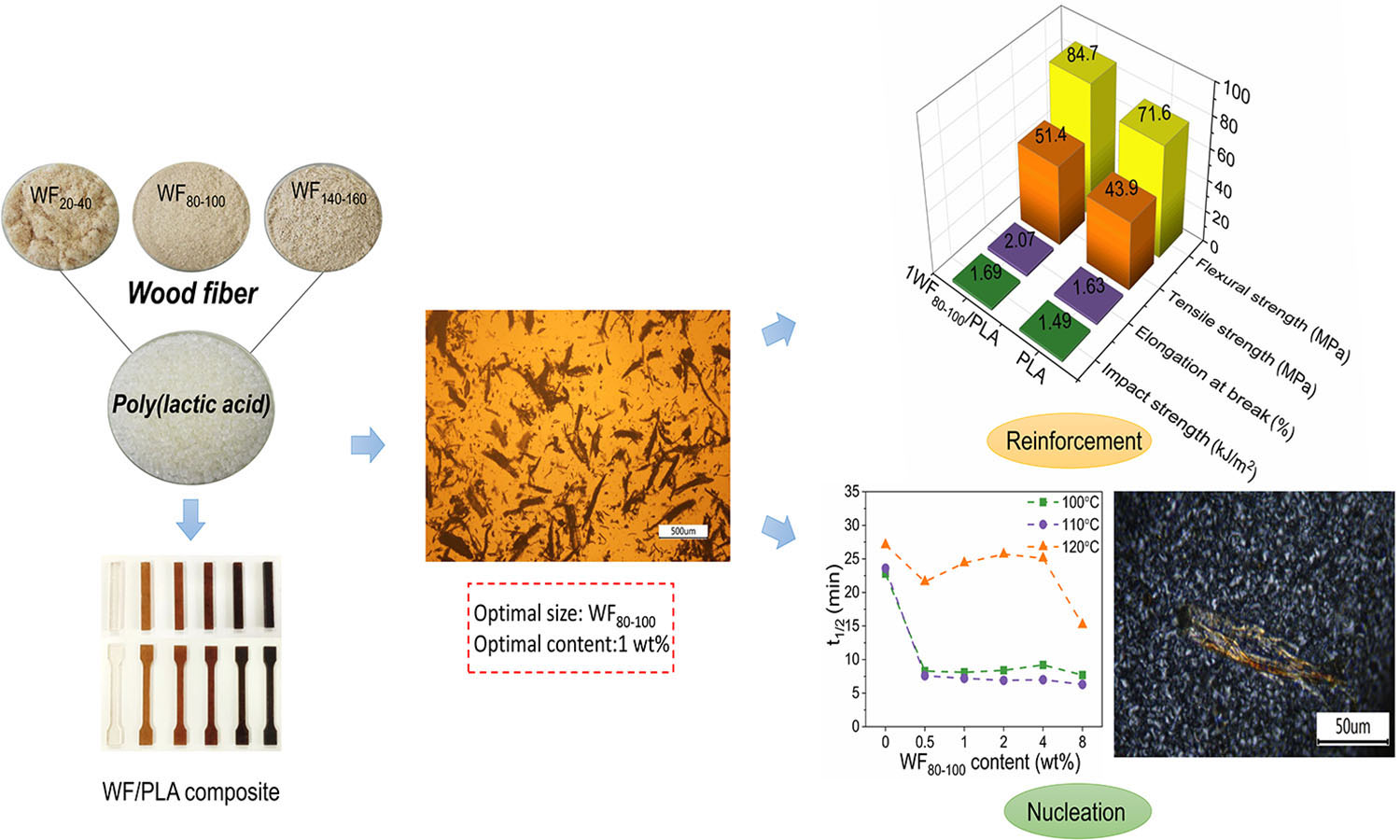

Chao Lv, Shupin Luo, Wenjing Guo

Vol. 17., No.4., Pages 434-448, 2023

DOI: 10.3144/expresspolymlett.2023.31

Vol. 17., No.4., Pages 434-448, 2023

DOI: 10.3144/expresspolymlett.2023.31

Biodegradable plastics such as poly(lactic acid) (PLA) are gaining considerable interest as promising substitutes for conventional petroleum-based plastics due to ecological, health, and environmental concerns. PLA possesses good biodegradability and biocompatibility but is limited by its slow crystallization rate, low impact resistance, and high costs. In this study, a small amount of natural wood fiber (WF) was incorporated into PLA to improve mechanical and crystallization properties as well as cost reduction. The effects of WF size (20–40, 80–100, and 140–160 mesh) and loading content (0.5–8 wt%) on the mechanical and crystallization properties were investigated and compared. Results indicated that WF of 80–100 mesh (WF80-100) exhibited a better reinforcement effect on PLA than the other two sizes of WF. The optimal loading content for WF80-100 was 1 wt%, at which the flexural and tensile strength increased by about 18% compared to neat PLA, and the elongation at break increased by 27%. Moreover, the degree of crystallinity and crystallization rate significantly increased with the addition of WF80-100. Polarized optical microscopy observation revealed that the number of spherulites increased in 1WF80-100/PLA composite and the spherulite size decreased compared to neat PLA. These findings confirmed that WF, even at a low addition level, could act as both a reinforcement material and an efficient nucleating agent for PLA, which is closely related to its size.

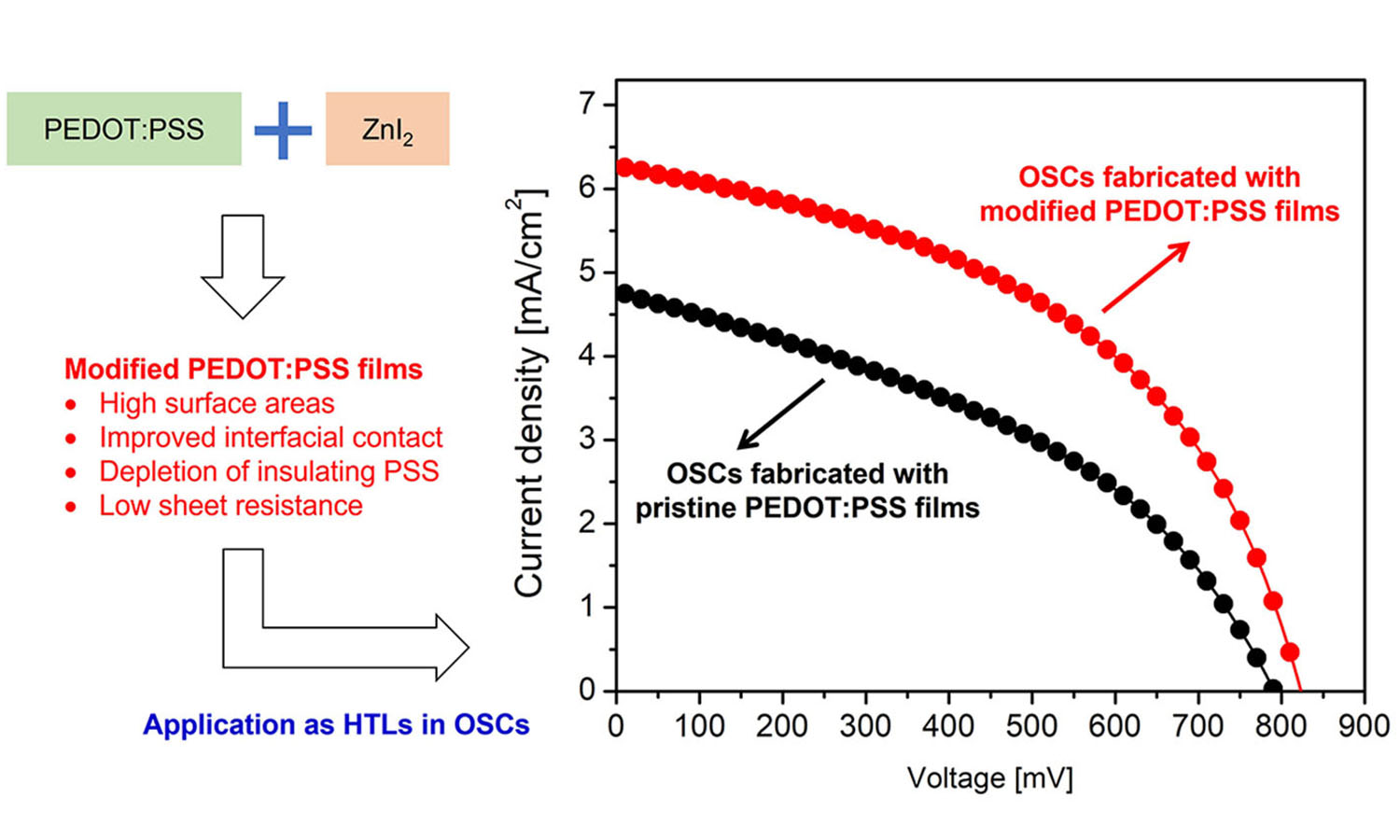

Sucheewan Krobthong, Sutthipoj Wongrerkdee, Sawitree Wongrerkdee, Khathawut Lohawet, Anusit Kaewprajak, Pisist Kumnorkaew

Vol. 17., No.4., Pages 449-456, 2023

DOI: 10.3144/expresspolymlett.2023.32

Vol. 17., No.4., Pages 449-456, 2023

DOI: 10.3144/expresspolymlett.2023.32

Organic solar cells (OSCs) fabricated with poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) films often have limited performance due to high sheet resistances since commercial PEDOT:PSS contains a high insulating PSS to conducting PEDOT ratio. To resolve this issue, zinc iodide (ZnI2) additive was utilized to modify PEDOT:PSS films, which was carried out by mixing ZnI2 with PEDOT:PSS solution. The mixture was deposited on a fluorine-doped tin oxide substrate to derive the modified PEDOT:PSS films for application as a hole-transporting layer in OSCs. This resulted in an enhanced power conversion efficiency for OSCs fabricated with modified PEDOT:PSS films. The enhancement was primarily due to the improved PEDOT:PSS/PCDTBT:PC70BM (poly[N-9′-heptadecanyl-2,7-carbazole-alt-5,5-(4′,7′-di-2-thienyl-2′,1′,3′-benzothiadiazole)] – PCDTBT, [6,6]-phenyl-C71-butyric acid methyl ester – PC70BM) interfaces, which facilitates enhanced hole collection performance and results in a high current density for OSC devices. Moreover, the ZnI2 plays a role in the depletion of insulating PSS from the film’s surface. This behavior causes lower sheet resistance and results in an increased Jsc and Voc for OSC devices. Therefore, the improved interfacial contact and depletion of PSS are considered synergistic functions for OSC enhancement.