Content

All issues / Volume 17 (2023) / Issue 2 (February)

Kalappa Prashantha, Krishnappa Amita

Vol. 17., No.2., Pages 118-119, 2023

DOI: 10.3144/expresspolymlett.2023.9

Vol. 17., No.2., Pages 118-119, 2023

DOI: 10.3144/expresspolymlett.2023.9

This is an editorial article. It has no abstract.

Shritama Mukherjee, Samrat Mukhopadhyay

Vol. 17., No.2., Pages 120-151, 2023

DOI: 10.3144/expresspolymlett.2023.10

Vol. 17., No.2., Pages 120-151, 2023

DOI: 10.3144/expresspolymlett.2023.10

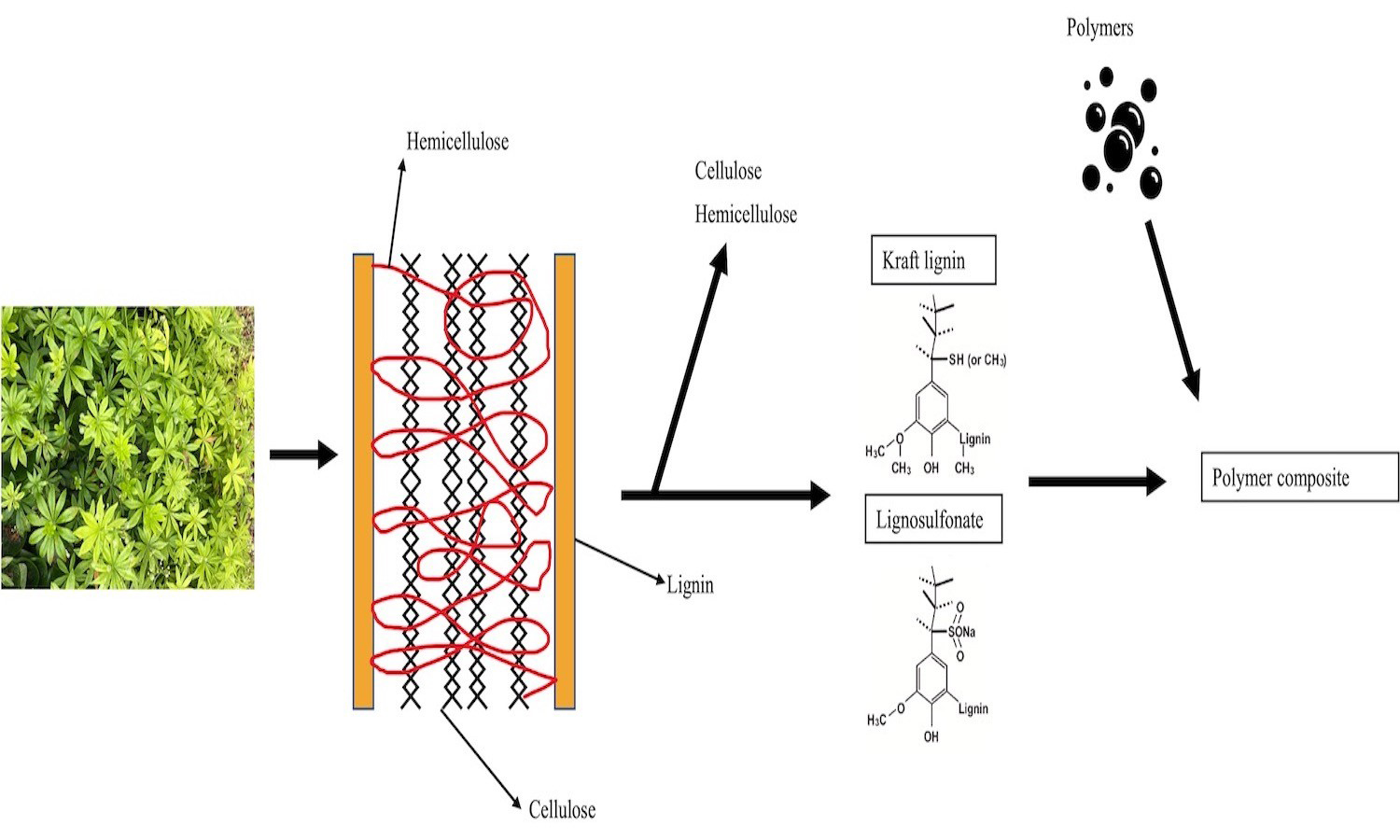

The aromatic biopolymer lignin, present in lignocellulosic material, can act as an antioxidant and has antimicrobial and UV blocking properties due to the presence of aromatic ring and phenolic hydroxyl groups with aliphatic hydroxyl, carboxyl, methoxy groups. It is produced in huge amounts as a by-product during the delignification process in the paper and pulp industries. Lignin-based polymer composites with advantageous properties can fulfill the growing demand for lightweight polymer composites. Incorporating lignin as reinforcement in polymer composite can make it more environmentally friendly. Among four technical lignin, kraft lignin and lignosulfonate have a unique molecular structure that includes sulfur and can be extracted from black liquor and spent liquor, respectively. Moreover, the negatively charged sulfite groups in lignosulfonate can have an electrostatic attraction to a wide range of positively charged polymers and materials, making it an ideal additive for the adsorbent material. The main intention of this review is to increase the knowledge on the use of cheap and widely available kraft lignin and lignosulfonate as reinforcement in polymer composites and to find the shortcomings to advance further research on the application of technical lignin. The article mainly focuses on advancements in kraft lignin and lignosulfonate polymer composites.

Varikkadinmel Binaz, Kaushik Deepak, Inderdeep Singh

Vol. 17., No.2., Pages 152-168, 2023

DOI: 10.3144/expresspolymlett.2023.11

Vol. 17., No.2., Pages 152-168, 2023

DOI: 10.3144/expresspolymlett.2023.11

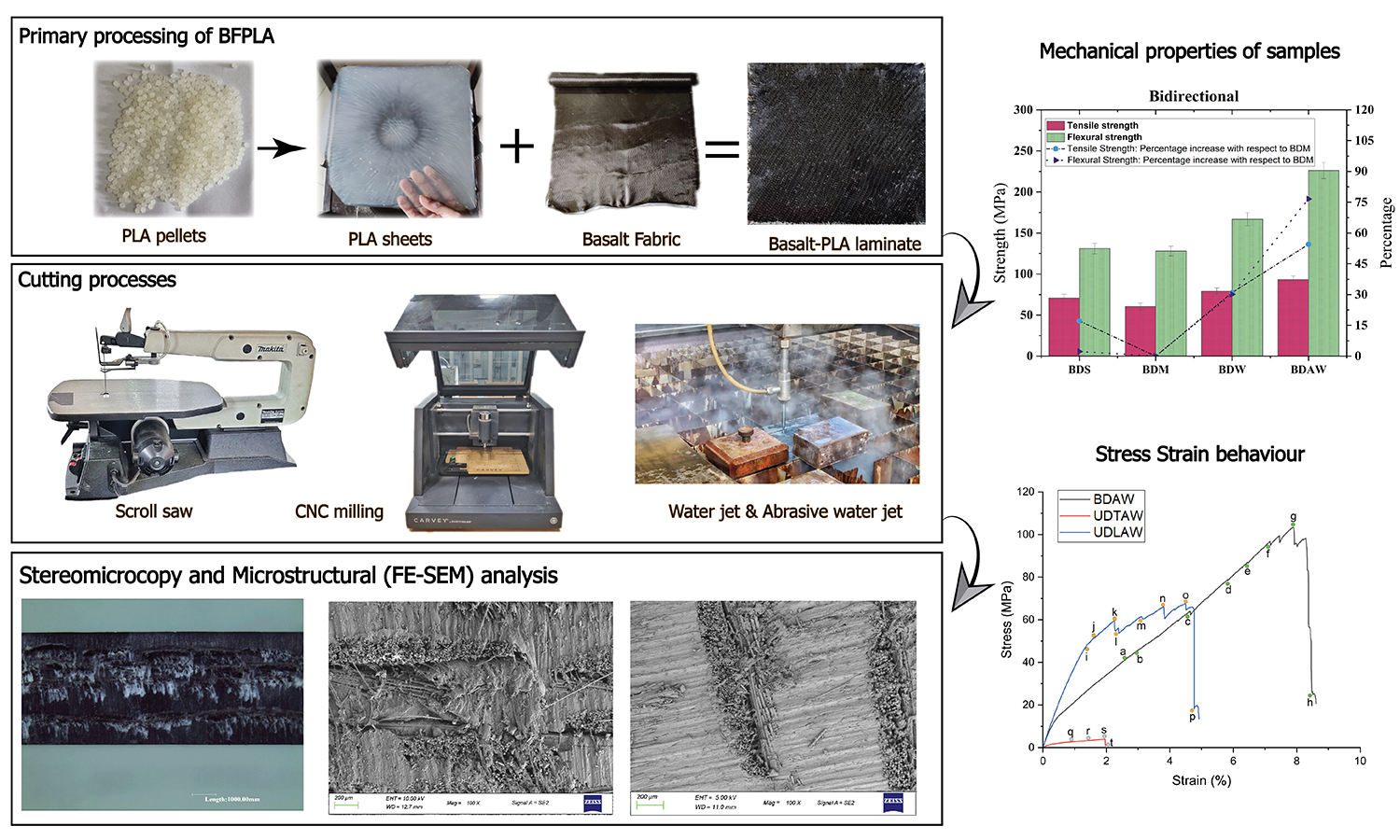

To be used in semi-structural applications, the components of sustainable composites must have good mechanical properties and excellent dimensional/geometrical integrity, both of which are influenced by secondary processing techniques. Less emphasis has been placed on the development, mechanical/microstructural characterization, and secondary processing of sustainable basalt fiber/poly(lactic acid) composites (BFPLA), which can be an excellent choice for semi-structural applications. The present investigation aims to determine the best cutting process to create samples from BFPLA, as well as to experimentally evaluate the effect of different cutting processes (scroll sawing, computer numerical control (CNC) milling, water jet cutting, and abrasive water jet cutting (AWJ)) on the tensile and flexural properties of samples. Stereomicroscopy and field-emission scanning electron microscope (FE-SEM) are used to assess and correlate the influence of surface defects caused by cutting methods with mechanical behavior. AWJ machining consistently generated uniform surface profiles across all specimens, with minimum thermal degradation and fiber roll-out. Compared to the tensile strength values of unidirectional longitudinal, transversal, and bidirectional samples cut using milling, AWJ specimens exhibited a percentage increase of 27.9, 70.2, and 54.4%, respectively. It has been concluded that the choice of cutting technique has a significant impact on the strength of cut samples.

Nóra Lukács, Kata Enikő Decsov, Béla Molnár, Ferenc Ronkay, Katalin Bordácsné Bocz

Vol. 17., No.2., Pages 169-180, 2023

DOI: 10.3144/expresspolymlett.2023.12

Vol. 17., No.2., Pages 169-180, 2023

DOI: 10.3144/expresspolymlett.2023.12

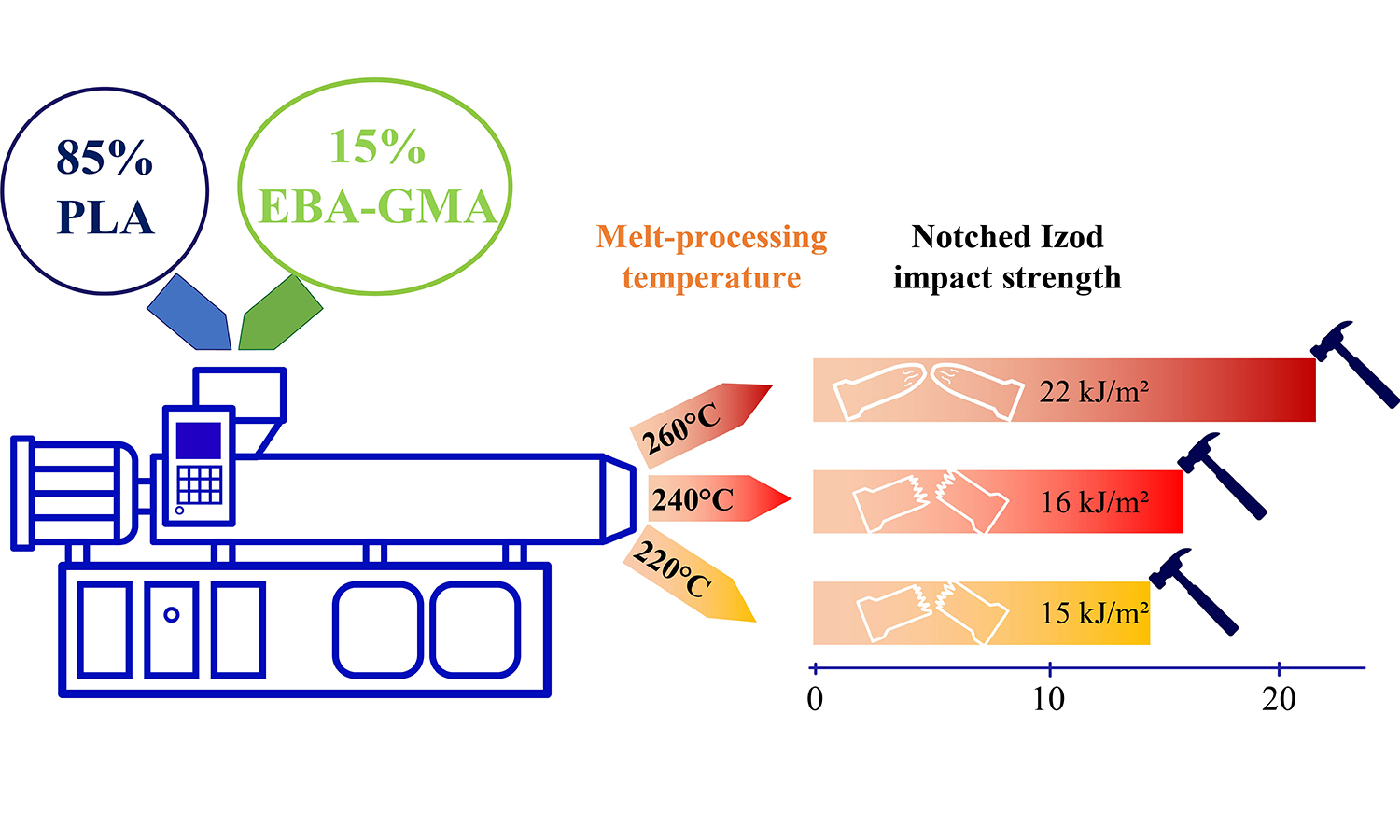

Toughening efficiency of poly(ethylene-n-butylene-acrylate-co-glycidyl methacrylate) (EBA-GMA) in poly(lactic acid) (PLA) matrix has been found to significantly increase at elevated blending temperature. In the case of PLA/EBAGMA blends having 10.0 or 12.5 wt% EBA-GMA contents, the accelerated PLA degradation at raised processing temperature resulted in reduced mechanical performance. At 15.0 wt% EBA-GMA ratio, however, increased elongation and by 250% improved notched Izod impact strength was achieved when the blending temperature was raised from 240 to 260 °C. This beneficial effect is attributed to the accelerated compatibilization reactions between the components in the presence of shortchain PLA molecules, which allow the rapid formation of a toughening enhancer interphase (TEI) during melt processing. As a result, the brittle-ductile transition can be reached at lower elastomer content than expected. Decreased melt flow index (MFI) values besides stabilized blend morphology indicated efficient PLA–EBA-GMA compatibilization at elevated processing temperature. Accordingly, enhanced nucleation ability of the PLA/EBA-GMA interphase and hindered chain crystallization of PLA were found by differential scanning calorimetry (DSC) analyses. In association with the intensified compatibilization reactions cross-linking of the terpolymer was also revealed using the thermally stimulated depolarization current (TSDC) technique.

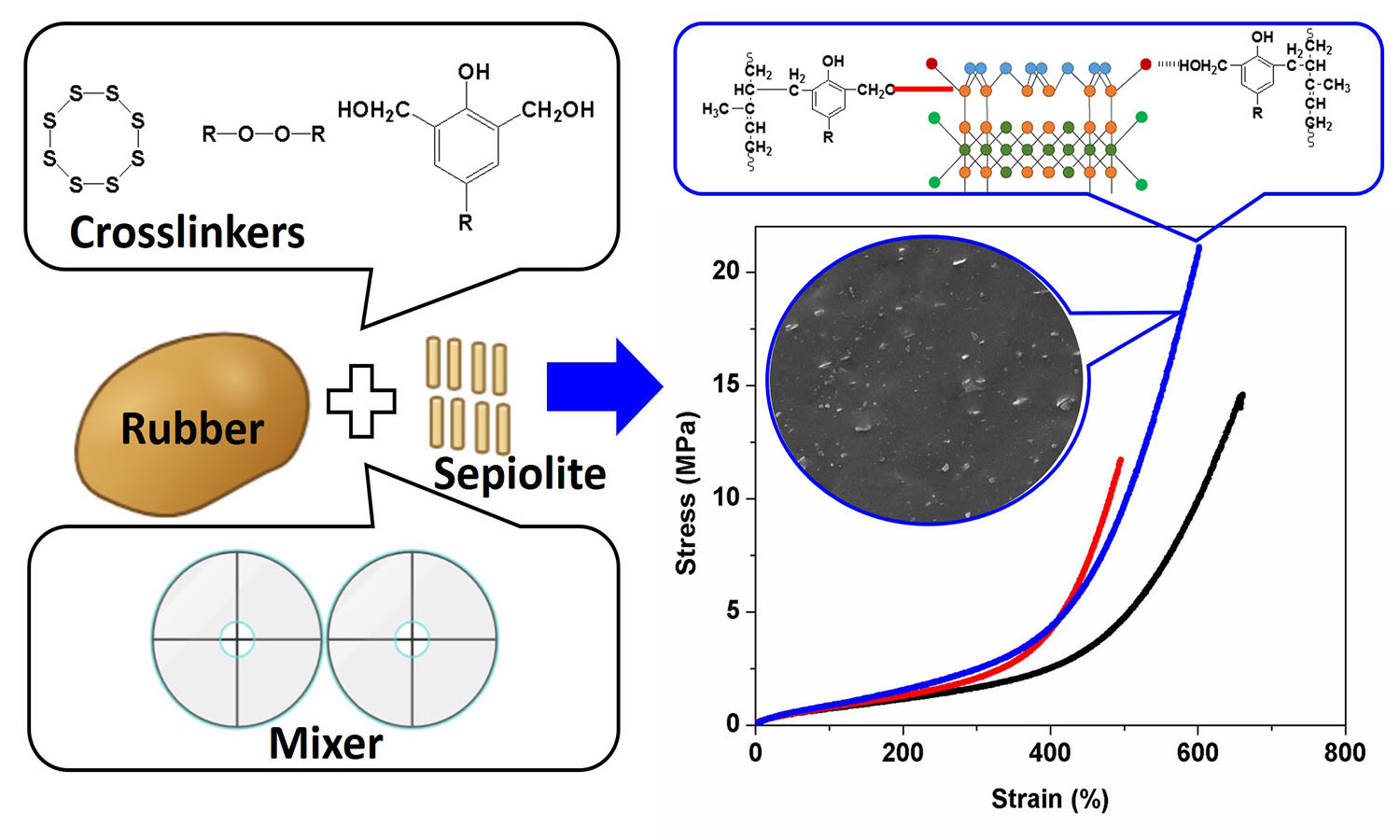

Nabil Hayeemasae, Siriwat Soontaranon, Abdulhakim Masa

Vol. 17., No.2., Pages 181-195, 2023

DOI: 10.3144/expresspolymlett.2023.13

Vol. 17., No.2., Pages 181-195, 2023

DOI: 10.3144/expresspolymlett.2023.13

This study aimed to explore the best cross-link agent for preparing natural rubber (NR) composites containing sepiolite as filler. Three types of vulcanizing agents, namely, sulfur, peroxide, and phenolic resin, were employed, and their effects on the thermomechanical and mechanical properties and microstructures were investigated. Compared to other vulcanizing agents, the greatest thermomechanical and mechanical properties improvement was achieved by using phenolic resin as a crosslinker. The highest tensile stress and tensile strength improvement were also achieved from the phenolic resin system. Tensile strength was improved by approximately 78%, nearly twice as much as that in the sulfur system. Such drastic improvement was attributed to the combined effect of homogeneity dispersion and strong adhesion between rubber and filler, as revealed by Fourier-transform infrared spectroscopy, facilitating the strain-induced crystallization process in NR. The phenolic resin was the best vulcanizing agent for preparing NR/sepiolite composites.

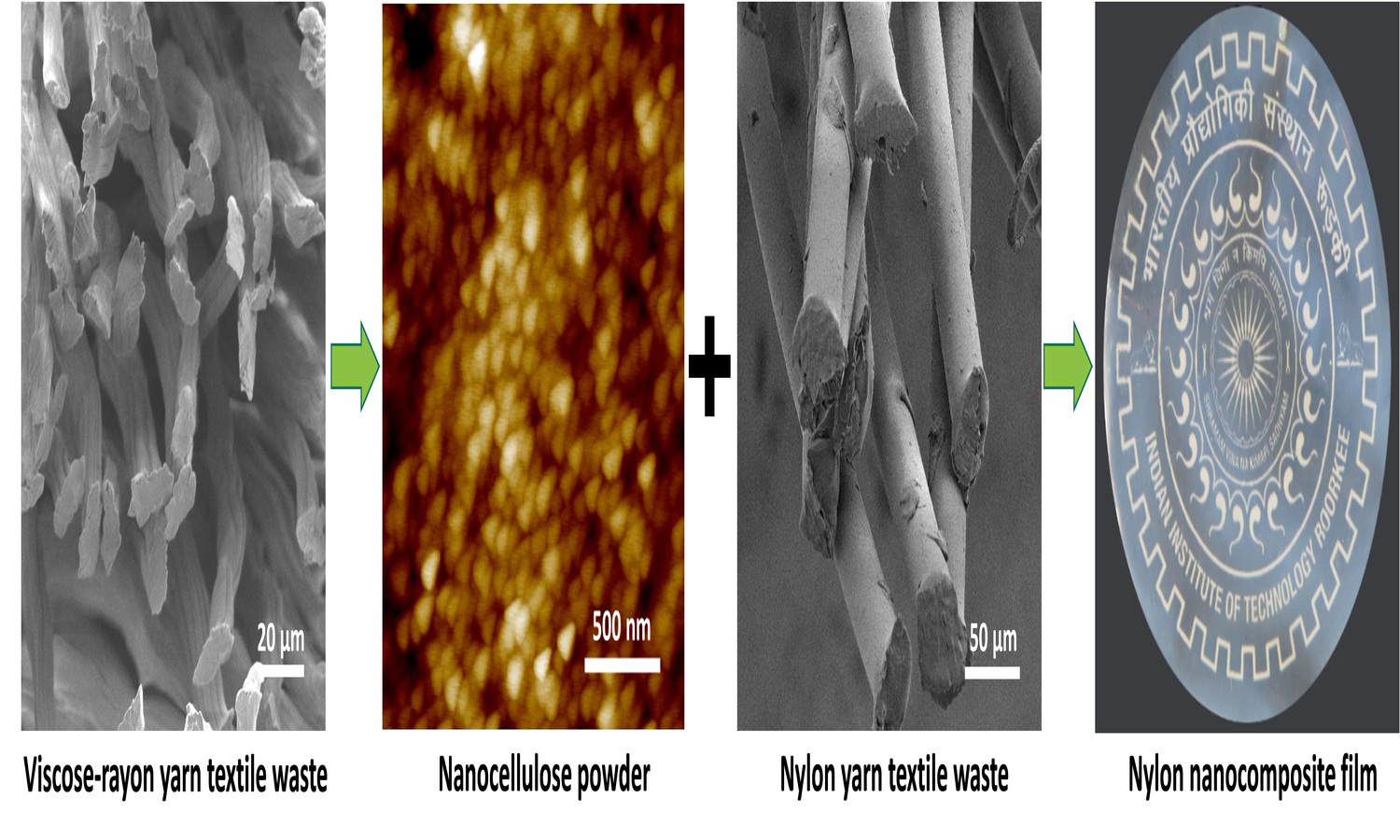

Prince Kumar Mishra, Arihant Ahuja, Bhupender Kumar Mahur, Vibhore Kumar Rastogi

Vol. 17., No.2., Pages 196-210, 2023

DOI: 10.3144/expresspolymlett.2023.14

Vol. 17., No.2., Pages 196-210, 2023

DOI: 10.3144/expresspolymlett.2023.14

In this work, two types of pre-consumer textile waste, namely, viscose-rayon and nylon yarn, were utilized for nanocomposite filmmaking using the green solvent casting method. The nanocellulose was extracted from the viscose-rayon and incorporated as a filler in nylon films. The effects of nanocellulose on thermal, chemical, mechanical, structural, and barrier properties of films containing 0.1, 0.5, and 1 wt% nanocellulose were investigated in detail. The thermal study of films using differential scanning calorimetry (DSC) confirmed that adding nanocellulose into the nylon matrix does not act as a nucleating agent as nylon yarn waste already had ~5 wt% nucleating agents (thermogravimetric analysis, TGA). Rather, a decrease in the crystallinity of films was determined with the addition of nanocellulose. No significant changes in the mechanical properties were observed for nylon nanocomposite films. However, an increased hydrogen bonding was observed between the nanocellulose and nylon, along with the reorientation of hydrogen bonds (Fourier-transform infrared spectroscopy, FTIR). A dense cross-section and structured surface were observed in the scanning electronmicroscopic (SEM) images for nanocomposite films. The water vapor barrier of films increased as the concentration of nanocellulose increased in the nylon films and resulted in a 55% decrease in water vapor transmission rate (WVTR) compared to neat nylon film.

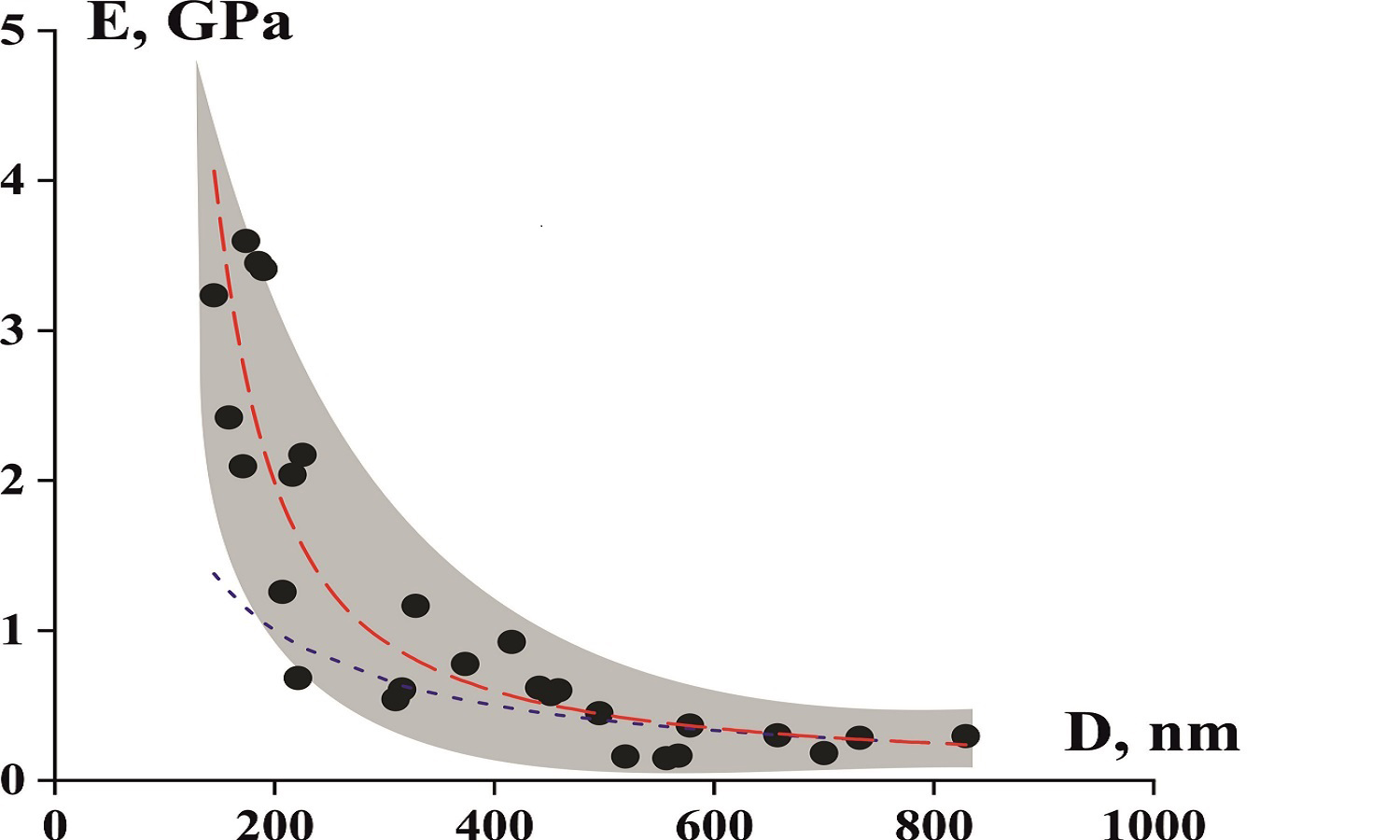

Andrei V. Subbotin, Alexander Ya. Malkin, Andrei V. Andrianov, Valerii G. Kulichikhin

Vol. 17., No.2., Pages 211-217, 2023

DOI: 10.3144/expresspolymlett.2023.15

Vol. 17., No.2., Pages 211-217, 2023

DOI: 10.3144/expresspolymlett.2023.15

The problem of the size dependence of physical properties is one of the most intriguing when we transit to the nano-level. Experiments have shown that this effect is characteristic of the elastic modulus of many polymeric nanofibers obtained by electrospinning. Existing explanations of this effect did not offer a general understanding of the physical nature of this phenomenon. In this study, we propose a universal model of this phenomenon. We consider the structure of fibers within the framework of the core-shell model, in which the shell is approximated by a thin elastic surface. The analysis of deformation is based on the fundamental laws of the mechanics of deformation of twisted thin shells and, unlike the theories proposed earlier, does not require any additional artificial arguments. This approach made it possible to obtain a simple analytical expression for the size dependence of the elastic modulus, which represents it as the sum of the bulk modulus of the core and two additional moduli proportional to D–1 and D–3, respectively. The resulting model corresponds to all available (from published sources) experimental data, related to polymer of very different chemical structure, and therefore can be considered as universal.

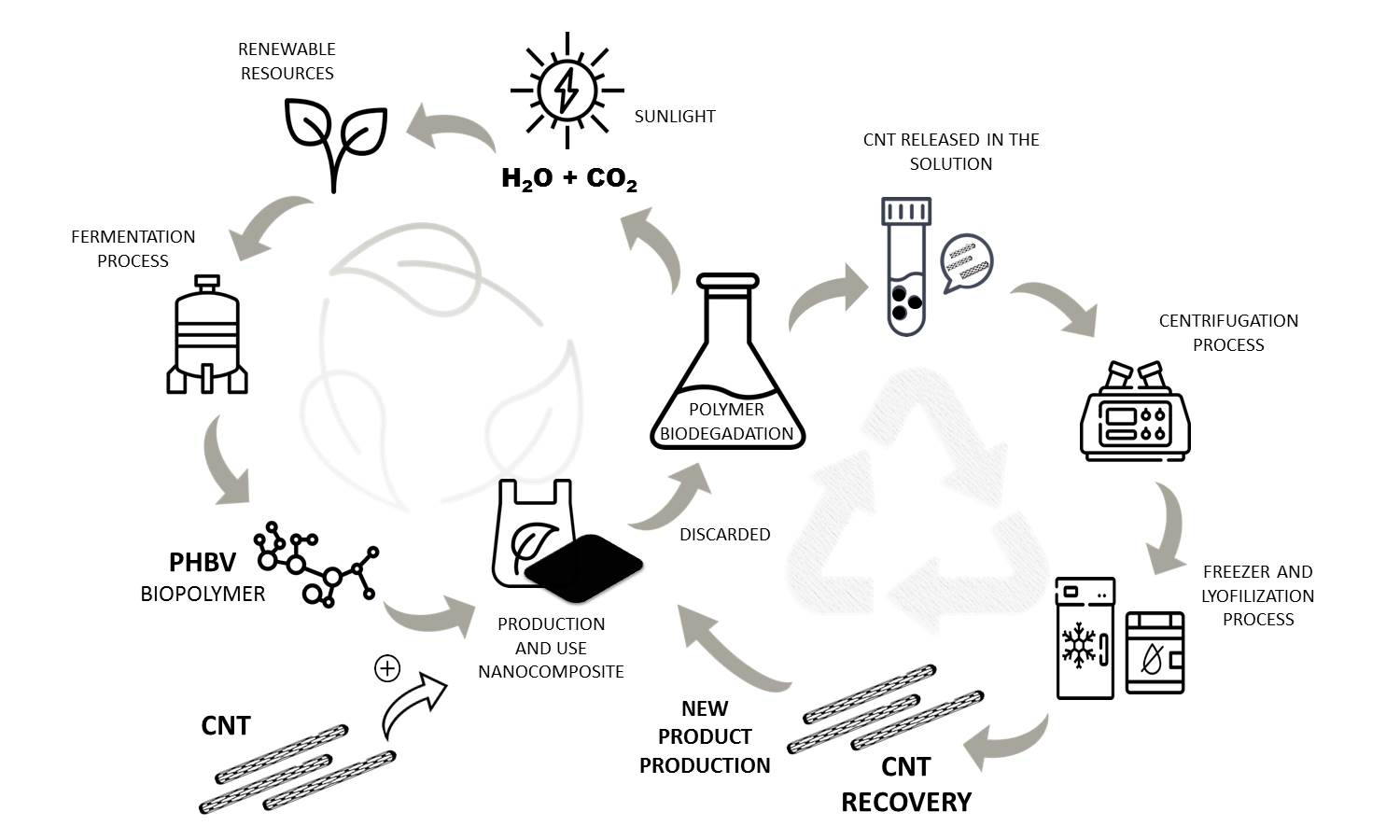

Ana Paula Bernardo da Silva, Cássia Costa Girotto, Thaís Larissa Amaral Montanheiro, Marcelo Alexandre de Farias, Larissa Stieven Montagna, Dayane Batista Tada, Fernando Henrique Cristovan, Ana Paula Lemes

Vol. 17., No.2., Pages 218-235, 2023

DOI: 10.3144/expresspolymlett.2023.16

Vol. 17., No.2., Pages 218-235, 2023

DOI: 10.3144/expresspolymlett.2023.16

The present study carried out the characterization of carbon nanotubes (CNT) recovered from the biodegradation process of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/CNT nanocomposites and the use of this recovered CNT (CNT-rec) in the production of new PHBV nanocomposites. The results obtained by characterization of CNT-rec were very similar to the CNT. Therefore, it was possible to state that CNT properties were preserved during the biodegradation process; however, CNT-rec contained impurities such as proteins and residual PHBV. Regarding the performance as nanofillers, although both CNT and CNT-rec decreased the thermal stability of nanocomposites compared to neat PHBV, this effect was less intense in the CNT-rec nanocomposites. It is expected that both nanofillers acted as nucleating agents in the PHBV matrix crystallization process but with different effectiveness. There was no significant difference between the electrical conductivity comparing PHBV/CNT 2% and PHBV/CNT-rec 2% nanocomposites. Therefore, the recovery and use of CNT-rec is a feasible process.