Content

All issues / Volume 16 (2022) / Issue 1 (January)

Tamas Barany, Laszlo Meszaros

Vol. 16., No.1., Pages 1-1, 2022

DOI: 10.3144/expresspolymlett.2022.1

Vol. 16., No.1., Pages 1-1, 2022

DOI: 10.3144/expresspolymlett.2022.1

Express Polymer Letters has been published by the Department of Polymer Engineering at the Budapest University of Technology and Economics (BME) for 15 years. Under the guidance and dedicated work of Prof. József Karger-Kocsis and Prof. Tibor Czigány, it quickly developed into a prestigious journal and still holds its position as one of the leading journals in its field (JCR IF(2020) 4.161; Q1 in 'Polymer Science'). Since then, the world has changed a lot, both in science and computing, and Prof. Karger-Kocsis is no longer with us. In the last 15 years, the focus of polymer science research has also changed dramatically: e.g. the rise of graphene, functional and smart polymers, biopolymers like polylactic acid, and recycling and environmental issues. Readers' needs have also changed. A significant proportion of articles are being read on smartphones and tablets rather than at a computer desk or in a library.

Duygu Yanardag, Gulnare Ahmetli, Mustafa Karaman, Suheyla Kocaman

Vol. 16., No.1., Pages 2-20, 2022

DOI: 10.3144/expresspolymlett.2022.2

Vol. 16., No.1., Pages 2-20, 2022

DOI: 10.3144/expresspolymlett.2022.2

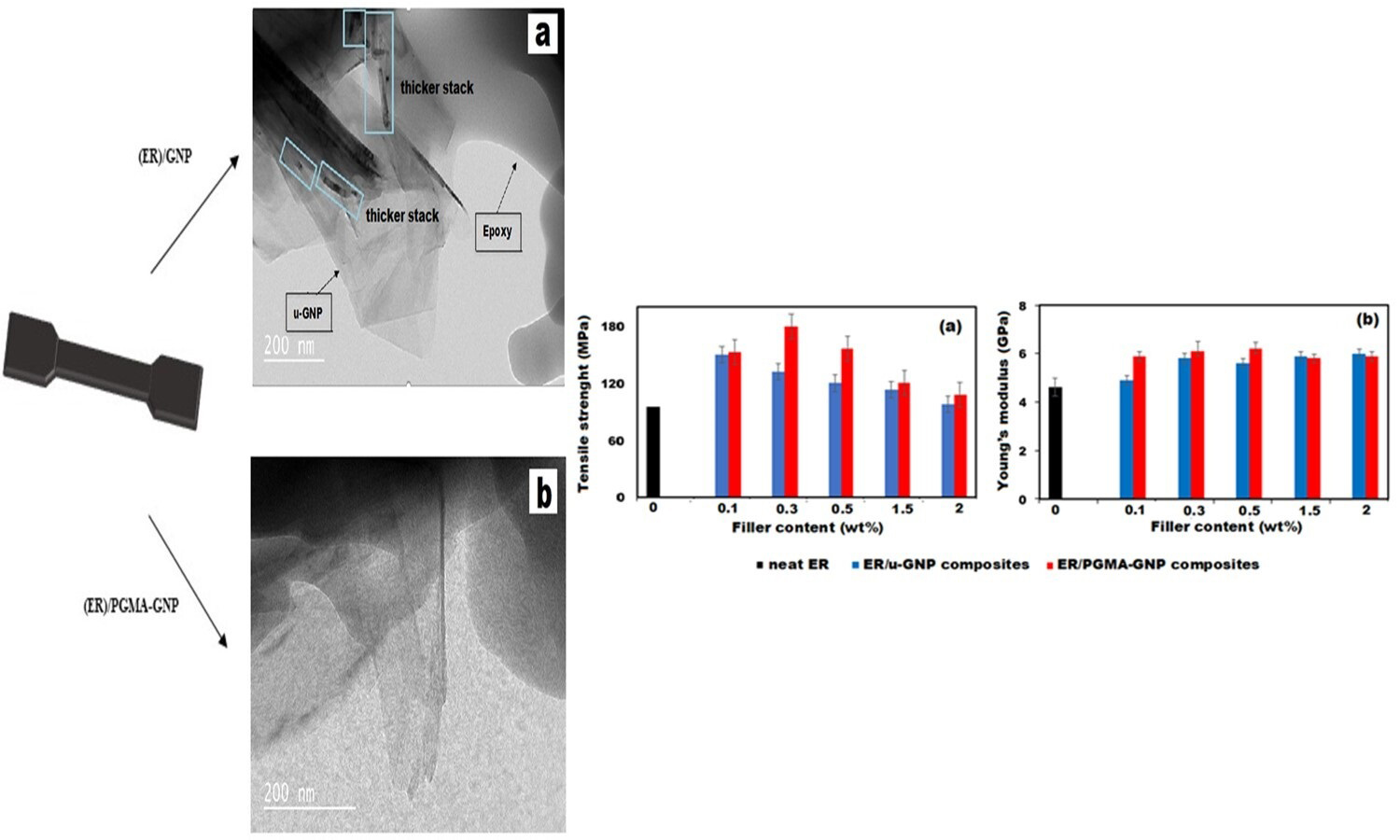

In this study, graphene nanoplatelets (GNPs) were synthesized from graphite by a liquid-phase exfoliation (layer separation) method, and their surfaces were functionalized with poly(glycidyl methacrylate) (PGMA) by using the rotatingbed plasma-enhanced chemical vapor deposition (PECVD) method. Fourier-transform infrared spectroscopy (FT-IR), Raman spectroscopy, scanning electron microscopy (SEM), X-ray powder diffraction (XRD), and thermogravimetric (TGA) analyses were performed to characterize the unmodified (u-GNP) and modified GNP (PGMA-GNP). Epoxy nanocomposites were prepared with both types of GNPs at different loading levels (0.1–2% by weight). The role of the surface modification of the GNPs on the mechanical, thermal, electrical conductivity, contact angle, water sorption, and corrosion properties of the epoxy nanocomposite coatings was also investigated. Consequently, the tensile strength and Young’s modulus of the epoxy resin (ER)/PGMA-GNP nanocomposites were enhanced by 10.2–20 and 3.3–18.4%, respectively, as compared to the ER/u-GNP composites. Moreover, the nanocomposites prepared with PGMA-GNP had better water sorption and wettability properties than those prepared with u-GNP, but lower electrical conductivity. The corrosion test results showed that the addition of GNPs to epoxy effectively improved the corrosion resistance of the epoxy composites in high salinity, basic, and acidic environments.

Chin-San Wu, Dung-Yi Wu, Shan-Shue Wang

Vol. 16., No.1., Pages 21-33, 2022

DOI: 10.3144/expresspolymlett.2022.3

Vol. 16., No.1., Pages 21-33, 2022

DOI: 10.3144/expresspolymlett.2022.3

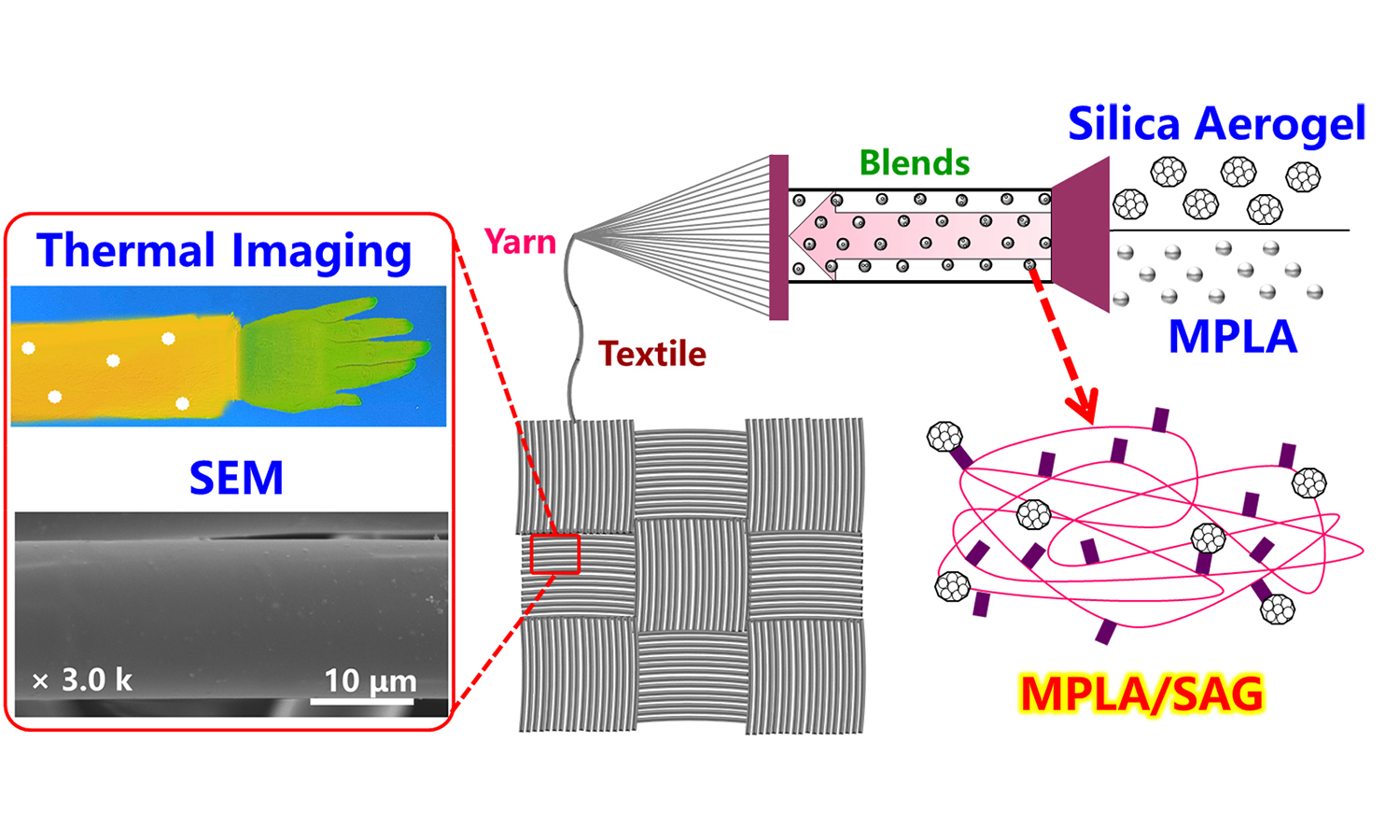

Heat regulation of the human body through textile fabrics is of great interest to the apparel industry. Herein, blends of environmentally friendly materials, including modified polylactic acid (MPLA) (polylactic acid (PLA) + acrylic acid (AA)-grafted PLA (PLA-g-AA) mixed complex) and silica aerogel (SA) composite, were used to make textiles. The tensile, thermal, heat/cold resistance and surface wettability of the novel composites were characterized. MPLA and SA improved the properties of these composites. The MPLA/SA textiles exhibited more favorable mechanical properties than the PLA/SA textiles; this effect was due to better compatibility between the MPLA and SA. Polylactic acid typically exhibits high hydrophilicity and poor thermal conductivity. Incorporating SA as a filler in the processed yarn significantly enhanced the functional performance of the PLA composite textiles. The addition of SA enhanced hydrophobicity and decreased thermal conductivity, which enabled better temperature regulation. The MPLA/SA textiles displayed superior tensile strength, insulation property, temperature adjustment, water resistance, and washing durability. Moreover, the developed MPLA/SA fabric is suitable for mass production and use in various types of textile goods.

Laszlo Merai, Agota Deak, Balazs Szalai, Gergely Ferenc Samu, Gabor Katona, Laszlo Janovak

Vol. 16., No.1., Pages 34-51, 2022

DOI: 10.3144/expresspolymlett.2022.4

Vol. 16., No.1., Pages 34-51, 2022

DOI: 10.3144/expresspolymlett.2022.4

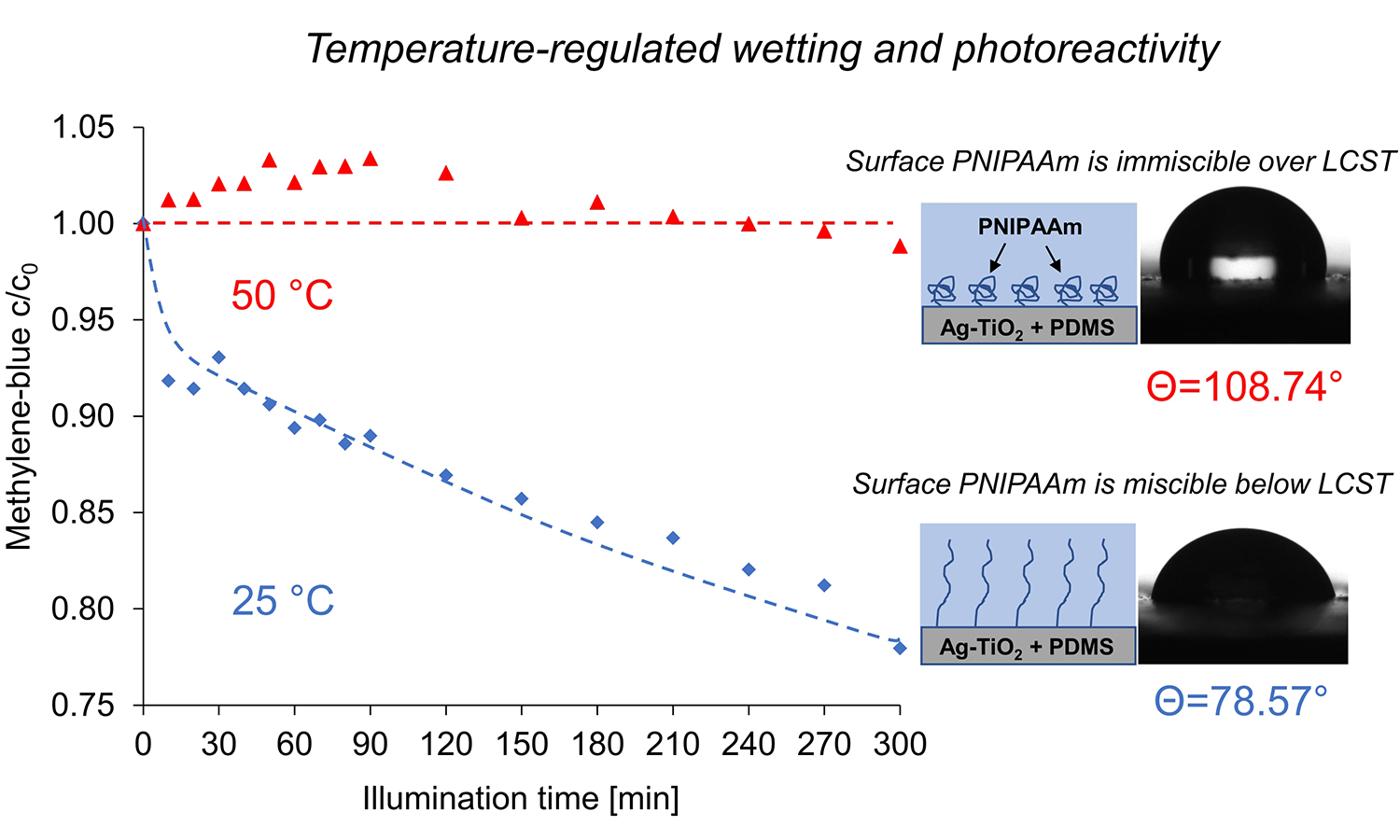

With the increasing demand for liquid manipulation and microfluidic techniques, surfaces with external stimuli induced real-time tunable wetting properties are getting into the focus of materials science research. In this study, we present poly(dimethylsiloxane) (PDMS) copolymer-based composite coatings with thermally adjustable wetting and visible-light photoreactivity. To give thermal responsivity to the spray-coated or doctor blade-casted PDMS surfaces, they were grafted with poly(N-isopropylacrylamide) (PNIPAAm), applying the Activators Regenerated by Electron Transfer – Atom Transfer Radical Polymerization (ARGET-ATRP) method. As the lower critical solution temperature (LCST) of the grafted PNIPAAm chains appeared to be 34°C, the copolymer films showed thermoresponsive, and PNIPAAm surface concentration-dependent wetting characteristics. The addition of 15 wt% visible light-active plasmonic Ag-TiO2 photocatalyst nanoparticles (dprimary ~50 nm) enriched the coatings with photocatalytic activity, which was also proven to be temperature-dependent during methylene-blue (MB; c0 = 6.25 mM) photodegradation tests (blue LED-light, λ = 405 nm) at the S/L-interface. Thanks to the real-time tunable wetting and photocatalytic properties, the presented coatings may offer a novel route towards sophisticated

liquid manipulation.

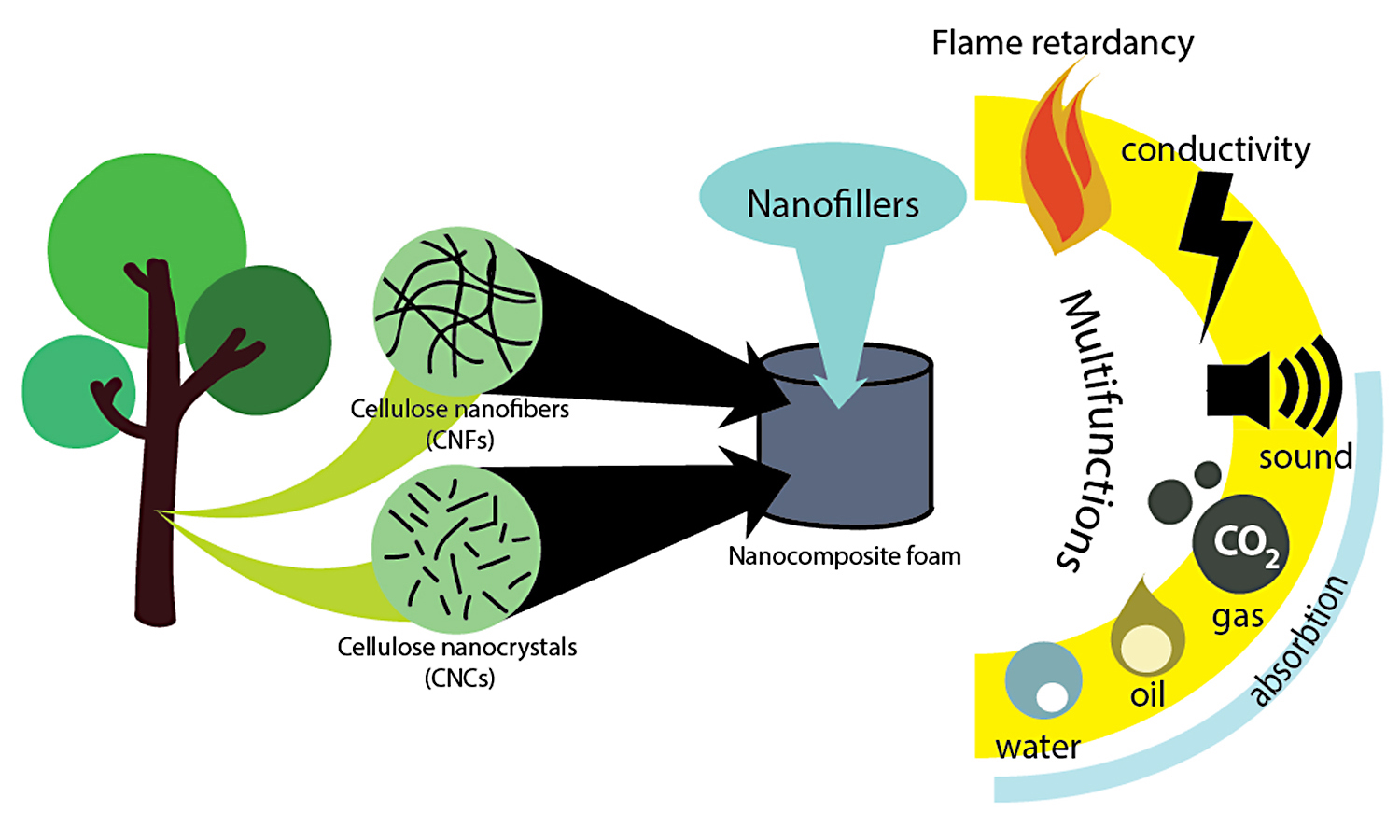

Supachok Tanpichai

Vol. 16., No.1., Pages 52-74, 2022

DOI: 10.3144/expresspolymlett.2022.5

Vol. 16., No.1., Pages 52-74, 2022

DOI: 10.3144/expresspolymlett.2022.5

Since last decades, nanocellulose has gained much attention in nanocomposite foams owing to high stiffness and strength, renewability, sustainability and biodegradability. Nanocellulose is hydrophilic, and could be easily dispersed in hydrophilic polymer matrices; however, there are challenges to introduce nanocellulose in less hydrophilic polymers. This review addresses the development of polymer nanocomposite foams with plant-based nanocellulose (cellulose nanofibers and cellulose nanocrystals), and the chemical modification and mechanical approaches to enhance the dispersibility of nanocellulose in hydrophobic polymer matrices. The combination of nanocellulose and other nanoparticles such as graphene nanoplatelets, montmorillonite clay, carbon nanotubes and zeolites to yield multifunctional porous nanocomposite materials with promising features such as self-extinguishment, dye adsorption, microwave absorption, conductivity and biocompatibility is also discussed in this paper.

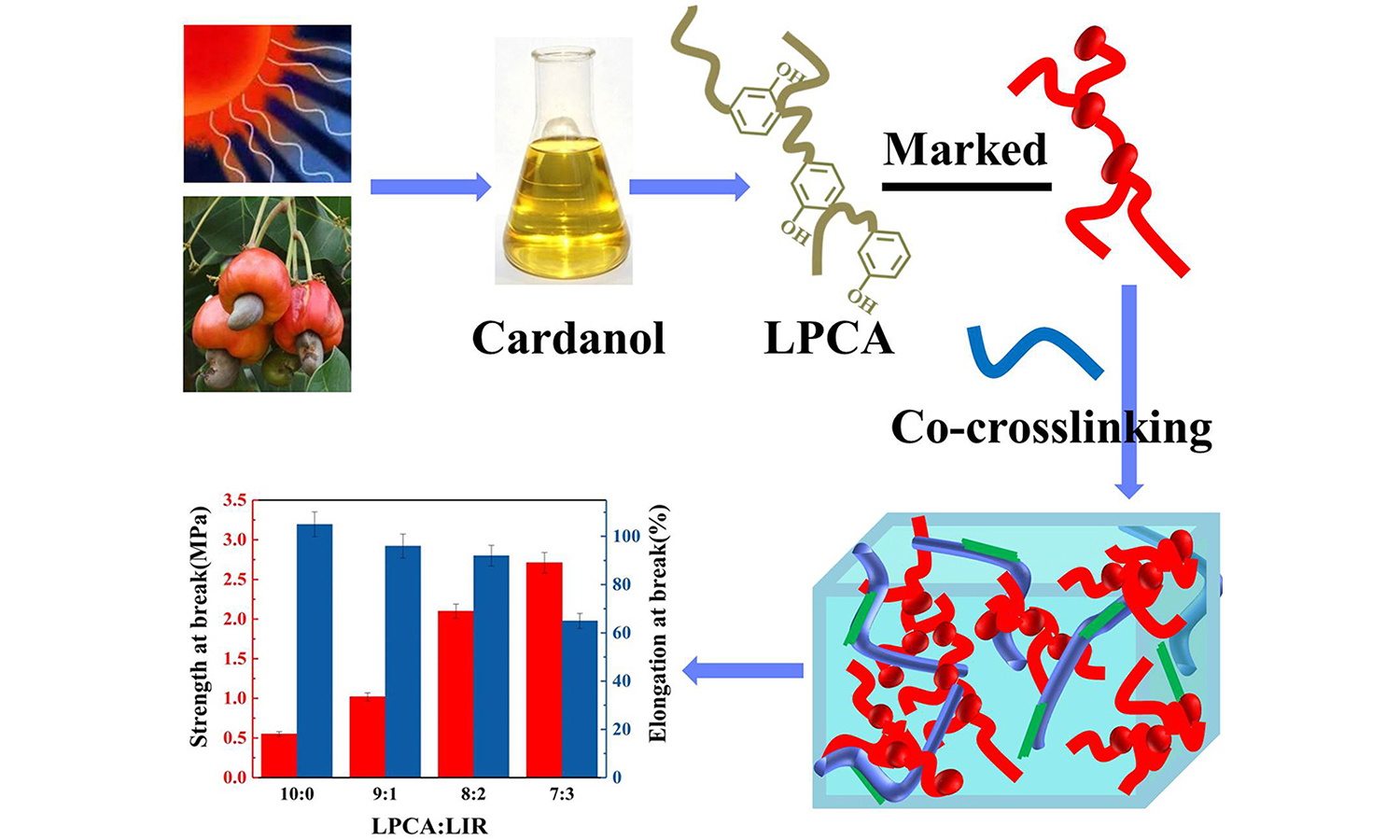

Wei Qian, Jinling Liu, Yuxia Zhang, Chongyi Chi, Denglong Chen, Qinhui Chen

Vol. 16., No.1., Pages 75-84, 2022

DOI: 10.3144/expresspolymlett.2022.6

Vol. 16., No.1., Pages 75-84, 2022

DOI: 10.3144/expresspolymlett.2022.6

People have been trying to find natural products that can replace rubber due to the land occupied by rubber planting and the environmental pollution caused by waste rubber. Herein, the linear poly-cardanol (LPCA) is obtained by undergoing a Friedel-Crafts alkylation reaction at 100 °C for 2 h at the catalyst of 5% of p-toluene sulfonate. The Mw of LPCA is about 4·104, and its polymeric degree is about 133. The weakening of 3009, 1263, and 1154 cm–1 in IR spectrum, the blue shift of UV absorption, the new chemical shifts of protons in 1H-NMR spectrum all certify the formation of LPCA. LPCA has obvious characteristics of elastomer. Its glass transition temperature (Tg) is –20.7 °C on the DSC curve. During the cocrosslinking of LPCA and liquid polyisoprene rubber (LIR), LPCA induces the crystallization of long LIR chain segments, which is confirmed by the transition peaks of the DSC curve in 40°C. This partial crystal structure is beneficial for LPCA/LIR blends to possess high strength. The tensile strength and the elongation at break of LPCA/LIR blend with 20% of LIR are about 2.04 MPa and 92%, respectively. LPCA possesses flexible alkyl chains and hydrophilic phenolic hydroxyl groups, so it can be used as a plasticizer just like LIR and compatibilizer at the same time. This study affords a possible way for renewable cardanol to replace rubber partially or completely.

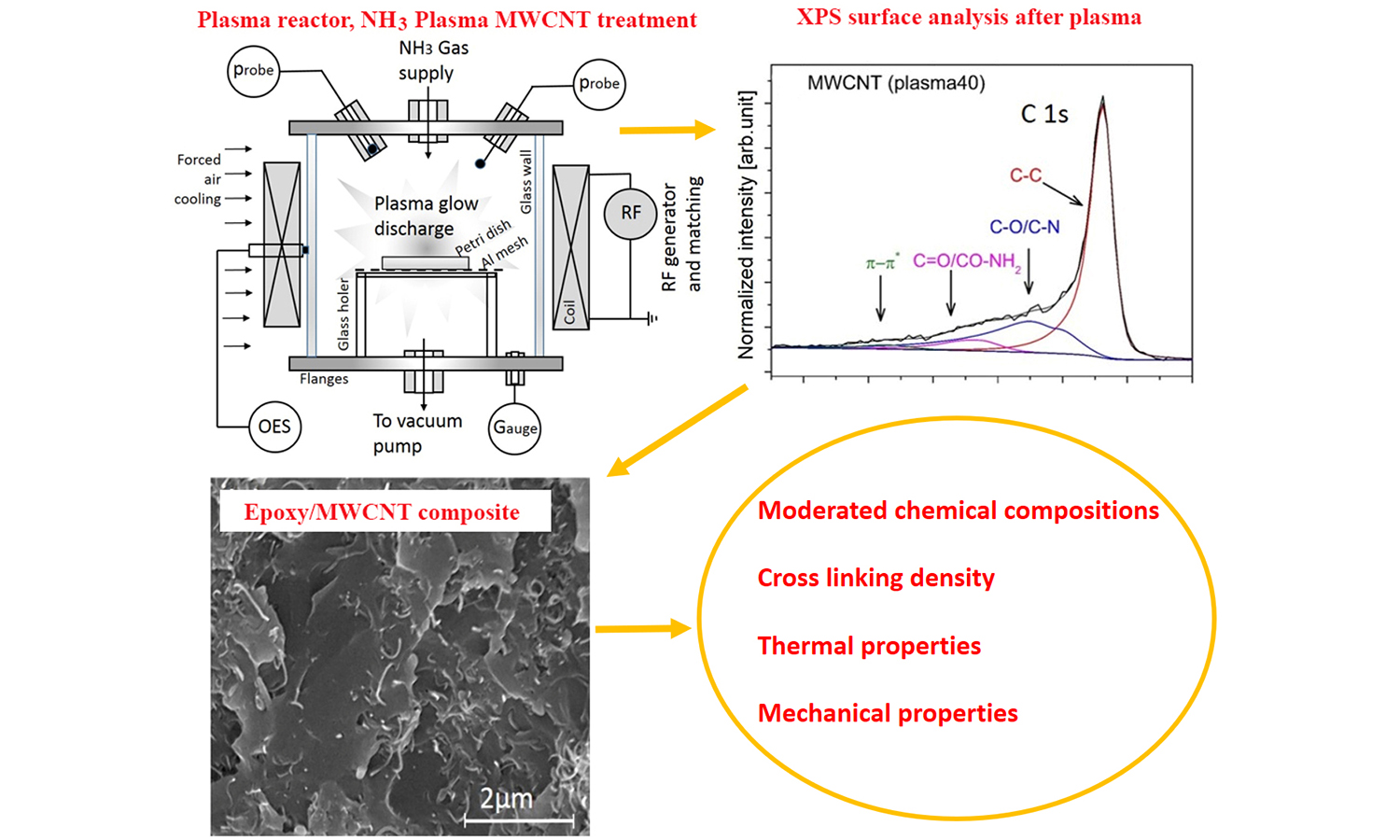

Ruhan Benlikaya, Petr Slobodian, Pavel Riha, Harinarayanan Puliyalil, Uros Cvelbar, Robert Olejnik

Vol. 16., No.1., Pages 85-101, 2022

DOI: 10.3144/expresspolymlett.2022.7

Vol. 16., No.1., Pages 85-101, 2022

DOI: 10.3144/expresspolymlett.2022.7

Epoxy composites filled by multiwalled carbon nanotubes treated by inductively coupled ammonia plasma were prepared to improve composite intrinsic properties. The ammonia plasma treatment generated amine and oxygenated groups on the carbon nanotube surface, which facilitated its interaction with the epoxy ring and restricted the slippage of epoxy from the carbon nanotube surface. As a result, an improvement in the elastic modulus of the composite by the embedded carbon nanotubes and a decrease in the glass transition temperature and the cure degree were found. It indicated a strengthening effect of the carbon nanotube filler in the epoxy matrix explained by the generation of chemical reaction pathways between treated filler and the epoxy matrix detected by Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy during different stages of the composite formation. To demonstrate the use of carbon nanotube-filled epoxy composites, a microstrip resonant vapor sensor was assembled that was used to detect the occurrence of volatile organic compounds and to monitor the ambient temperature below and over the glass transition temperature.

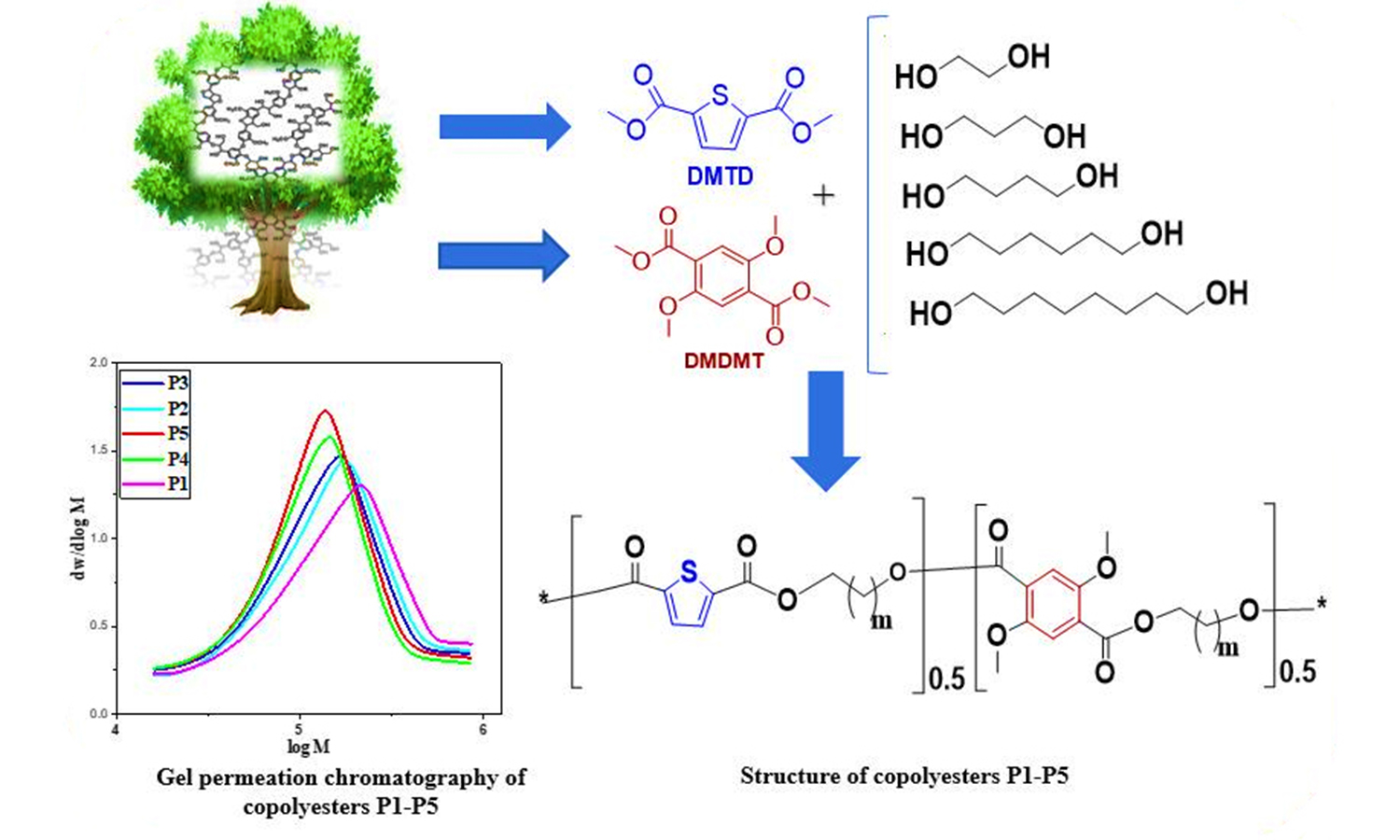

Lesly Dasilva Wandji Djouonkep, Zhengzai Cheng, William Mawuko Kodzo Siegu, Xiong Jing, Jun Chen, Elvis Kwame Adom, Abubakar Muaz, Mario Gauthier

Vol. 16., No.1., Pages 102-114, 2022

DOI: 10.3144/expresspolymlett.2022.8

Vol. 16., No.1., Pages 102-114, 2022

DOI: 10.3144/expresspolymlett.2022.8

In this investigation, a series of novel random bio-based thiophene–aromatic copolyesters, including thiophene and phenyl units, were successfully prepared from dimethyl 2,5-thiophenedicarboxylate, dimethyl 2,5-dimethoxyterephthalate, and the aliphatic diols ethylene glycol, 1,3-propanediol, 1,4-butanediol, 1,6-hexanediol and 1,8-octanediol, via twostep melt polymerization as a facile and green semi-continuous process. Techniques used to monitor the polymerization process included Fourier transform infrared (FTIR) and proton nuclear magnetic resonance spectroscopy (1H NMR), gel permeation chromatography (GPC), differential scanning calorimetry, thermogravimetric analysis, and dynamic mechanical analysis. The copolymers had tunable Tg values ranging from 47–120°C, while their 5% decomposition temperature (Td, 5%) under N2 varied from 405–370 °C. GPC analysis showed that the polyesters had weight-average molecular weights (Mw) of 41 400–48 500 g/mol and polydispersity indices of 1.47–2.24. A study of structure-property relations showed that the properties of these copolymers can be tailored by varying their composition. All the copolyesters exhibited high tensile strength (45–80 MPa) and toughness values (elongation at break of 200–540%). After 28 weeks of incubation in humid soil, weight losses of up to 7.2% were observed. Considering their good mechanical properties, thermal stability and biodegradability, these renewable sulfur-containing copolyesters have great potential to replace petroleum-based commercial poly(ethylene terephthalate) in the food packaging industry, which is helpful to implement carbon neutrality and sustainable development in the polymer industry.