Thermo-mechanical characterisation of polycarbonate-based sheet moulded composites fabricated from off-cut waste unidirectional tapes

Chethan Savandaiah , Andreas Kapshammer

, Andreas Kapshammer , Bernhard Plank

, Bernhard Plank , Vanja Stolcer

, Vanja Stolcer , Christian Marschik

, Christian Marschik , Zoltan Major

, Zoltan Major

, Andreas Kapshammer

, Andreas Kapshammer , Bernhard Plank

, Bernhard Plank , Vanja Stolcer

, Vanja Stolcer , Christian Marschik

, Christian Marschik , Zoltan Major

, Zoltan Major

Vol. 18., No.9., Pages 883-900, 2024

DOI: 10.3144/expresspolymlett.2024.66

DOI: 10.3144/expresspolymlett.2024.66

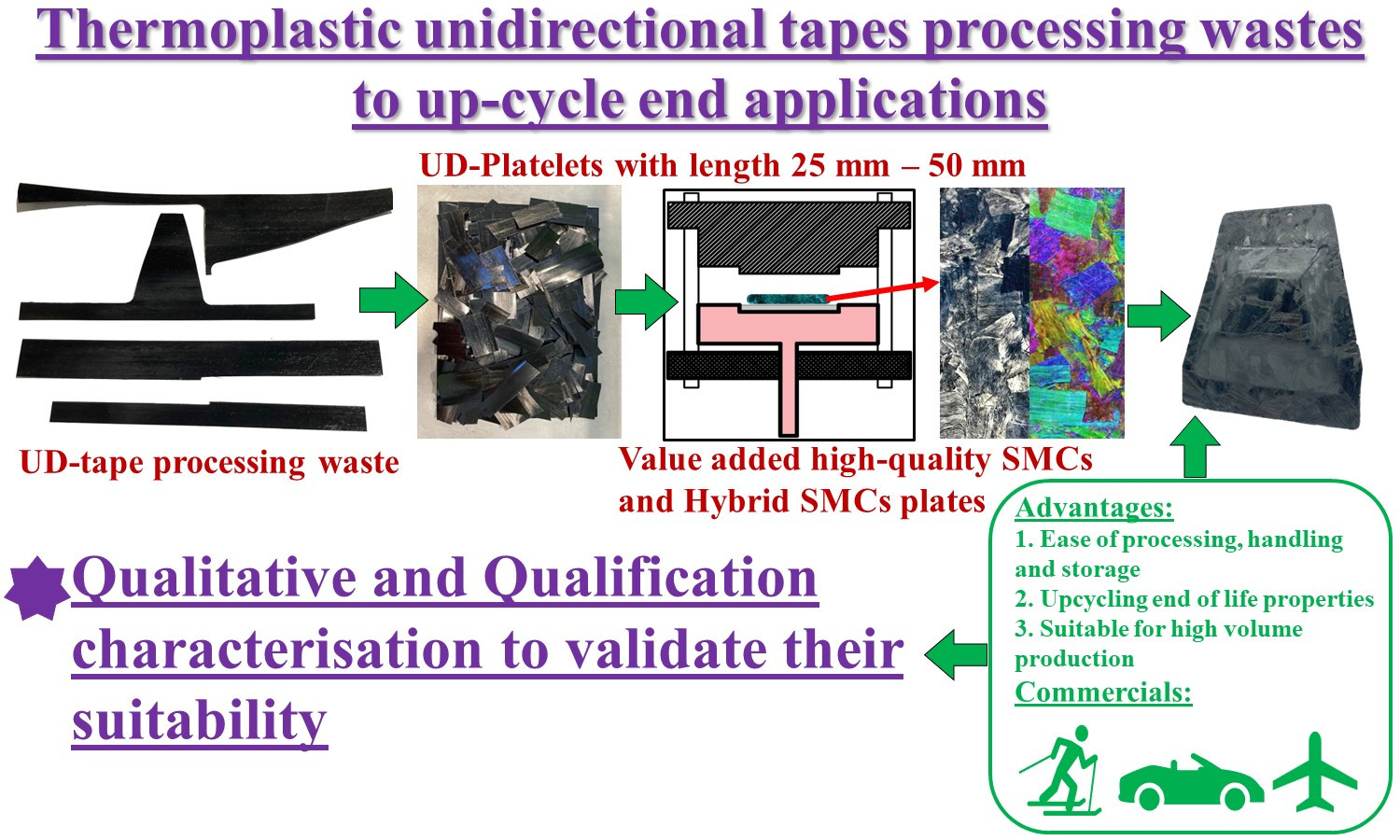

GRAPHICAL ABSTRACT

ABSTRACT

Thermoplastic (TP) composites, known for their ease of handling, suitability for high production rates, and recyclability, are emerging as a promising alternative to thermoset-based composites. The expected growth in TP-based composites in automotive, sports, and aerospace industries may result in increased post industrial waste. To address this, we repurposed our in-house process scrapped carbon fibre-reinforced polycarbonate tapes into sheet moulding compounds (SMCs) and Hybridised SMCs (Hy-SMCs) using compression moulding. In Hy-SMCs, the top and bottom layers were unidirectional tapes, while the core section had randomly oriented platelets in a 50:50 ratio. Our evaluation included qualitative and thermo-mechanical standard tests. The incorporation of unidirectional tapes in Hy-SMCs significantly improved the tensile and flexural properties of SMCs. Specifically, these enhancements resulted in an impressive 81 to 85% increase in mechanical strength compared to the standard aluminium grade. Additionally, Hy-SMCs exhibited a 120 to 130% increase in tensile and flexural properties compared to SMCs. Fractography revealed a complex relation between fractured surfaces, with multimode failures in both SMCs and Hy-SMCs. Also, the non-destructive evaluation showed platelet reorientation during consolidation and localised voids with increased specimen thickness.

RELATED ARTICLES

Abdulaziz Al-Shehri, John Sweeney, Paul Spencer, Phil Coates, Fin Caton-Rose, Ajay Taraiya

Vol. 19., No.12., Pages 1238-1255, 2025

DOI: 10.3144/expresspolymlett.2025.92

Vol. 19., No.12., Pages 1238-1255, 2025

DOI: 10.3144/expresspolymlett.2025.92

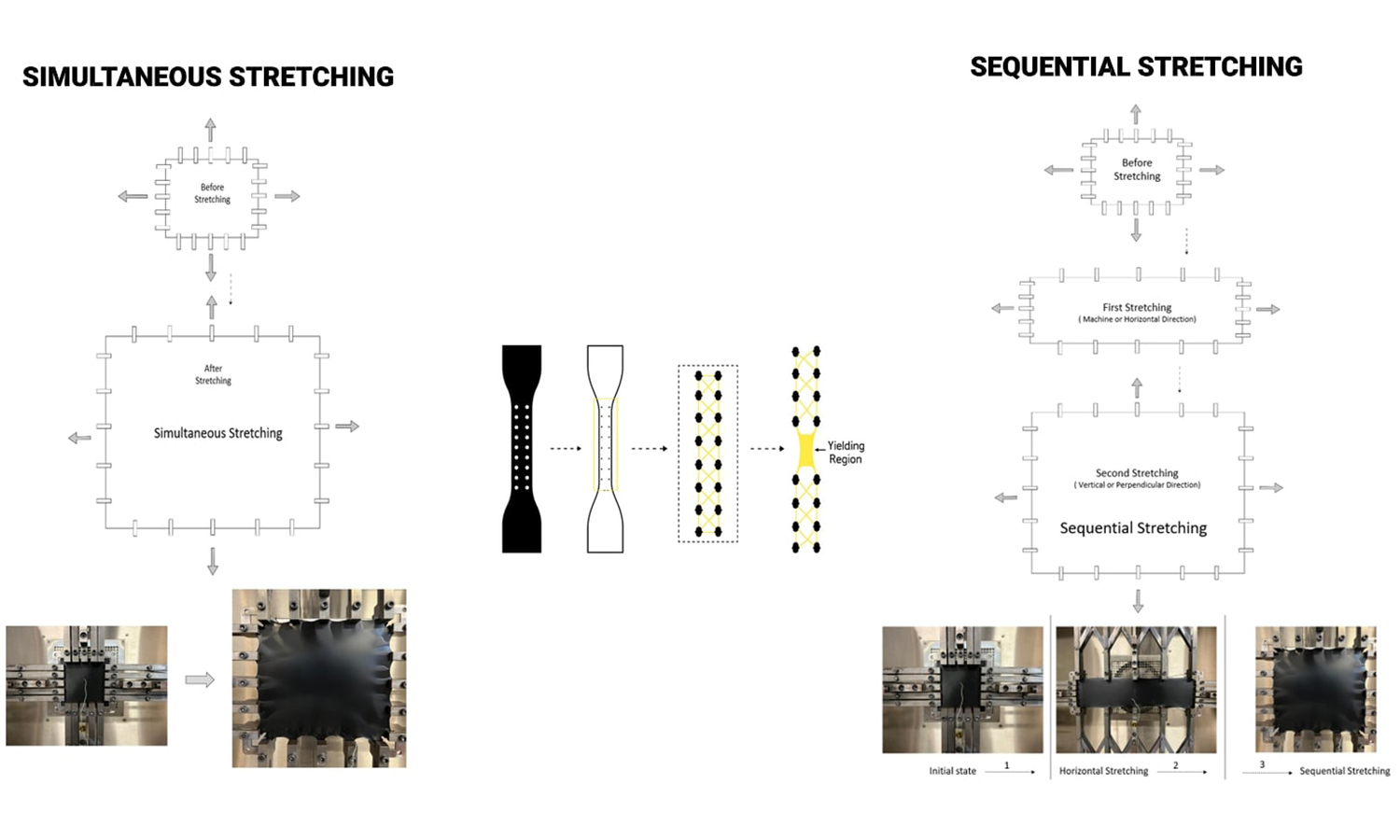

This study examines the combined effects of molecular modalities (unimodal, bimodal, trimodal) and biaxial stretching modes (sequential and simultaneous) on the yielding, stiffness, and necking behaviour of stretched high-density polyethylene (HDPE). Yield strength and stiffness were examined in relation to oriented material produced by drawing at linear strain rates 5.4·10–3, 2.2·10–2, and 8.6·10–2 s–1 under both stretching modes. Simultaneous stretching outperformed sequential stretching, with yield strength increasing with draw rate. Unimodal HDPE showed higher yield strength and stiffness than bimodal and trimodal grades, while trimodal HDPE had the lowest necking tendency from greater flexibility and uniformity. The highest necking tendency was observed in unimodal HDPE in strain localization analysis using the maximum strain/average strain ratio, while trimodal HDPE deformed more uniformly due to improved molecular weight distribution and strain hardening. Increasing the draw rate reduced strain localization, improving mechanical performance. Insights for optimising polyethylene materials in industry are provided by gel permeation chromatography (GPC), nuclear magnetic resonance (NMR) spectroscopy, and mechanical analyses, establishing the correlation between HDPE structure, processing, and properties.

Rebeka Lorber, Janez Slapnik, Borut Černe, Andreas Hausberger, Jan Sumfleth

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

The study investigates the use of repurposed milled carbon fibre (mCF) as reinforcement for polyamide 66 (PA66) in gear applications, addressing environmental and cost concerns of virgin carbon fibres. Neat PA66 and PA66 composites reinforced with mCF, glass fibres (GF), and carbon fibres (CF), with and without polytetrafluoroethylene (PTFE), were injection moulded and evaluated for microstructure (fibre length), thermal, mechanical, surface, and tribological properties, as well as gear performance under VDI 2736 guidelines. CF reinforced composites showed the highest modulus and tensile strength, followed by mCF and GF. PTFE reduced modulus and strength in binary composites. All reinforced composites significantly lowered the coefficient of friction (COF) and wear rate compared to neat PA66, with mCF showing the most notable improvements. PTFE slightly improved tribological performance only for GF (wear) and CF (COF) composites. In gear testing, binary composites outperformed neat PA66, with CF performing best, followed by mCF and GF. Ternary composites had slightly lower performance than their binary equivalents. Correlation analysis showed that gear performance is closely linked to structural integrity. Failure analysis revealed higher crack susceptibility in mCF reinforced gears due to shorter fibre length. The findings highlight mCF reinforced PA66 as a sustainable, cost-effective material for durable polymer gears.

Xue Xu, Rujie Li, Li Gao, Beibei Sun, Hongming Liu, Shiai Xu

Vol. 19., No.9., Pages 959-976, 2025

DOI: 10.3144/expresspolymlett.2025.72

Vol. 19., No.9., Pages 959-976, 2025

DOI: 10.3144/expresspolymlett.2025.72

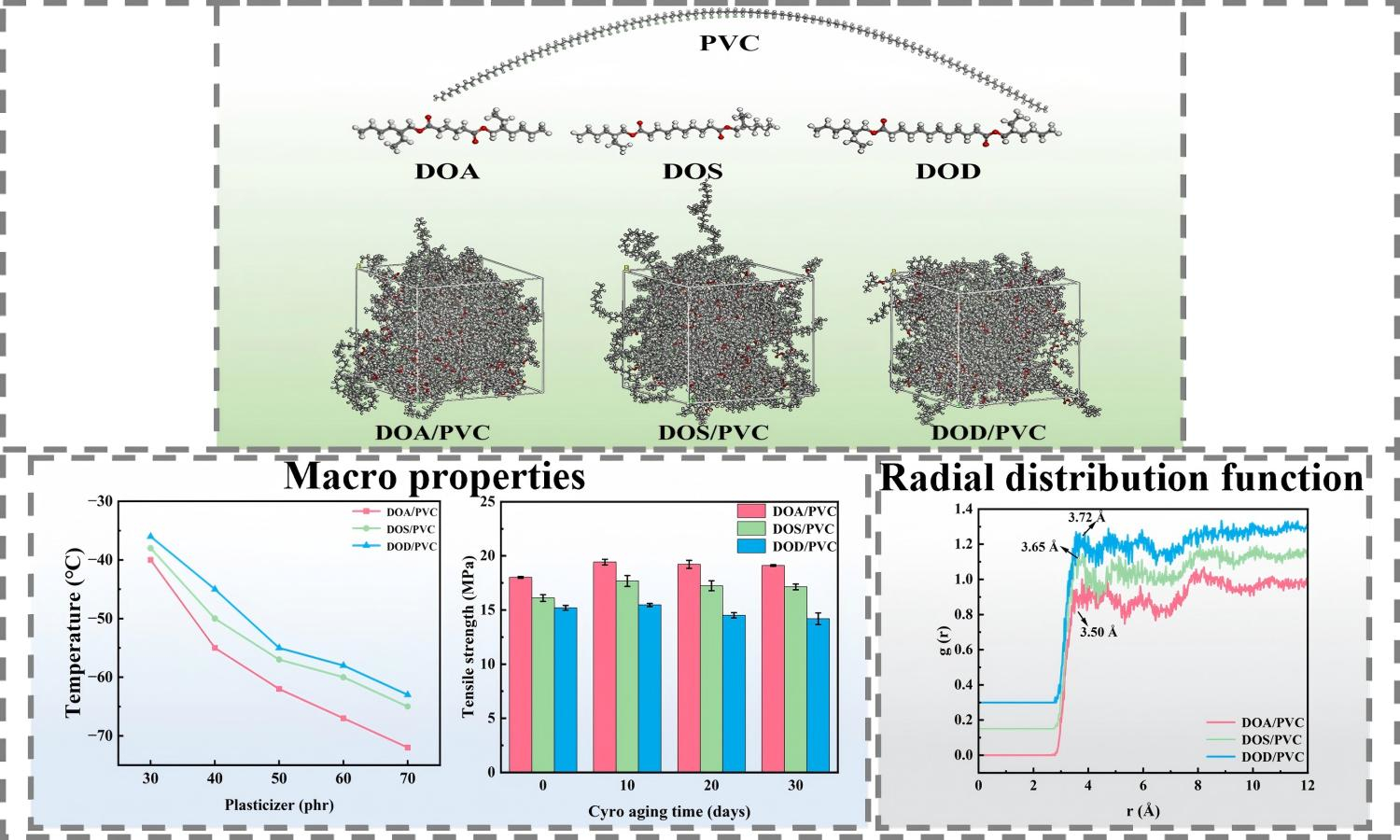

As polyvinyl chloride (PVC) films are hard and brittle in a low-temperature environment, aliphatic dibasic acid ester plasticizers with different acid chain lengths were fabricated, i.e. di(2-ethylhexyl) adipate (DOA), di(2-ethylhexyl) sebacate (DOS) and dioctyl dodecanedioate (DOD), and their effects on the cold-resistant properties of PVC were investigated using experiments and molecular dynamics (MD) simulations. The brittleness temperature and tensile properties of plasticizers/PVC are negatively related to the acid chain length of the aliphatic dibasic acid esters. The brittleness temperatures of the three systems are all below –50 °C. In-situ low-temperature tensile tests and aging tests indicate that DOA/PVC exhibits the best cold resistance and stability. MD simulations further reveal that the best compatibility between DOA and PVC is attributed to its strong binding energy and weak hydrogen bonding interactions, while van der Waals forces are dominant in DOS/PVC and DOD/PVC. This study elucidates the structure-property relationship between aliphatic dibasic acid ester plasticizers and PVC from the perspective of molecular interactions, and provides insights into the design of cold-resistant PVC plasticizers.

Sirithorn Kaewklum, Parisa Faibunchan, Apinya Krainoi, Banyat Cherdchim, Jutharat Intapun

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

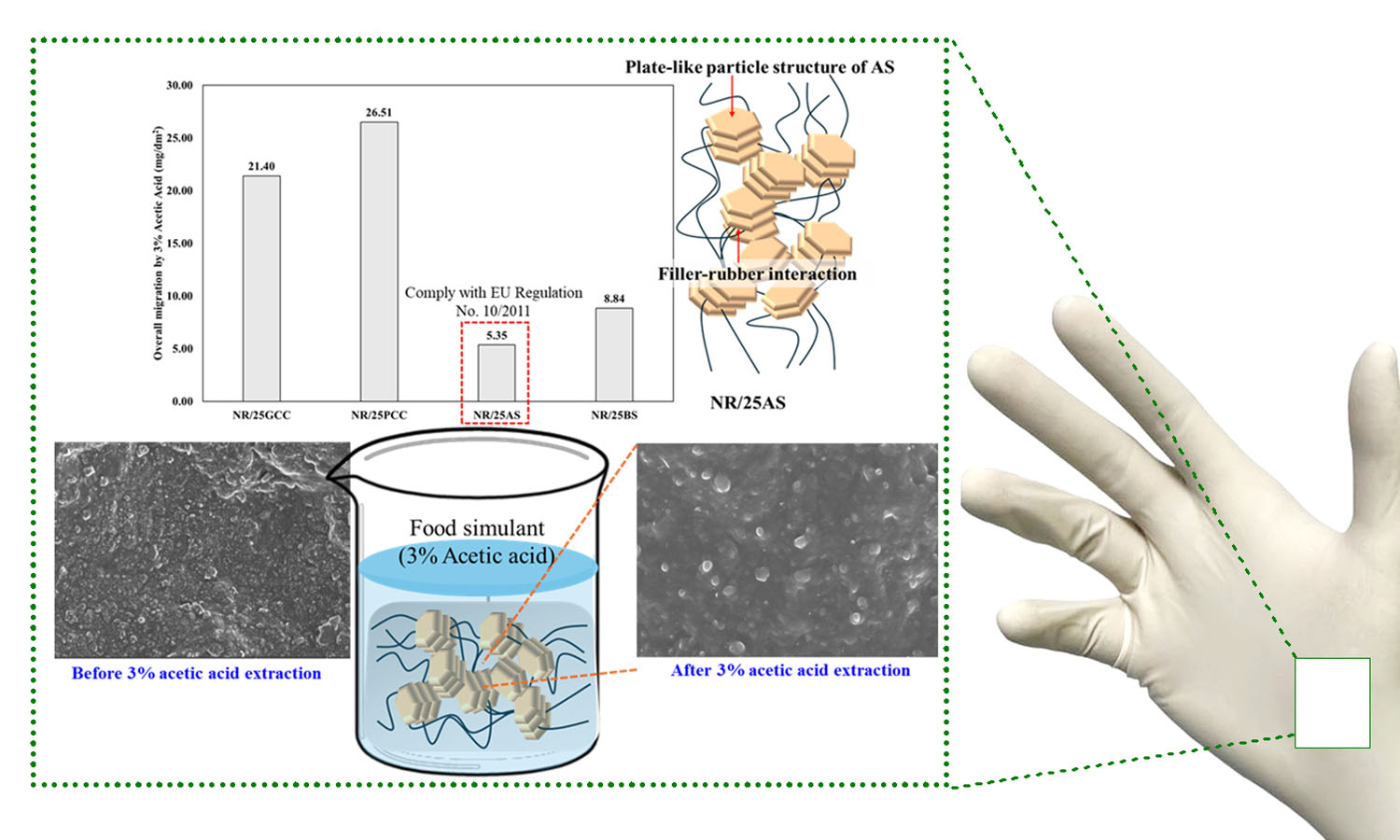

Powder-free natural rubber gloves for chemical migration resistance of food-contact grade are prepared using a variety of fillers, including ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), aluminum silicate (AS), and barium sulfate (BS)-filled natural rubber (NR), respectively. The properties of NR gloves, including mechanical, dynamic mechanical, and thermal properties, were investigated. Furthermore, the overall migration test of NR gloves was conducted according to the regulations for food contact gloves (EU Regulation No. 10/2011), using 3% acetic acid as the simulant. Among the fillers studied, the plate-like particles of AS facilitated the most effective filler-rubber interactions and reinforcement in AS-filled natural rubber (NR/AS). Consequently, the highest crosslink density, force at break, and damping properties of NR gloves were achieved by applying AS in the NR matrix. Moreover, the lowest overall migration level was observed for NR/AS with a value of 5.35 mg/dm2, which complies with EU Regulation (overall migration of food simulants shall not exceed 10 mg/dm2). Therefore, NR gloves filled with AS are suitable for food-contacting NR gloves.