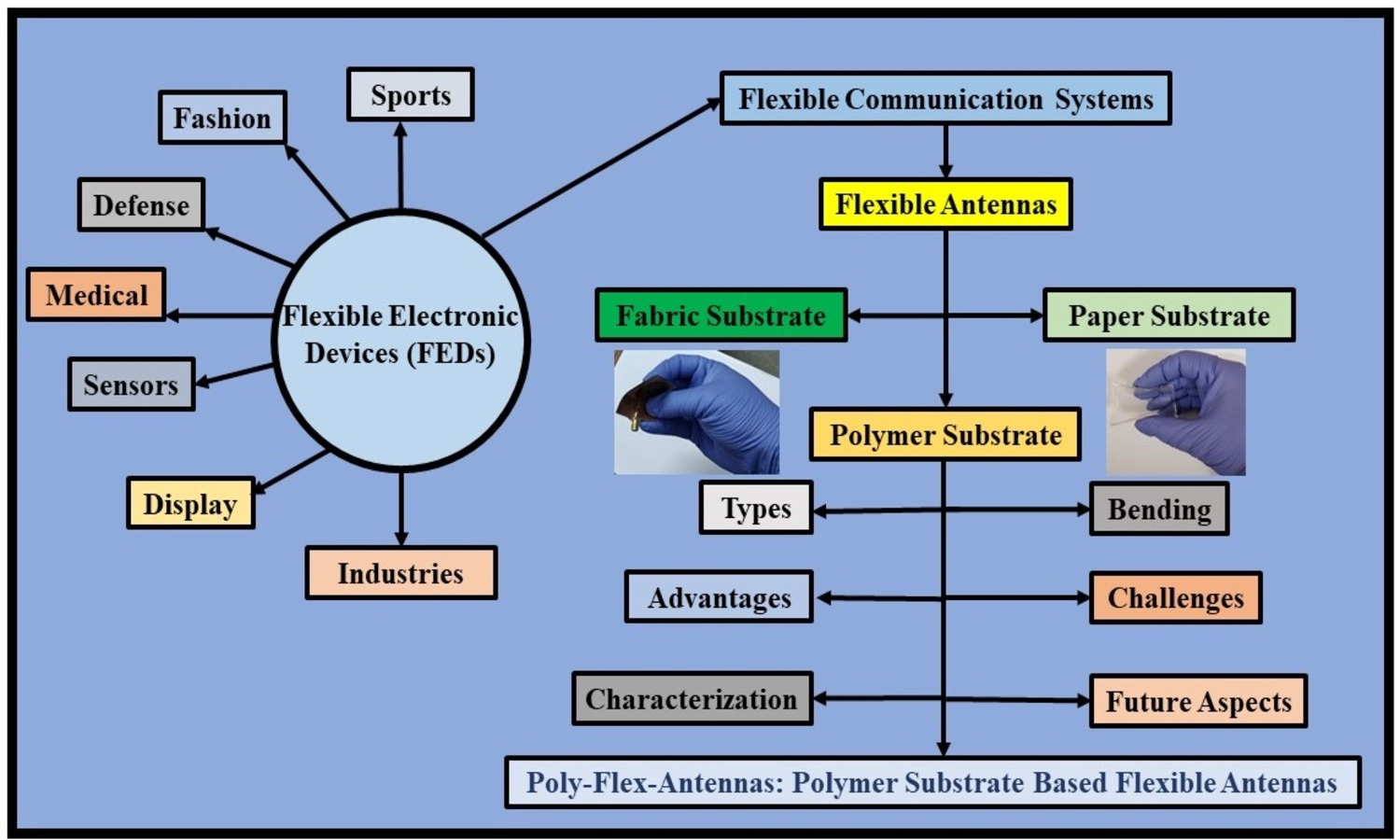

Poly-flex-antennas: Application of polymer substrates in flexible antennas

Vol. 18., No.4., Pages 371-390, 2024

DOI: 10.3144/expresspolymlett.2024.28

DOI: 10.3144/expresspolymlett.2024.28

GRAPHICAL ABSTRACT

ABSTRACT

The

proliferation of flexible electronics has entirely transformed the field of

antenna design and paved the door for cutting-edge uses in communication,

sensing, and other areas. The present research lends a succinct overview of the

intriguing advancements in flexible antenna technology, with specific emphasis

on the implementation of polymer substrates. As we refer to poly-flex antennas in

this article, they stand for the incorporation of polymer substrates in antenna

design. Polymer substrates are the optimum candidate for flexible antenna

applications as they have specific advantages, including being lightweight,

conformable, and inexpensive. The main features of poly-flex antennas, such as

their design concepts, fabrication processes, and performance characteristics,

are being explored in this proposed article. We delve into the wide variety of

polymer substrates that are appropriate for antennas, taking into account their

dielectric characteristics, flexibility, and environmental resistance. Their

dielectric characterization, bending effects, challenges, and future prospects

of this burgeoning field are also addressed. We conclude by emphasizing the

immense potential of poly-flex-antennas to shape the future of wireless

communication and sensing systems, and how the adoption of polymer substrates

is driving innovation in antenna engineering.

RELATED ARTICLES

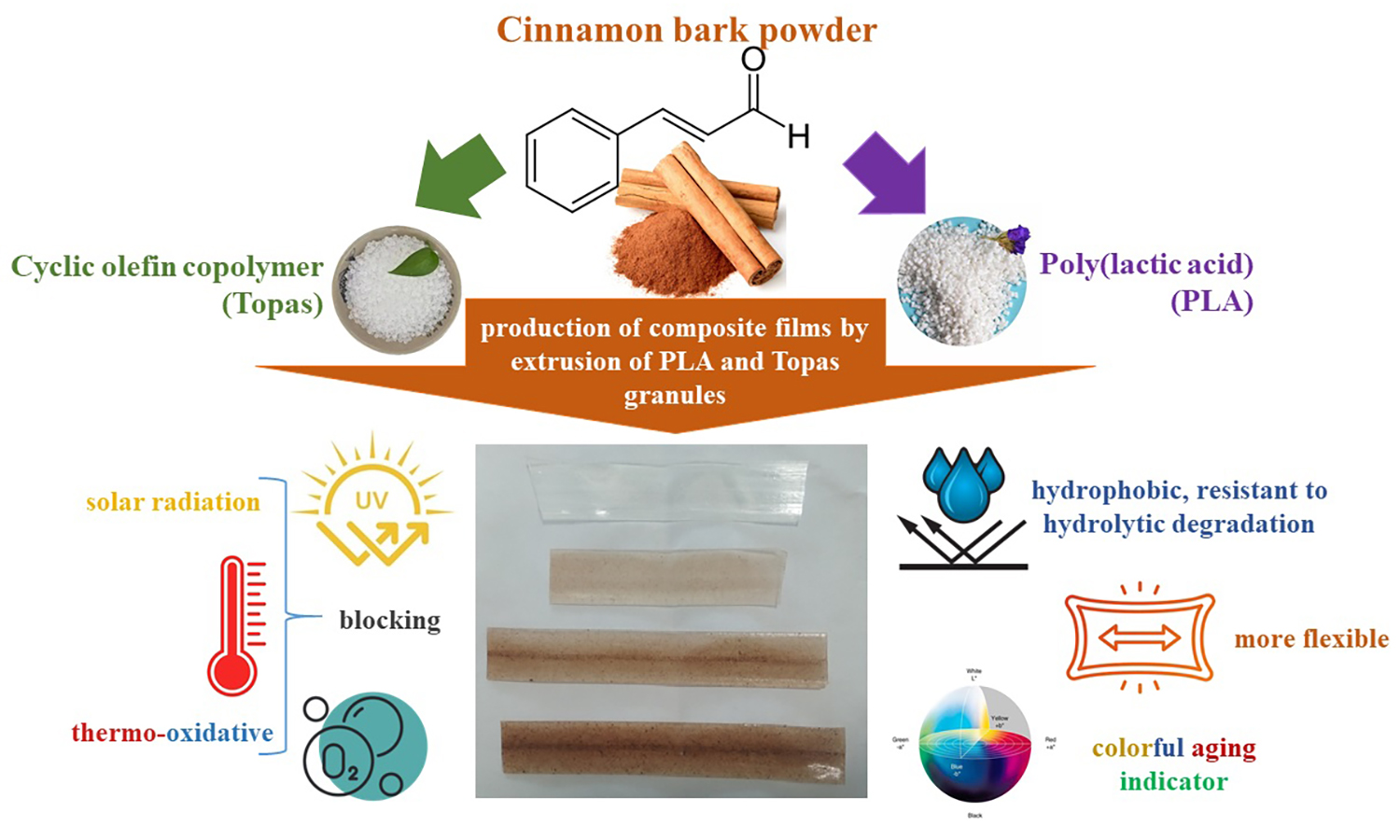

Effect of natural cinnamon extract on the stabilizing properties of biodegradable packaging polymers

Anna Kosmalska-Olańska, Anna Masek

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

The growing focus on sustainability, eco-friendly technologies, decarbonization, and reducing carbon footprints shapes current industry challenges. This article reviews the potential of cinnamon as a bio-additive for polymer stabilization in packaging. Samples were prepared from ethylene-norbornene copolymer (Topas), a cyclic olefin copolymer known for purity, transparency, and low gas permeability, and poly(lactic acid) (PLA), a bio-based alternative to petroleum plastics. Cinnamon powder was added in 0.5, 1.0, and 1.5 wt%. After solar and thermo-oxidative aging, hydrophobicity, chemical composition, mechanical, and color properties were analyzed. Results showed higher hydrophobicity and resistance to hydrolytic degradation due to reduced water penetration. PLA, normally brittle, became more flexible, with 0.5 wt% cinnamon showing optimal performance after 100 h of solar aging, similar to Topas composites. Overall, PLA and cyclic olefin copolymer (COC) films with cinnamon improved durability, extended food shelf life, and acted as natural color indicators of material aging.

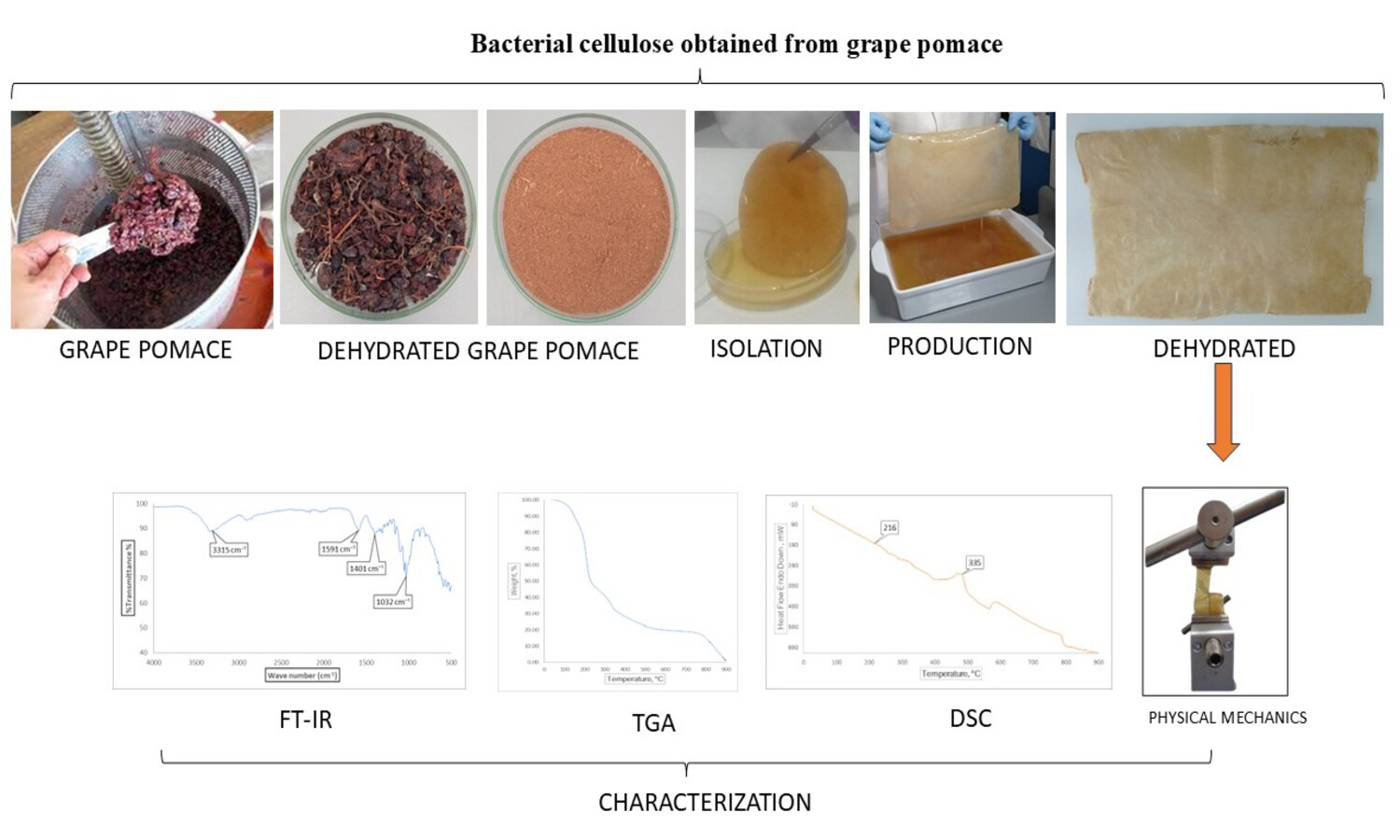

Isabel Milagros Gavilan-Figari

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Bacterial cellulose (BC) is an eco-friendly biopolymer with outstanding structural and functional properties, offering promising applications in sustainable packaging and bio-based materials. In this study, we demonstrate the feasibility of producing BC via spontaneous fermentation, using grape pomace supplemented with sucrose as the sole carbon source, nutrient substrate, and microbial inoculum, without the addition of commercial strains or nitrogen supplements. Fermentation was conducted under static conditions, yielding biofilms with stable structural characteristics and BC production of up to 14.1 g/L, thereby confirming the efficiency of this low-cost, residue-based process. The films obtained exhibited well-organized polymeric networks, with thermal stability in the range of Tg ≈ 159–266 °C and mechanical resistance comparable to or higher than conventional biopolymers. Characterization confirmed reproducible chemical profiles, thermal stability, and measurable variation in mechanical performance, with a tensile strength ranging from 0.0001 to 105 MPa and an elongation at break of 15±5%. The process highlights a resource-efficient and sustainable pathway, adaptable to rural contexts and aligned with circular economic principles. While minor variations among replicates reflected the intrinsic variability of biological systems, mean values and standard deviations demonstrated reproducible physicochemical and mechanical properties. These findings demonstrate that BC derived from agro-industrial residues can be produced under simple, low-input conditions, opening opportunities for scalable valorization in functional and sustainable materials.

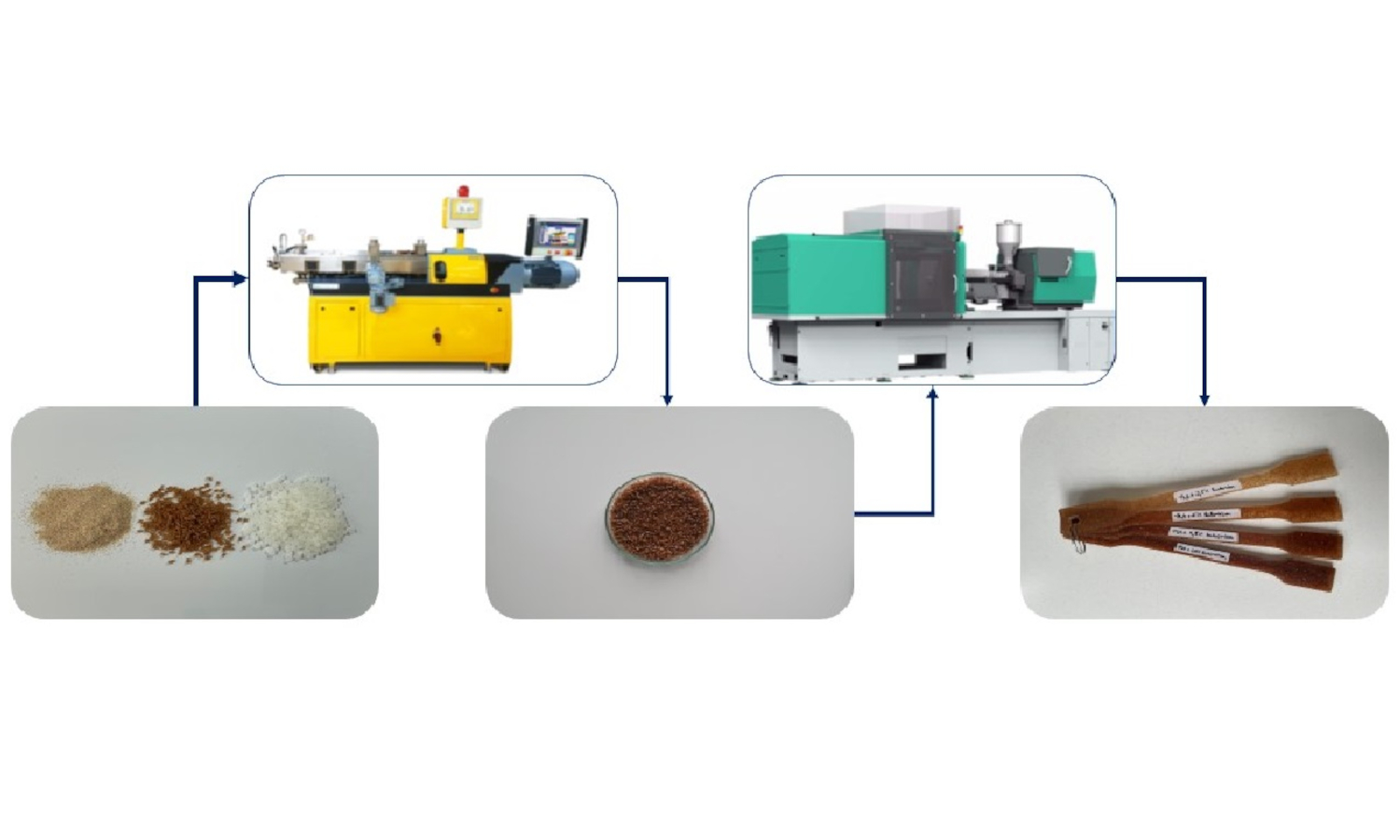

Lilla Bubenkó, Násfa Németh, Sára Frey, Tamás Molnár, Károly Belina, Orsolya Viktória Semperger

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Biocomposites have recently received more attention because of raising environmental awareness and the drive toward sustainable technologies. The most common biodegradable polymer is poly(lactic acid) (PLA), which has an excellent balance of physical and rheological properties, but there is some limit to its usage. PLA properties can be improved by adding different types of fibers or fillers that come from agricultural waste. In this study, corn cob and lavender stem were used to reinforce PLA without any coupling agent, and the properties of the composites were investigated. The melt flow rate (MFR) values decreased with the corn cob content and increased with the addition of lavender stem. Mechanical tests showed that the tensile and flexural modulus of the composites increased and the strengths decreased with the reinforcement material content. The rigidness of PLA slightly decreased with the addition of fillers. There was no significant effect on the thermal properties. The unremarkable improvement of the reinforcement was due to the lack of appropriate adhesion of the two phases. The structure of the compounds was found to be homogenous on the scanning electron microscopy (SEM) micrographs. The incorporation of corn cob and lavender stem can reduce the production cost of materials.

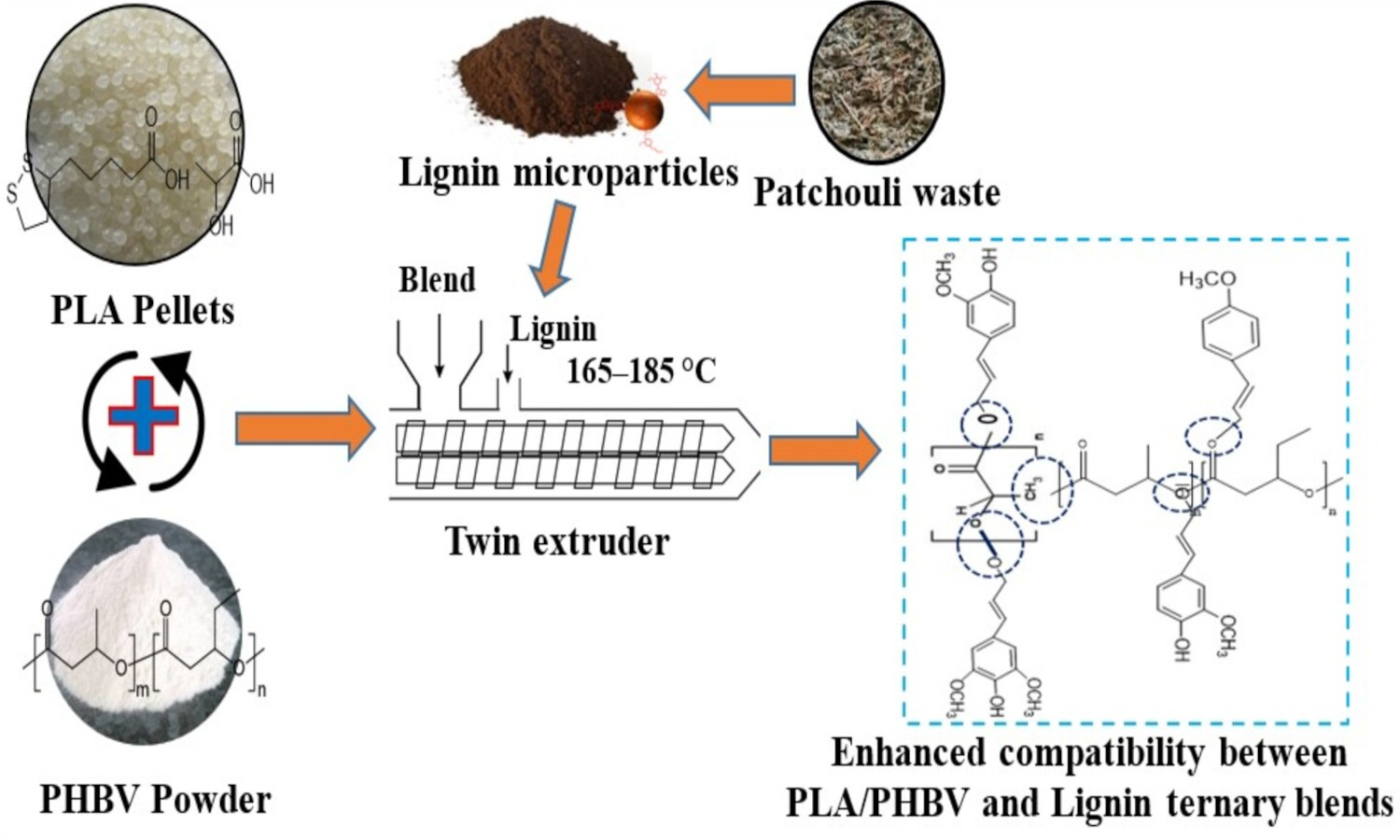

Syaifullah Muhammad, Rahul Dev Bairwan, H.P.S. Abdul Khalil, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

The study investigates a ternary biopolymer blend composed of biopolymers polylactic acid (PLA), polyhydroxybutyrate- co-valerate (PHBV), and lignin extracted from patchouli fiber waste for sustainable packaging applications. A PLA: PHBV blend (70:30) was enhanced by incorporating hydrophobic lignin as a filler in varying loadings of 0, 3, 6, 9, and 12 wt%. The ternary blend was prepared using twin-screw extrusion process, pelletized, and compression-molded into specimens. Comprehensive characterization of the ternary blend included evaluations of water barrier, mechanical, functional, thermal, and morphological properties. Results demonstrated that lignin addition notably improved the compatibility between PLA and PHBV, leading to enhanced barrier performance, mechanical strength, and thermal stability. SEM morphology confirmed improved interfacial adhesion due to hydrophobic nature of lignin, which facilitated better dispersion at lower filler loadings. However, at 12 wt% lignin, property reductions were observed, attributed to lignin agglomeration and poor dispersion. Optimal performance was achieved at 9 wt% lignin loading, offering a balance of improved properties without compromising processability or structural integrity. This study highlights the potential of the PLA/PHBV/lignin ternary blend as a viable, eco-friendly material for sustainable packaging, showcasing improved functionality and environmental compatibility compared to conventional polymers.

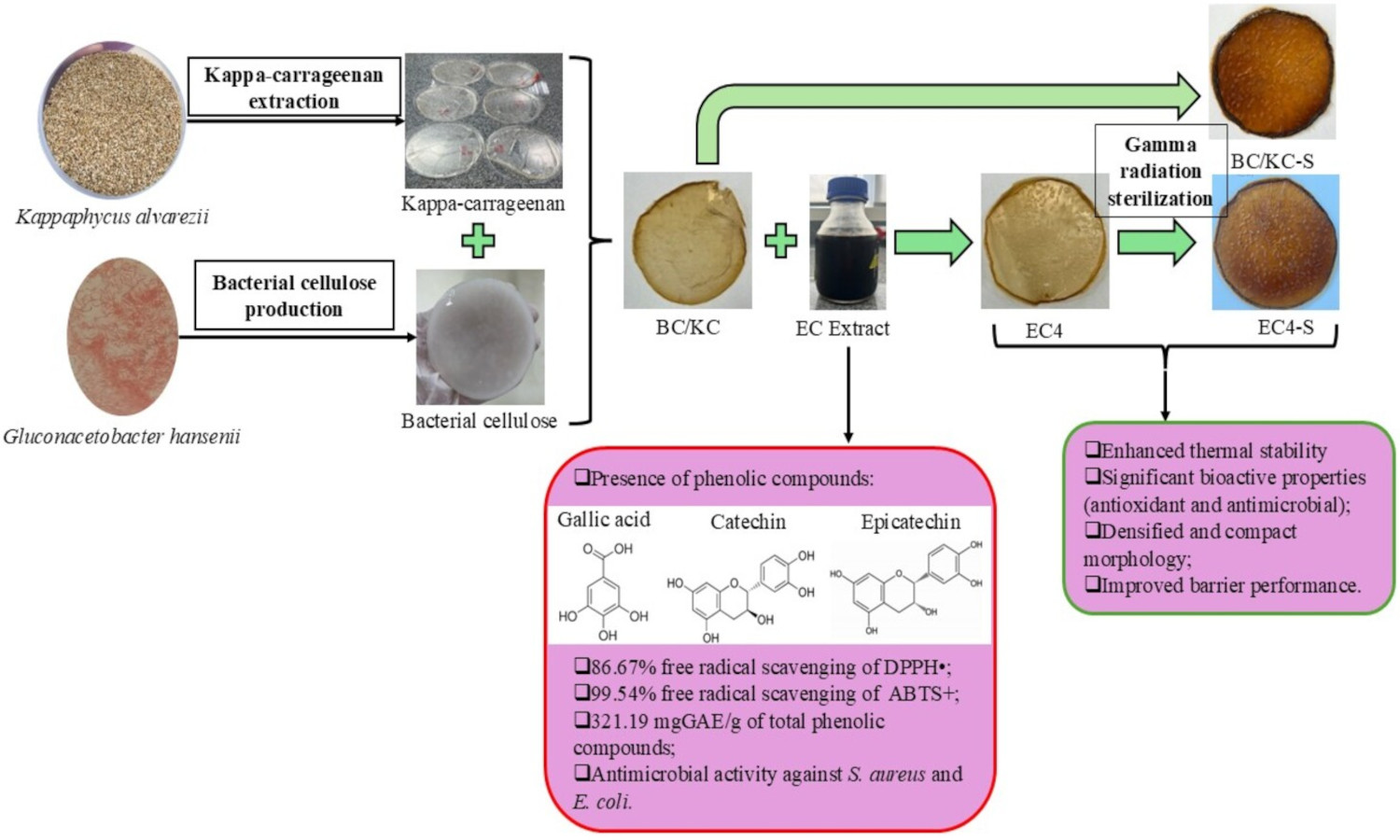

Alice da Conceição Alves de Lima, Andréa Monteiro Santana Silva Brito, Viviane Fonseca Caetano, Glória Maria Vinhas

Vol. 19., No.6., Pages 610-627, 2025

DOI: 10.3144/expresspolymlett.2025.46

Vol. 19., No.6., Pages 610-627, 2025

DOI: 10.3144/expresspolymlett.2025.46

Biopolymer-based packaging, such as bacterial cellulose (BC) and kappa-carrageenan (KC), offers a sustainable solution to environmental challenges. The incorporation of bioactive extracts enhances antioxidant and antimicrobial properties, while gamma radiation sterilization ensures microbiological safety, improving functionality for food preservation and promoting sustainability in the packaging industry. The objective of this work was to develop a BC film incorporated with KC solution (1%, v/v) and cashew bark extract (EC) at concentrations of 1, 2, and 4% (v/v) for use as active food packaging. EC exhibited a total phenolic content of 321.19 mgGAE/g and showed 86.67 and 99.54% radical scavenging activity for 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2″-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), respectively. EC also displayed antimicrobial activity against S. aureus and E. coli, confirming its antimicrobial potential. BC/KC films incorporated with EC and irradiated with gamma radiation exhibited a thermal degradation in the range of 275–287 °C, maintaining good thermal stability. The water vapor permeability decreased by 55.12%, indicating improved barrier properties and the film’s morphology became more compact after EC incorporation and irradiation. BC/KC films show promises for extending the food shelf life as active packaging.